Coal-fired power plant carbon dioxide ammonia process trapping and low-temperature liquefaction system and method

A carbon dioxide and coal-fired power plant technology, applied in the field of resources and environment, can solve problems such as unfavorable storage and transportation, low equipment efficiency, poor selectivity of gas separation membranes, etc., and achieve the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

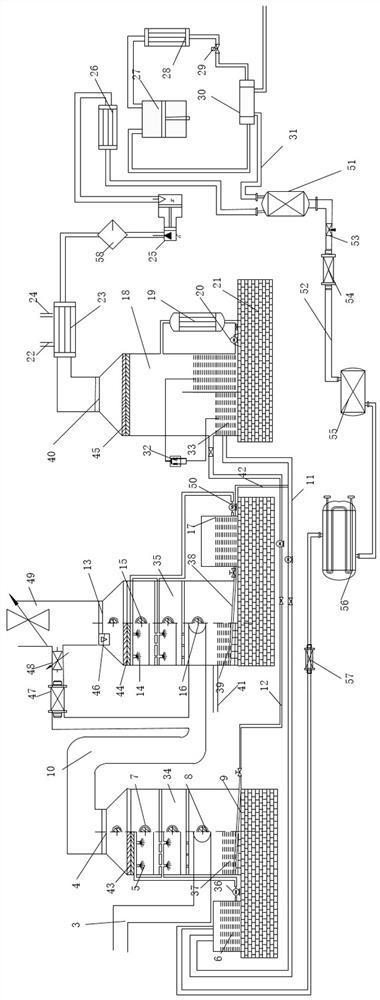

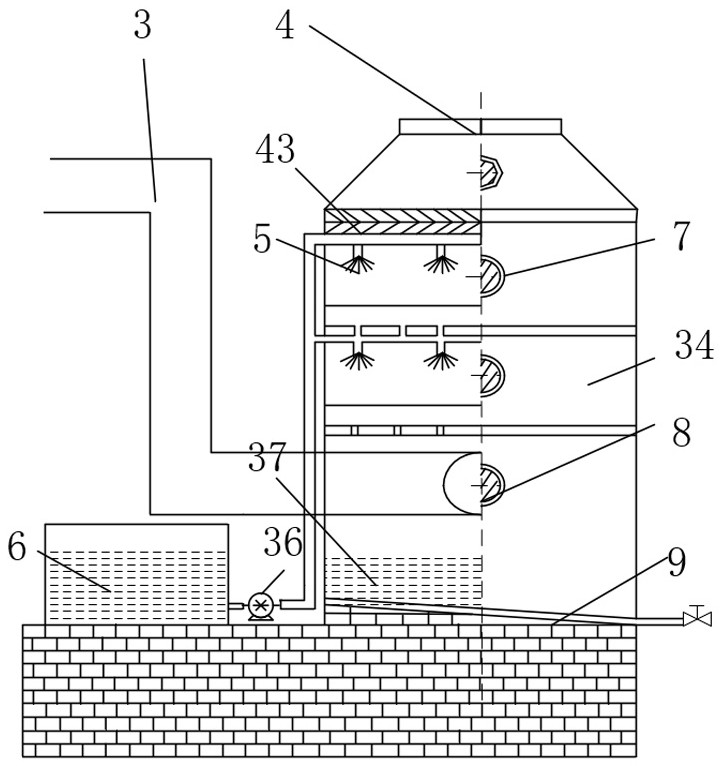

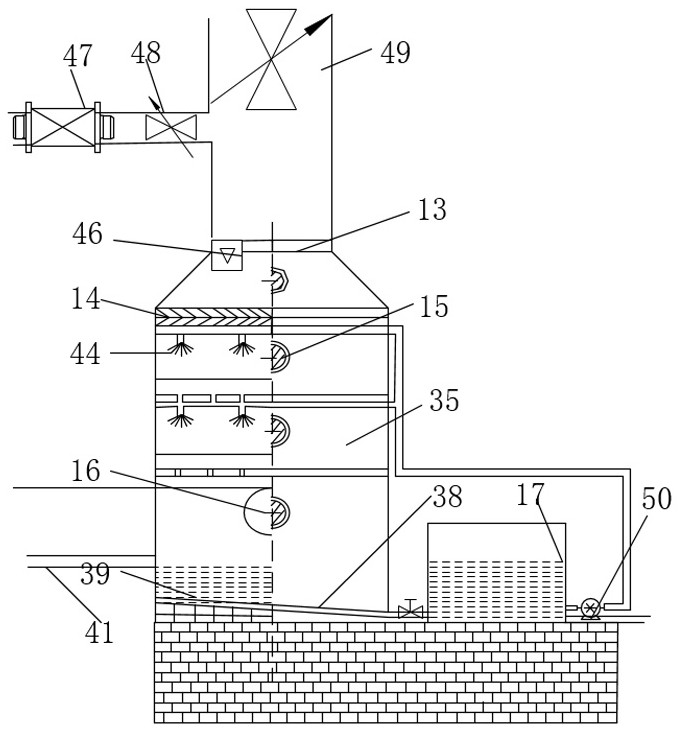

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0031] The invention relates to a carbon dioxide ammonia method capture and low-temperature liquefaction system in a coal-fired power plant, including a carbon dioxide chemical method capture system, a low-temperature liquefaction system and an absorbent recovery and reuse system. like figure 1As shown, the carbon dioxide chemical method capture system includes a carbon dioxide absorption tower, an ammonia gas absorption tower, and a carbon dioxide desorption tower, which are connected in turn through pipelines; the low-temperature liquefaction system includes a drying part, a booster part, a power part, a heat exchange part and a pressure regulation part ;The drying part is an airflow dryer, and the pressurizing part is a gas booster, which is used to increase the pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com