Patents

Literature

73results about How to "Size reduction requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

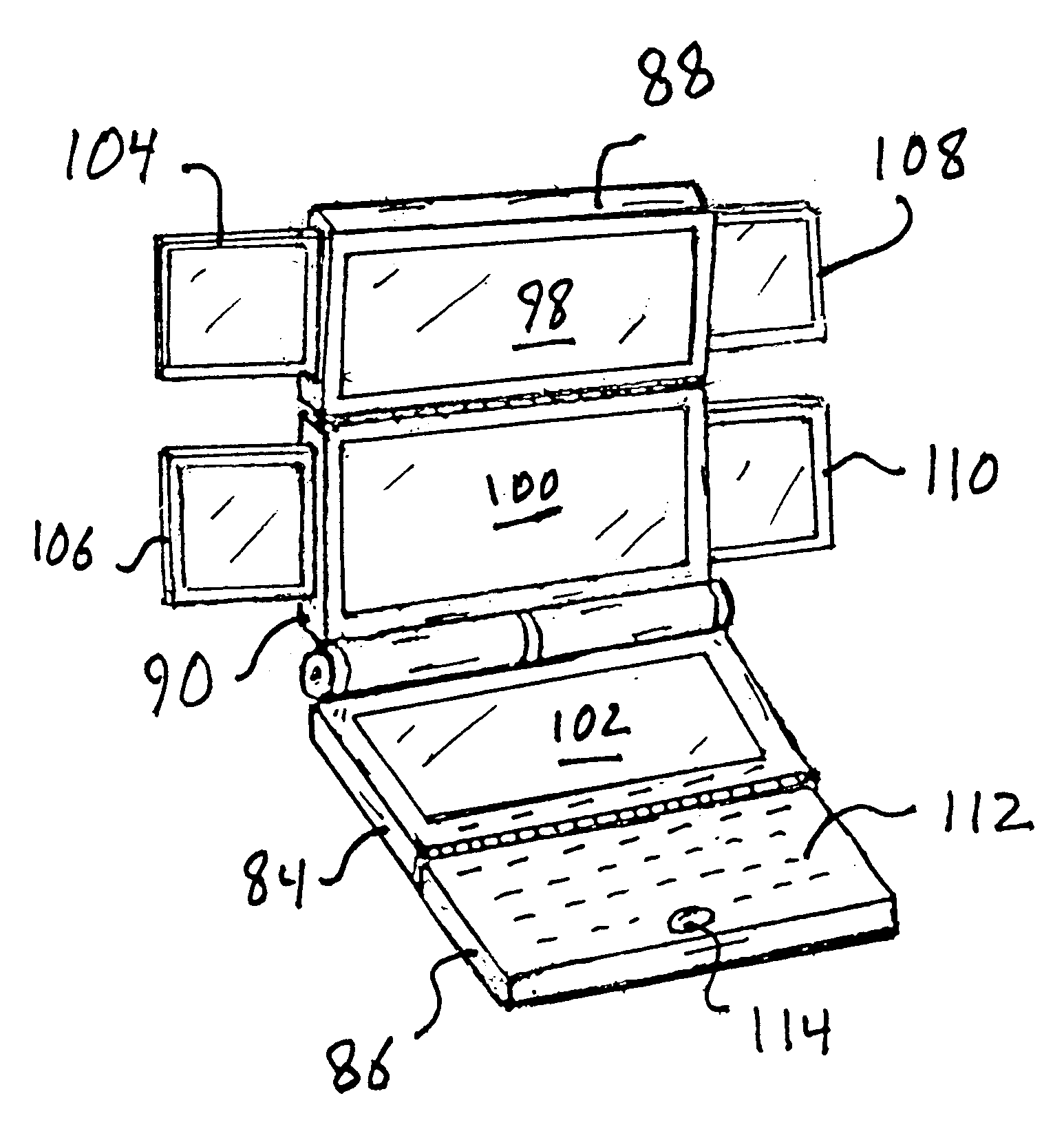

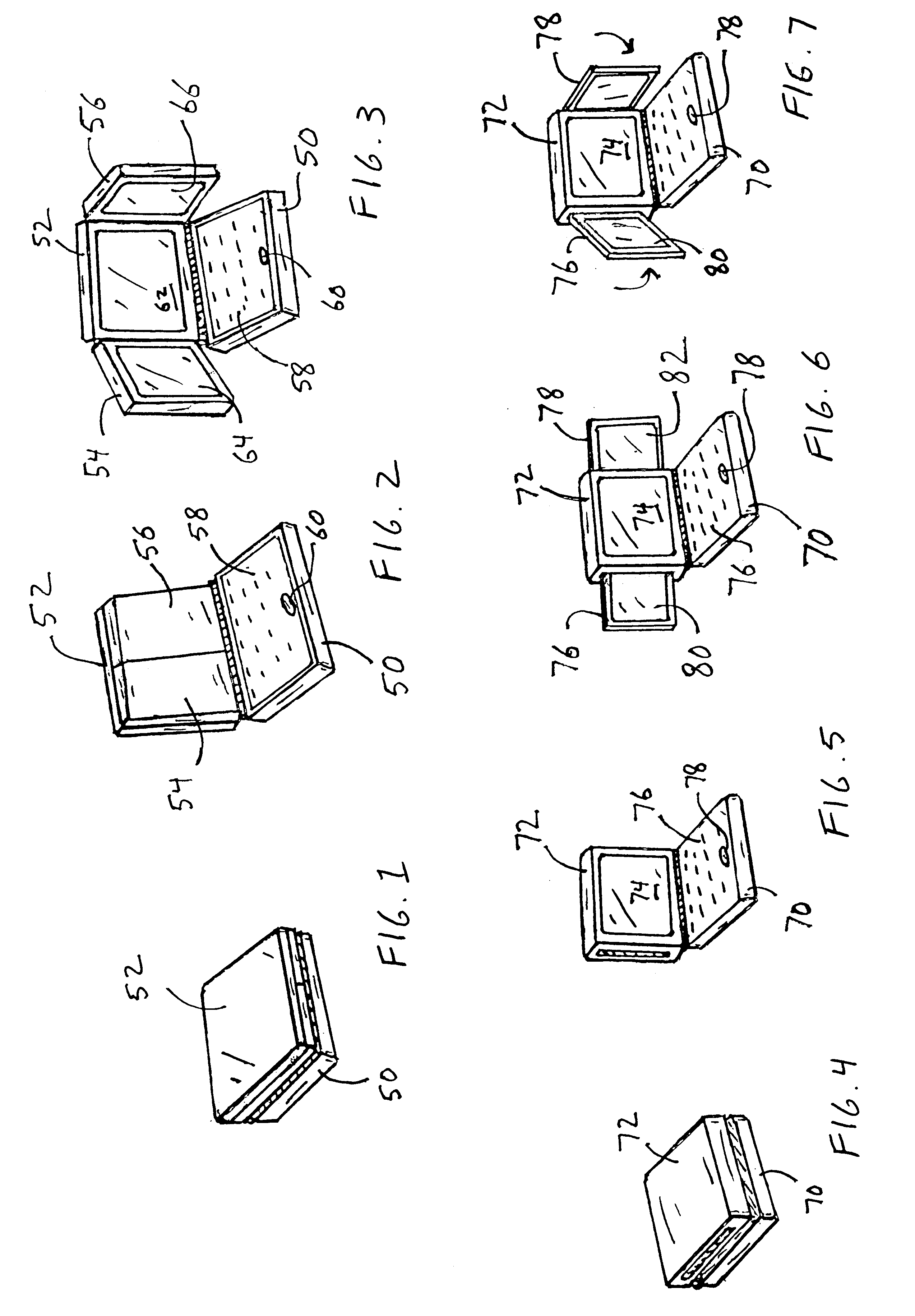

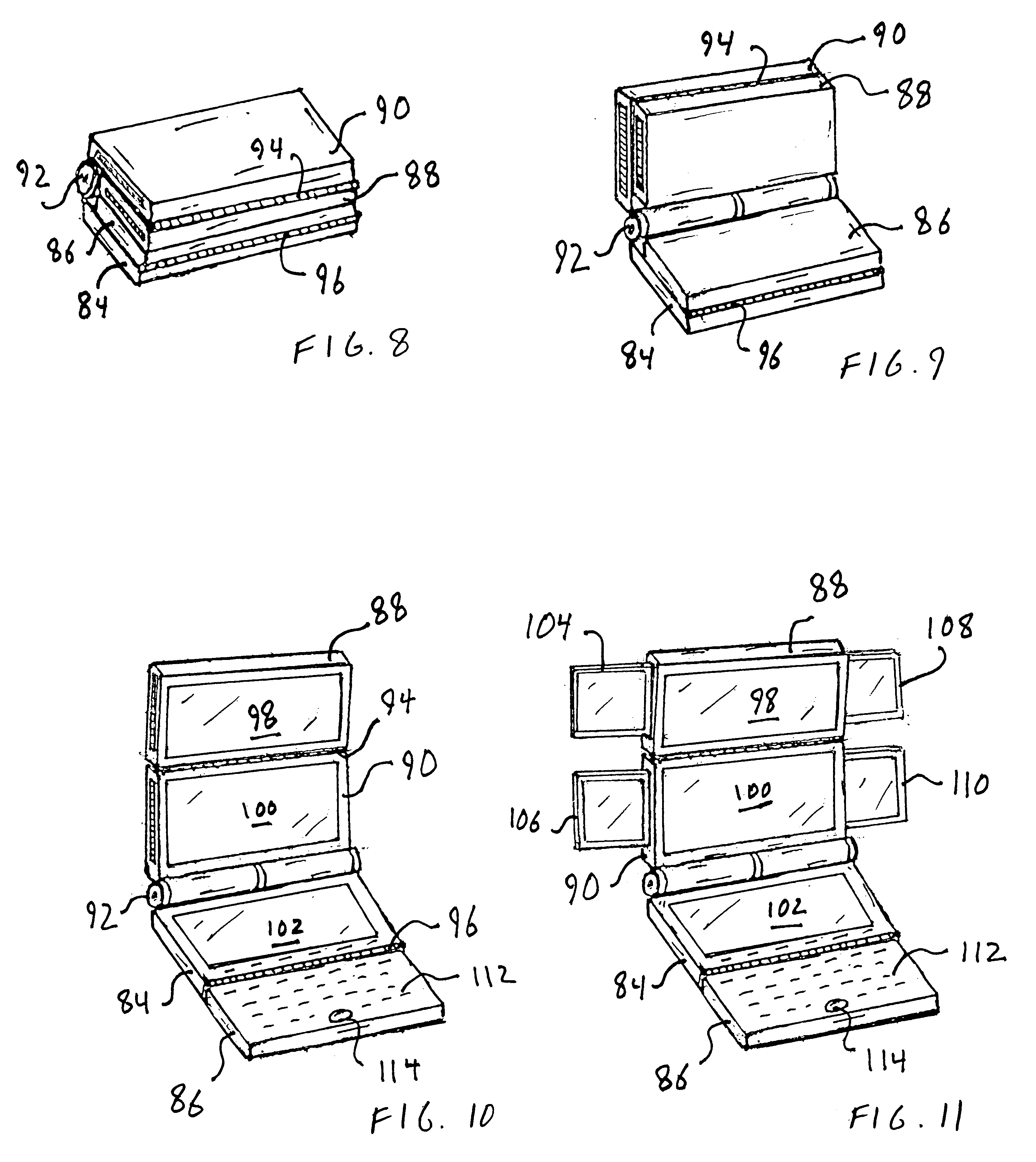

Multiple display portable computing devices

InactiveUS6643124B1Easy to useDifficult to differentiateInput/output for user-computer interactionDevices with multiple display unitsEngineeringMotherboard

A portable computing device is equipped with multiple display panels. The display panels and hinged, jointed or otherwise disposed to rotate or slide with respect to one another in a transition from a compact configuration to an expanded configuration. In a basic embodiment three output screens take a form of a triptych for which an input panel forms a base. The output panels are deployed with a bend when opened and images angled in towards an observer. The display panels comprise a main panel and two auxiliary panels. In a variation a forth display panel is rotatably or foldably joined to the central display panel so that a total of four display panels may be deployed in a hub and petal configuration. The side panels may be eliminated from the four panel embodiment so that the input panel and two remaining display panels form a vertically orientable triptych with the input panel serving as base.

Owner:WILK PETER J

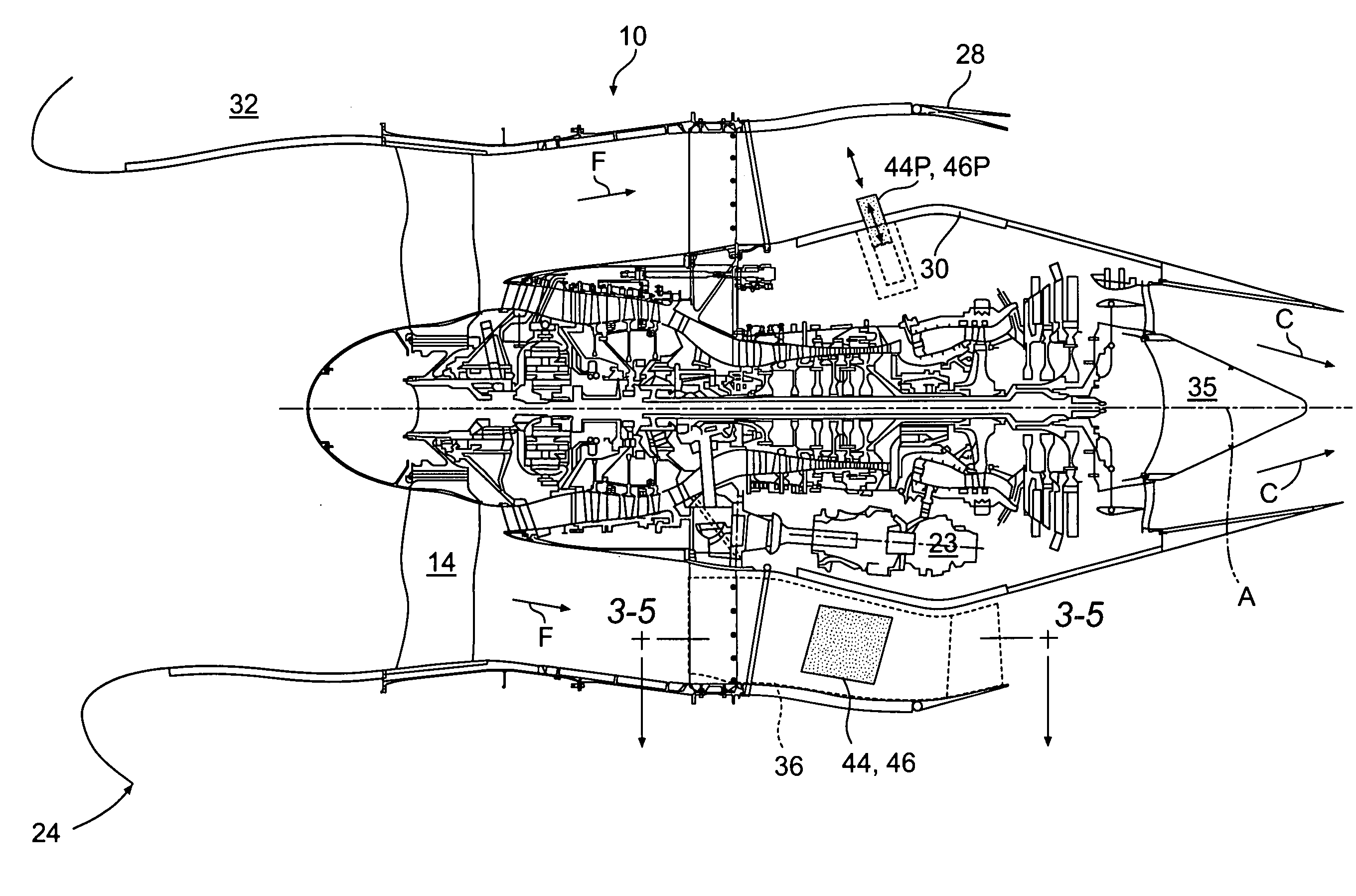

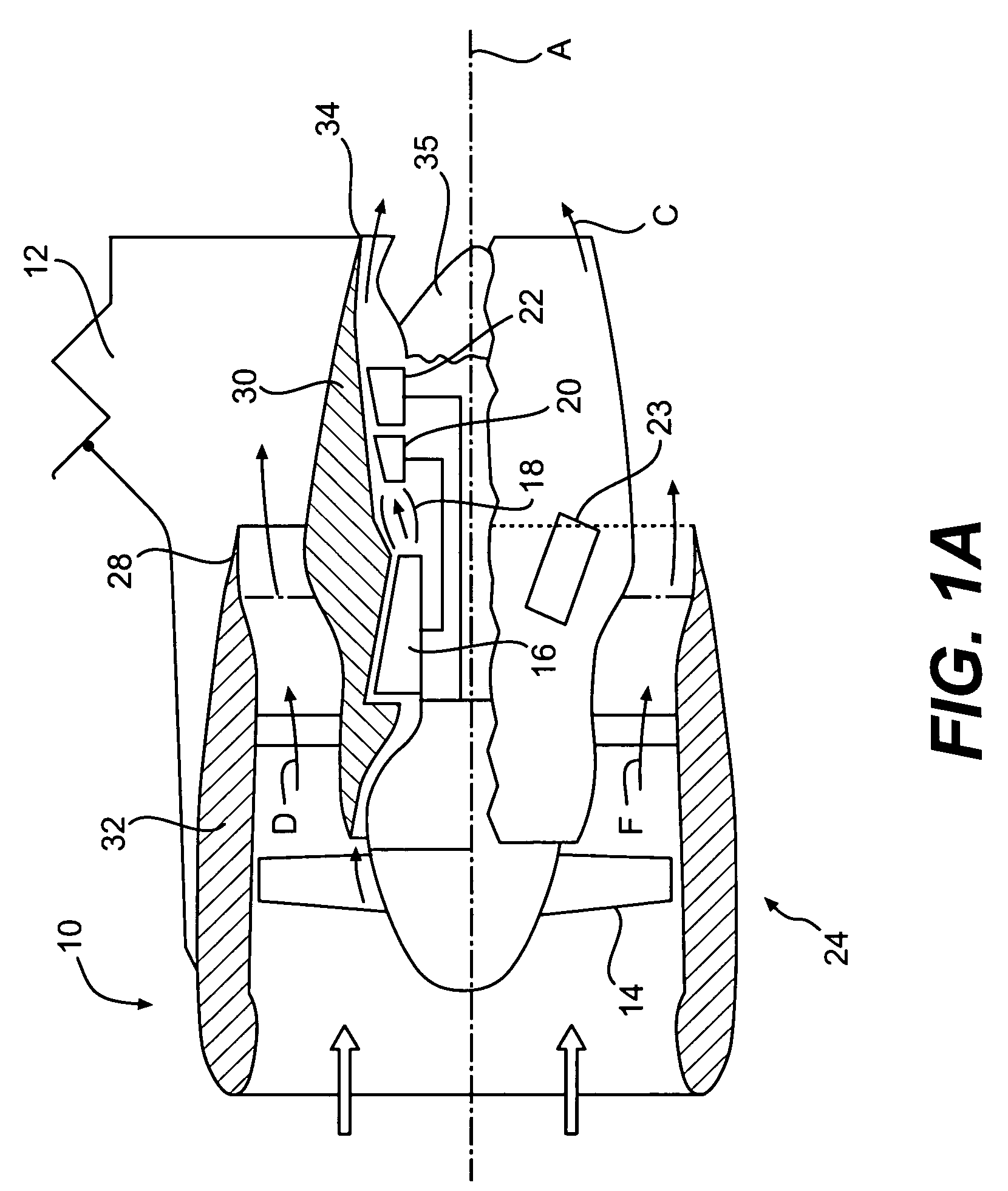

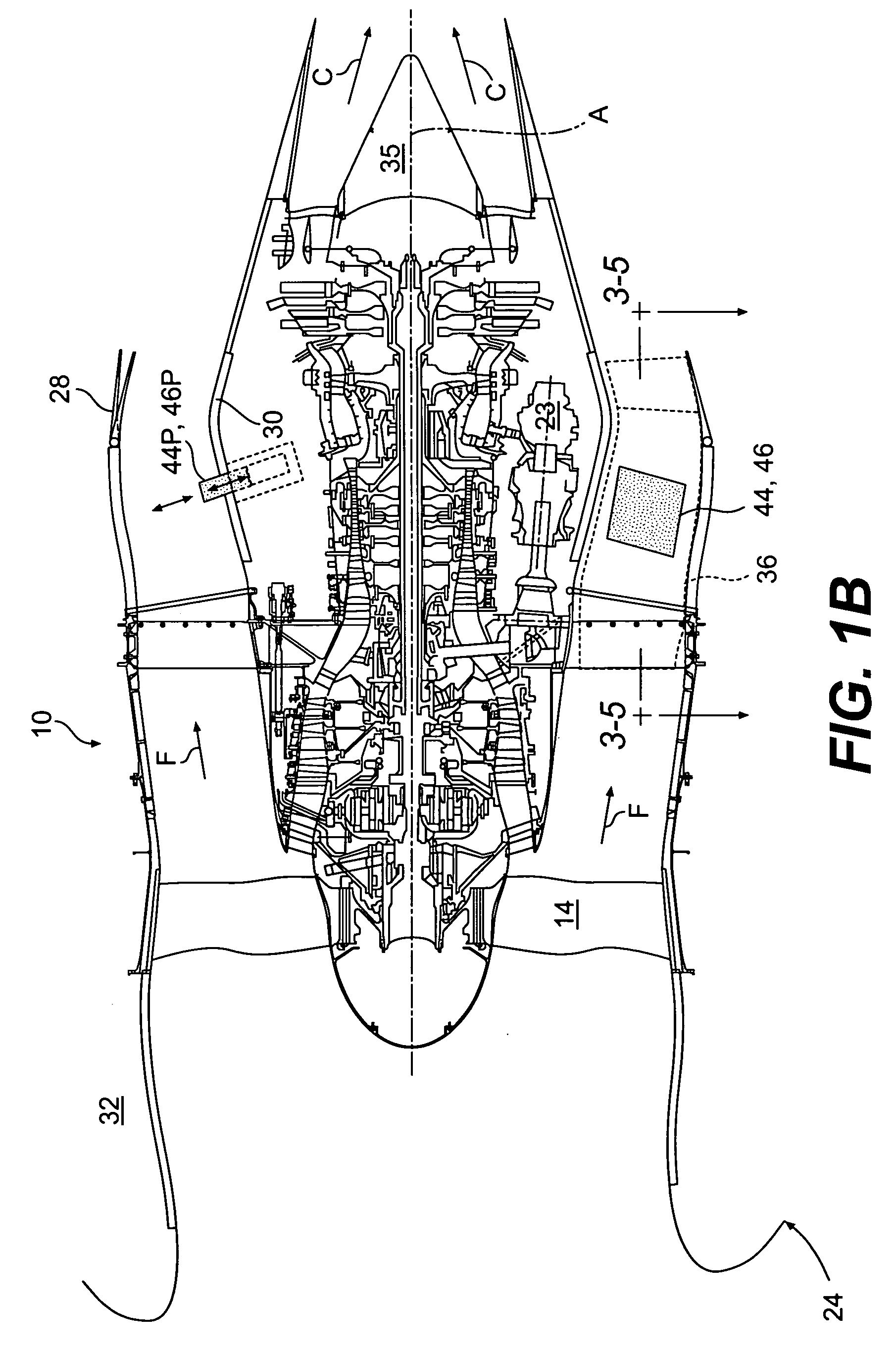

Thermal management system with thrust recovery for a gas turbine engine fan nacelle assembly

InactiveUS20080028763A1Reduces thrust lossesSize reduction requirementsEngine fuctionsEfficient propulsion technologiesNacelleHeat rejection

A thermal management system locates a separate engine heat exchanger and generator heat exchanger into an engine nacelle pylon that is split to provide independent control of both a generator cooling circuit and an engine cooling circuit. A variable exhaust nozzle is provided downstream of each heat exchanger as each has different thermal and heat rejection requirements such that intake air is minimized and maximum thrust is produced in response to the current generator load and engine heat rejection.

