Flue gas carbon dioxide trapping system and method based on organic solvent absorption-extraction regeneration cycle

An organic solvent and carbon dioxide technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of increased absorbent loss cost, damage to system water balance, slow absorption rate, etc., to reduce carbon capture costs, The effect of reducing heat consumption and reducing pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

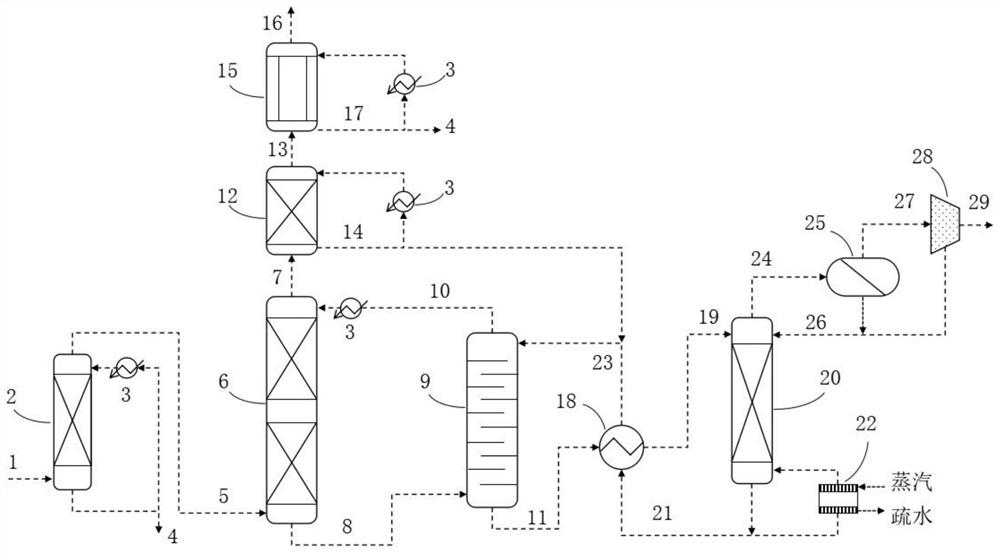

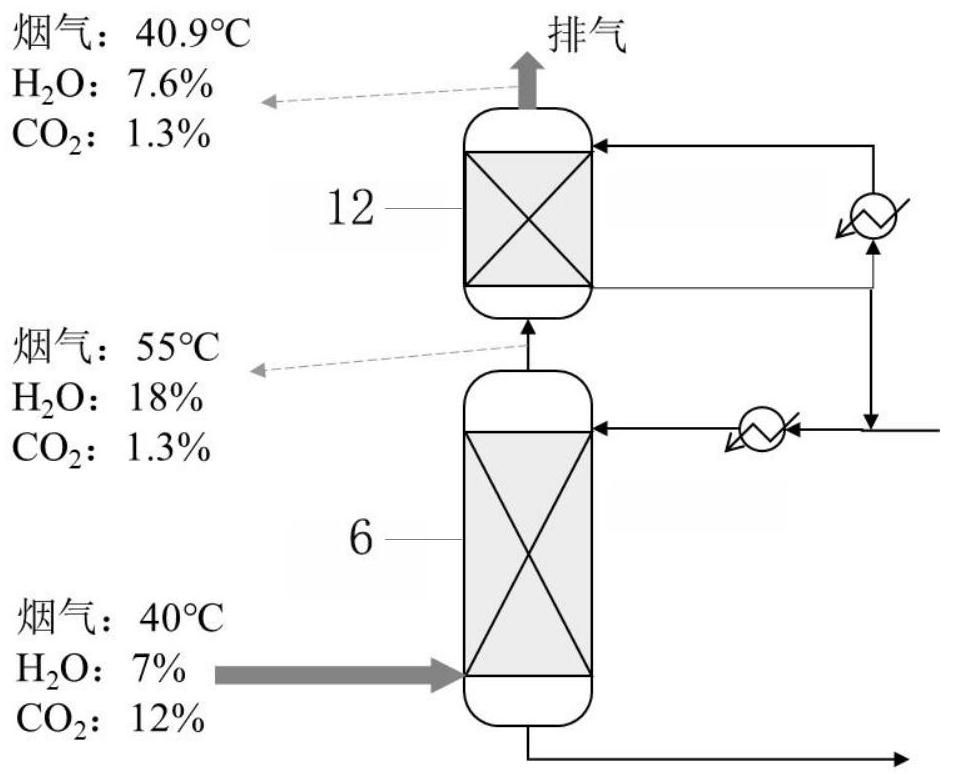

[0035] The flue gas carbon dioxide capture system based on organic solvent absorption-extraction regeneration cycle includes flue gas pretreatment tower 2, absorption tower 6, extraction regeneration tower 9, desorption tower 20, water balance tower 12 and solvent recovery tower 15; The flue gas outlet at the top of the gas pretreatment tower 2 is connected to the flue gas inlet at the bottom of the absorption tower 6; the flue gas outlet at the top of the absorption tower 6 is connected to the flue gas inlet at the bottom of the water balance tower 12; the flue gas outlet at the top of the water balance tower 12 The flue gas inlet that is connected to the bottom of the solvent recovery tower 15 through the flue gas pipeline; the rich liquid outlet of the absorption tower 6 is connected to the rich liquid inlet at the bottom of the extraction regeneration tower 9, and the organic phase outlet at the top of the extraction regeneration tower 9 is connected to the The organic solv...

Embodiment 2

[0044] The working method of the flue gas carbon dioxide capture system based on the organic solvent absorption-extraction regeneration cycle: the lower part of the flue gas pretreatment tower 2 is provided with a flue gas inlet 1, and the flue gas passes through the flue