Particulate matter trapping device

A particle and shell technology, applied in the direction of external electrostatic separator, electrostatic separation, etc., can solve secondary pollution and other problems, achieve the effect of low air resistance, large air flow, and reduce secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

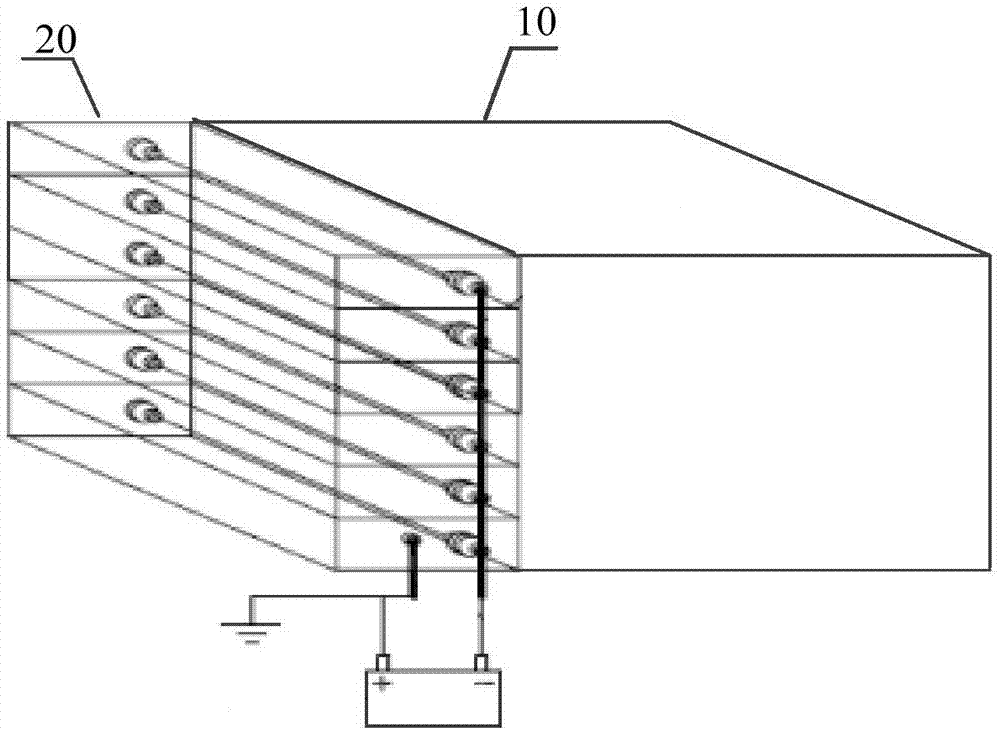

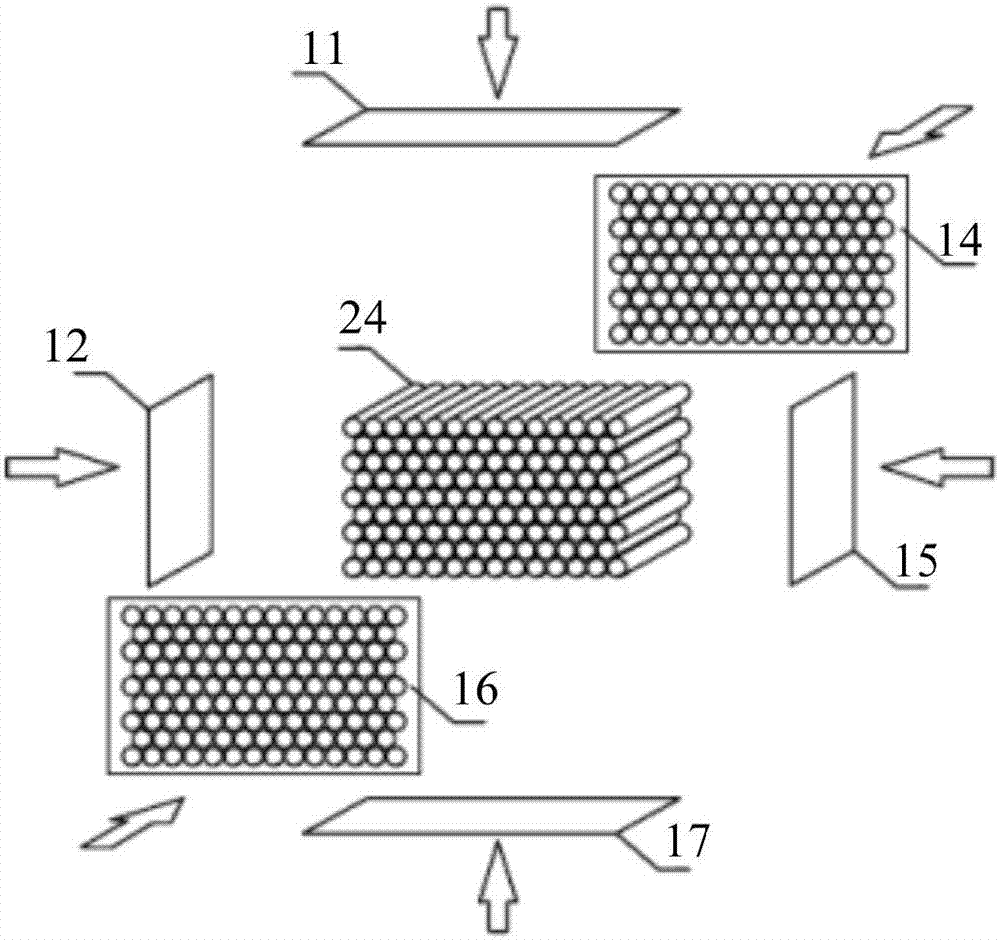

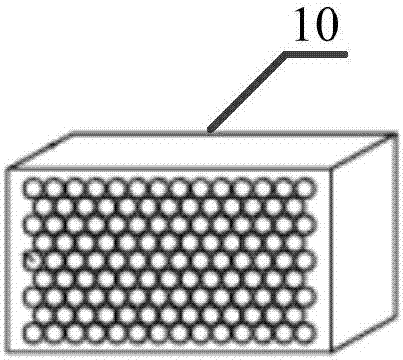

[0029] figure 1 It is a schematic structural diagram of a particulate matter trapping device provided in Embodiment 1 of the present invention, which can be used to trap particulate matter in gas, and the device specifically includes: a filter brush ( figure 1 not shown), housing 10 and gas ionization device 20, wherein,

[0030] The air inlet surface of the casing 10 runs through several through holes to the air outlet surface of the casing 10, and filter brushes are inserted one by one in the through holes, and the filter brushes are in contact with the side walls of the corresponding through holes. The casing 10 is made of conductive metal, and the filter brushes Including piezoelectric materials, the gas ionization device 20 is installed on the air intake surface of the housing 10, and the air flows through the gas ionization device 20 to charge the particles in the air flow and then pass through the through hole. When the air flows through the through hole, the air will ...

Embodiment 2

[0047] This embodiment is further optimized on the basis of the foregoing embodiments. In this embodiment, the filter brush includes a brush rod and brush filaments, and the brush filaments are fixed around the brush rod, so that after the charged particles enter the corresponding through holes, there are brush filaments in all directions to block and enhance the collection. Particle effect.

[0048] In the above solution, optionally, the brush rod is made of conductive metal, and the brush wire is made of piezoelectric material.

[0049] In the above solution, optionally, one end of the brush filament is fixed on the outer wall of the brush rod, and the other end of the brush filament is in contact with the side wall of the corresponding through hole.

[0050] When the brush rod is made of conductive metal, after the air enters the corresponding through hole, the pressure of the air on the brush wire makes the brush wire deform, and then the end of the brush wire fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com