Owner:UNITED TECH CORP

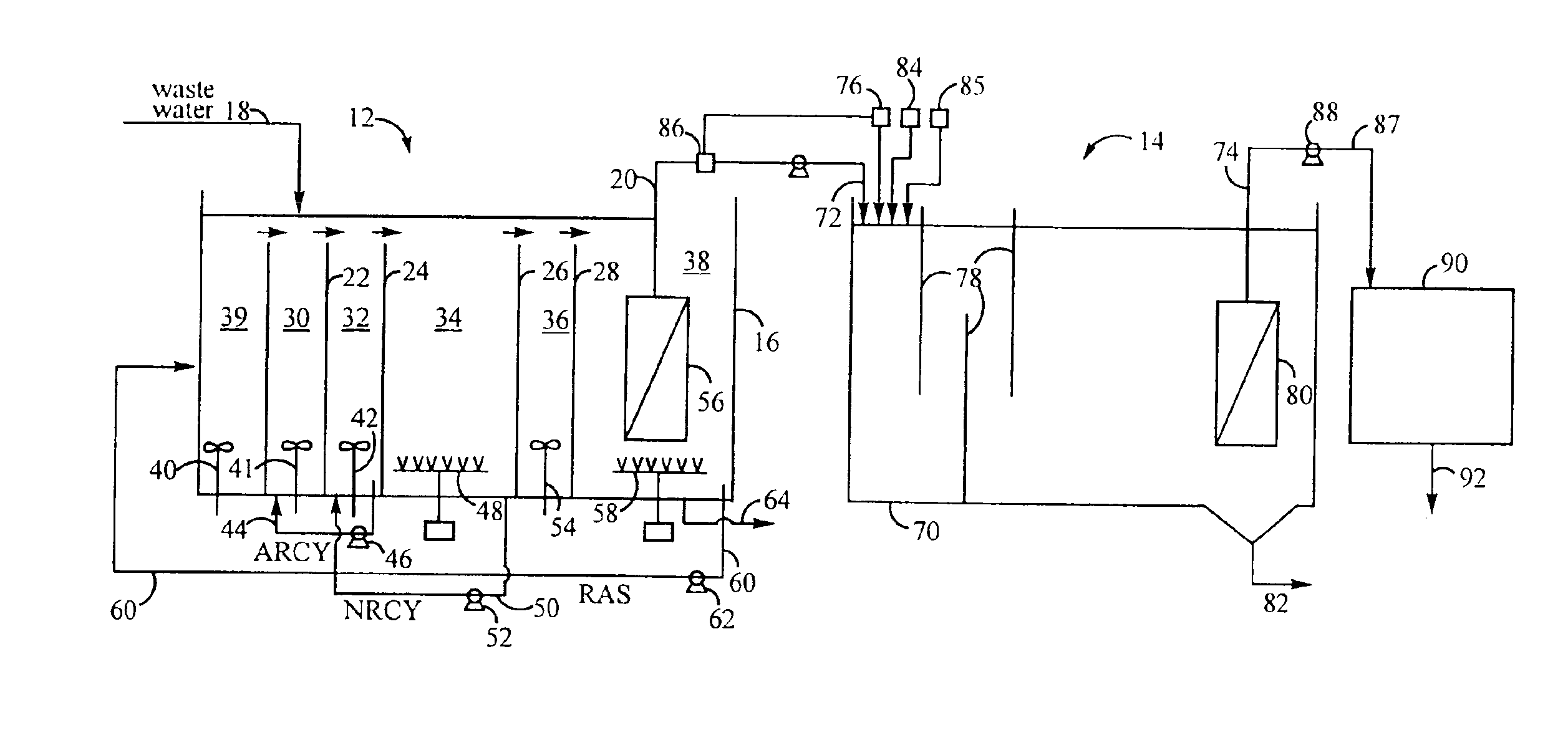

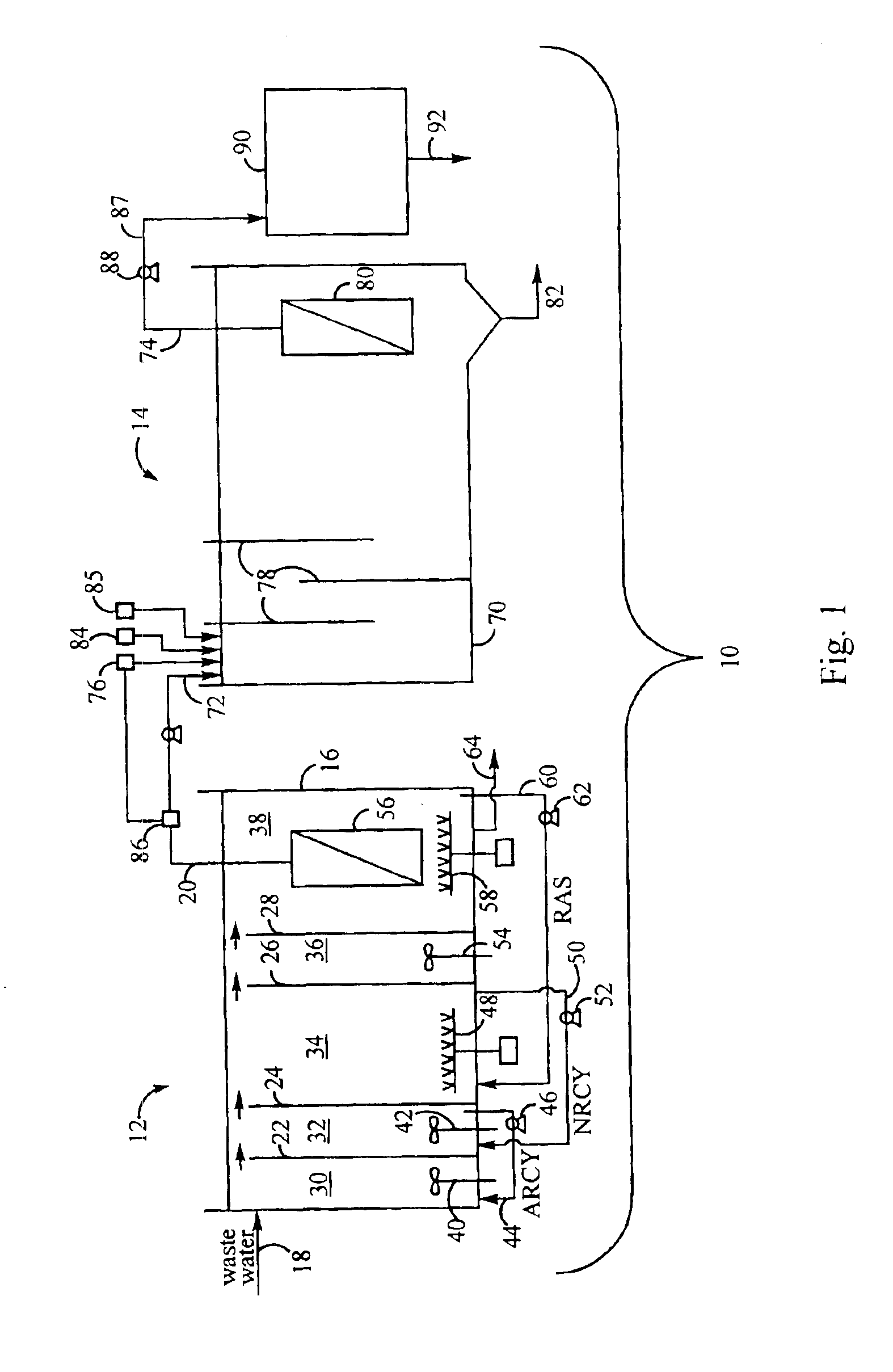

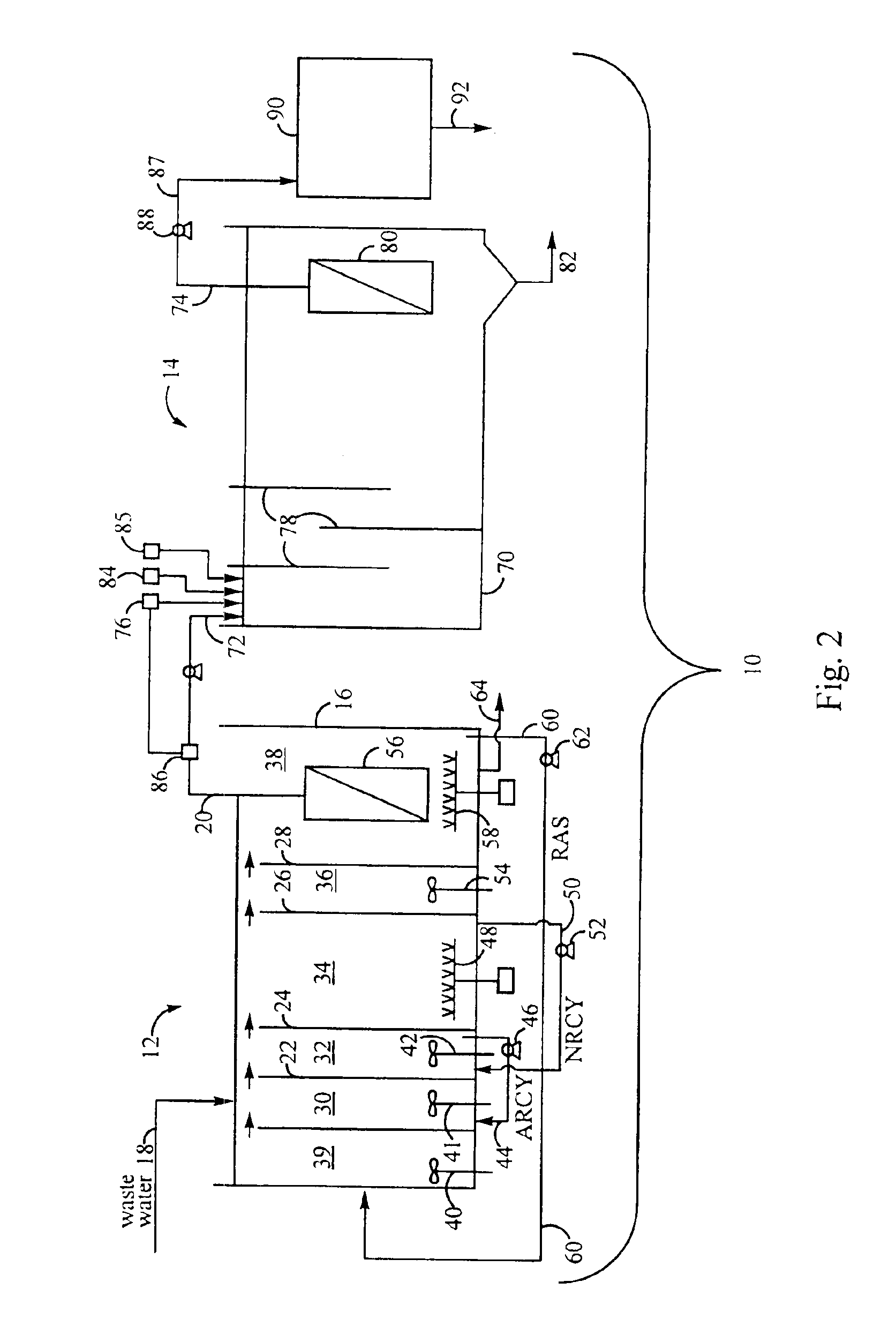

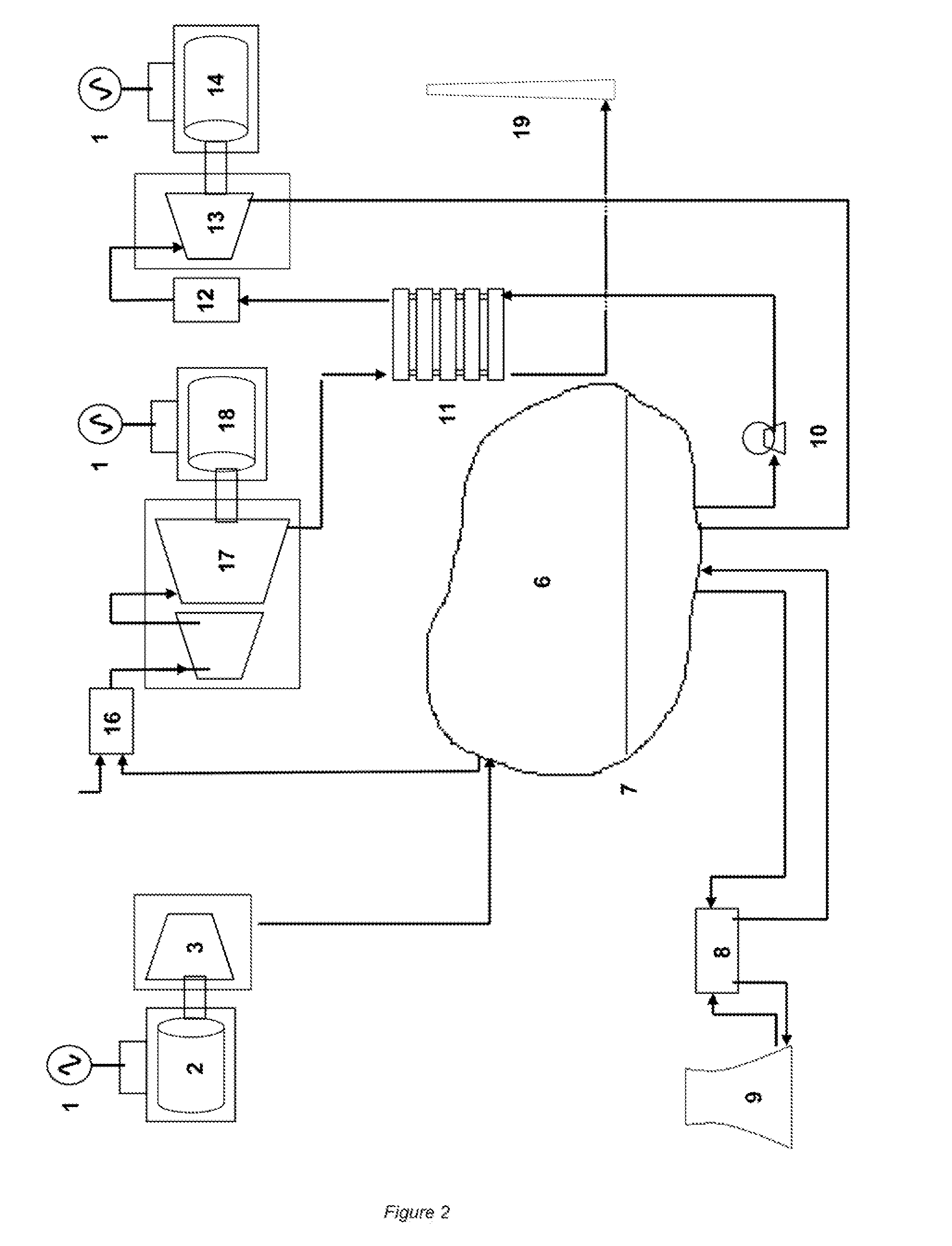

Method and apparatus for treating wastewater using membrane filters

InactiveUS6863818B2Good removal effectEfficient workTreatment using aerobic processesBiological treatment regulationActivated sludgeBioreactor

An apparatus using activated sludge for the removal of biological nutrients from a wastewater includes a bioreactor for containing a mixture of wastewater under treatment and activated sludge. The bioreactor is divided into a plurality of serially connected treatment zones and includes a wastewater inlet, a downstream aerobic zone and an upstream aerobic zone between the wastewater inlet and the downstream aerobic zone, the upstream and downstream aerobic zones being separated by an anoxic zone. A method for removal of nutrients from a wastewater includes providing a wastewater to an inlet of a serial, multi-zone, activated sludge bioreactor containing an activated sludge. The bioreactor has a downstream aerobic zone from which water is removed and an upstream aerobic zone between the wastewater inlet and the downstream aerobic zone, the upstream and downstream aerobic zones being separated by an anoxic zone.