gas pretreatment tower 2, the absorption tower 6, Empty after the water balance tower 12 and the solvent recovery tower 15; the organic solvent absorbs CO in the absorption tower 6 2 , after entering the extraction and regeneration tower 9, it is sent back to the absorption tower 6 for cyclic absorption of CO 2 ; Enriched CO 2 The aqueous solution phase desorbs CO in the desorption tower 20 2 After that, enter the extraction regeneration tower 9, and then send back to the desorption tower 20 to circulate and desorb CO 2 . Specifically include the following steps:

[0045] S1. The flue gas enters from the lower part of the flue gas pretreatment tower 2 and flows from bottom to top, and the aqueous solution...

Embodiment 3

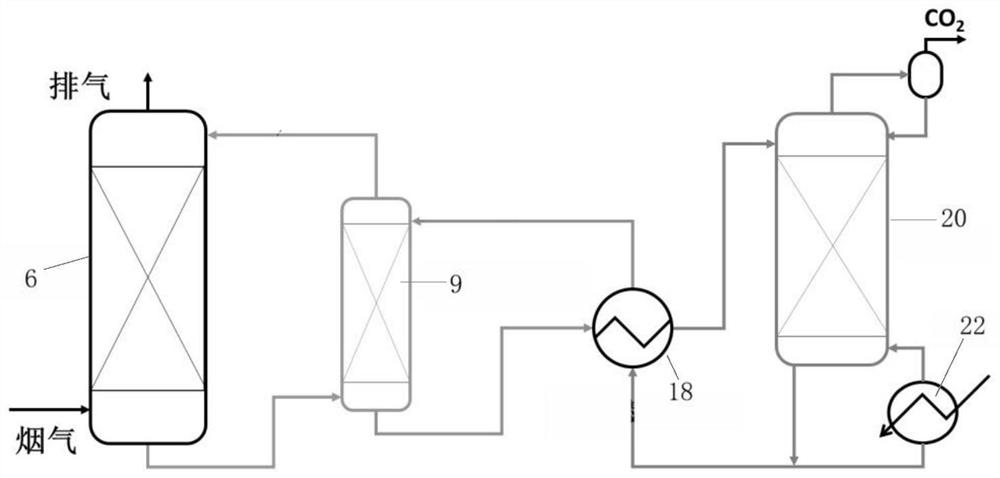

[0055] Such as figure 2 Shown is a three-column CO capture 2 Schematic diagram of the process scheme, using organic solvents to absorb CO in the absorption tower 2, the composition and mass concentration are: 92% DEEA / 2% AEEA / 6% H 2 O. Absorption tower operates at 40°C, after absorbing CO 2 The final organic solvent is sent to the lower part of the extraction regeneration tower, discharged from the top and then returned to the absorption tower to absorb CO 2 .

[0056] CO 2 The aqueous solution phase is used in the desorption tower, and the components and mass concentrations are: 40% AEEA / 40% H2O / 10% DEEA. The desorption tower operates at 120°C to desorb CO 2 The final aqueous solution phase recovers heat through the lean-rich liquid heat exchanger, and sends it to the extraction liquid inlet on the upper part of the extraction regeneration tower. It is discharged from the bottom of the extraction tower from top to bottom, and returns to CO2 through the lean-rich liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com