Carbon dioxide trapping agent and preparation method thereof

A carbon dioxide and capture agent technology, applied in chemical instruments and methods, separation methods, reagents, etc., can solve the problems of volatile toxic and harmful substances, poor regeneration ability of capture agents, and long capture cycle, so as to avoid the process of mining ore and transportation , lower capture cost, and shorter capture time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] On the other hand, the embodiment of the present application provides a preparation method of the aforementioned carbon dioxide capture agent, comprising the following steps: pulverizing calcium orthosilicate to obtain calcium orthosilicate powder; pulverizing alkali metal carbonate to obtain alkali metal carbonate powder , mixing the calcium orthosilicate powder and the alkali metal carbonate powder evenly to obtain a carbon dioxide capture agent.

[0024] In some embodiments of the present invention, in the preparation method of the above-mentioned carbon dioxide capture agent, the alkali metal carbonate is melted at 600° C. for 2 hours before pulverization.

Embodiment 1

[0027] The purpose of this embodiment is to provide a carbon dioxide capture agent in which calcium orthosilicate and alkali metal carbonate cooperate to capture carbon dioxide and use the carbon dioxide capture agent to capture carbon dioxide.

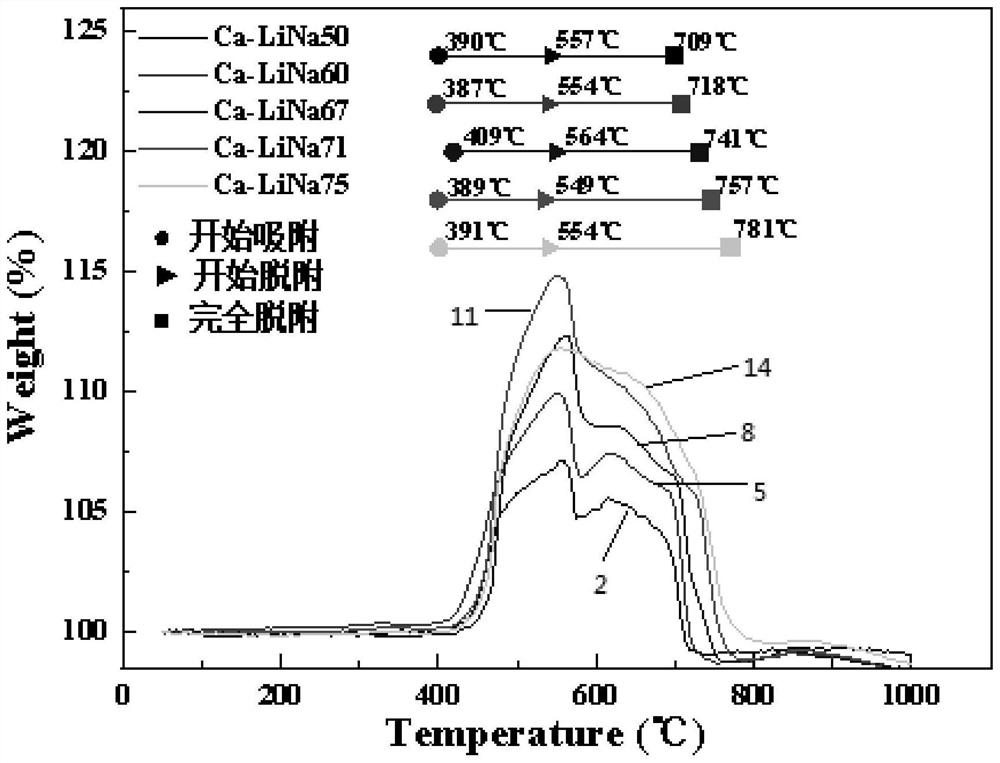

[0028] (1) Ca 2 SiO 4 , Li 2 CO 3 and Na 2 CO 3 Mixed to prepare the capture agent system Ca-LiNa, where Li 2 CO 3 and Na 2 CO 3 The molar amount of Ca 2 SiO 4 , Li 2 CO 3 and Na 2 CO 3 50% of the sum of the molar quantities of Li 2 CO 3 and Na 2 CO 3 The molar ratio of Ca is 51:49, the Ca 2 SiO 4 , Li 2 CO 3 and Na 2 CO 3 Grind homogeneously in a mortar, Ca 2 SiO 4 , Li 2 CO 3 and Na 2 CO 3 The particle size is 200-300 mesh, take 20mg sample and place it in a platinum crucible with a diameter of 2mm;

[0029] (2) The heating program and the atmosphere composition of the thermogravimetric analyzer are set, the platinum crucible with 20mg sample is housed in the thermogravimetric analyzer, and the test is ...

Embodiment 2

[0036] The purpose of this embodiment is to provide a carbon dioxide capture agent in which calcium orthosilicate and alkali metal carbonate cooperate to capture carbon dioxide and use the carbon dioxide capture agent to capture carbon dioxide.

[0037] (1) Ca 2 SiO 4 , Li 2 CO 3 and Na 2 CO 3 Mixed to prepare the capture agent system Ca-LiNa, where Li 2 CO 3 and Na 2 CO 3 The molar amount of Ca 2 SiO 4 , Li 2 CO 3 and Na 2 CO 3 50% of the sum of the molar quantities of Li 2 CO 3 and Na 2 CO 3 The molar ratio of Ca is 52:48, the Ca 2SiO 4 , Li 2 CO 3 and Na 2 CO 3 Grind homogeneously in a mortar, Ca 2 SiO 4 , Li 2 CO 3 and Na 2 CO 3 The particle size is 200-300 mesh, take 20mg sample and place it in a platinum crucible with a diameter of 2mm;

[0038] (2) The heating program and the atmosphere composition of the thermogravimetric analyzer are set, the platinum crucible with 20mg sample is housed in the thermogravimetric analyzer, and the test is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com