Owner:CH2M HILL

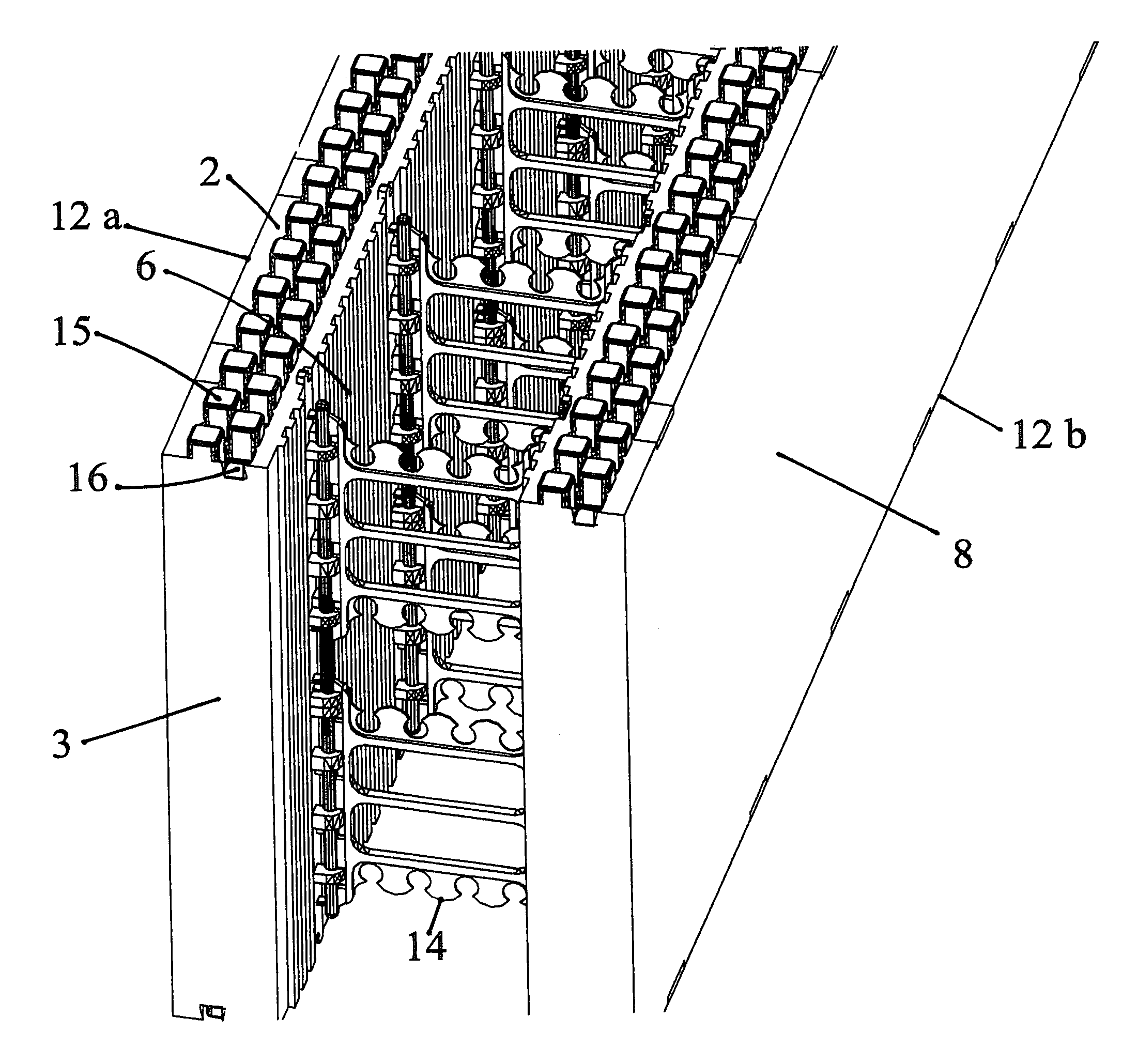

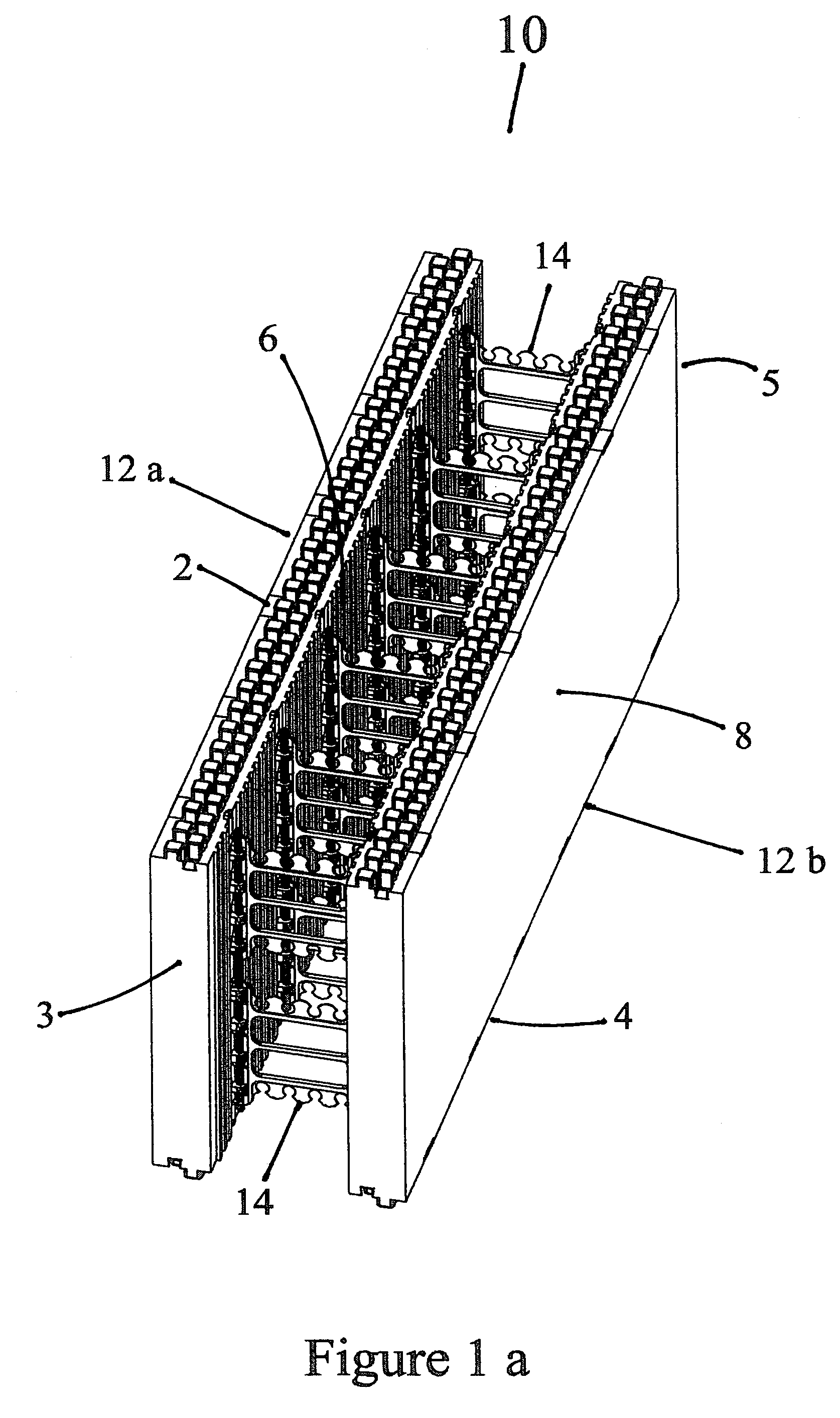

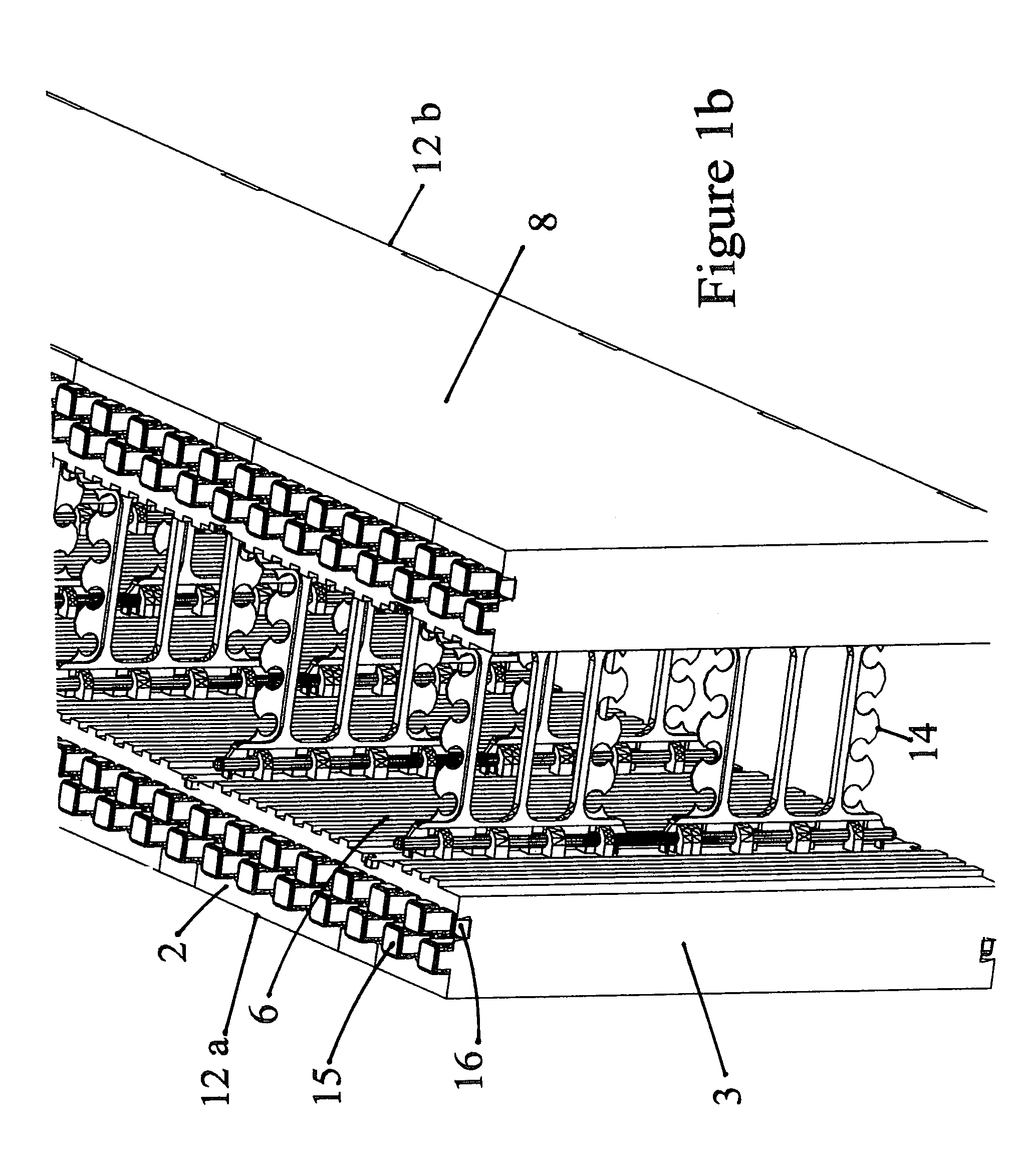

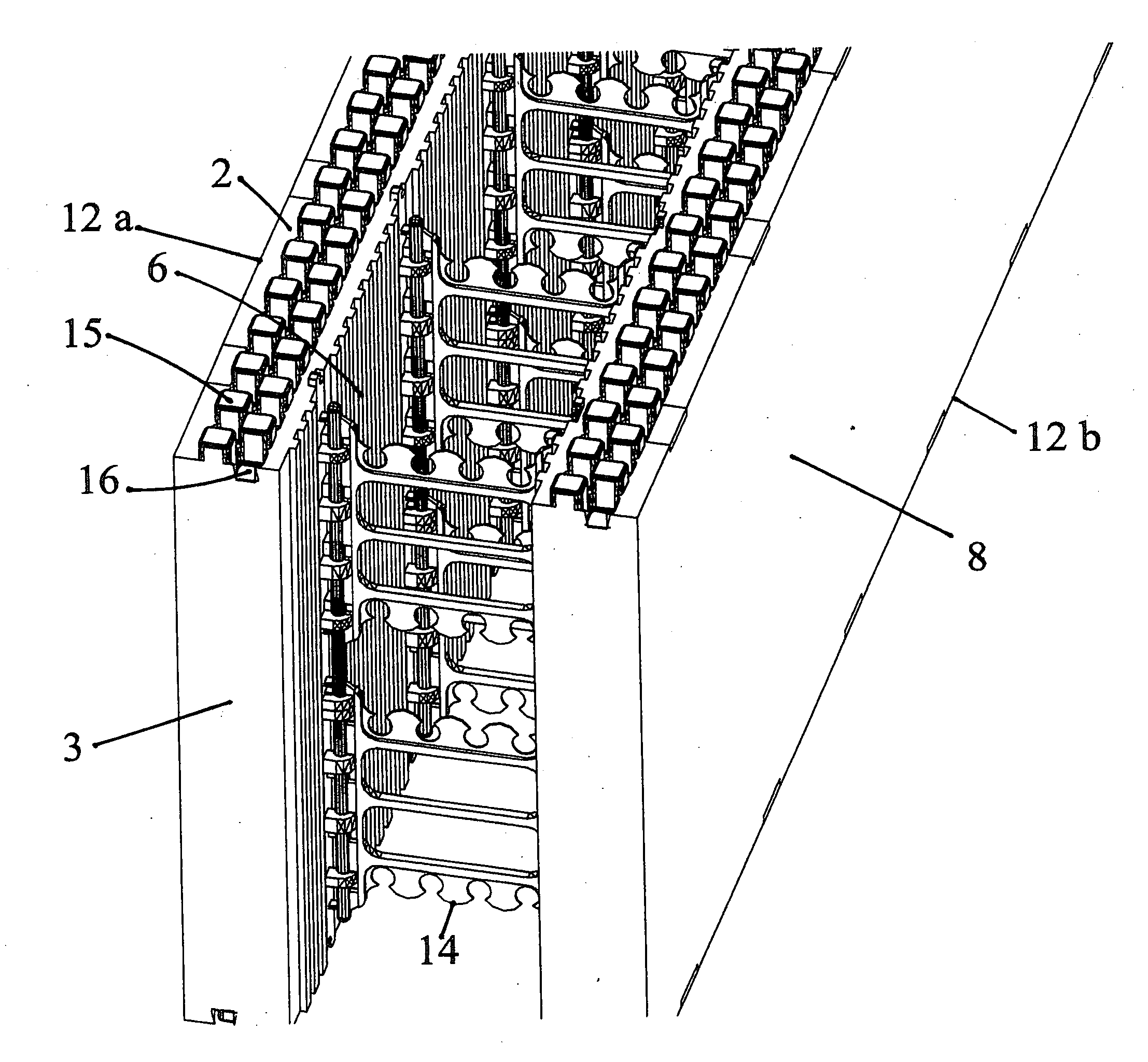

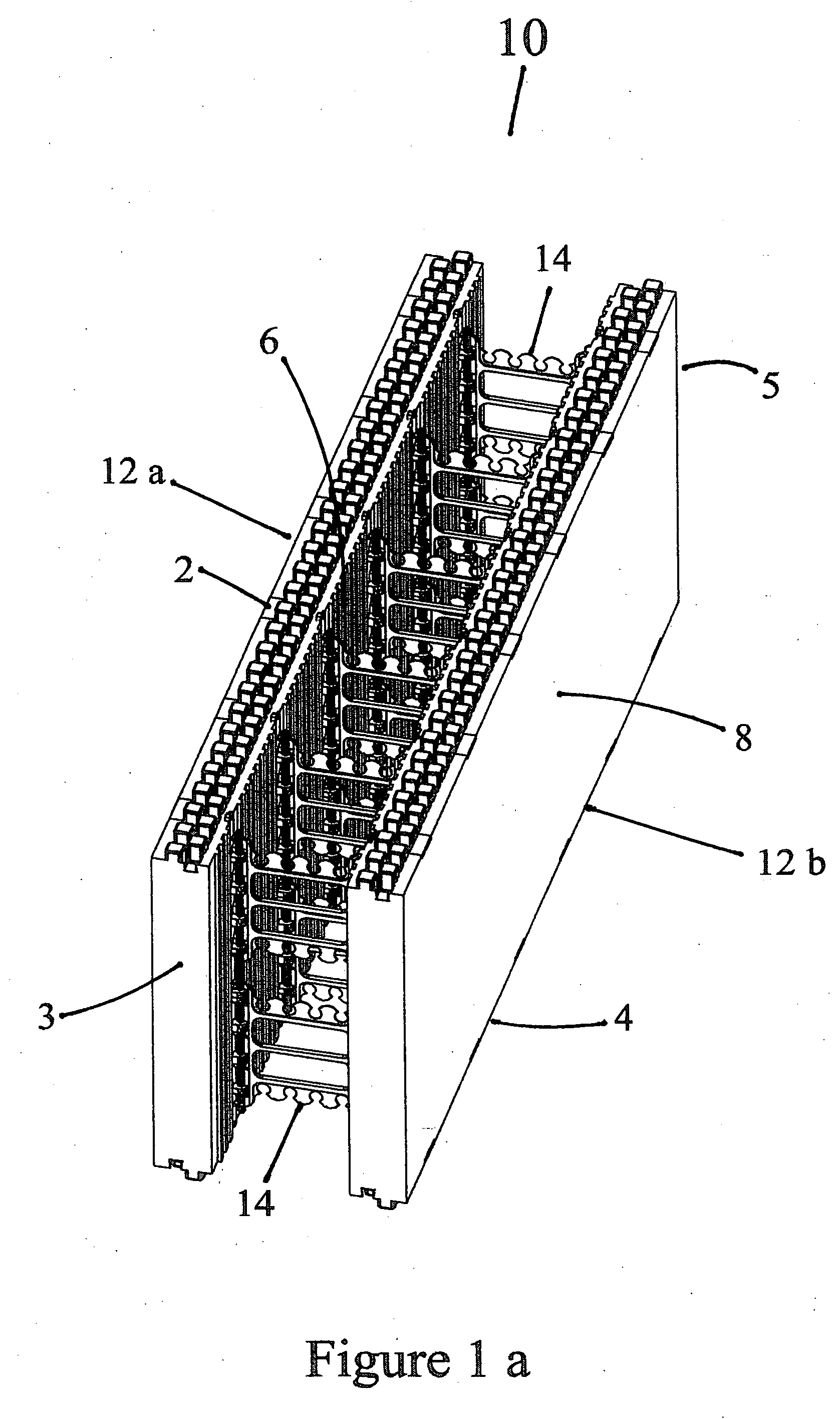

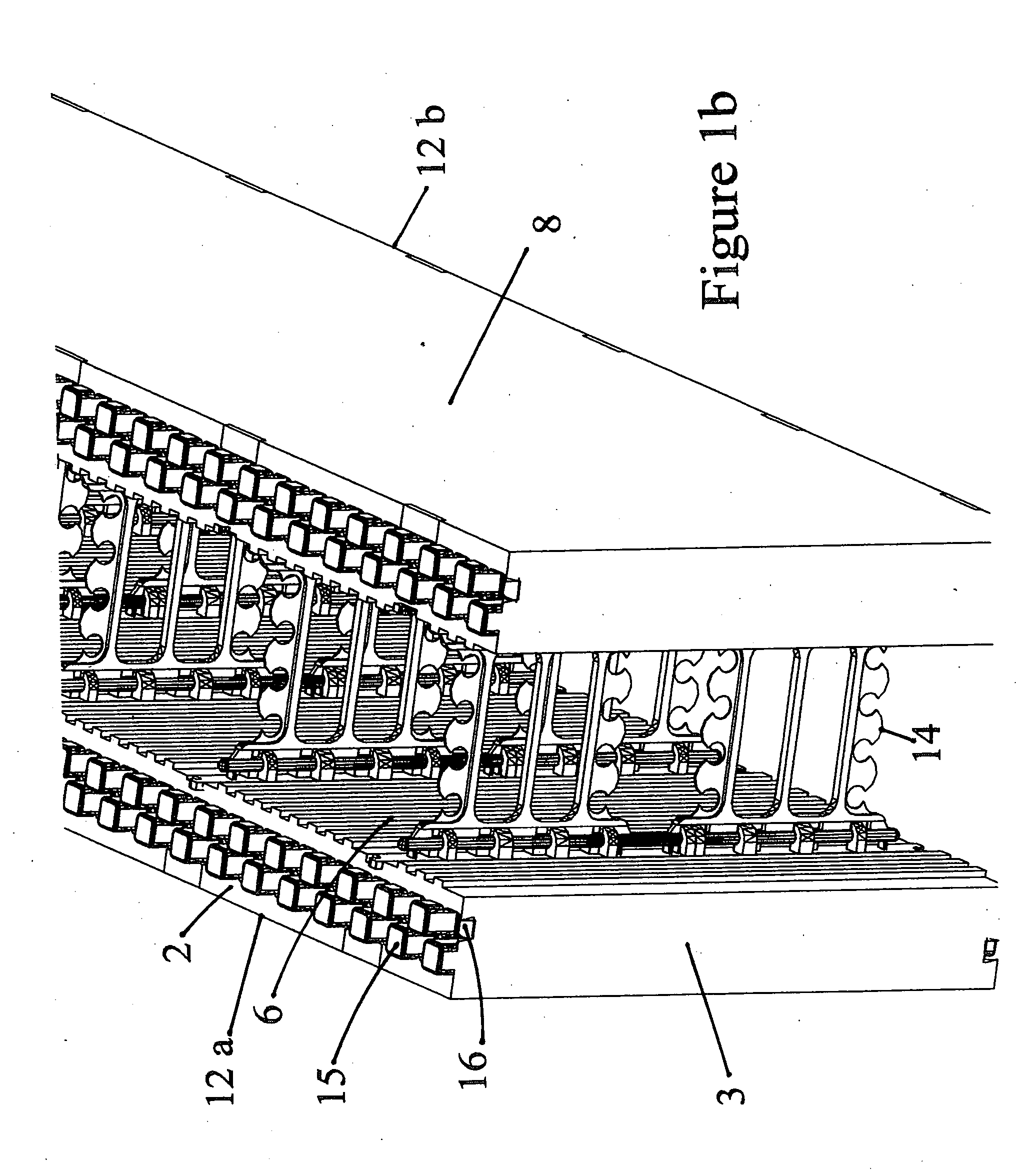

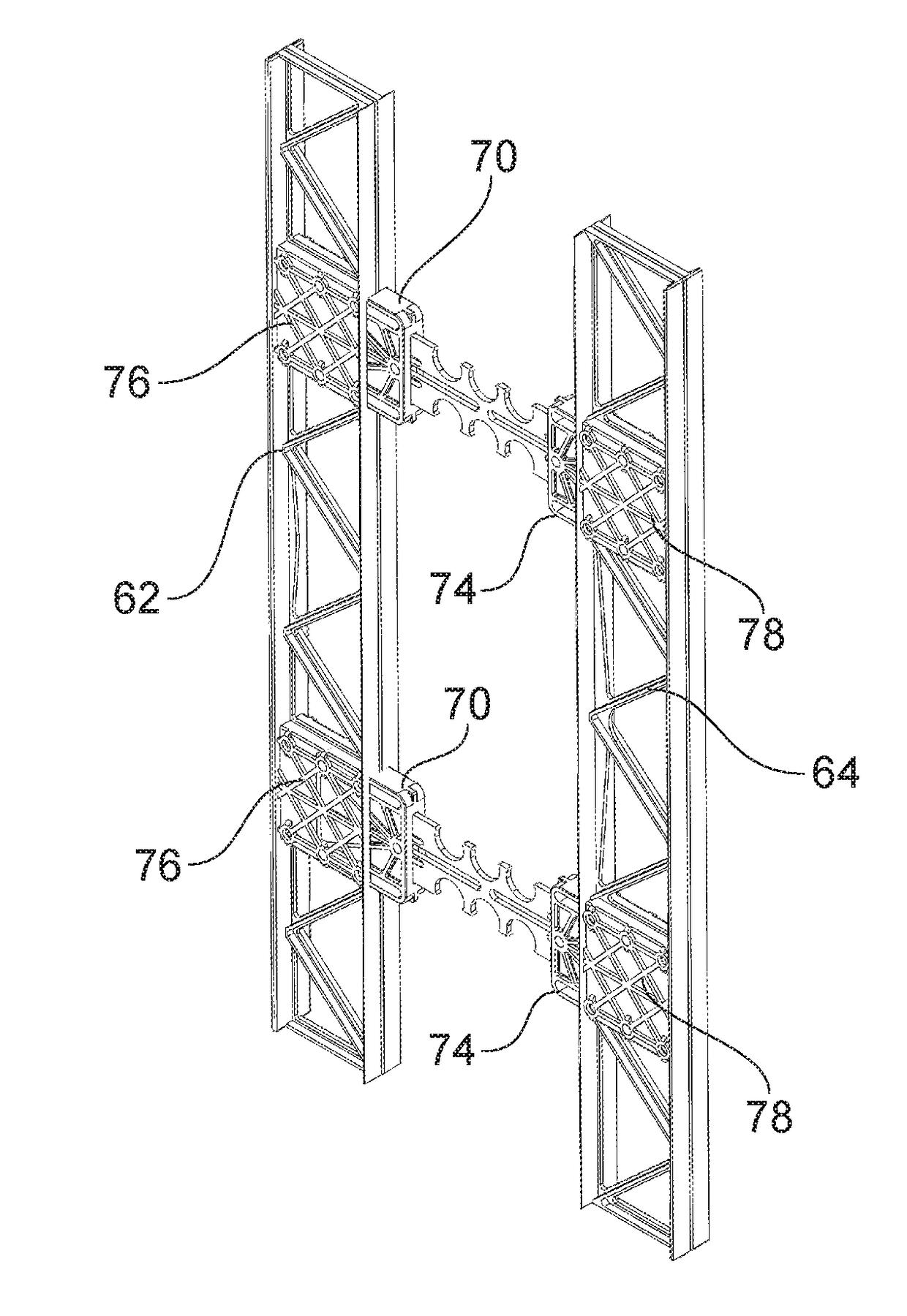

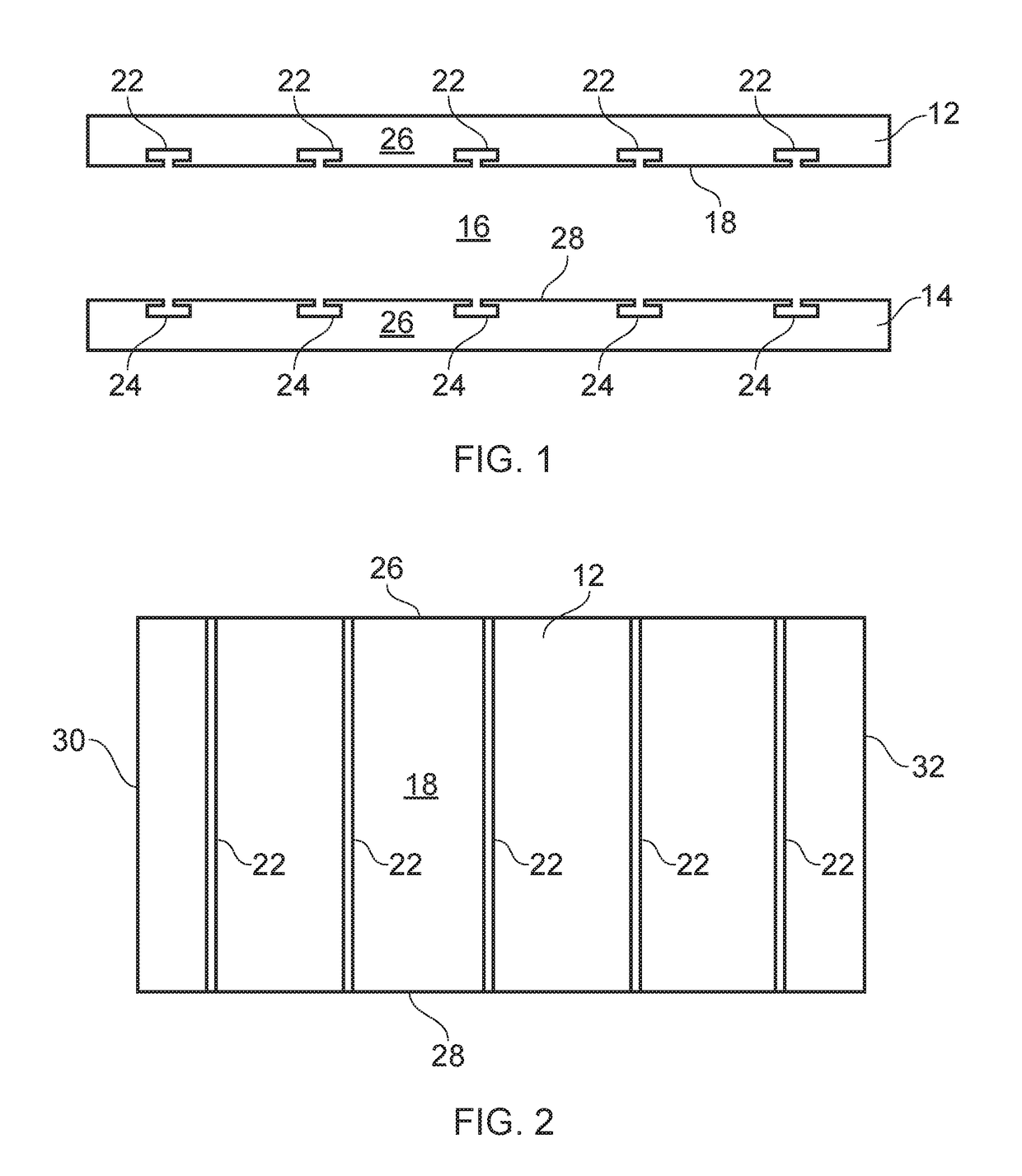

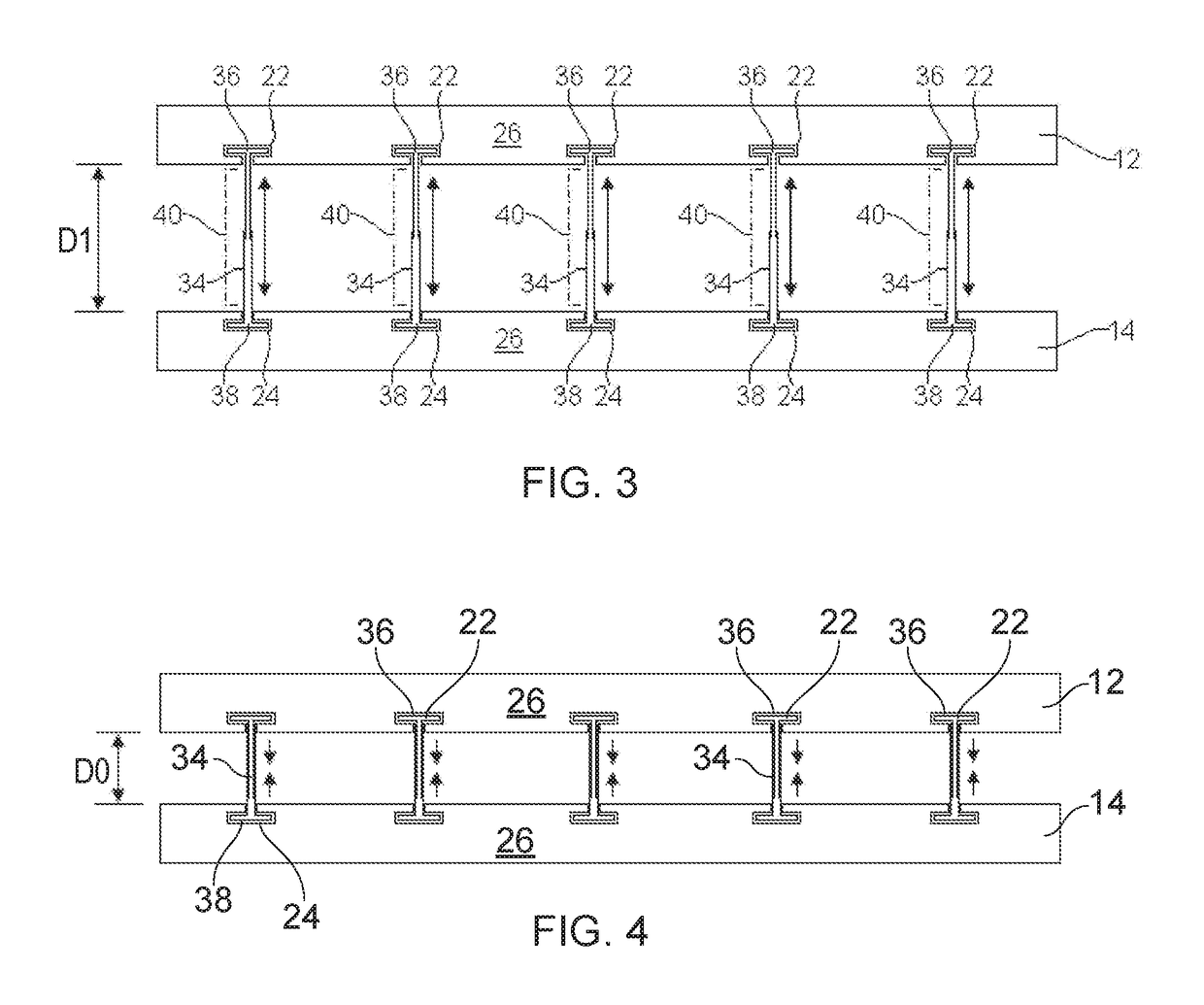

Insulated concrete wall forming system and hinged bridging webs

InactiveUS7082732B2Size reduction requirementsLower the volumeCeilingsStrutsEngineeringMechanical engineering

Owner:CANSTROY INT INC

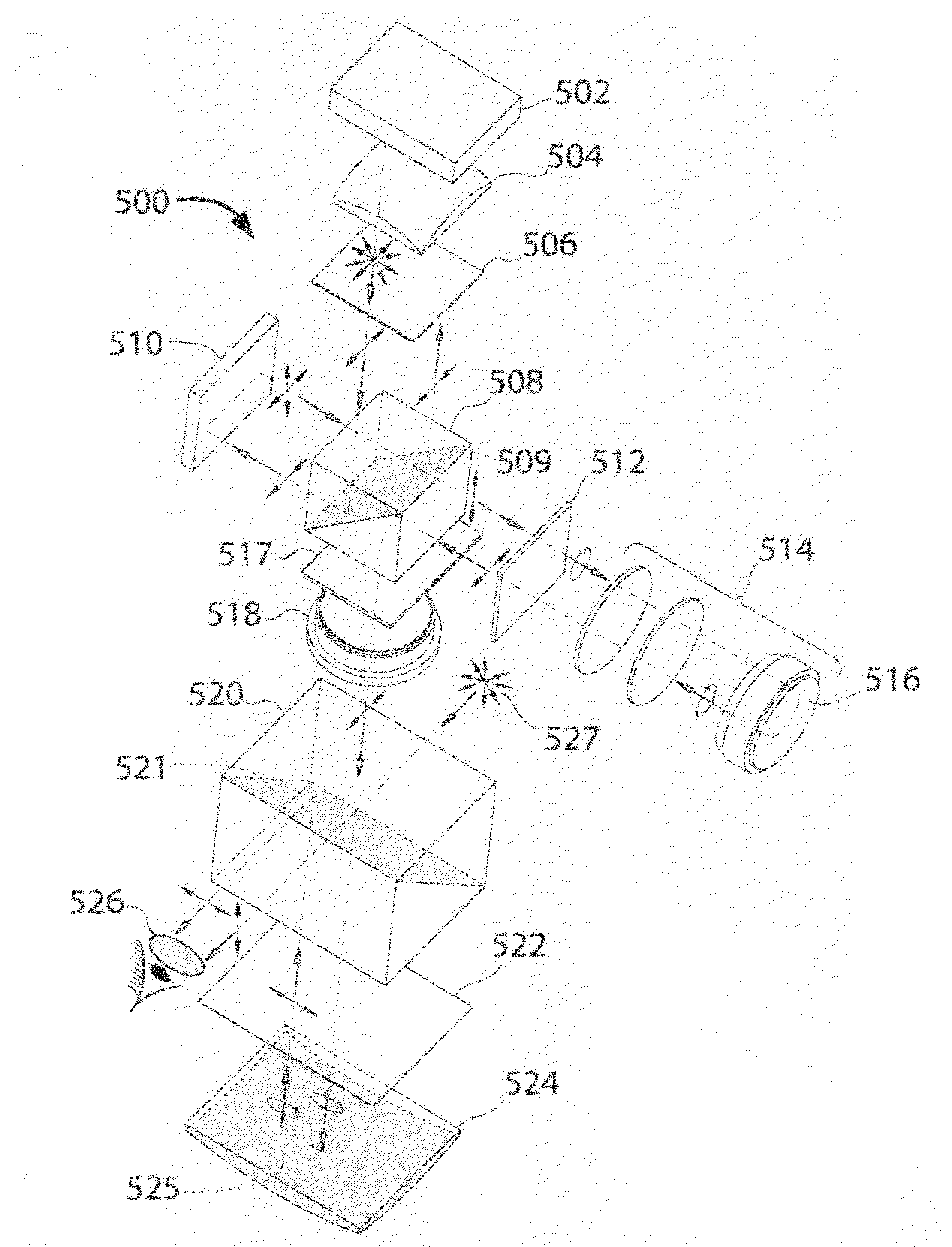

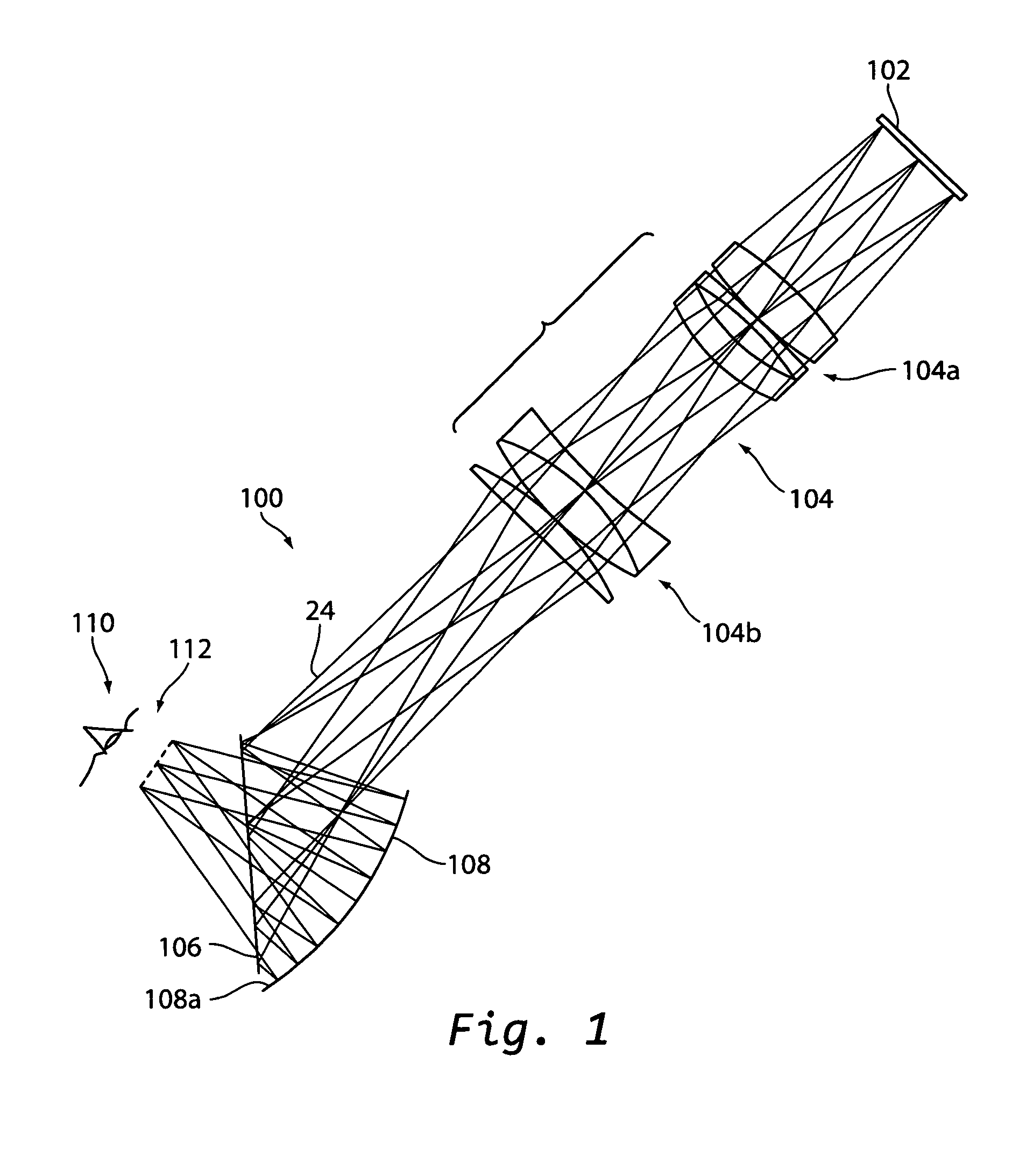

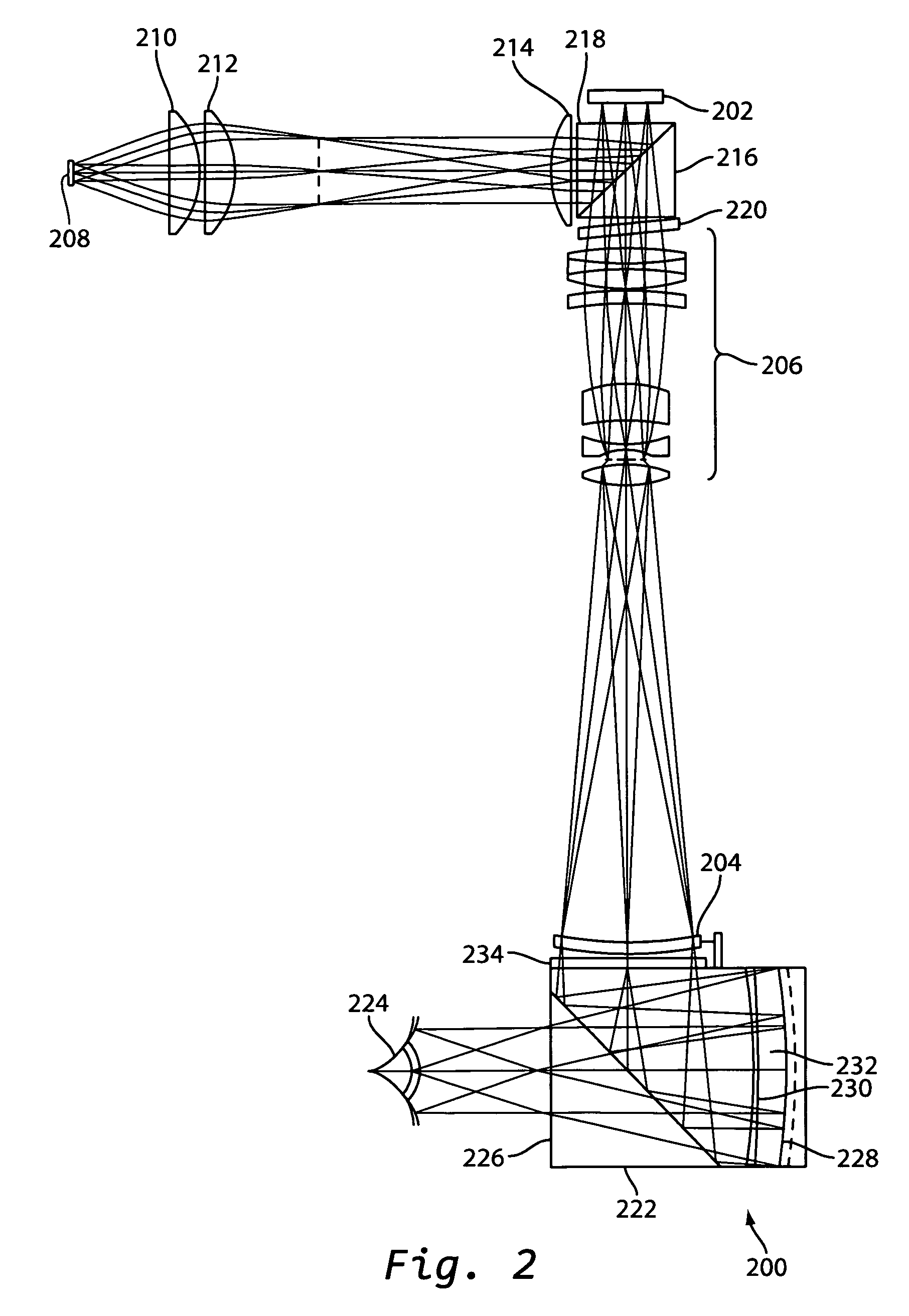

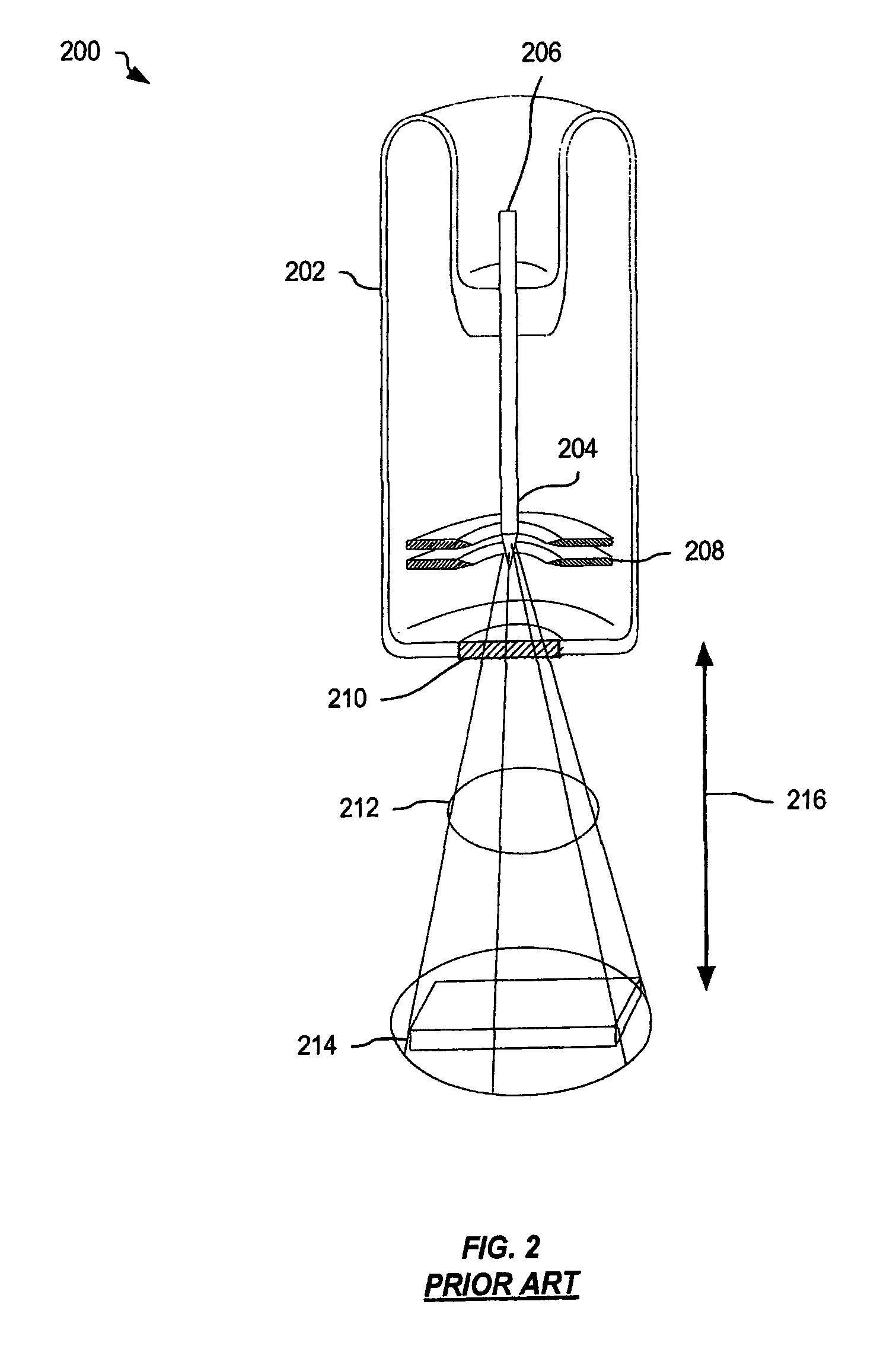

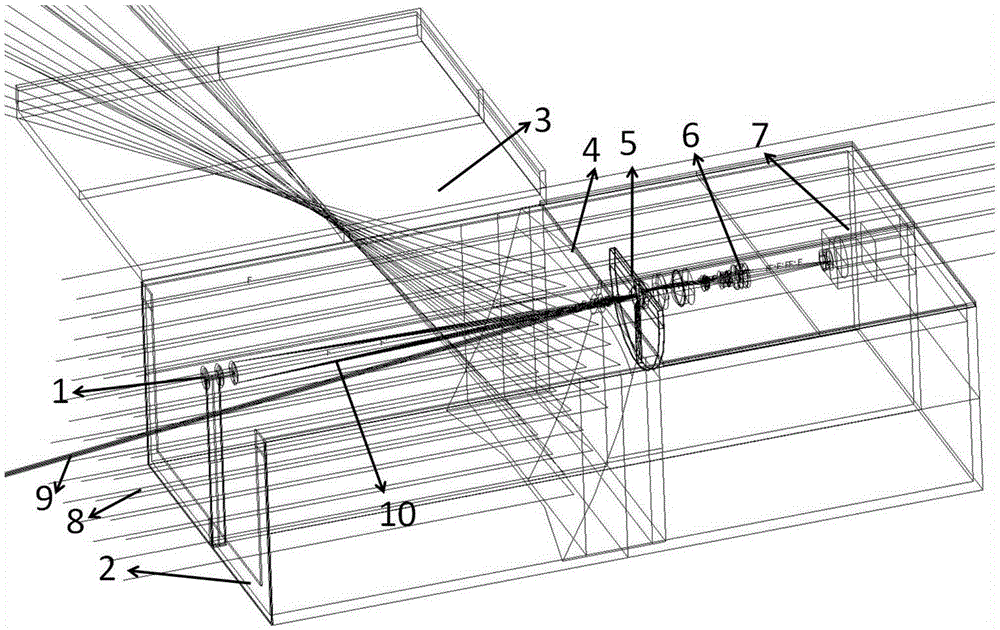

Compact optical system

InactiveUS7675684B1Reduce in quantitySize reduction requirementsPolarising elementsCamera lensSpatial light modulator

The invention relates to compact optical arrangement for a helmet mounted display. The arrangement is well suited to use with spatial light modulators which require front illumination such as LCoS modulators but can also be adapted to rear illuminated devices such as LCD's and to self luminous devices such as OLEDs. The device uses polarization and reflection to make dual use of both volumes and lenses.

Owner:NVIS

Insulated concrete wall forming system and hinged bridging webs

InactiveUS20050028466A1Size reduction requirementsLower the volumeCeilingsStrutsEngineeringMechanical engineering

A bridging web for linking a first and second wall panel, the first and second wall panels extending parallel to one another. The bridging web has a first and second end member, each of which extend between a first edge mountable within the wall panels and a second edge. The second edge has a first hinge element. The first end member is mountable within the first wall panel and the second end member is mountable within the second wall panel. A central section extends between a pair of second hinge elements and is mountable between the first hinge element of the first end member and the first hinge element of the second end member. One of the first and second hinge elements is a pin and the other of the first and second hinge elements includes at least one first knuckle and at least one second knuckle. The pin defines a vertical hinge axis. The first knuckle is vertically displaced from the second knuckle, and the first and second knuckles are adapted to bear on opposing surfaces of the pin.

Owner:CANSTROY INT

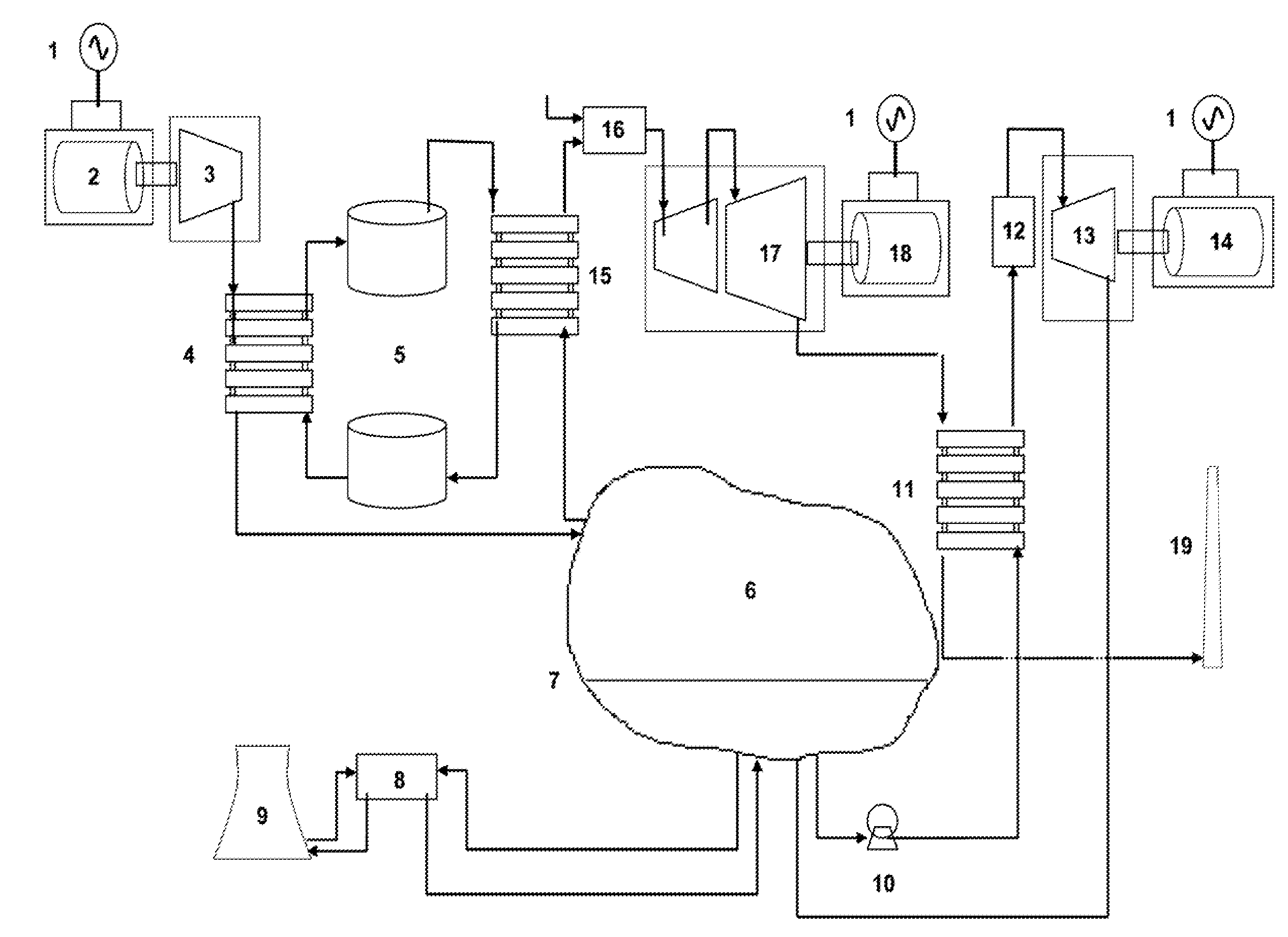

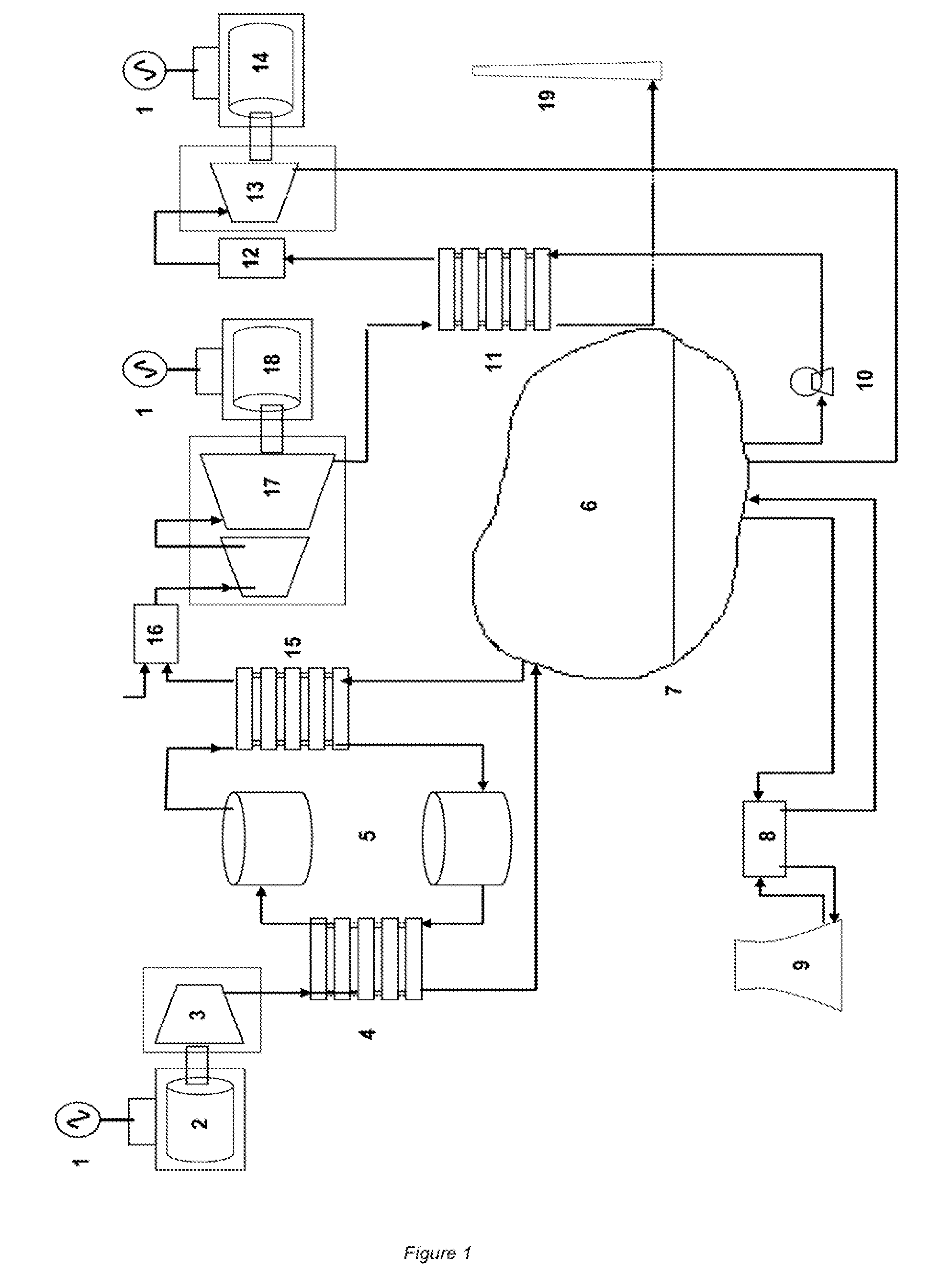

Combined Cycle CAES Technology (CCC)

InactiveUS20150000248A1Size reduction requirementsImprove efficiencySteam accumulatorsGas turbine plantsBrayton cycleAir compression

This is a system that stores energy by compressing atmospheric air and confining it in tanks or caverns, combining the thermodynamic cycle followed by the atmospheric air (Brayton cycle) with another thermodynamic cycle followed by an auxiliary fluid, that is confined in the same cavern within a membrane, following two sections of a Rankine cycle, one during the air compression and entry into the cavern process and the other during the air outlet and turbininig process, using heat from the exhaust gases from the turbine as a heat source for an additional Rankine cycle, and being able to use the tanks or caverns for making an extra constant volume heating of compressed air and I or of the auxiliary fluid

Owner:PREXTOR SYST

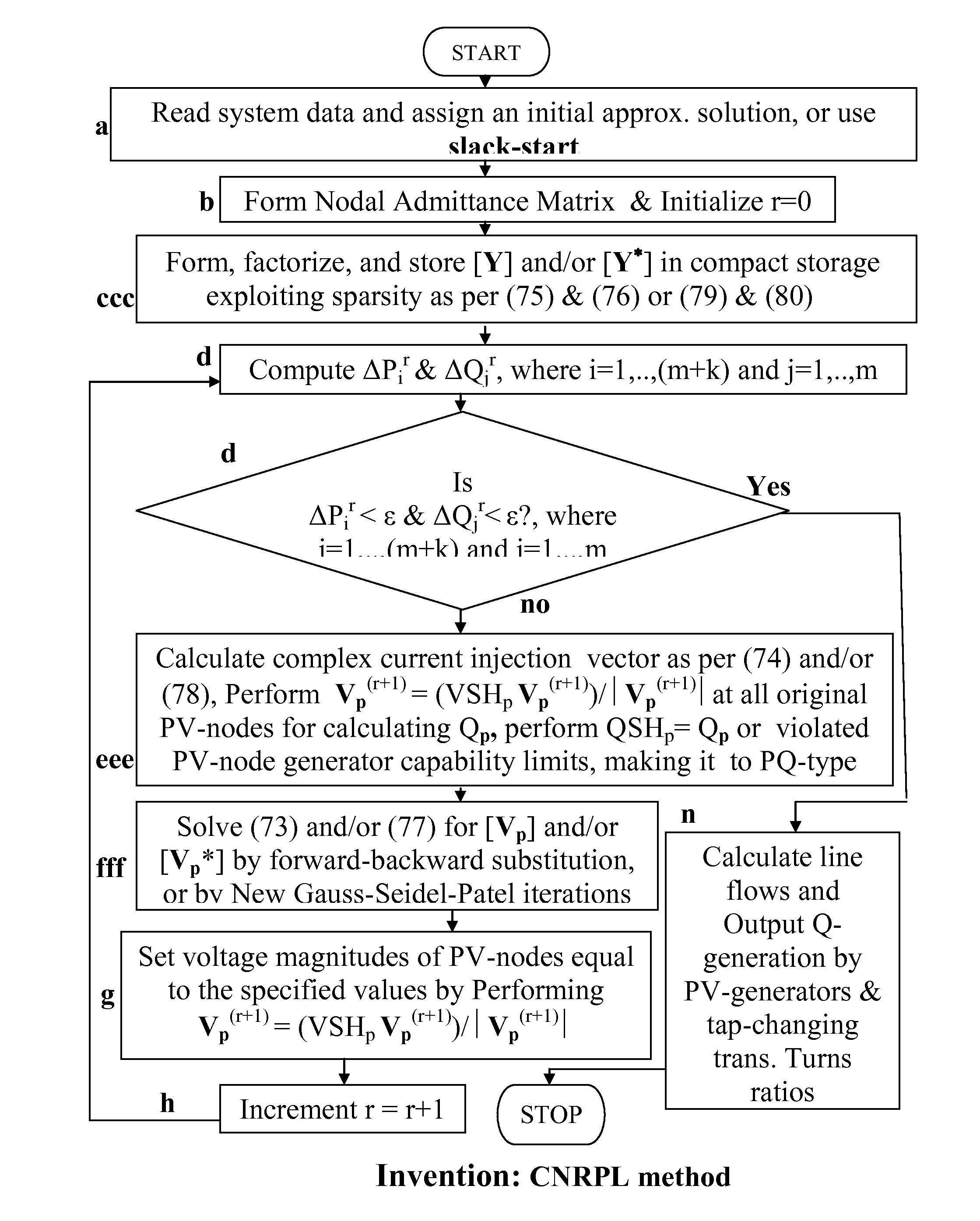

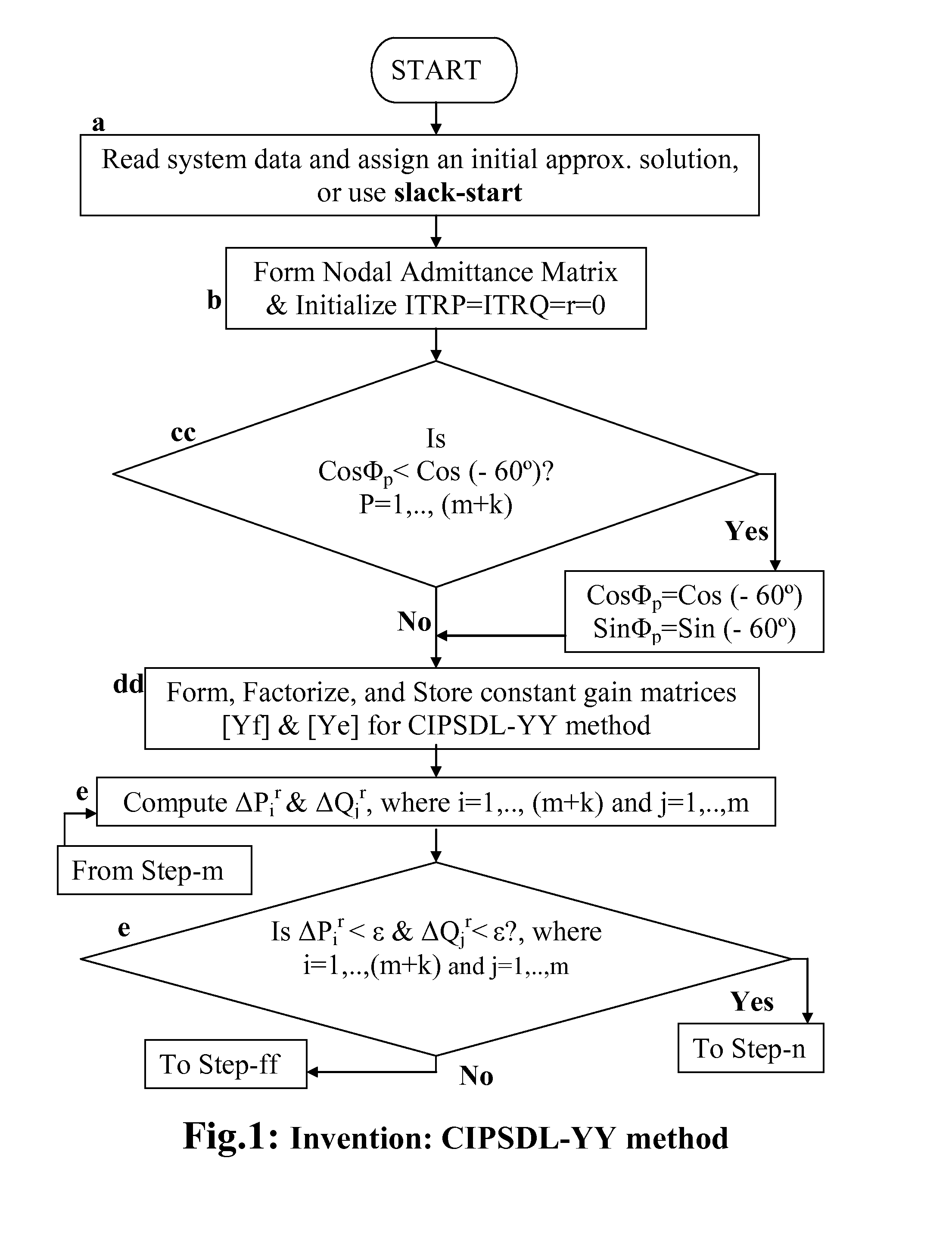

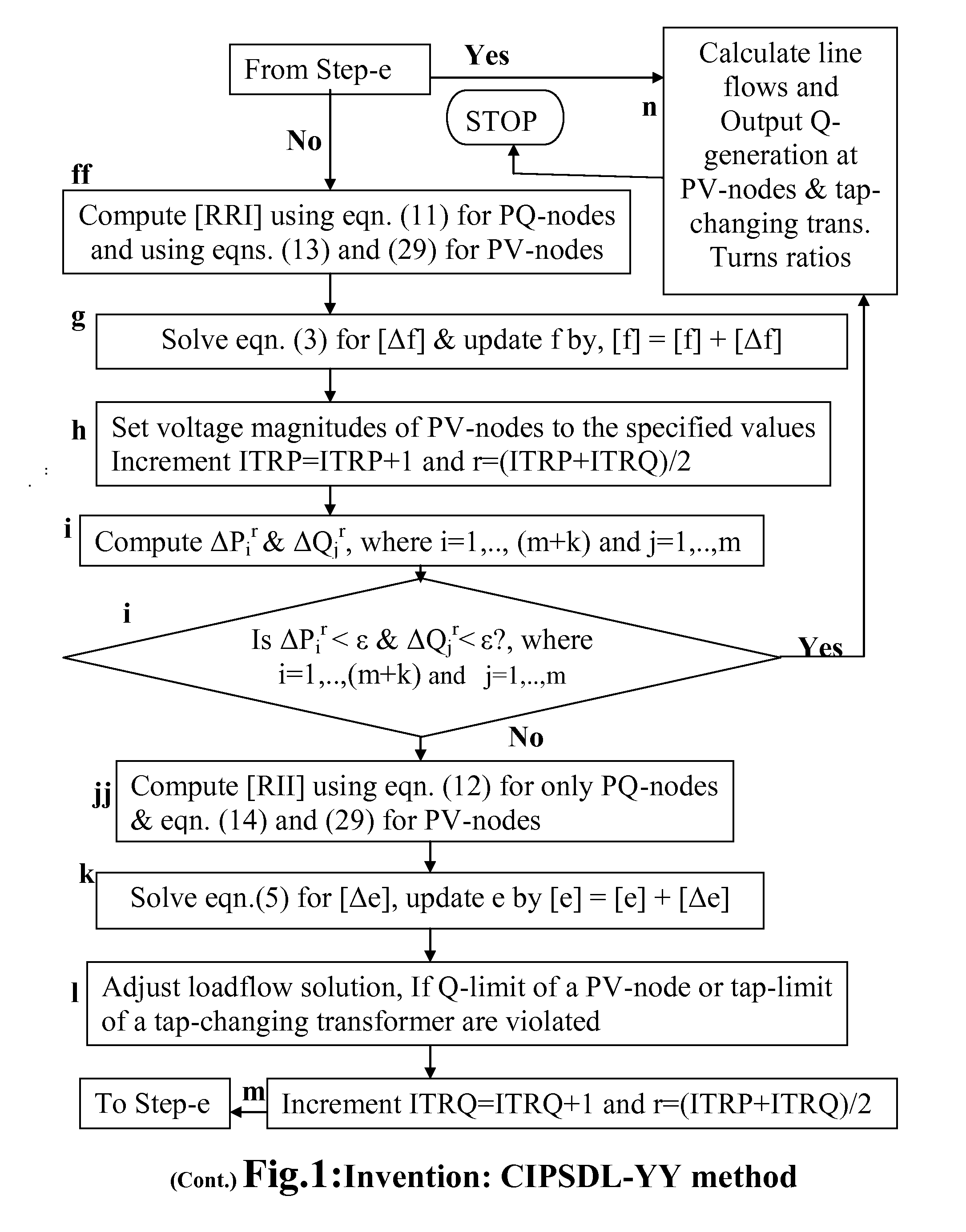

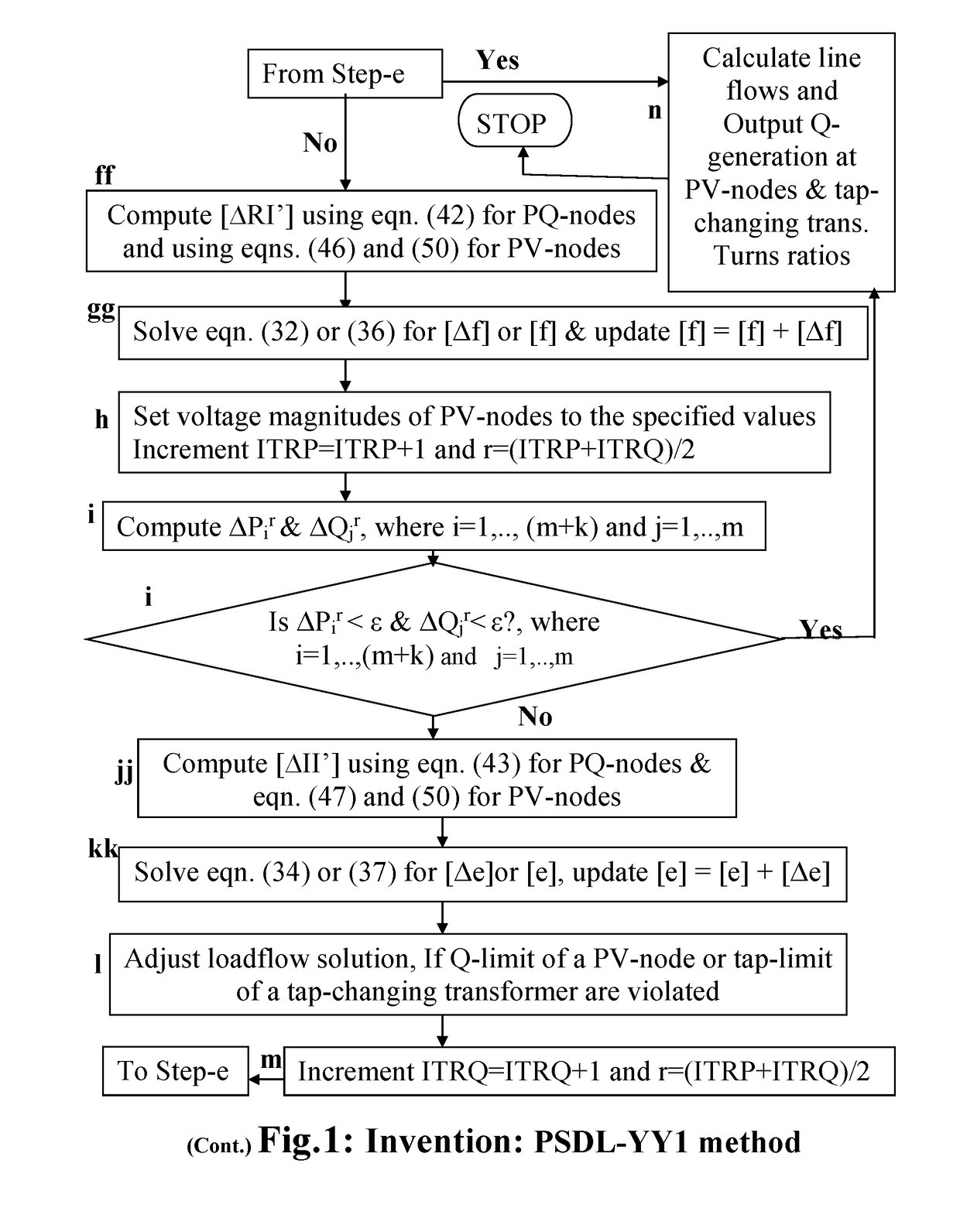

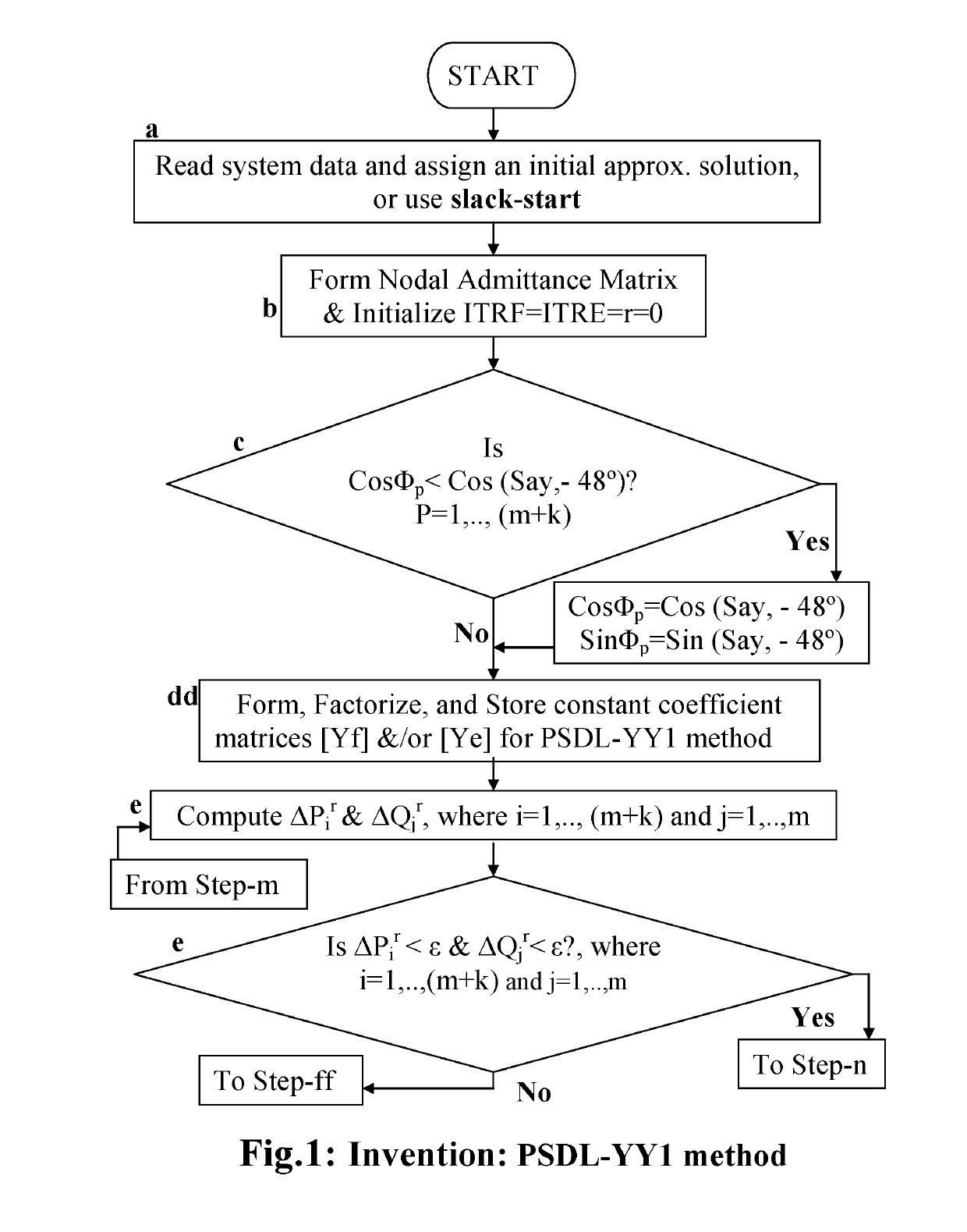

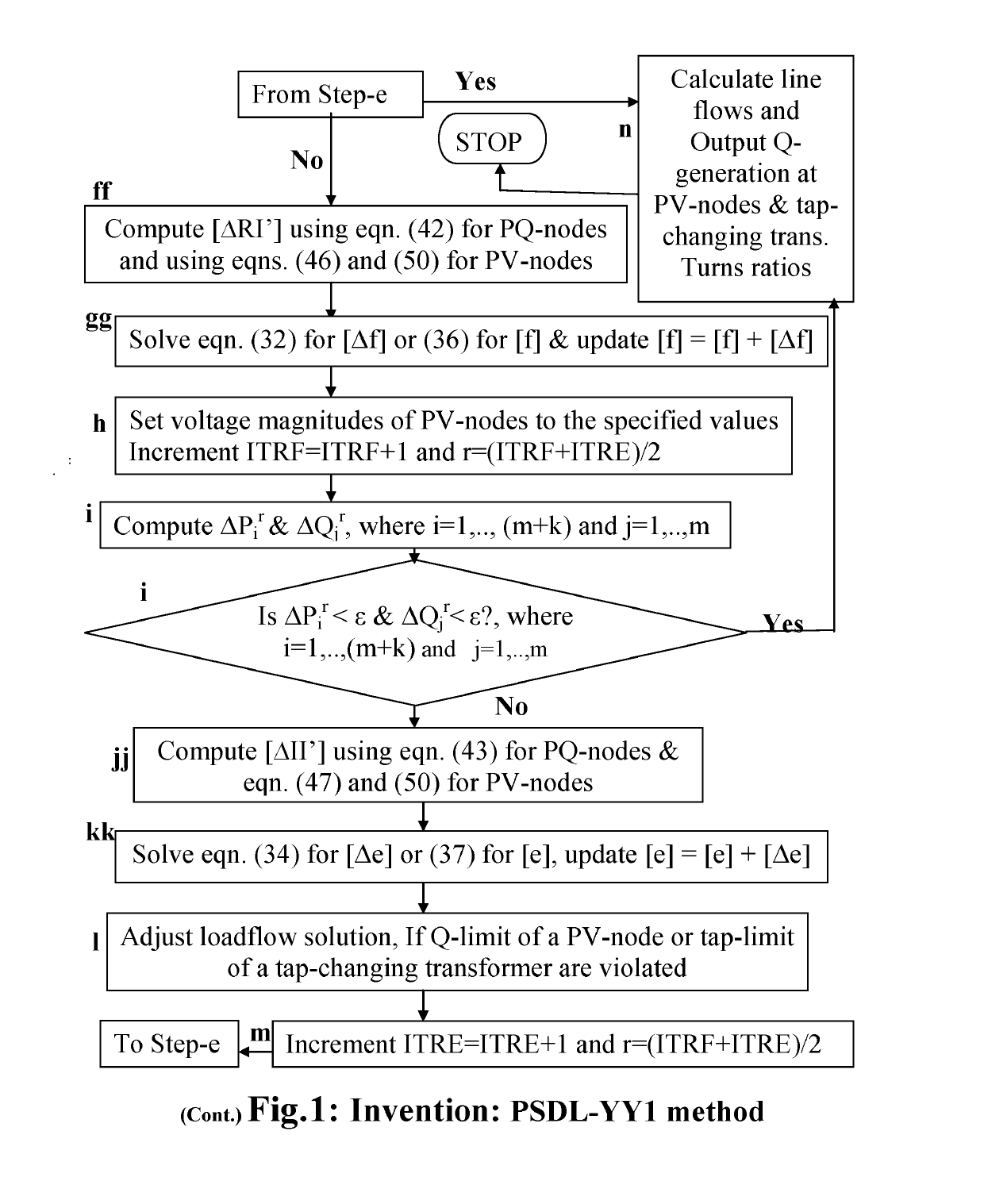

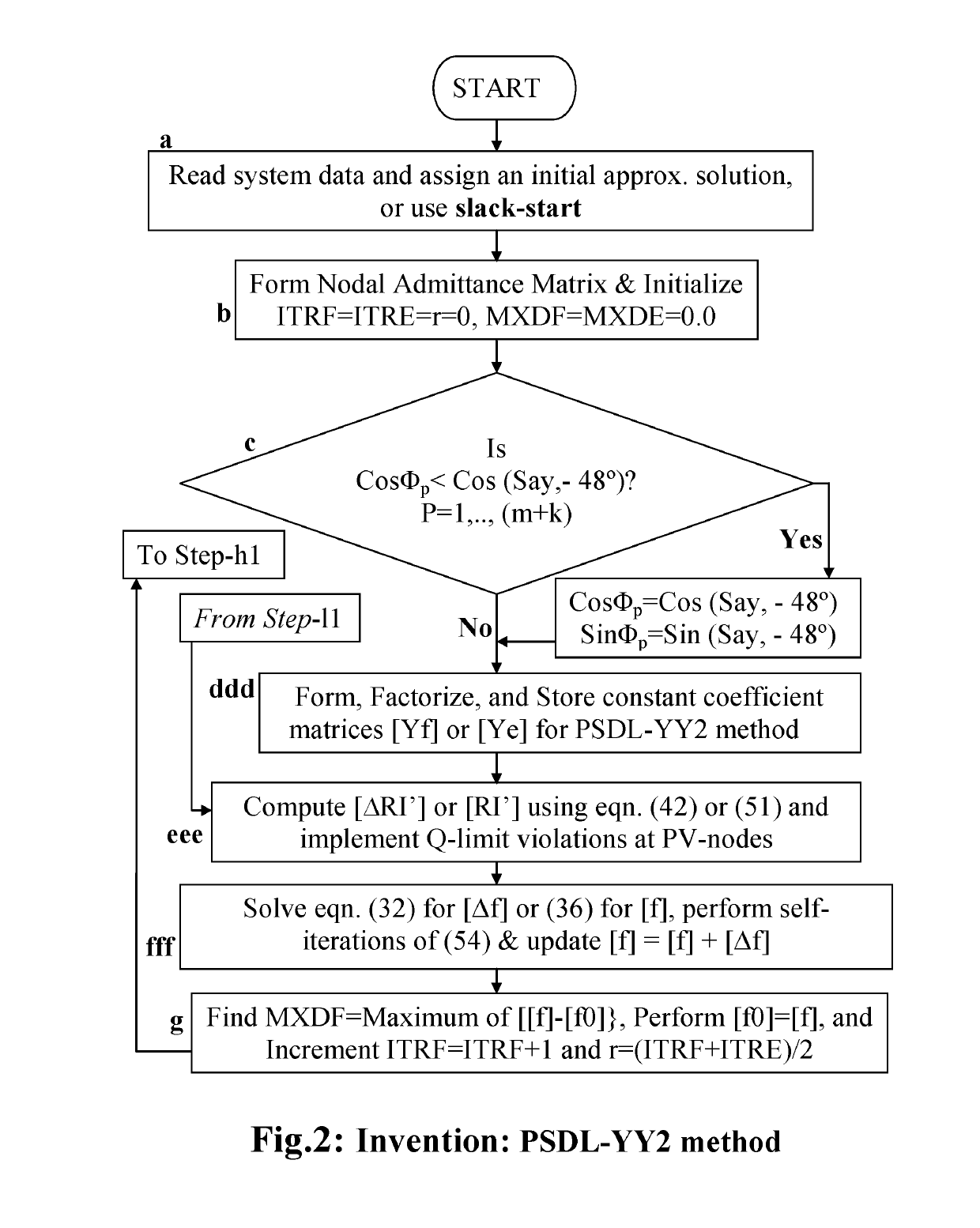

Methods of Patel Loadflow Computation for Electrical Power System

InactiveUS20150112498A1Fast convergenceImprove efficiencyMechanical power/torque controlLevel controlElectric power systemComputer science

Highly efficient and reliable methods of Current Injection Patel Super Decoupled Loadflow (CIPSDL), New Gauss-Seidel-Patel Loadflow (NGSPL), Decoupled Gaus-Seidel-Patel Loadflow, and Current Injection Newton-Raphson-Patel Loadflow (CINRPL) are invented. One of the versions CIPSDL method is characterized in 1) the use of the same coefficient matrix [−Y] for both the RI-f and II-e sub-problems, and in all the methods 2) all the nodes being active, no re-factorization of gain matrices [−Y], [Y], [Y*] are required for implementation of Q-limit violations. The invented DGSPL calculation method is characterized in decoupling the calculation of real and imaginary components of complex node voltage leading to increased stability and efficiency of the DGSPL calculation method. Also invented are Constant Matrix Patel Loadflow (CMPL) and Patel Transformation Decoupled Loadflow (PTDL) methods.

Owner:PATEL SURESHCHANDRA B

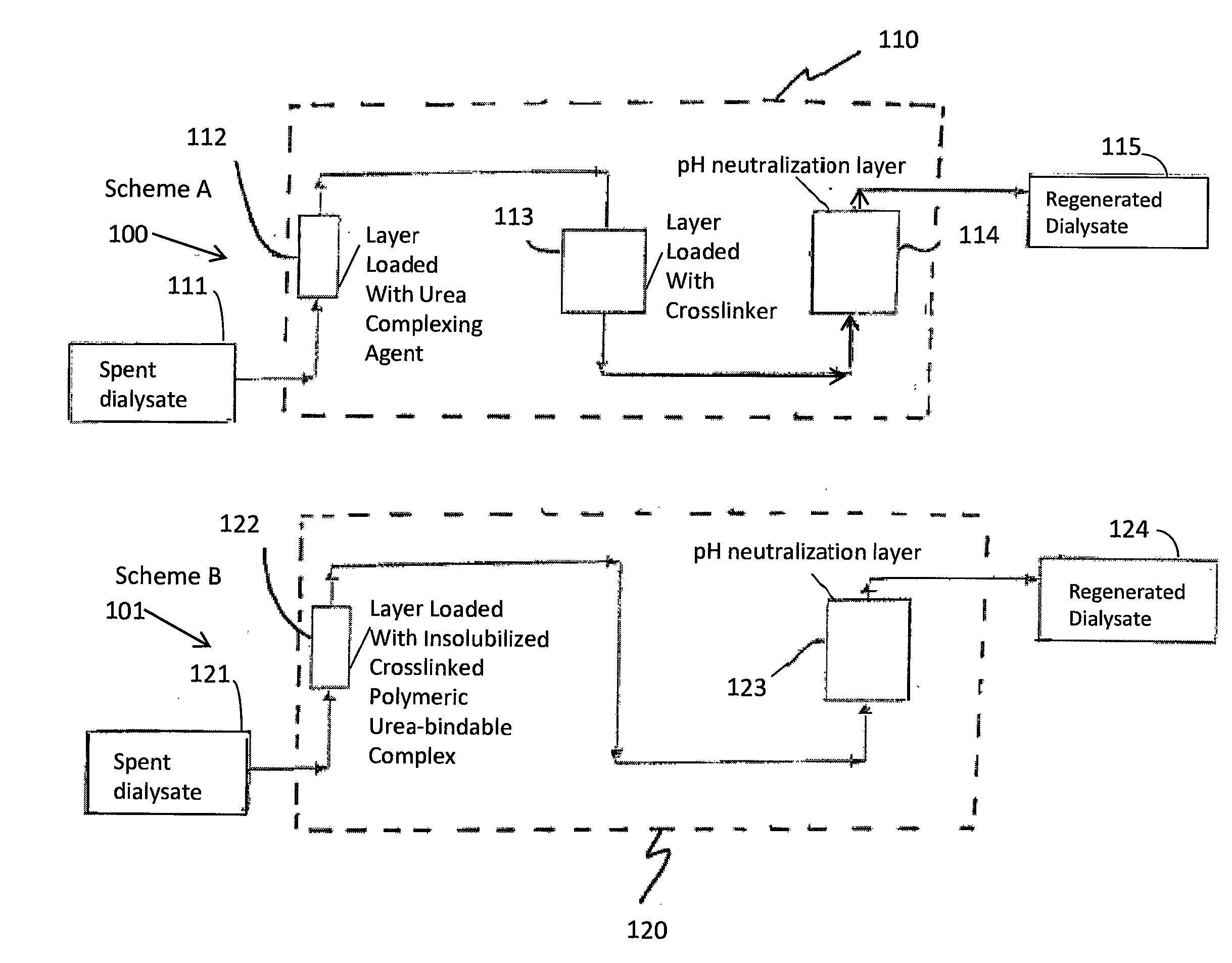

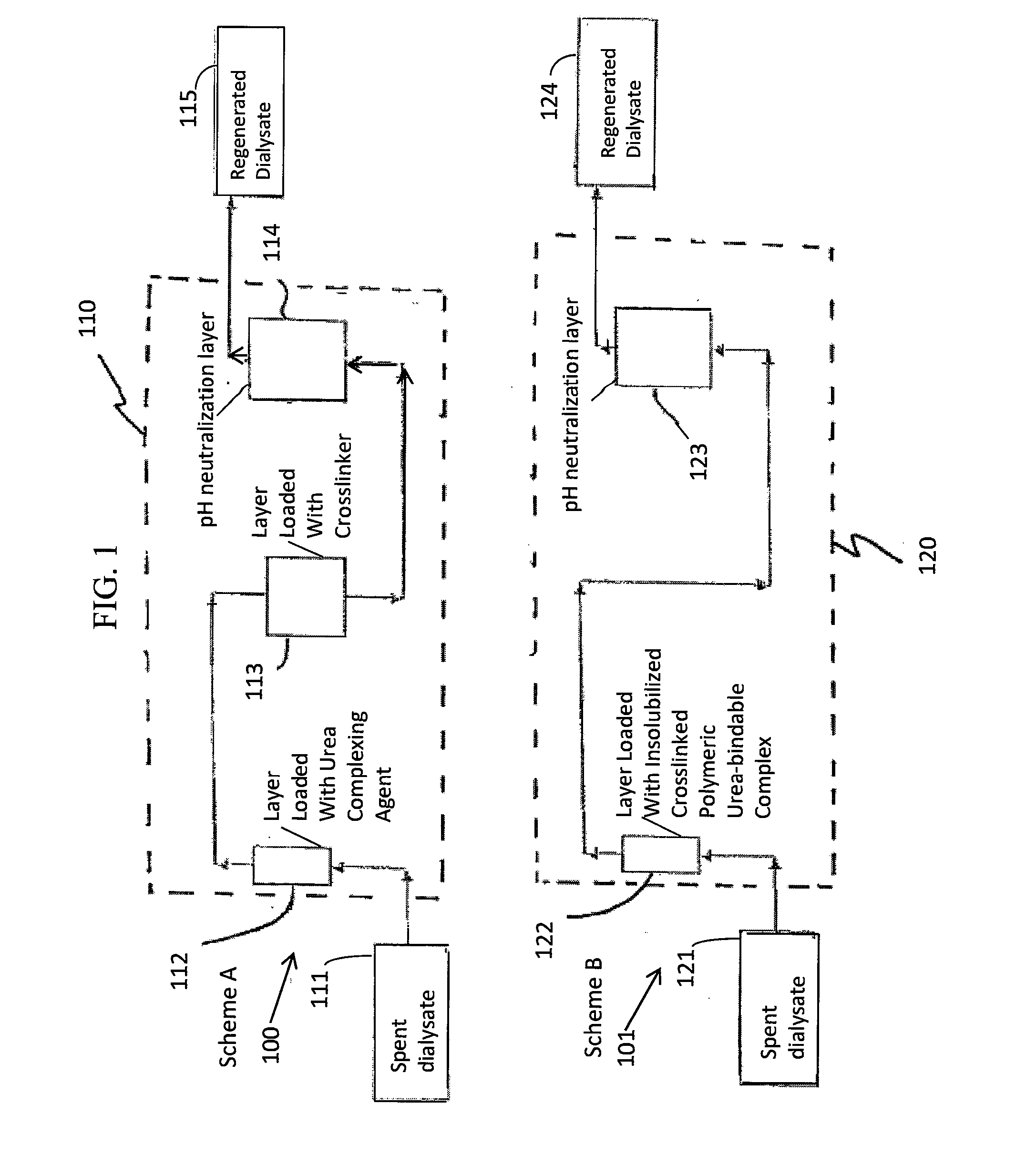

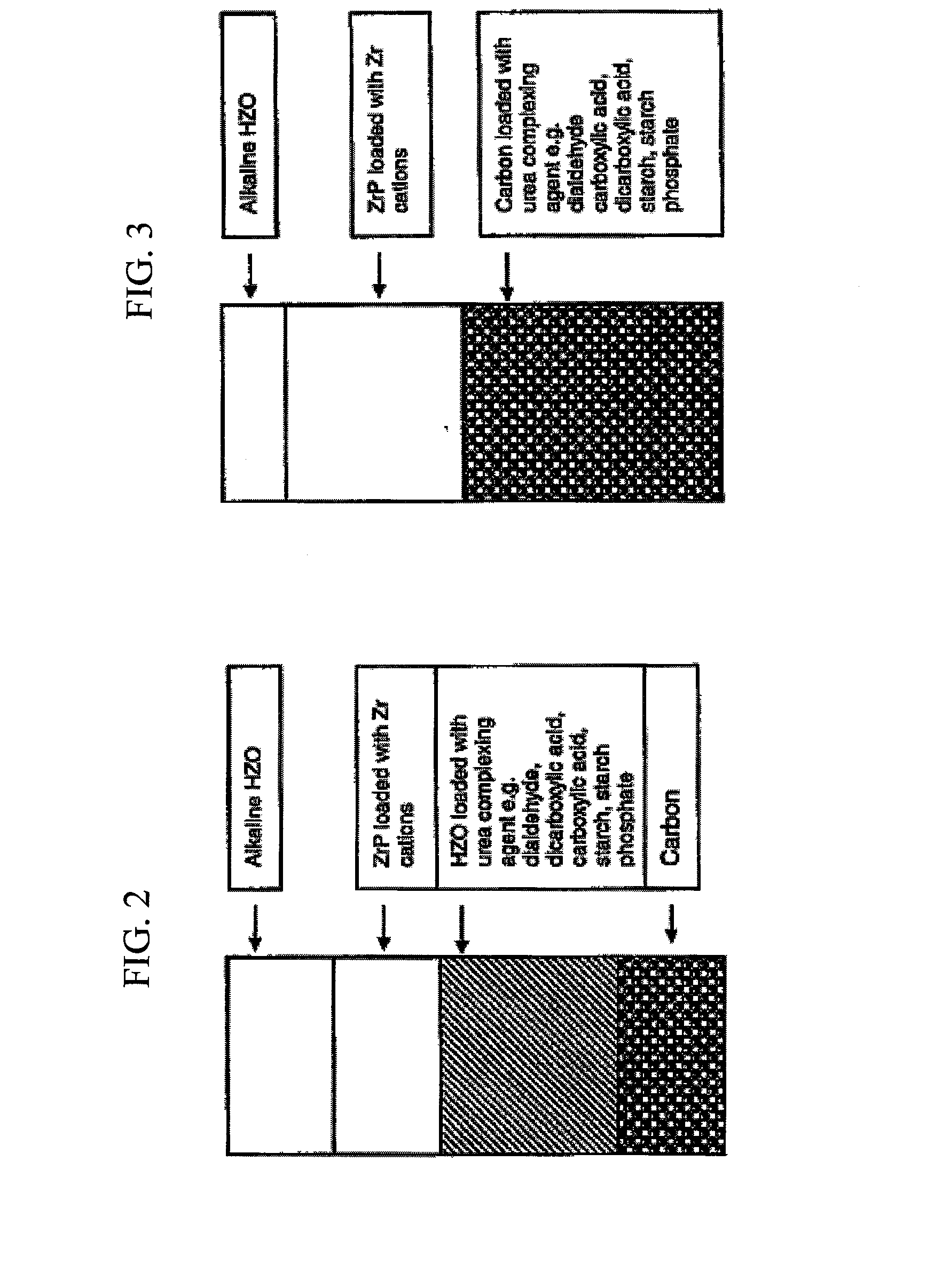

Materials For Removal Of Toxins In Sorbent Dialysis And Methods And Systems Using Same

ActiveUS20140336568A1Size reduction requirementsSemi-permeable membranesOther chemical processesUrocaninaseCross linker

A sorbent dialysis cartridge is provided for removal of uremic toxins from dialysate wherein the sorbent cartridges can use non-enzymatic urea-binding materials in place of urease. The cartridge can have a first sorbent layer loaded with a polymerizable urea complexing agent and a second sorbent layer loaded with a crosslinker. The crosslinker can be crosslinkable with a soluble urea complex reaction product of the polymerizable urea complexing agent and urea when passing through the first sorbent layer to form a crosslinked polymeric urea complex which is attachable to the second sorbent layer. In another option, a sorbent layer can be used which has an insolubilized crosslinked polymeric urea-bindable complex attached thereto, wherein the crosslinked polymeric urea-bindable complex can be a reaction product of a crosslinker and polymerizable urea complexing agent. Methods and sorbent dialysis systems using the cartridge, and methods of making the sorbent material, are provided.

Owner:FRESENIUS MEDICAL CARE HLDG INC

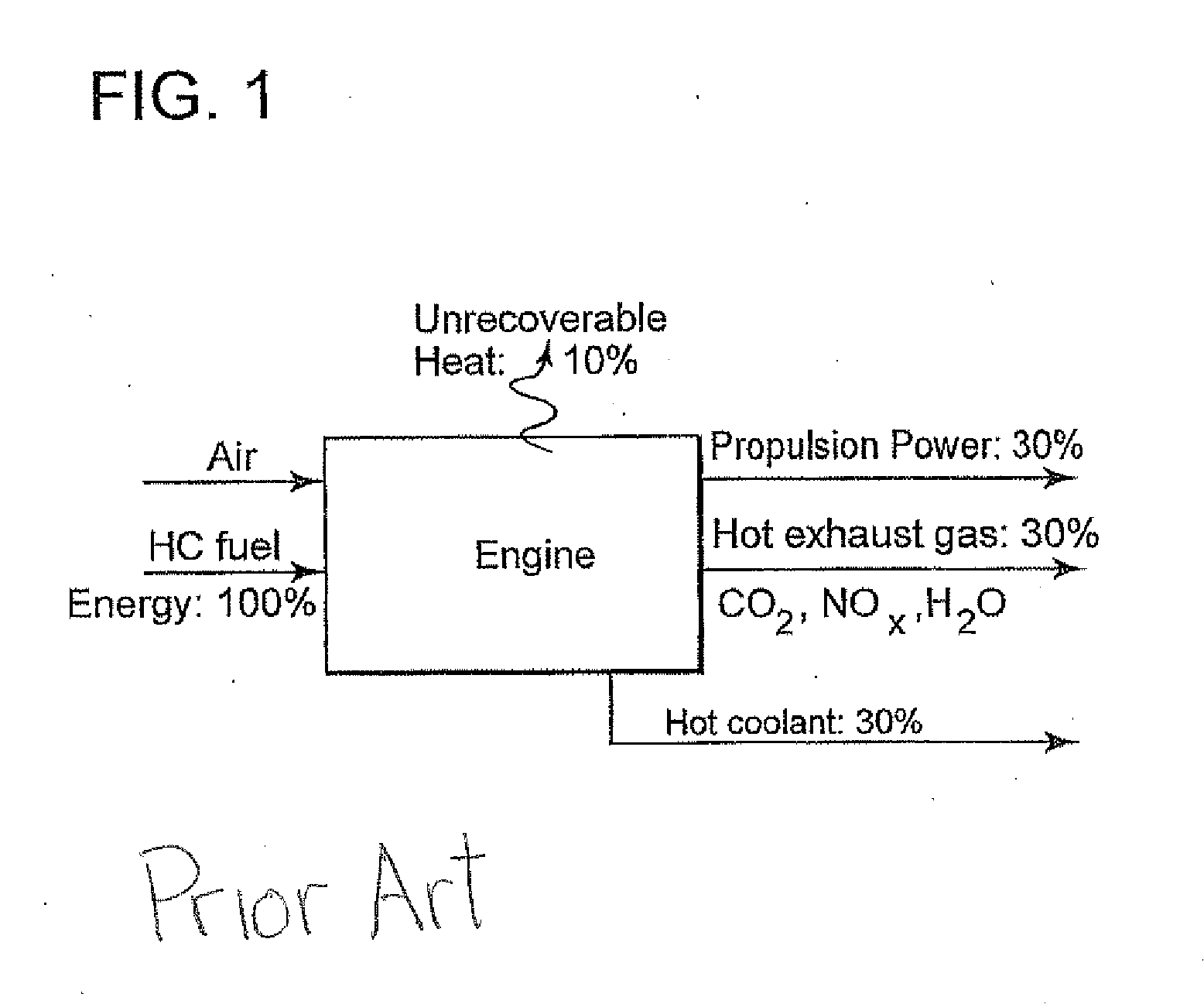

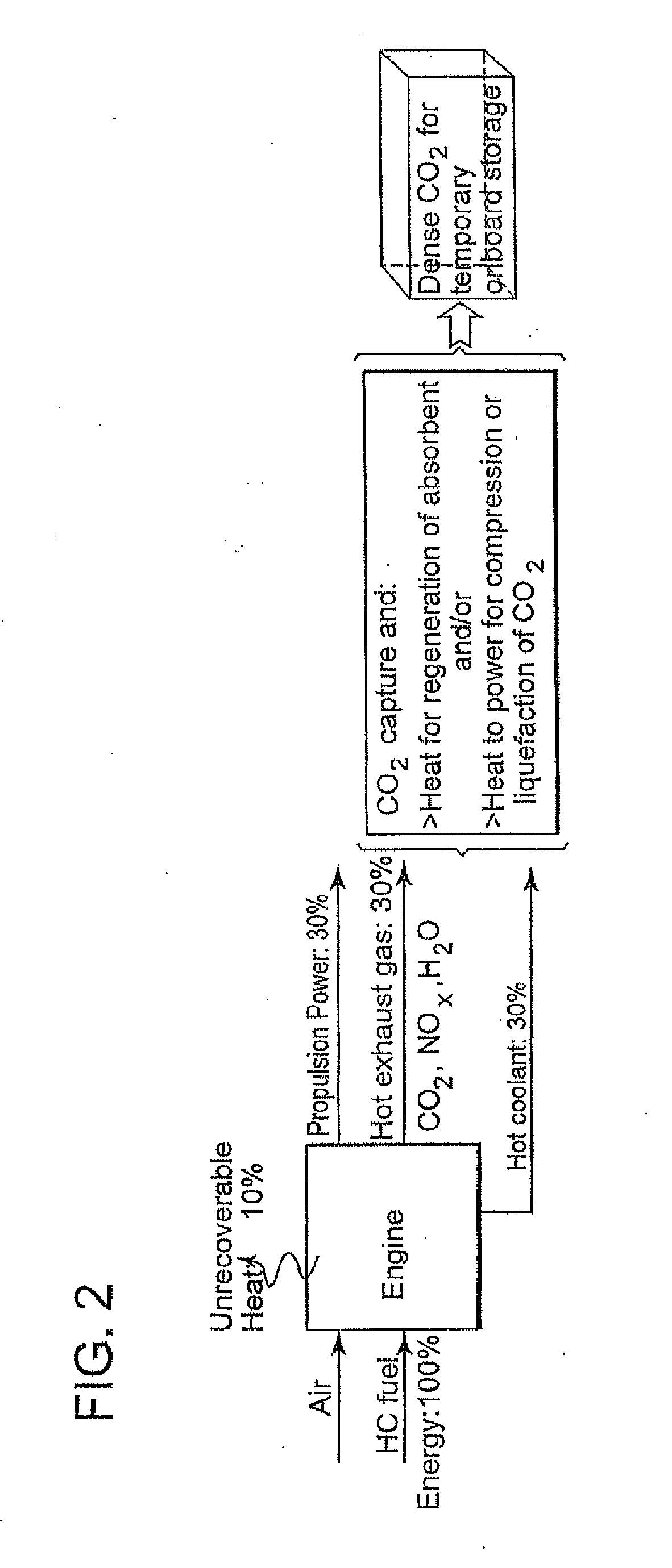

Reversible solid adsorption method and system utilizing waste heat for on-board recovery and storage of co2 from motor vehicle internal combustion engine exhaust gases

ActiveUS20130298532A1Emission reductionModerate temperatureGas treatmentCarbon compoundsOn boardAtmospheric air

A method and system are described for on-board treatment of an exhaust stream containing CO2 emitted by a hydrocarbon-fueled internal combustion engine (ICE) used to power a vehicle in order to reduce the amount of CO2 discharged into the atmosphere which include:a. a treatment zone on board the vehicle containing a capture agent having a predetermined capacity for extracting CO2 from the exhaust stream,the treatment zone preferably operating in swing mode with at least two subsystems, each having an inlet for admitting the exhaust gas stream and an outlet for passage of a treated exhaust stream having a reduced CO2 content,the treatment zone preferably operating in swing mode with at least two subsystems, each including a heat exchanger with an inlet for receiving the hot exhaust gas stream from the ICE for passage in heat exchange relation with the capture agent to release CO2 and regenerate the capture agent, and an outlet for the cooled exhaust gas stream,the treatment zone having a CO2 discharge outlet for CO2 released from the regenerated capture agent;b. a compression zone in fluid communication with the CO2 discharge outlet from the treatment zone, the compression zone including one or more compressors for reducing the volume of the CO2;c. a storage zone for receiving the compressed CO2 for temporary storage on board the vehicle; andd. an exhaust gas conduit in fluid communication with the treated exhaust gas stream outlet from the treatment zone.

Owner:SAUDI ARABIAN OIL CO

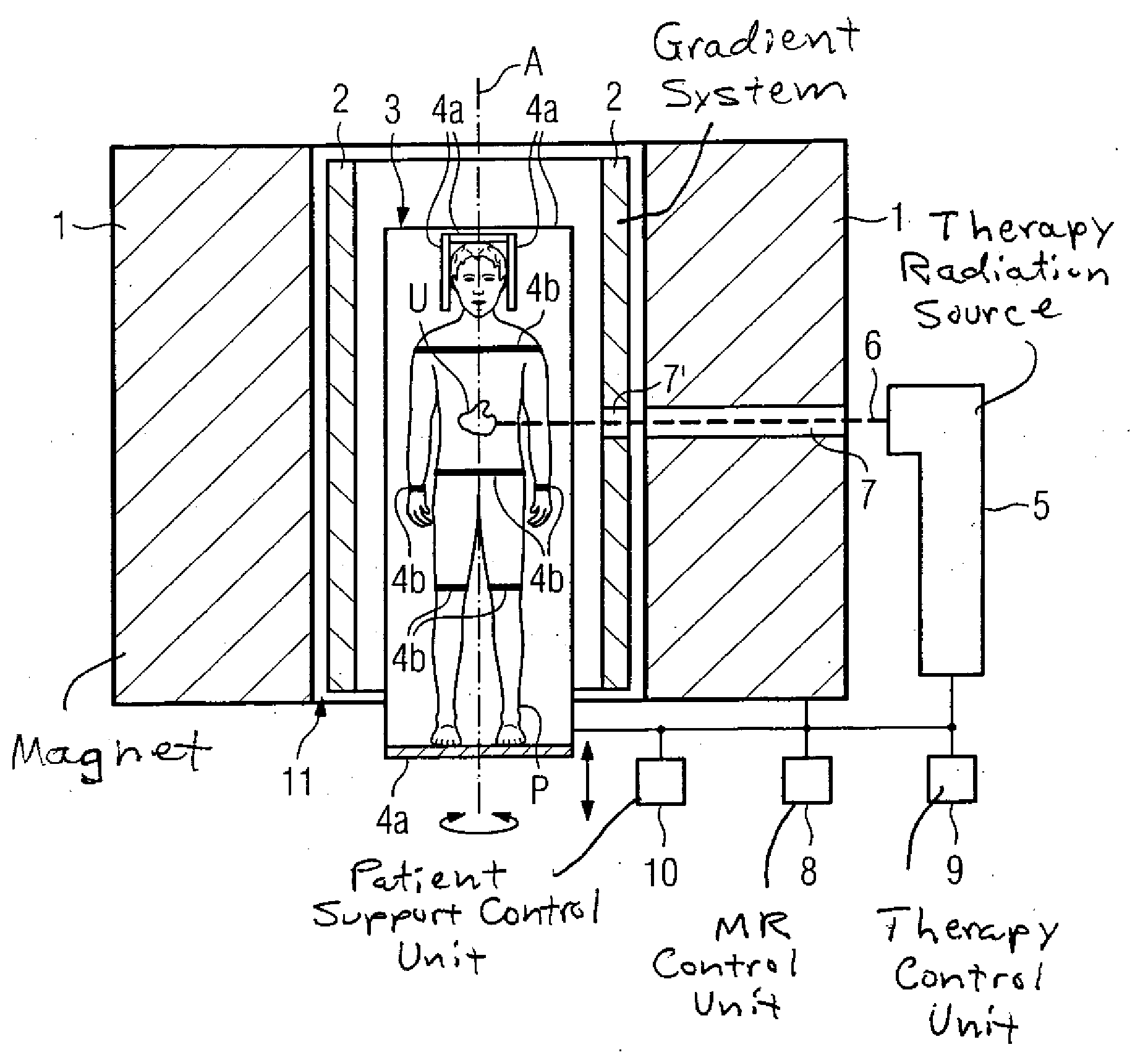

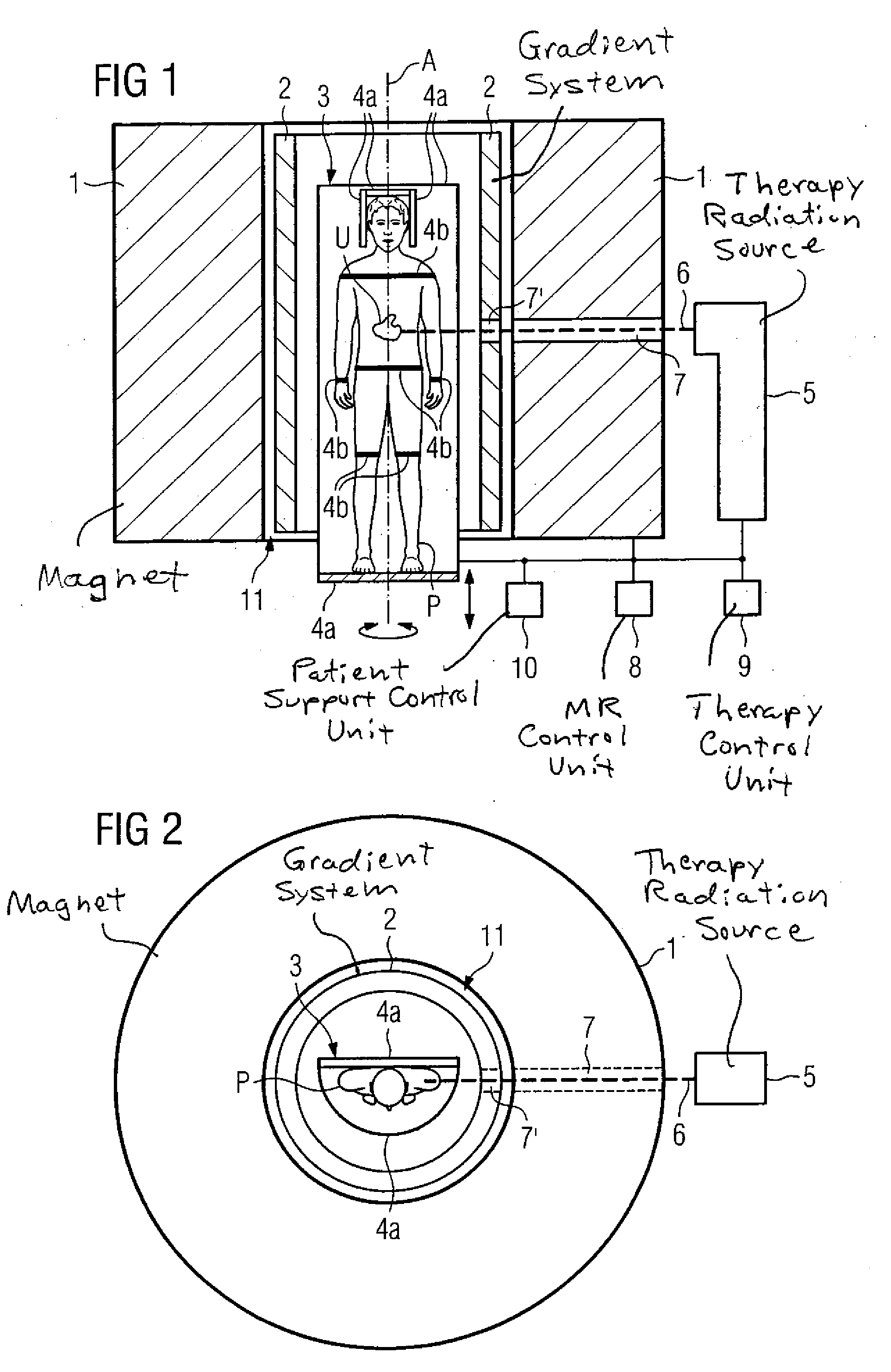

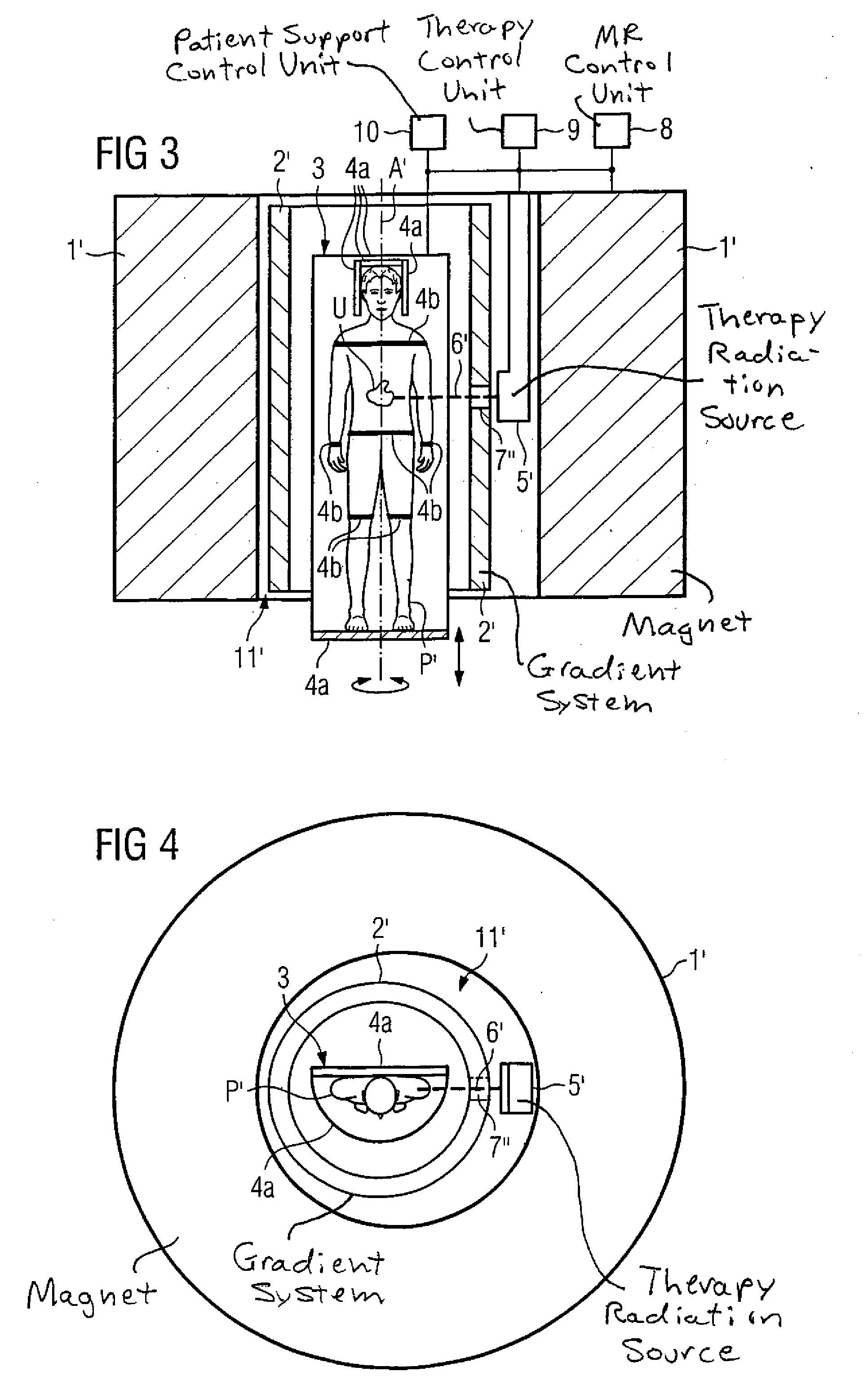

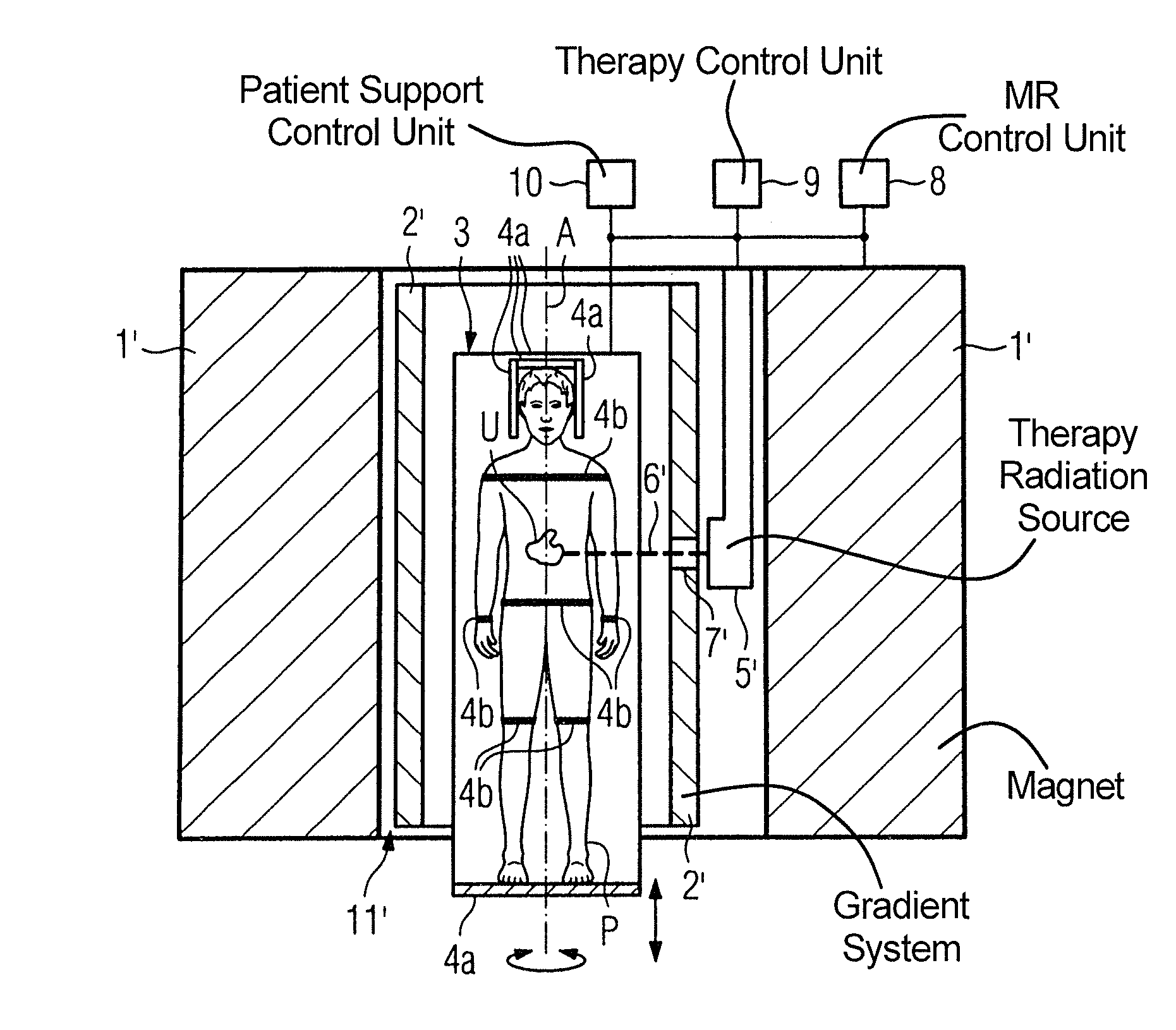

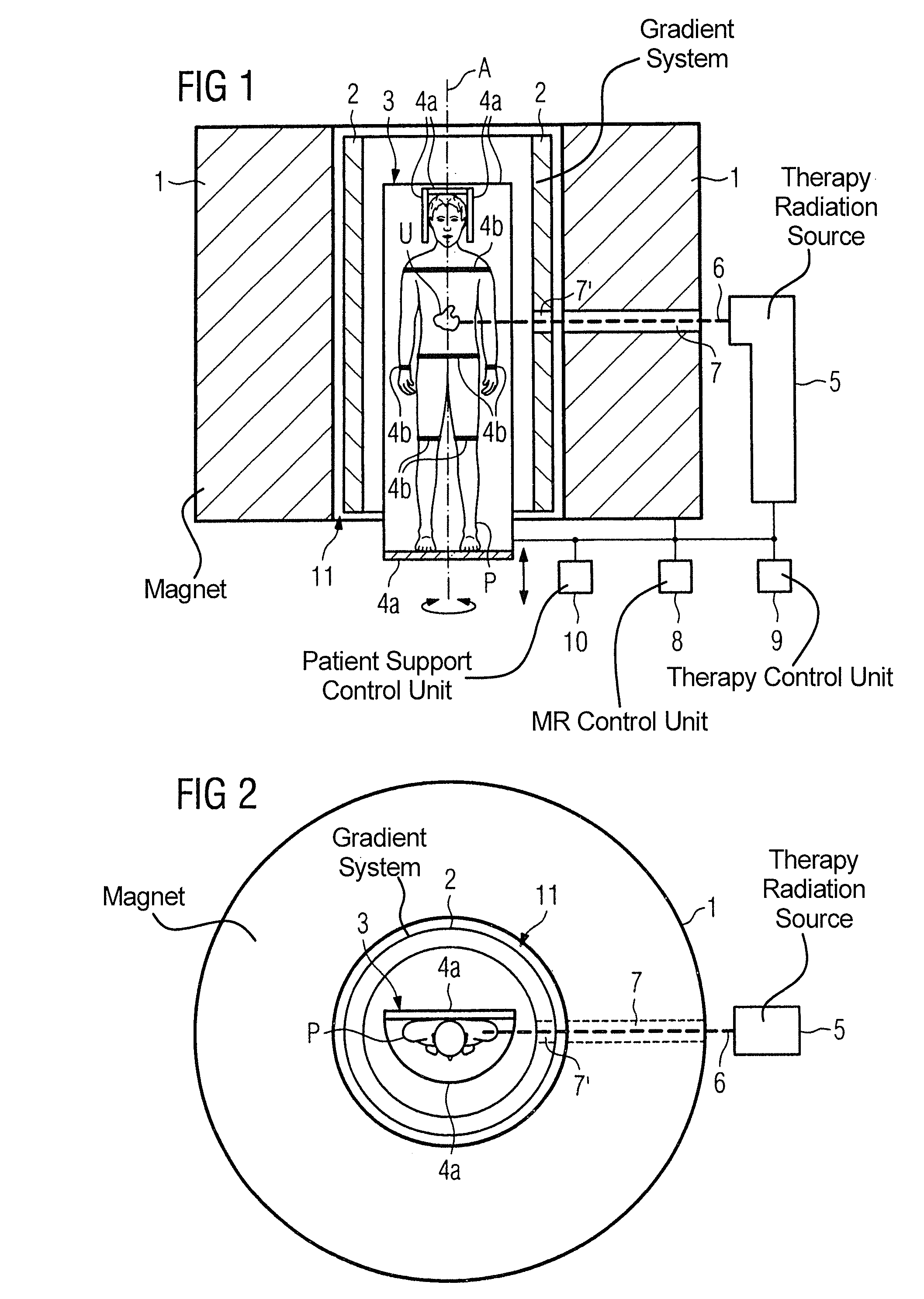

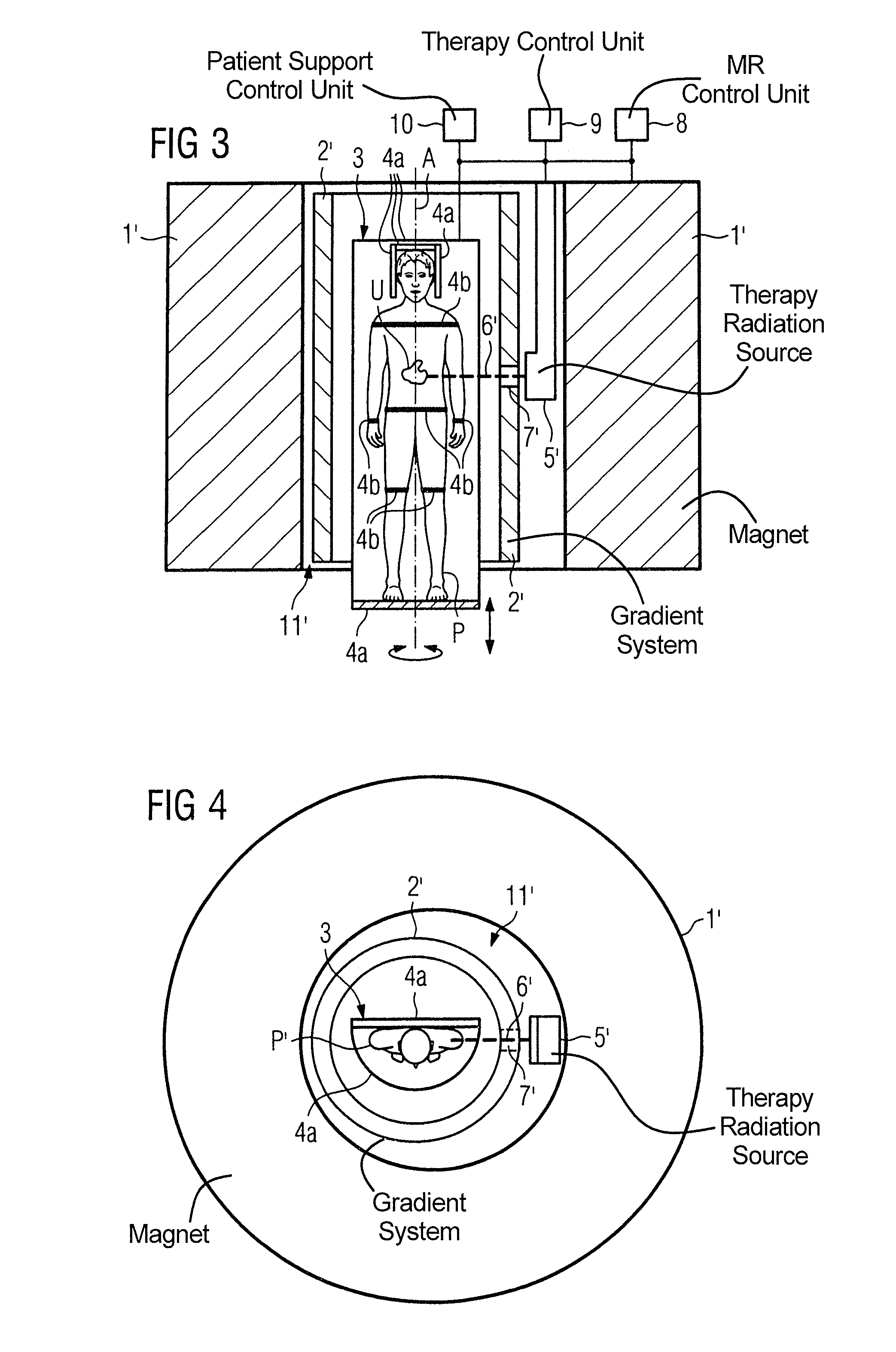

Device for radiation therapy under image monitoring

InactiveUS20090124887A1Reduce volume requirementsEasy and cheap to realizeMagnetic measurementsDiagnostic recording/measuringMedical physicsMagnet

A device for radiation therapy implemented with image monitoring has a magnetic resonance device and an exposure device. The magnetic resonance device has a magnet and primarily serves for image monitoring an examination object of a patient in an examination volume of the magnetic resonance device. The exposure is fashioned to be static and serves to expose the examination subject in the examination volume with therapeutic beams. The patient (and therefore the examination subject) are supported by a patient positioning device such that the examination subject can be moved relative to the magnetic resonance device and the exposure device around at least one rotation axis.

Owner:SIEMENS HEALTHCARE GMBH

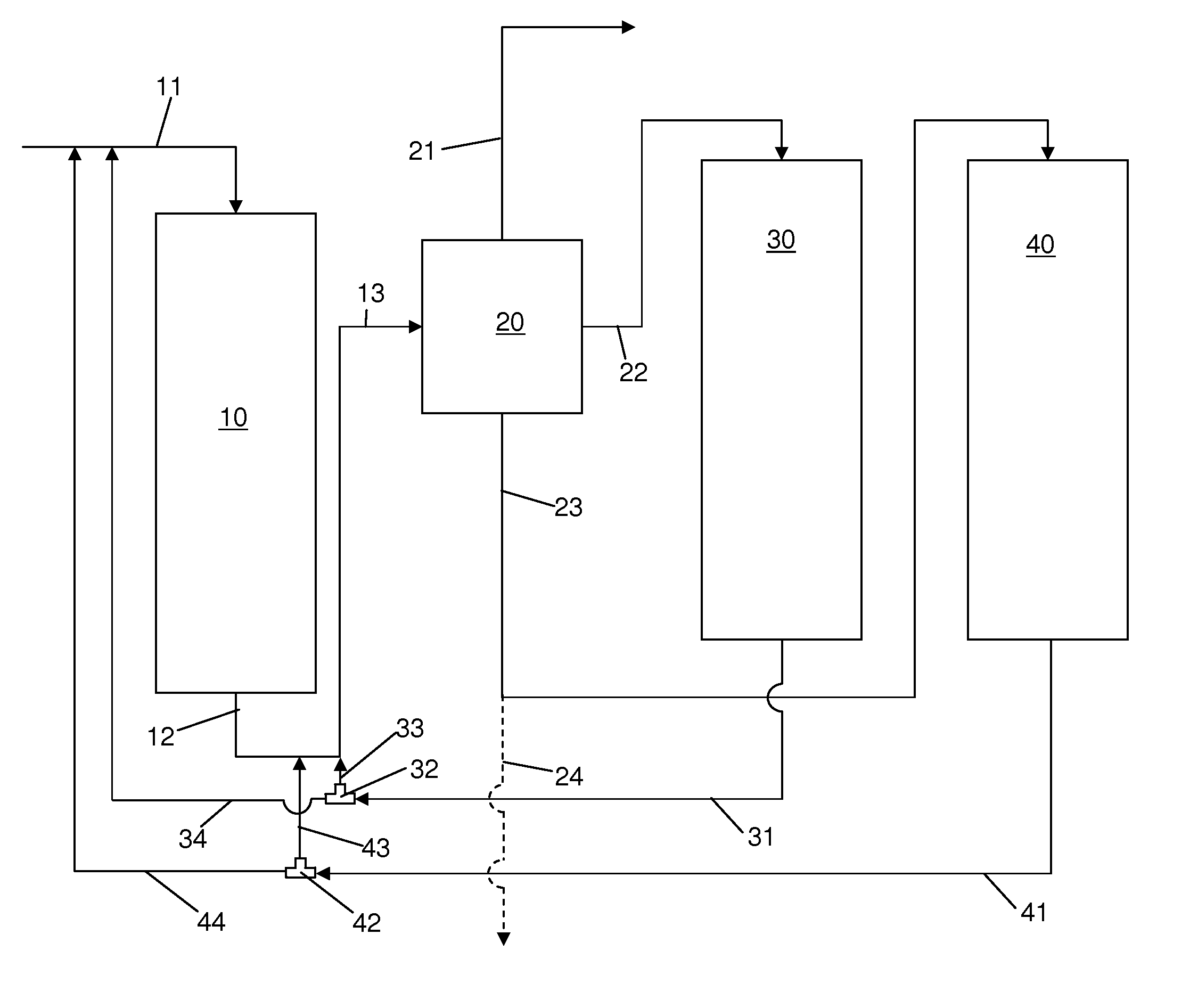

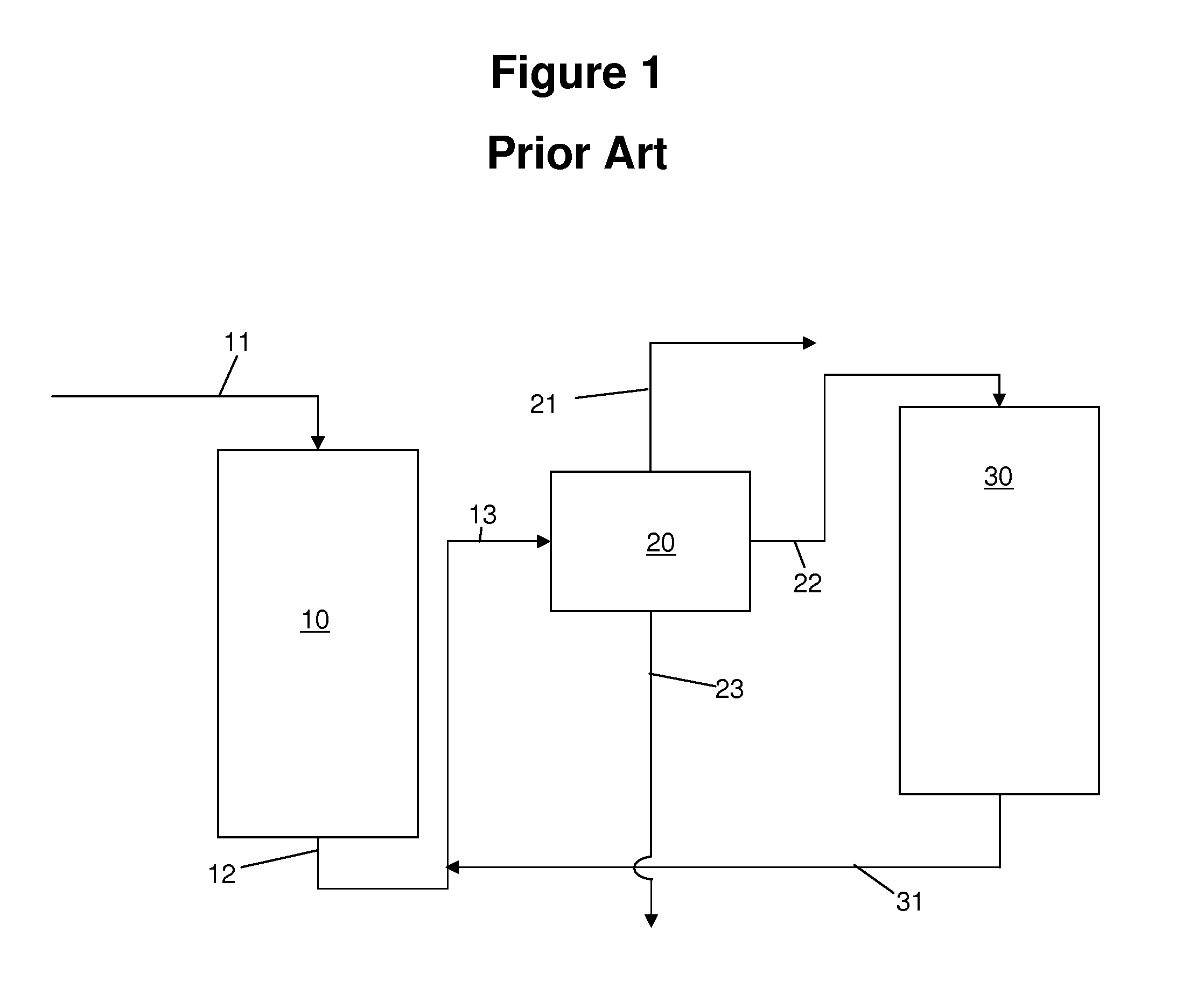

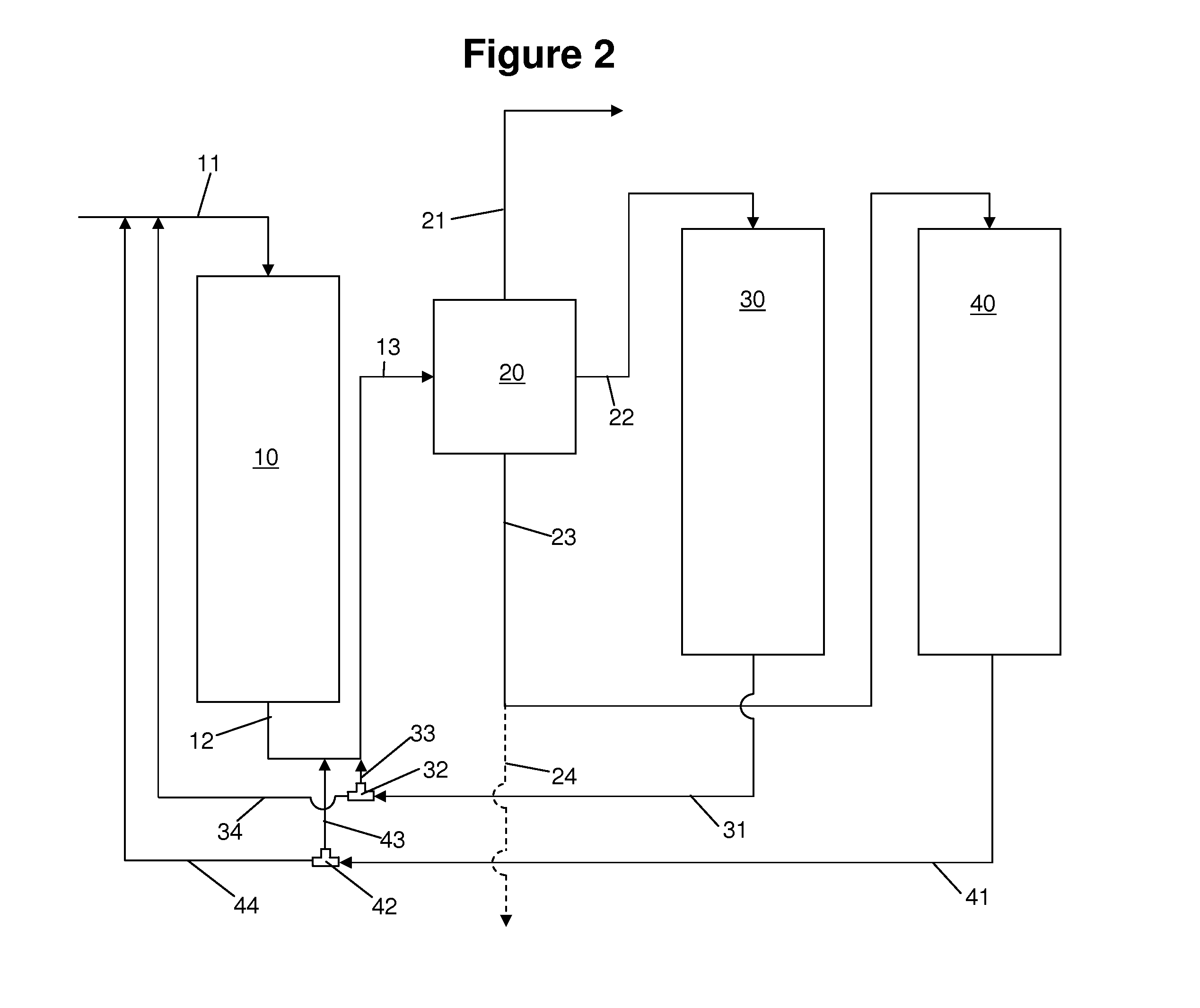

Pressure cascaded two-stage hydrocracking unit

ActiveUS20110079541A1Reduce capital investmentSolve the real problemMolecular sieve catalystsHydrocarbon oil crackingNaphthaBoiling point

A method and apparatus for hydrocracking an oil feedstock to produce a light oil stream without build-up of heavy polynuclear aromatic (HPNA) hydrocarbons in the recycle stream is provided. The method includes the steps of (1) hydrocracking the oil feedstock with a hydrotreating catalyst in a first reactor to produce an effluent stream; (2) fractionating the effluent stream into first, second and third product streams, wherein the first product stream includes C1-C4, naphtha and diesel boiling in the range of 36-370° C., the second product stream includes hydrocarbon components with an initial nominal boiling point of 370° C. and a final boiling point ranging from 420-480° C., and the third product stream that includes HPNA hydrocarbons and other hydrocarbons boiling above about 420° C. to about 480° C., depending upon the final boiling point of the second product stream; (3) cracking the second product stream in a second reactor; and (4) cracking the third product stream in a third reactor at a higher operational pressure than the second reactor.

Owner:SAUDI ARABIAN OIL CO

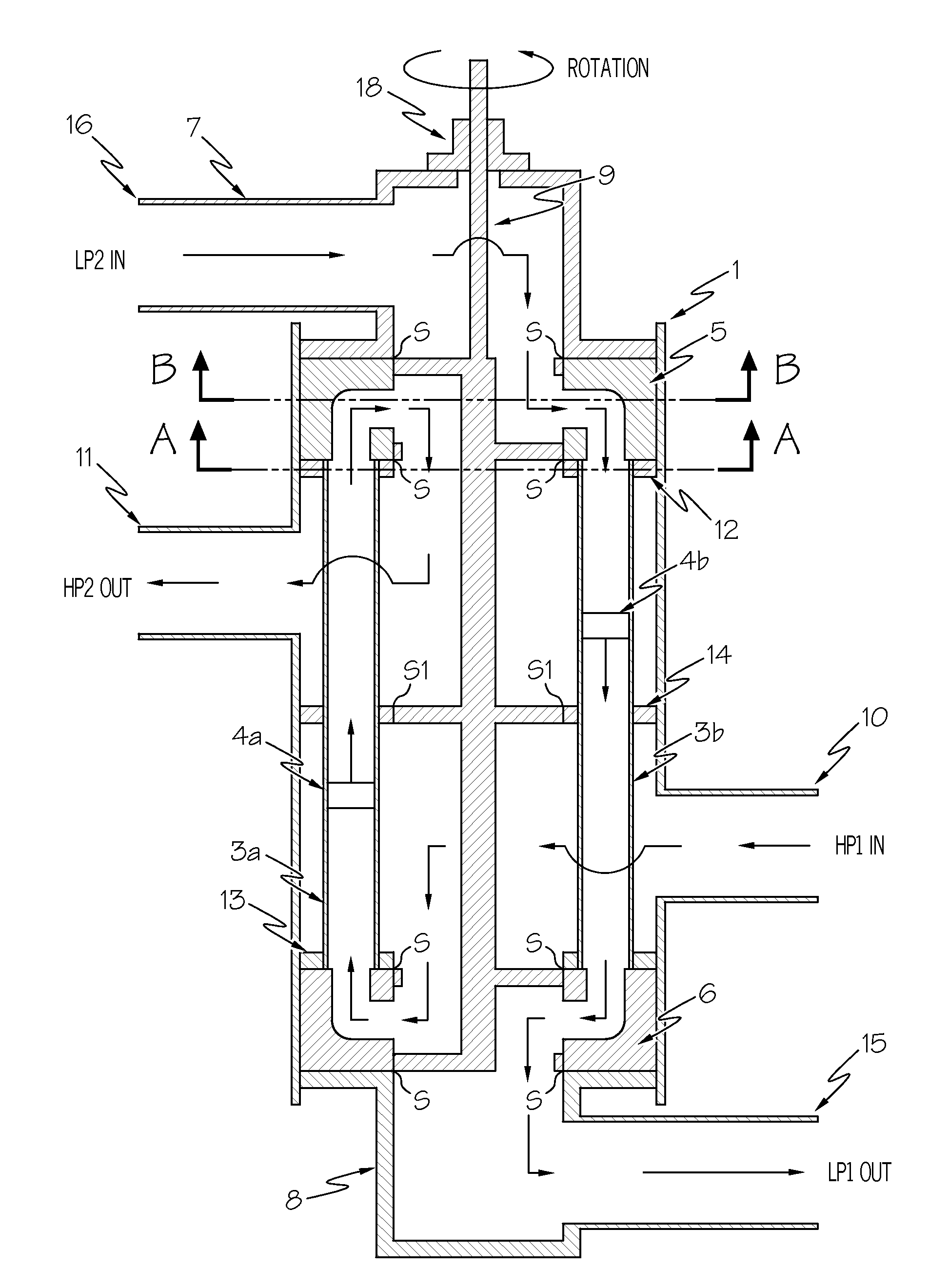

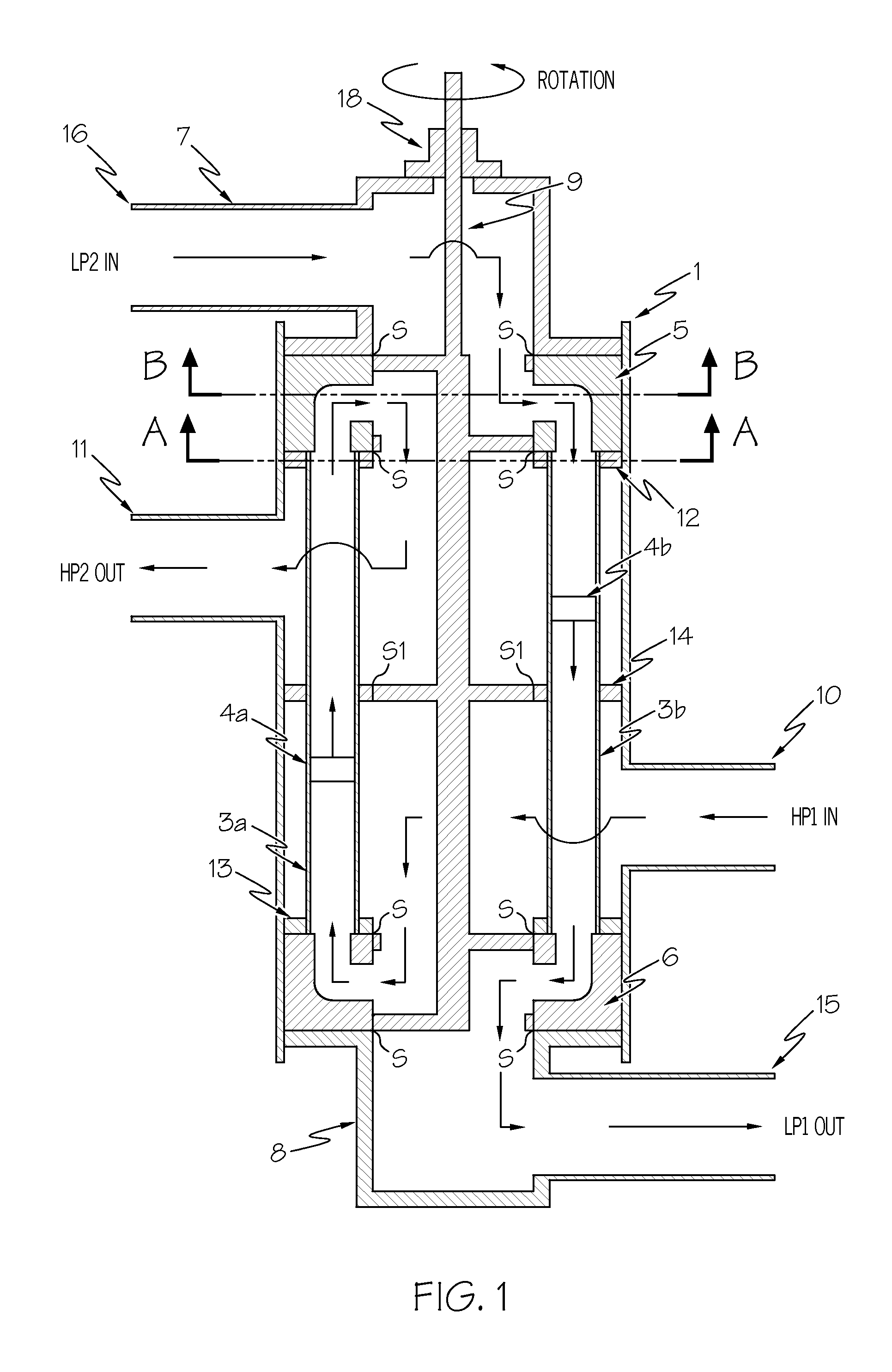

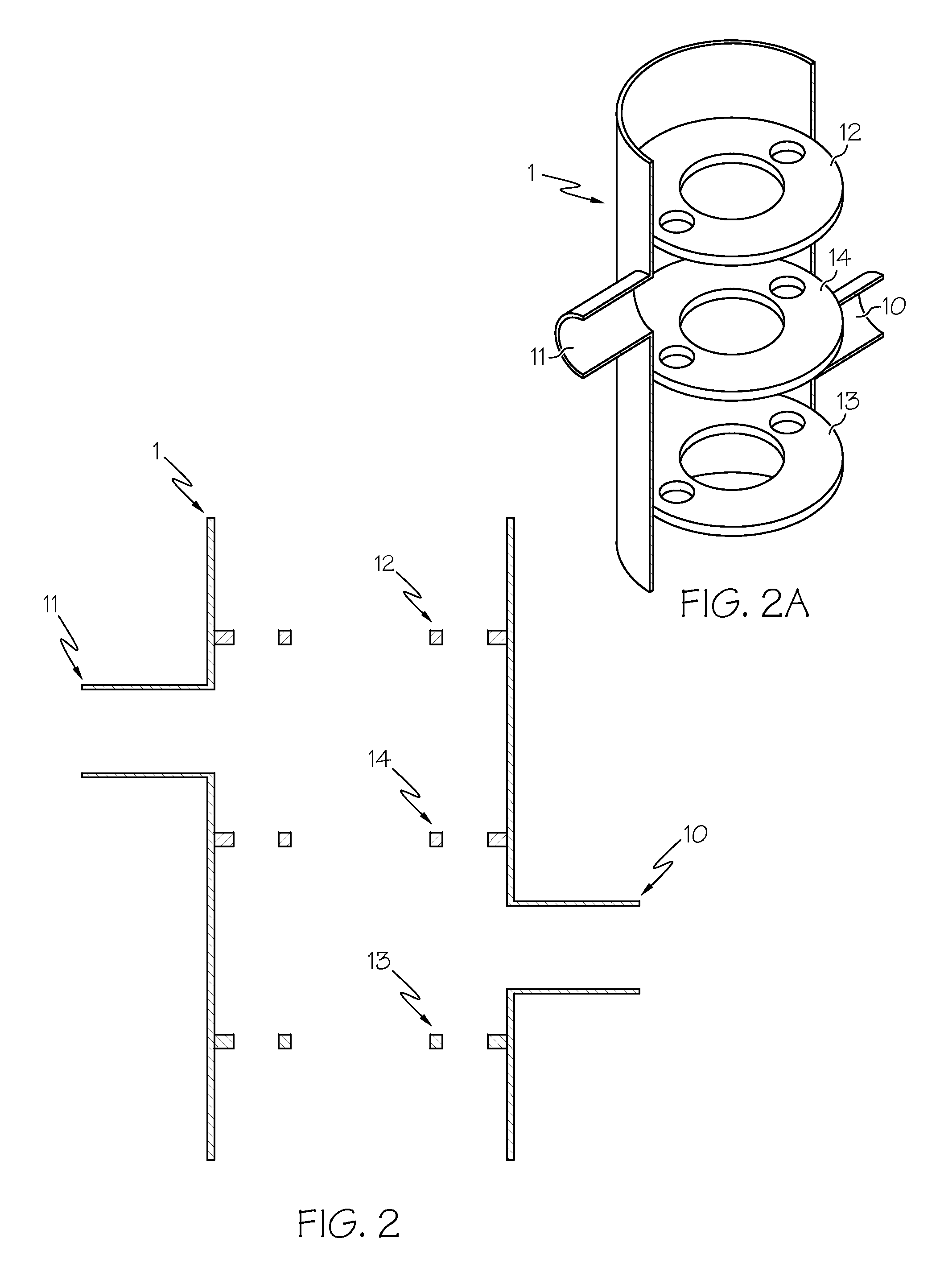

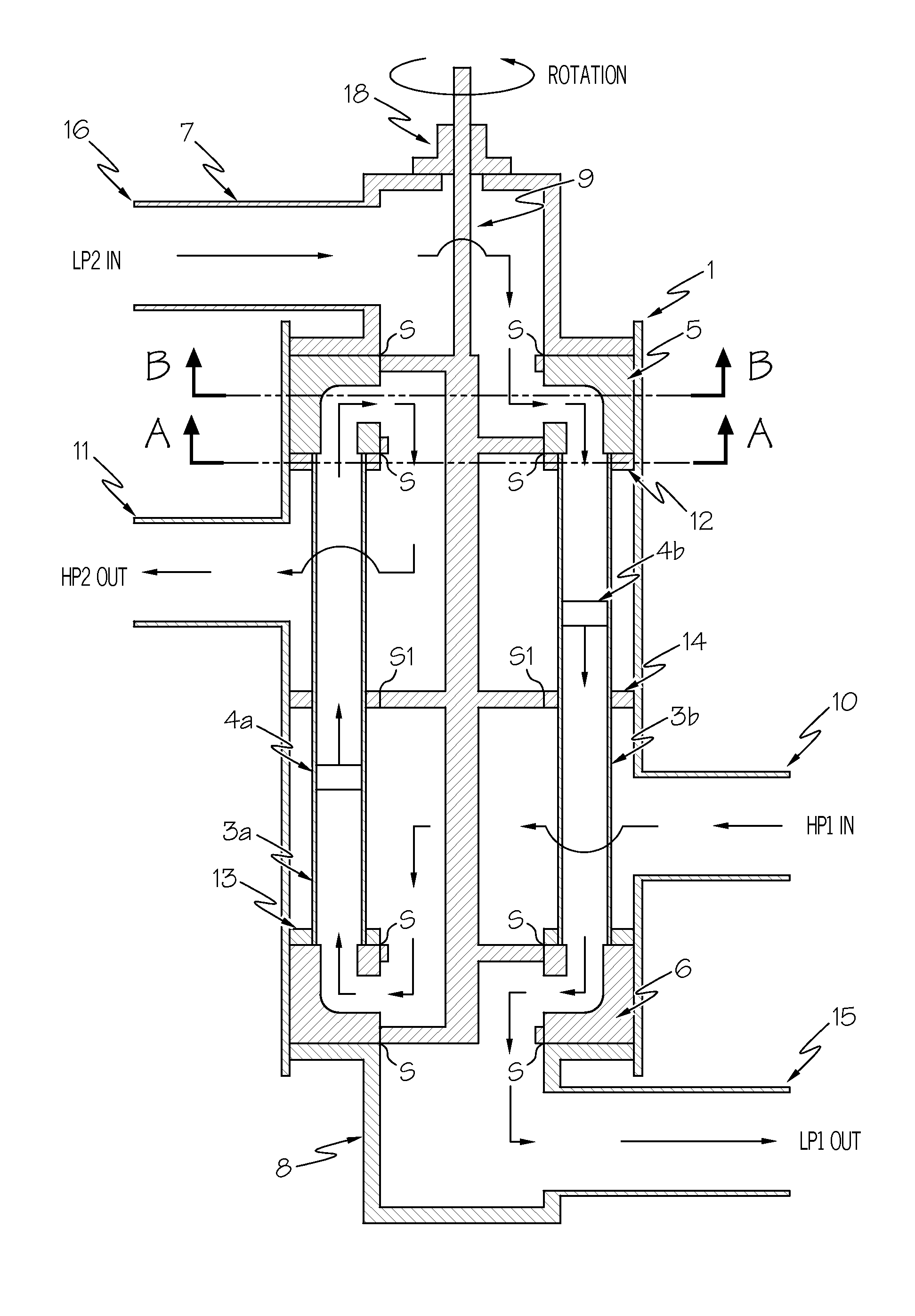

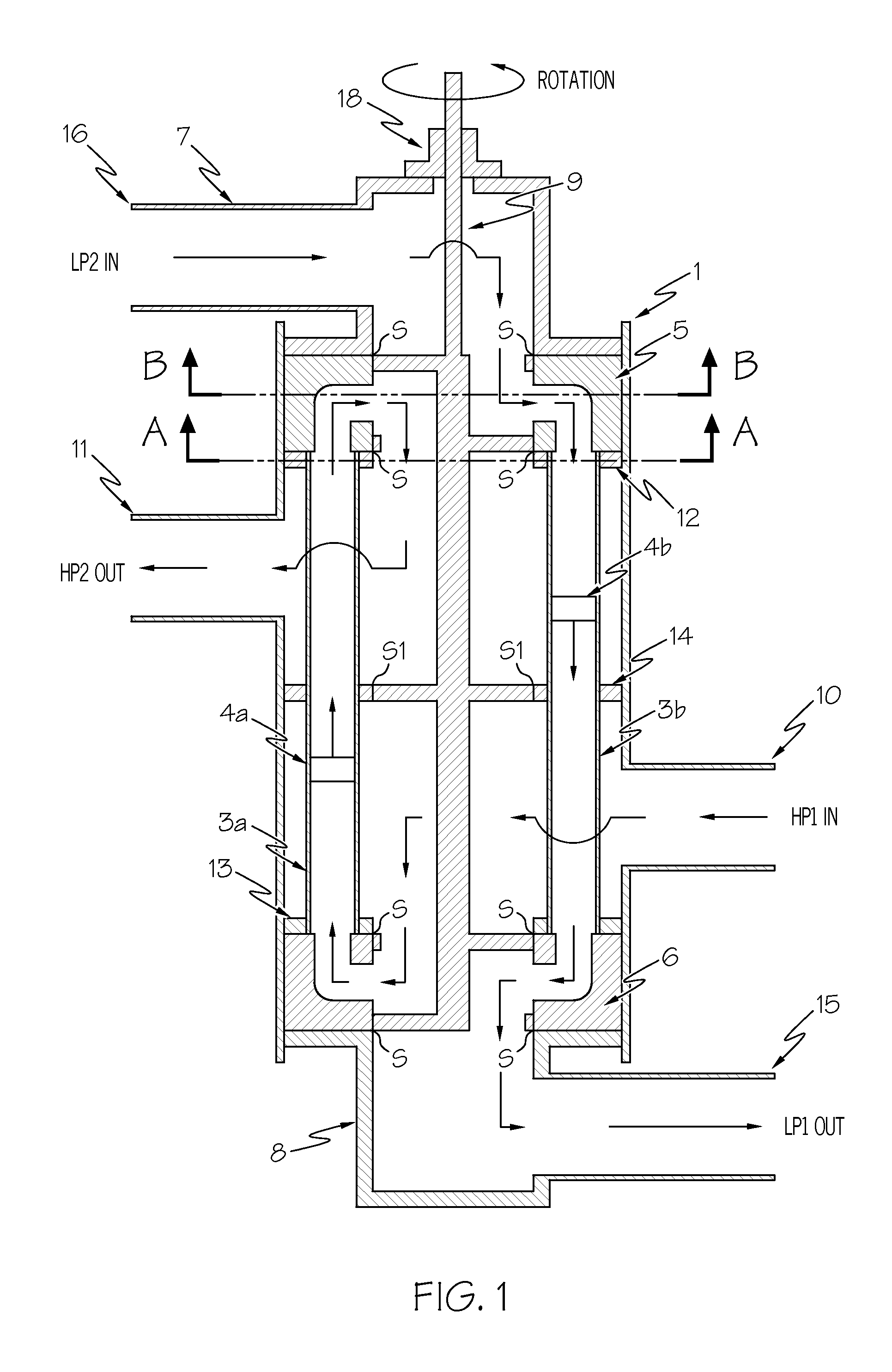

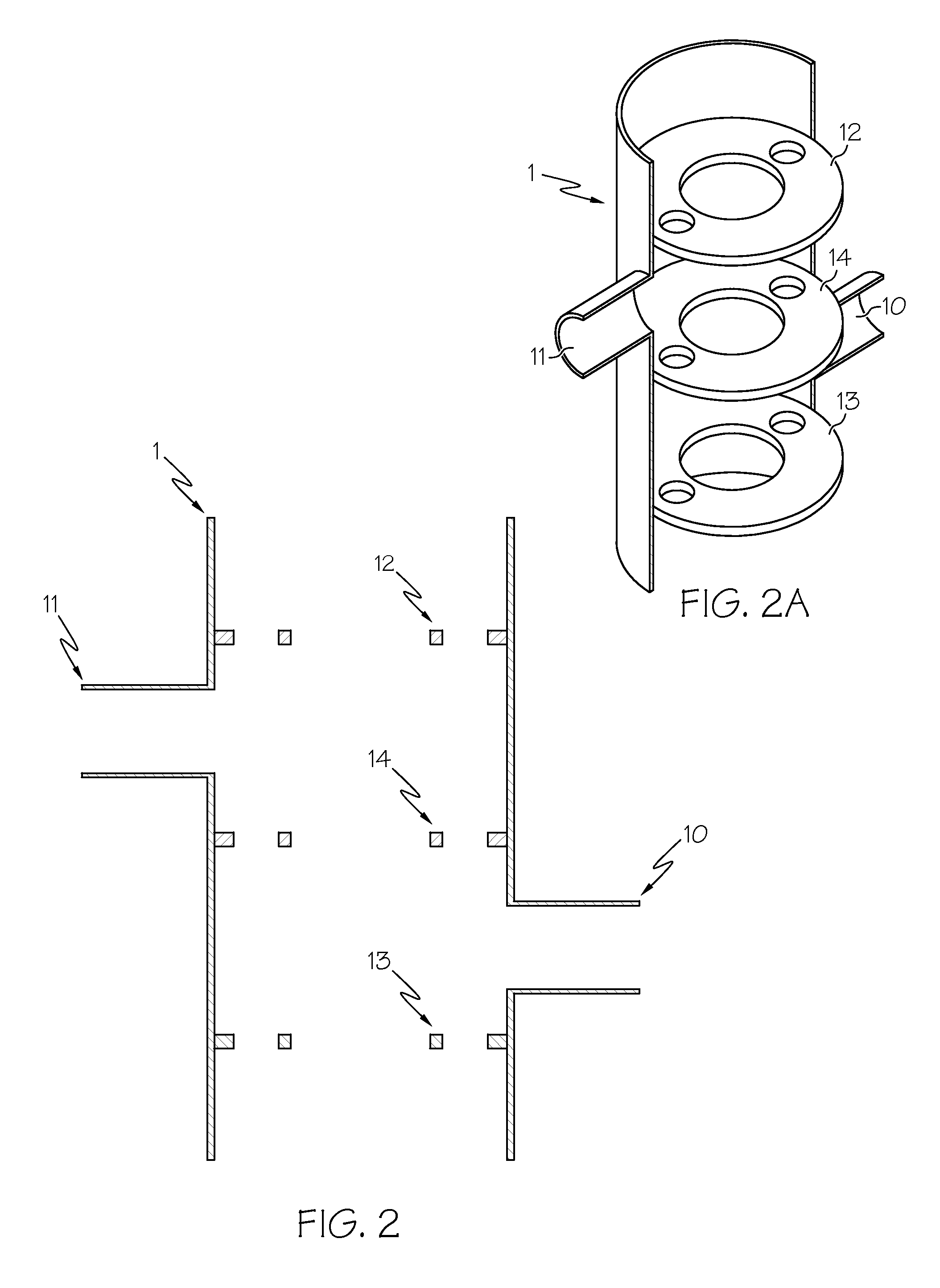

Pressure exchanger

A pressure vessel provided with a first port acting as a high pressure inlet of a first stream and a second port acting as a high pressure outlet. A rotatable valve element is located in the centre of the machine and includes a centre plate, which is utilized to separate high pressure streams. At each end of the valve element are valves. The valves ensure that as the valve element rotates the exchange ducts are either both isolated or that one is exposed to high pressure while the other is exposed to low pressure. In operation, a fluid stream is introduced to the machine at high pressure through port and flows around the outside of the exchange duct towards the centre of the machine. The stream then flows downwardly to the valve element, where it then passes through the open ports of the valve element and into flow distributor. The stream then passes into and upwardly in the exchange duct, causing upward displacement of the duct piston, resulting in the pressurization and flow of the second fluid above the duct piston. The second fluid then flows into the upper flow distributor, into the valve element, and then downwardly and finally between the exchange duct and out through the high pressure port. At the same time a fluid stream is introduced to the machine at low pressure through port. This flows into the valve element and then into the flow distributor. From the flow distributor it flows and downwardly into the pressure exchange duct, causing downward displacement of duct piston and resulting in flow of the first fluid below the duct piston, which then flows into the lower flow distributor, into the valve element, and then out of the lower sealing plate at port. A planar radial sealing surface promotes sealing connection between the rotatable valve element and various pressure exchange ducts within the pressure vessel.

Owner:FLOWSERVE HLDG

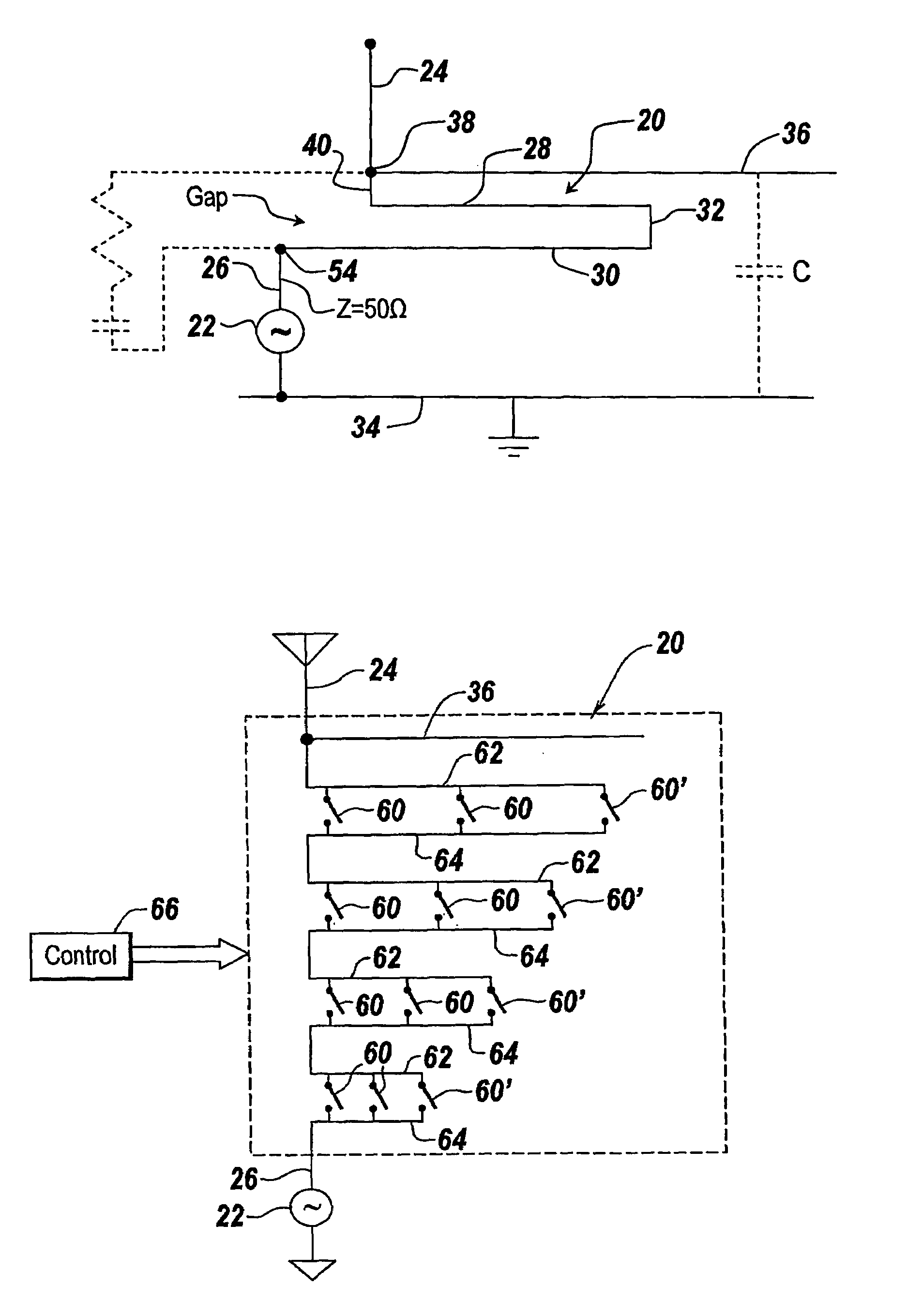

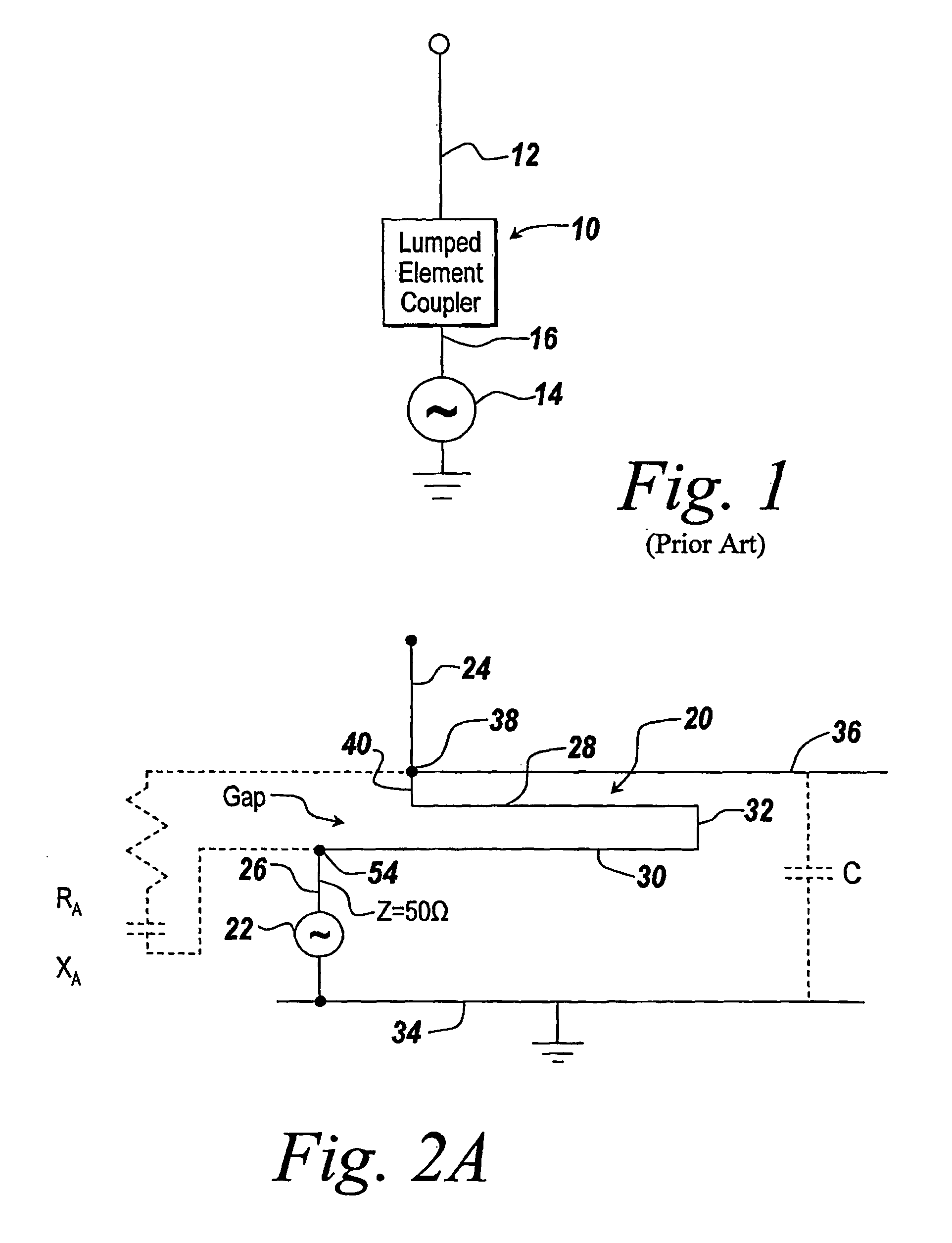

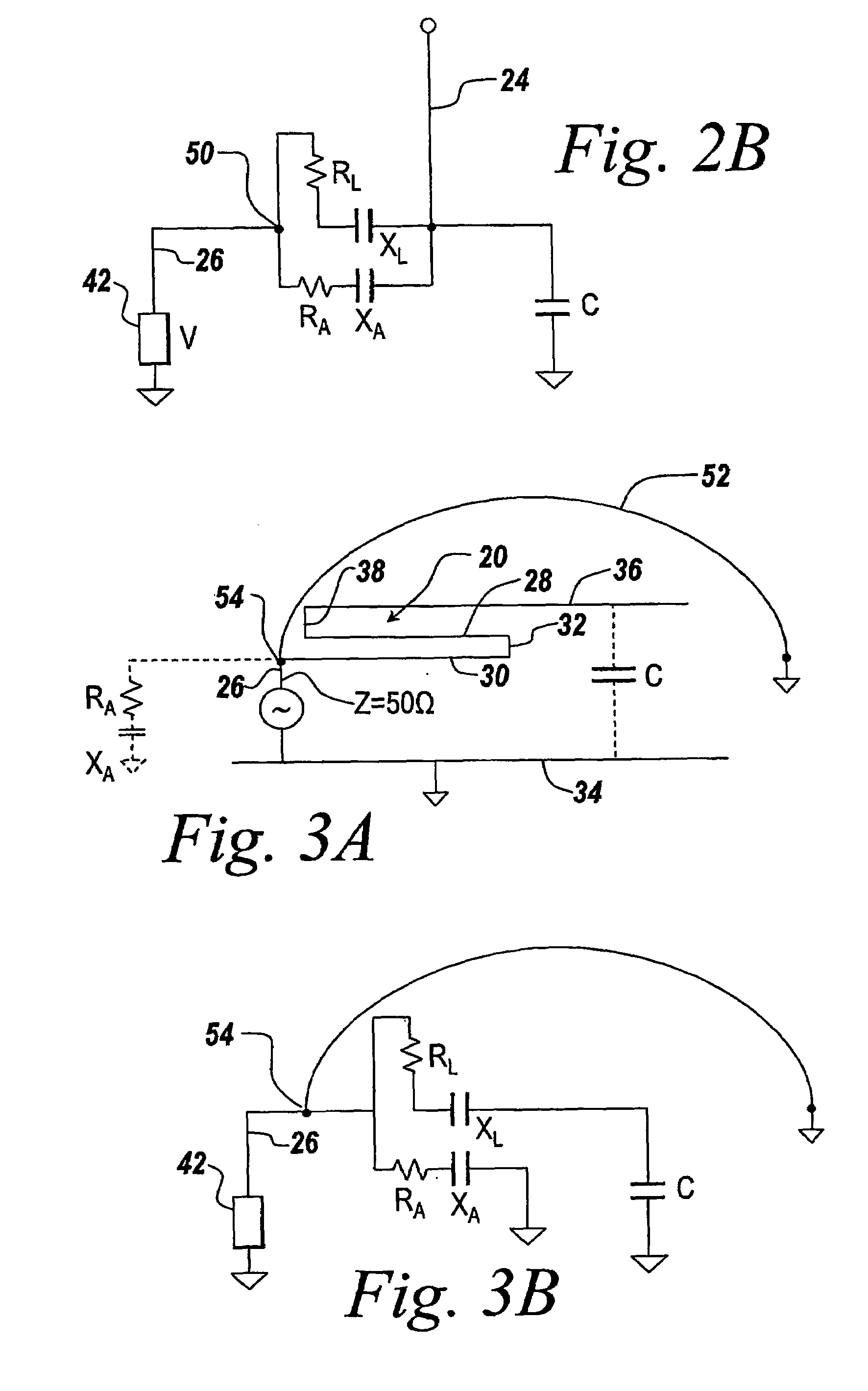

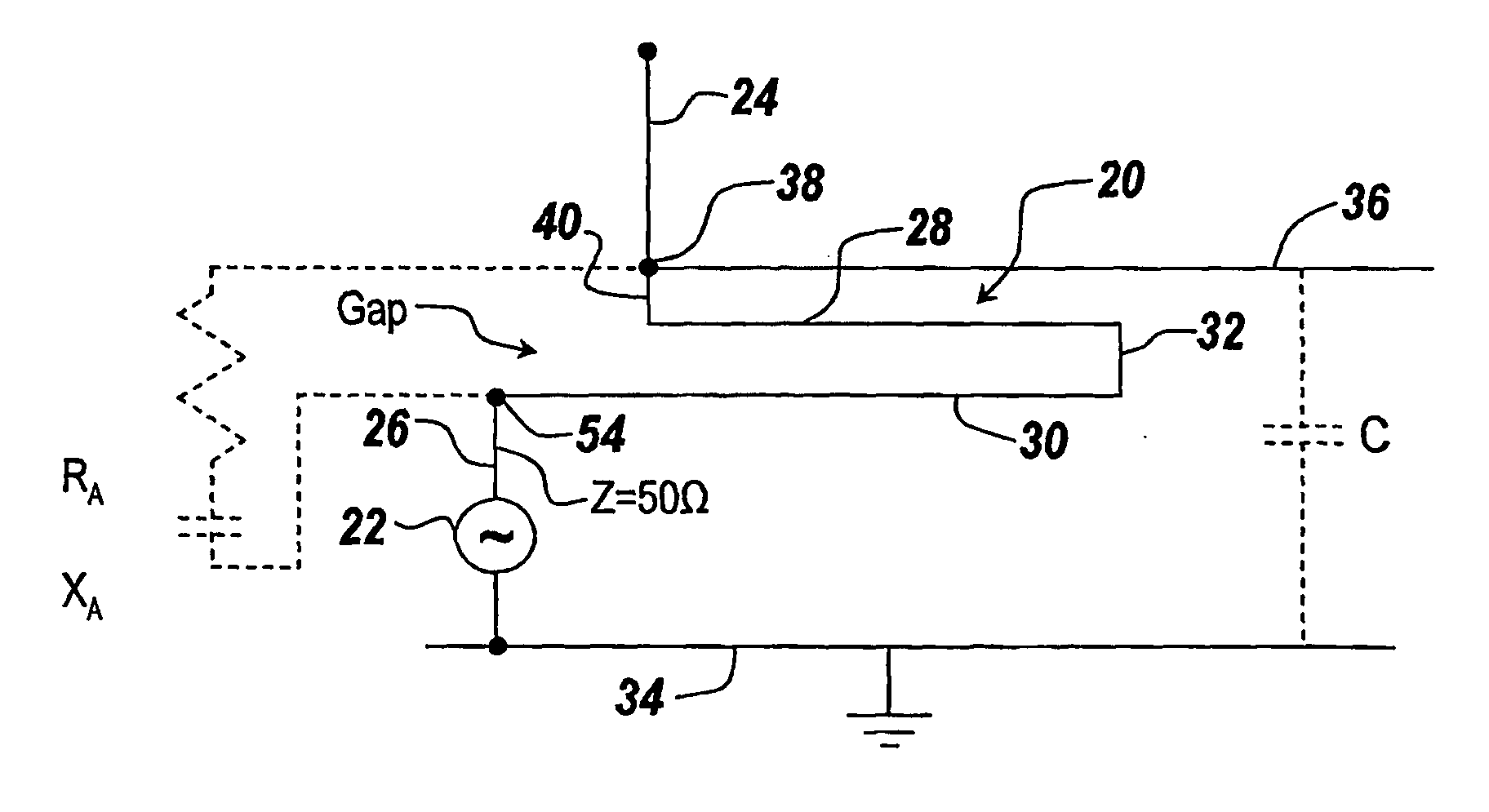

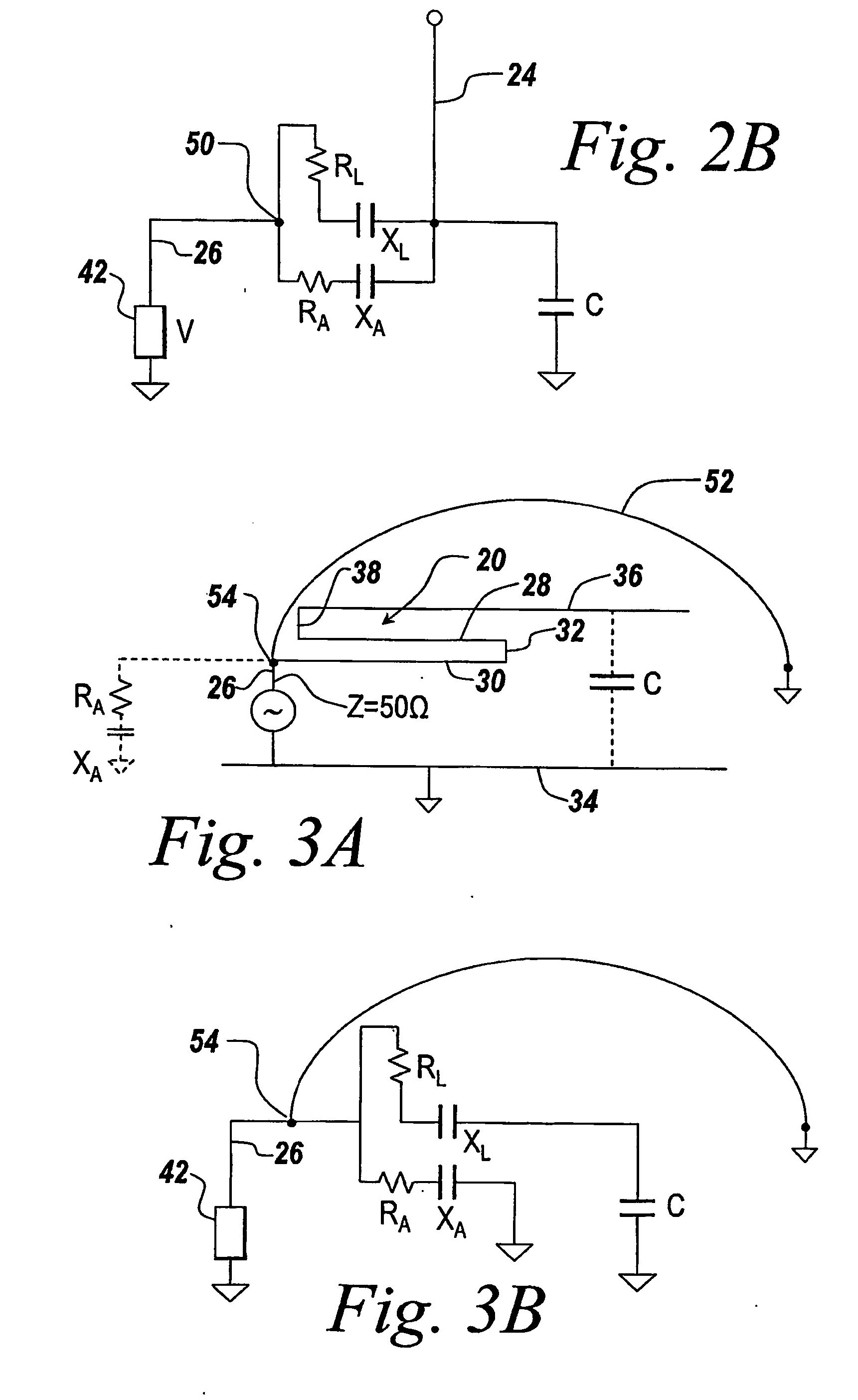

Meander line antenna coupler and shielded meander line

InactiveUS7190322B2Less ohmic lossEliminates down firingResonant long antennasRadiating elements structural formsInductorOrder of magnitude

A switched meander line structure is substituted for a lumped element antenna tuner for an order of magnitude increase in gain due to the use of the switched meander line architecture. The use of the meander line with relatively wide and thick folded legs markedly decreases I2R losses over wire inductors whose wire diameters at one-tenth of an inch contribute significantly to I2R losses. Additionally, placing solid state switches to short out various sections of a multi-leg meander line at high impedance nodes reduces I2R losses across the switching elements in the tuner.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

Meander line antenna coupler and shielded meander line

InactiveUS20050225496A1Less ohmic lossEliminates down firingResonant long antennasRadiating elements structural formsResonanceEngineering

A switched meander line structure is substituted for a lumped element coupler (10) for an order of magnitude increase in gain due to the use of the switched meander line architecture. The use of the meander line (20) with relatively wide and thick folded legs markedly decreases I2R losses over wire inductors whose wire diameters at one-tenth of an inch contribute significantly to I2R losses. Additionally, placing solid state switches to short out various sections of a multi-leg meander line at high impedance nodes reduces I2R losses across the switching elements in the coupler. It has been found that, regardless of the impedance of the antenna, this impedance may be matched by switching in and out various sections of a folded multileg meander line due to the fact that the square of the sum of the capacitive reactances of the meander line decreases with frequency in synchronism with the unloaded Q of the meander line, thus to provide the ability to maintain a good match over frequency as the meander line is tuned to achieve resonance by shorting out combinations of sections of the meander line. The result of the substitution of the meander line architecture for the lumped element coupler is the reduction of losses associated with the use of wire inductors and losses due to the interposition of solid state switches at high-current nodes.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

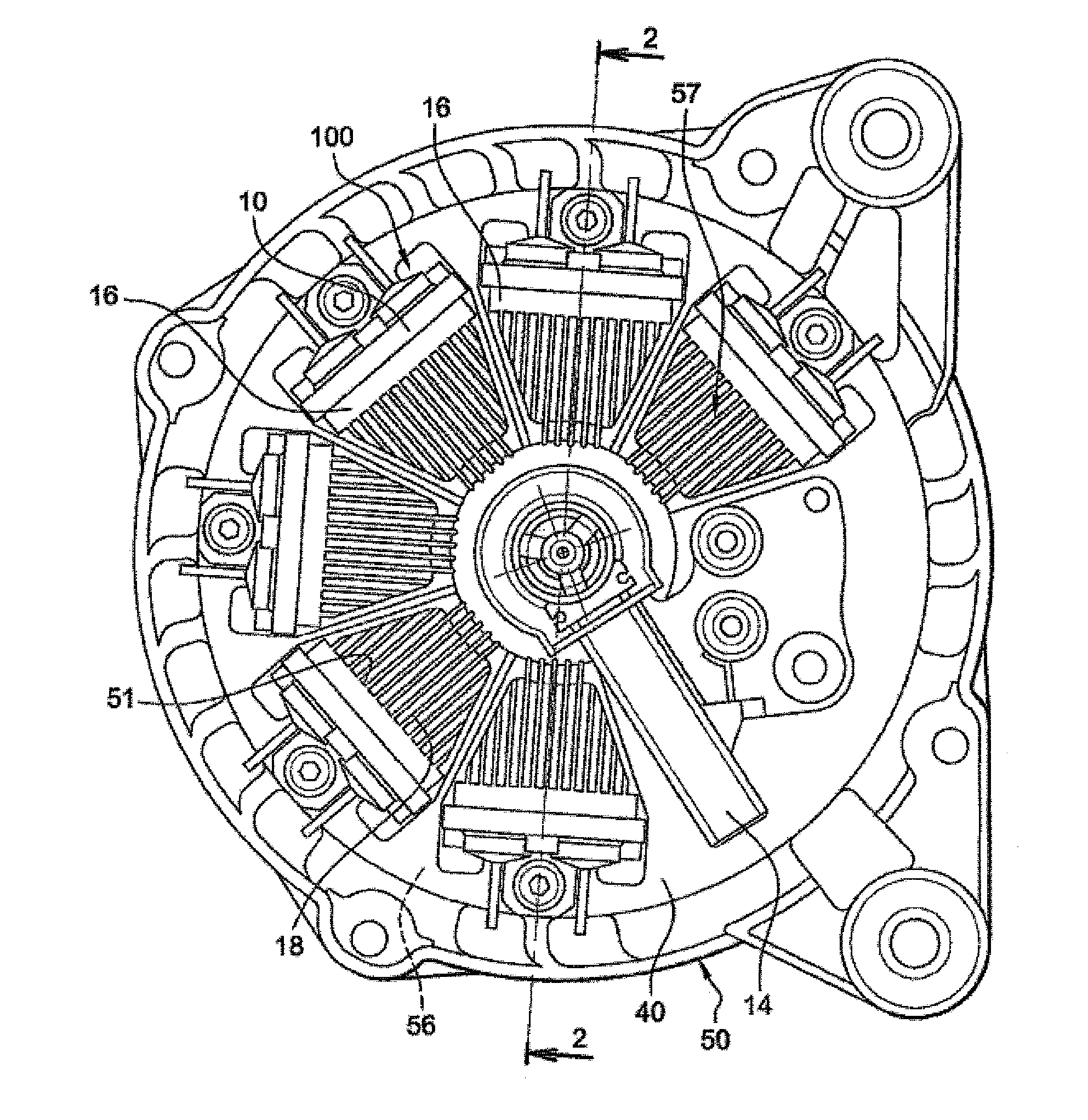

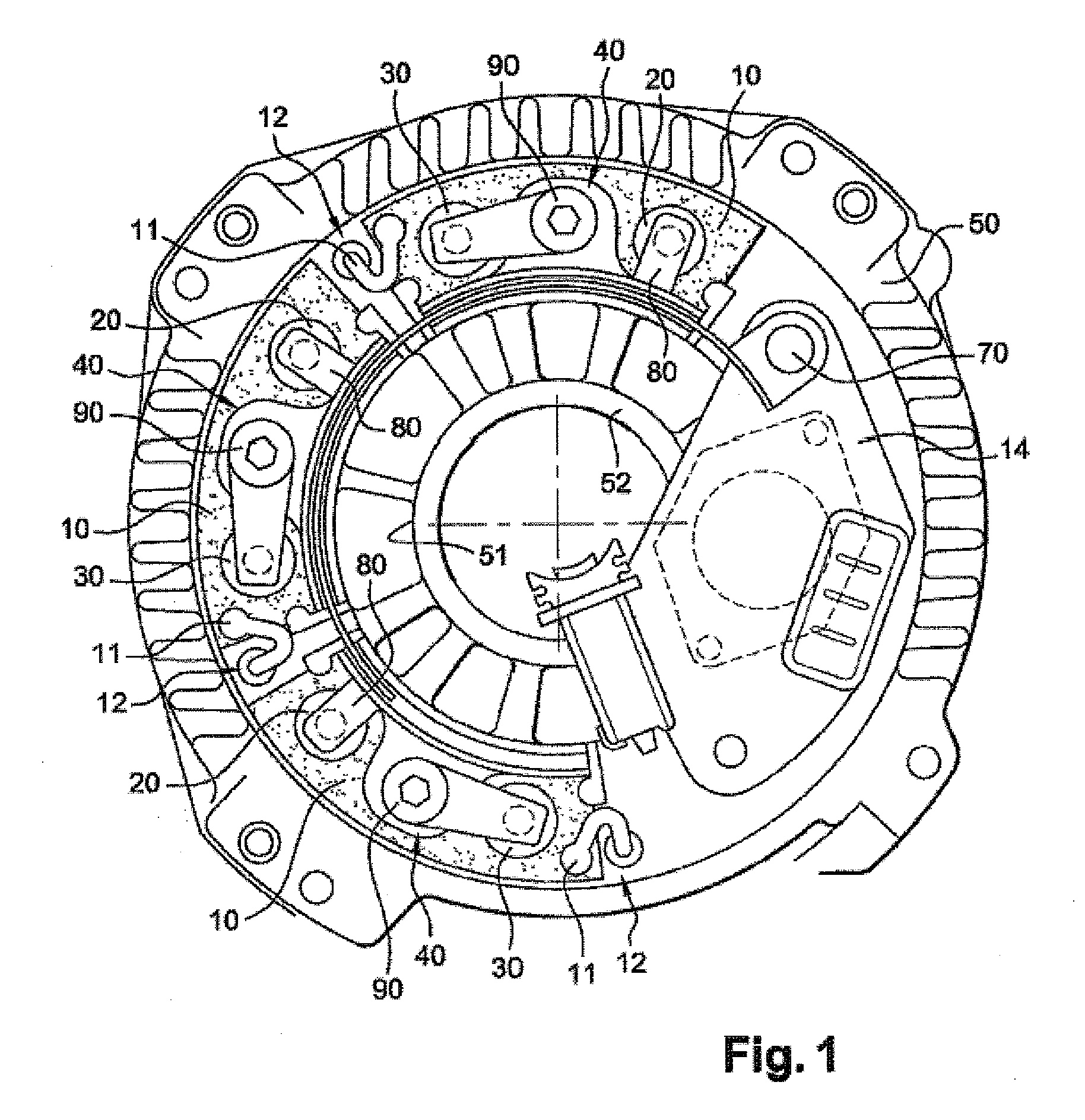

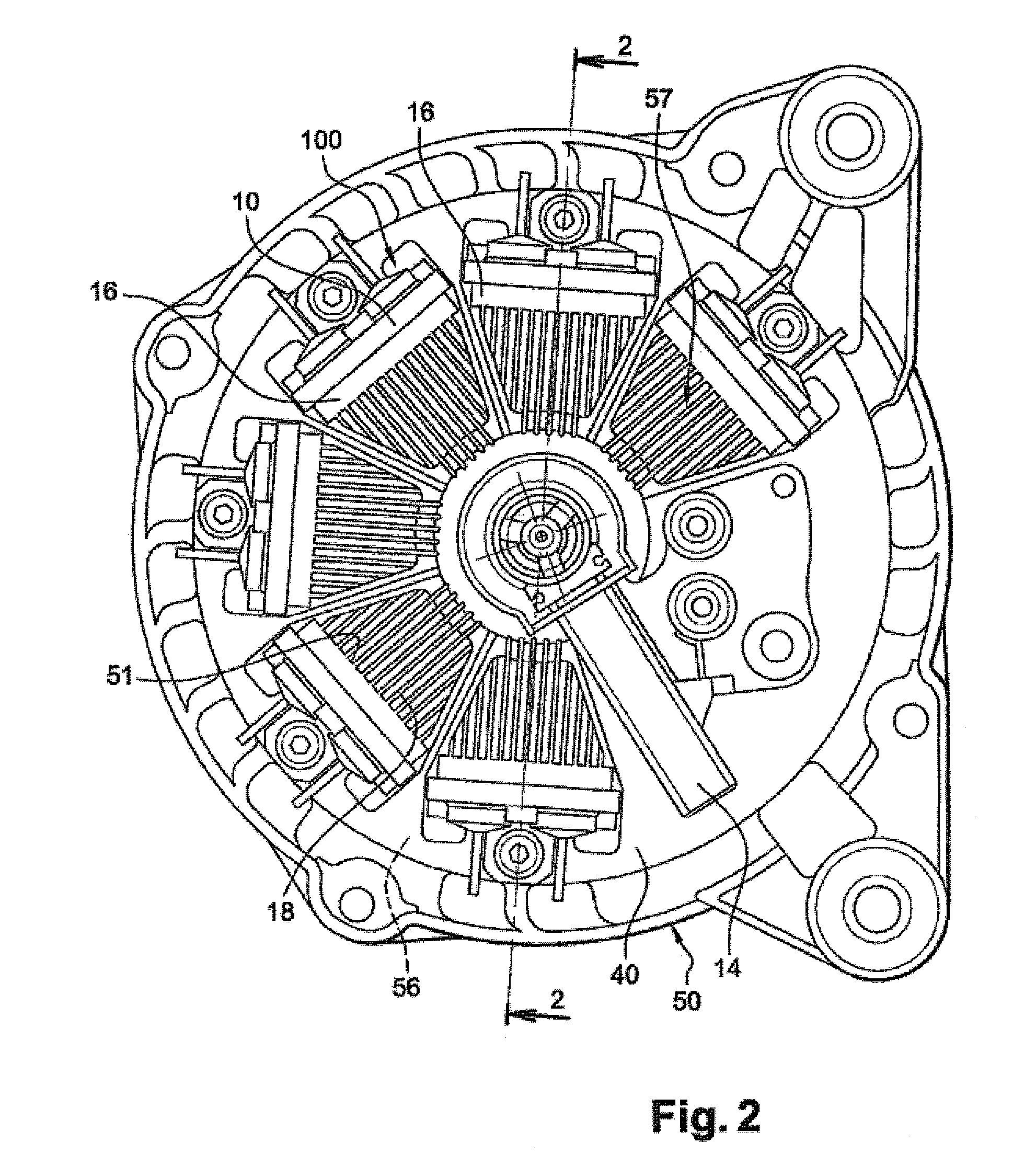

Device for rectifying the current of an electric rotary machine and rotary electric machine including such device

InactiveUS20100117466A1Increase the ambient temperatureIncrease powerSynchronous generatorsRotary current collectorAlternatorElectric machine

A device for rectifying the current of a rotary electric machine comprising a bearing (50) with through openings (51) for a coolant, that comprises at least one module (100) including a holder (10, 16) for holding current rectifying members (93, 94) having the same phase as the machine, said holder (10, 16) including a heat sink (16) with vanes (18) at least partially covering an opening (51) in the bearing (50). A rotary electric machine including such a current rectifying device. Application: alternators of automotive vehicles with internal ventilation.

Owner:VALEO EQUIP ELECTRIC MOTEUR

Pressure exchanger

ActiveUS8622714B2Reduce complexityEasy to operatePump componentsGas turbine plantsEngineeringDistributor

A pressure vessel provided with a first port acting as a high pressure inlet of a first stream and a second port acting as a high pressure outlet. A rotatable valve element is located in the center of the machine. In operation, a fluid stream is introduced to the machine at high pressure where it then passes through the open ports of the valve element and into flow distributor causing upward displacement of a first duct piston, resulting in pressurization and flow of a second fluid. At the same time the second fluid is introduced to the machine at low pressure and flows into the pressure exchange duct, causing downward displacement of a second duct piston and resulting in flow of the first fluid below the duct piston, which then flows into the lower flow distributor, into the valve element, and then out of the pressure vessel.

Owner:FLOWSERVE HLDG

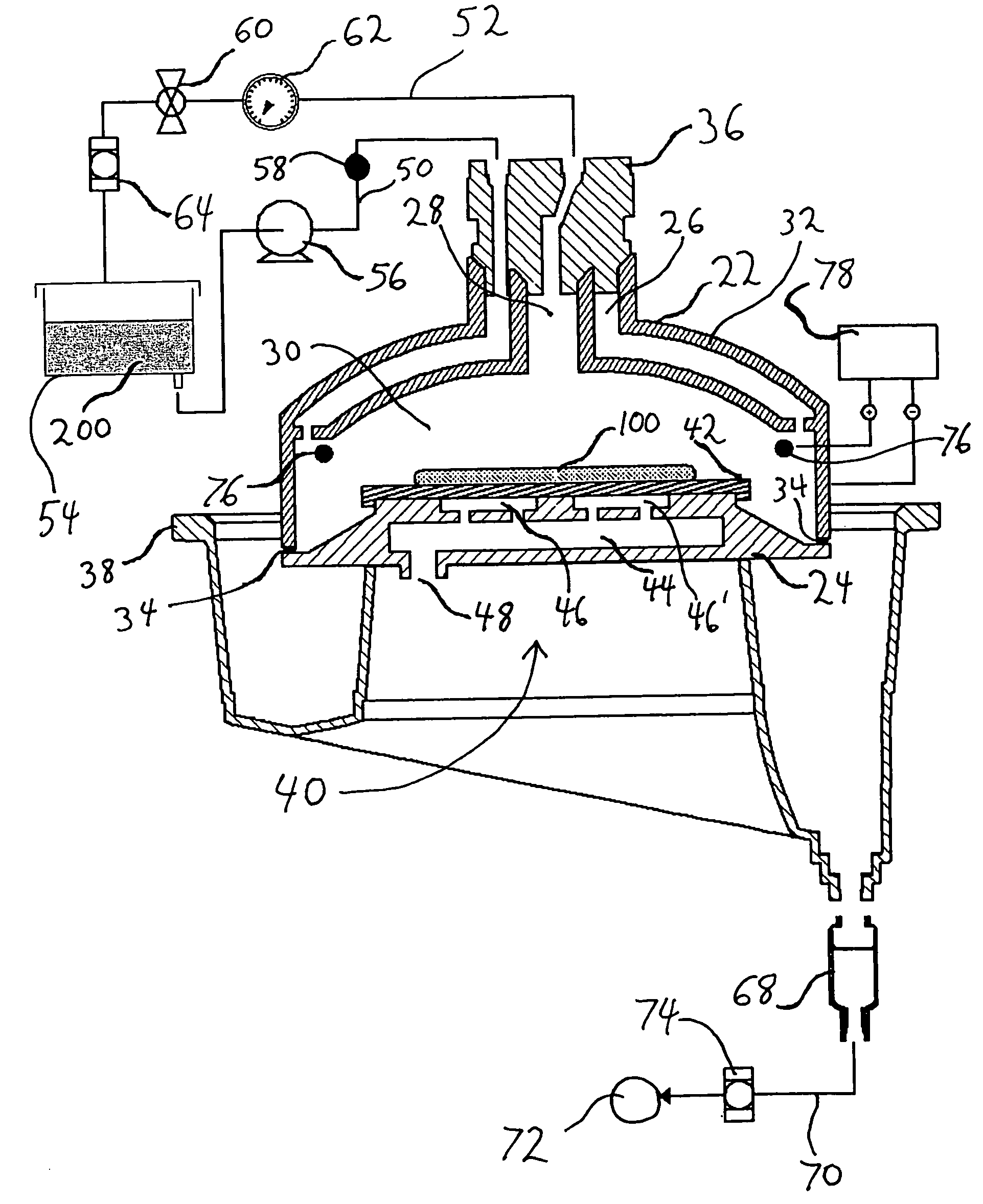

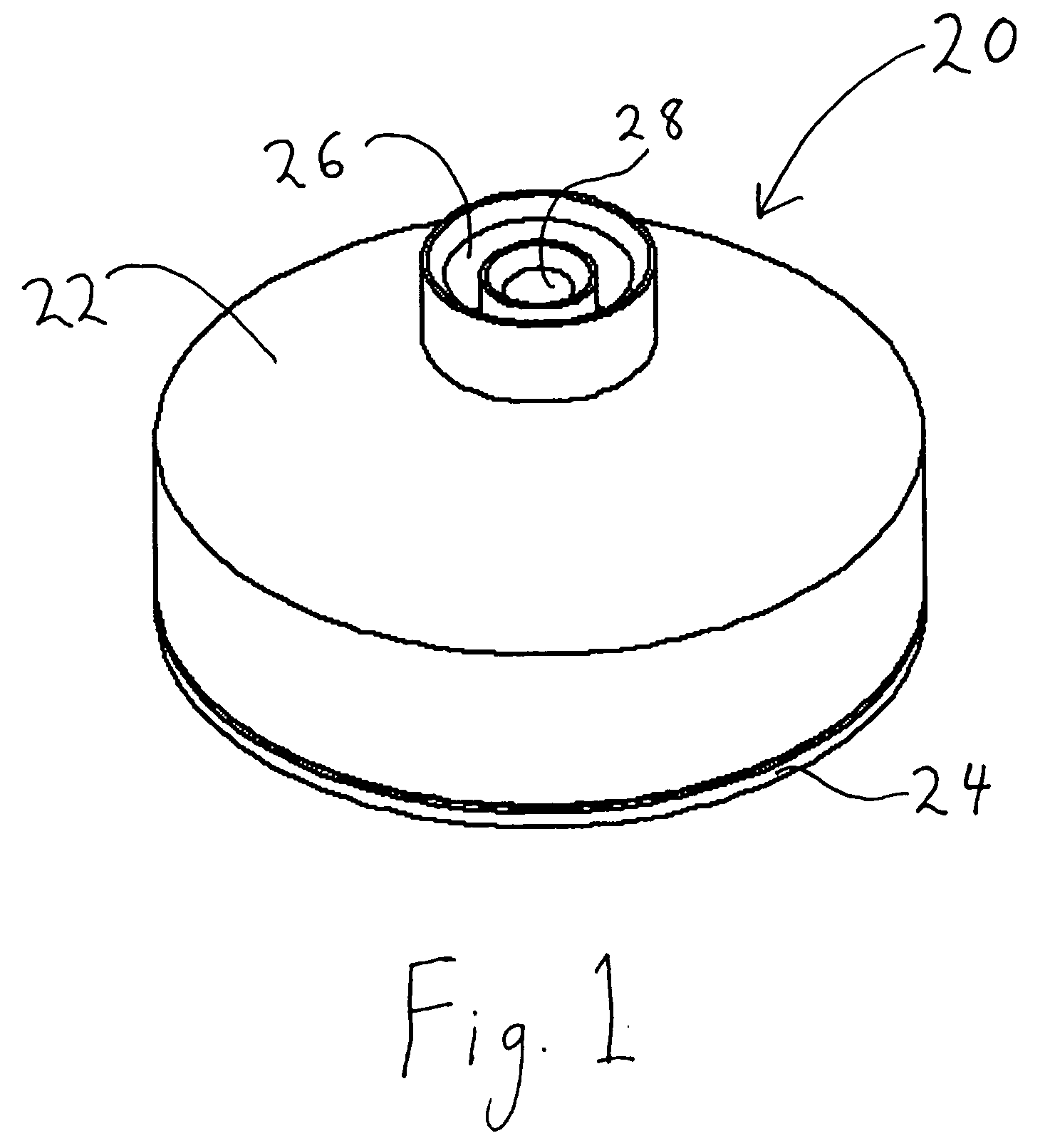

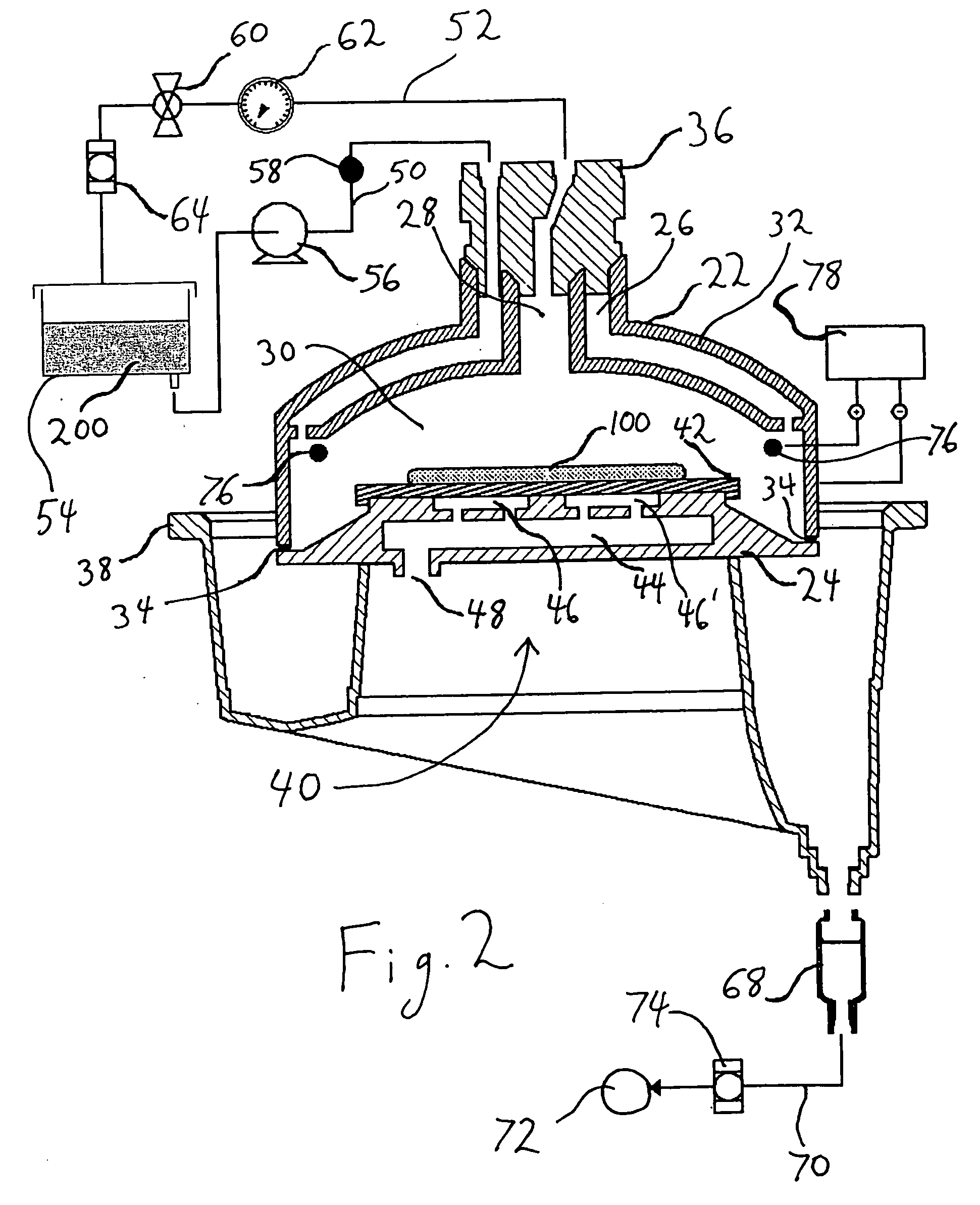

Plating apparatus and method

InactiveUS20050230260A1Easy to controlLower the volumeCellsLiquid/solution decomposition chemical coatingEngineeringElectroplating

The present invention comprises a metal plating apparatus and method, particularly suitable for autocatalytic (i.e., electroless) plating, comprising a pressurized sealable vessel for disposing a substrate to be plated and for the circulation of plating solutions wherein temperatures and pressure are highly controllable.

Owner:SURFECT TECH

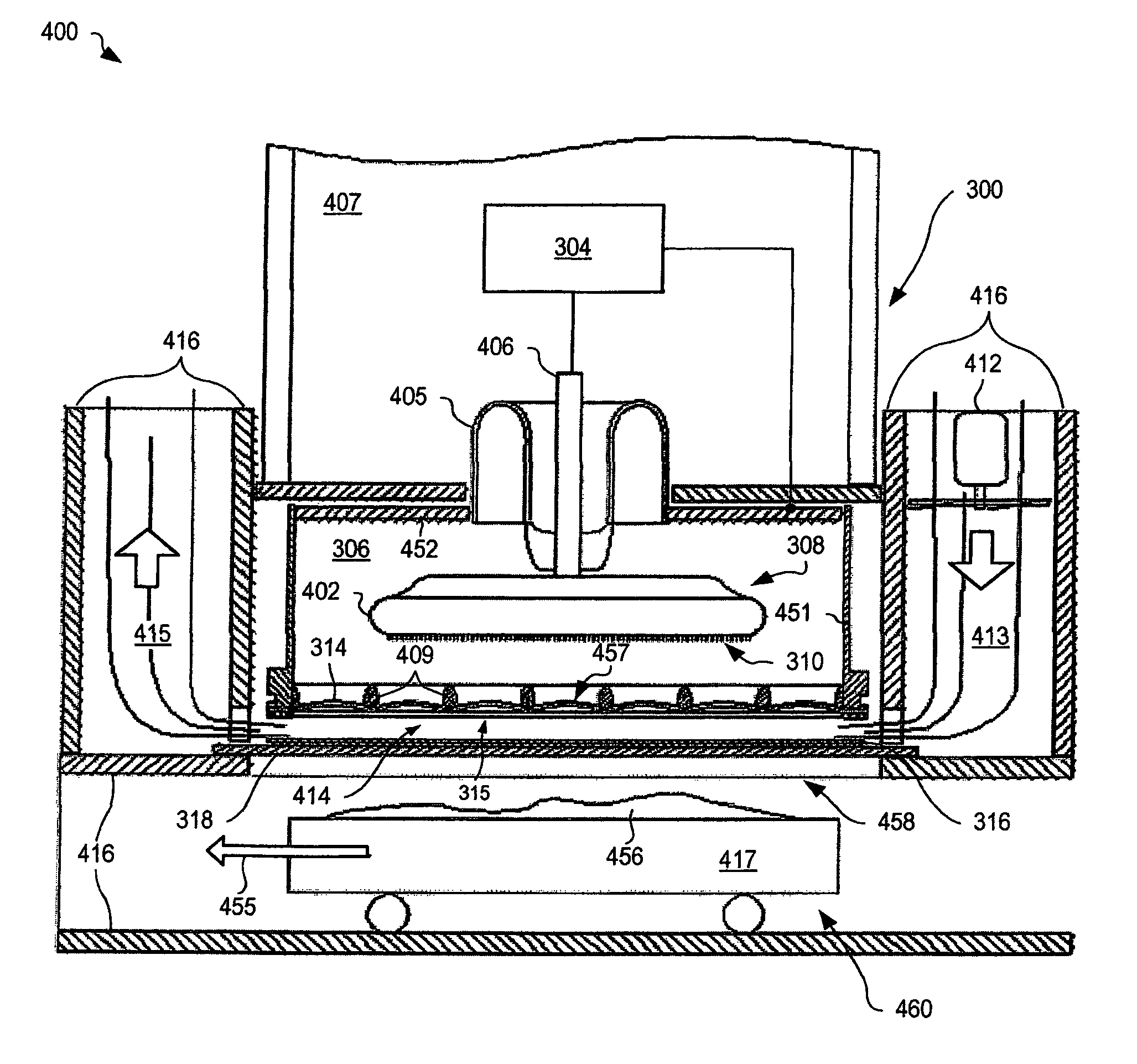

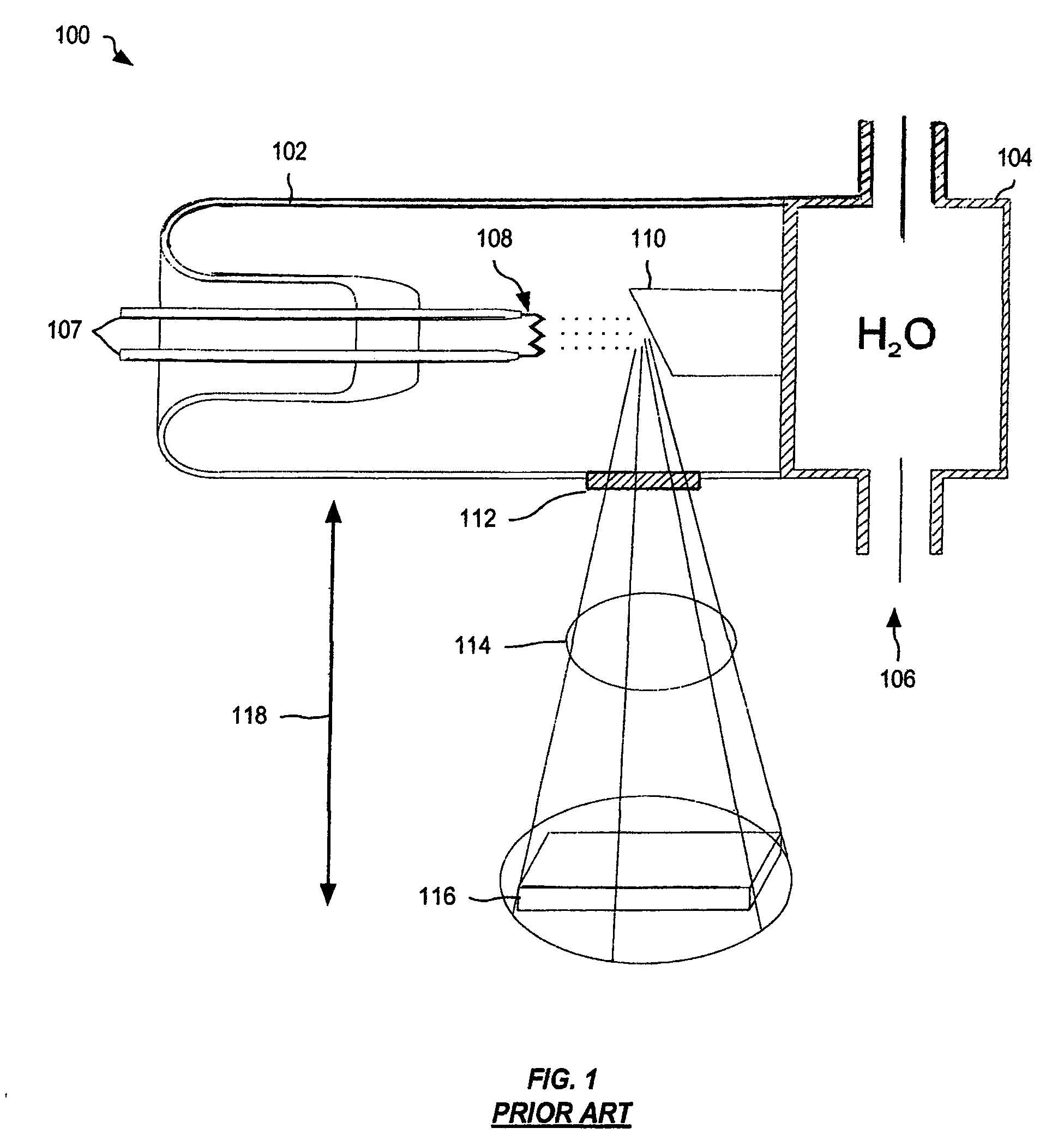

X-ray system for irradiating material used in transfusions

InactiveUS7706506B1Improve uniformityReduce necessityRadiation/particle handlingX-ray tube anode coolingShaped beamHigh energy

A system for irradiating material used in transfusions. The material can be pre-transfused blood, blood components and marrow. The system includes a vacuum chamber with a plate cathode inside. The cathode has a large beam electrode field-electron emissive surface with a selected cross-sectional shaped area. A power supply is connected to the cathode for generating negative high-voltage pulses and causing a selected cross-sectional shaped beam of electrons to be emitted. An electron window is also disposed inside the vacuum chamber and made of thin metal foil. The electron window receives the selected cross-sectional shaped beam of electrons therethrough and onto an electron target disposed outside the vacuum chamber. The electron target receives the selected cross-sectional shaped beam of electrons thereon and generates a selected cross-sectional shaped X-ray beam. A cathode filter is disposed next to the electron target and eliminates low energy beams from the spectrum of the X-ray beam. The filtered X-ray beam exposes the material to high energy beams for irradiation.

Owner:APPLIED X RAD TECH

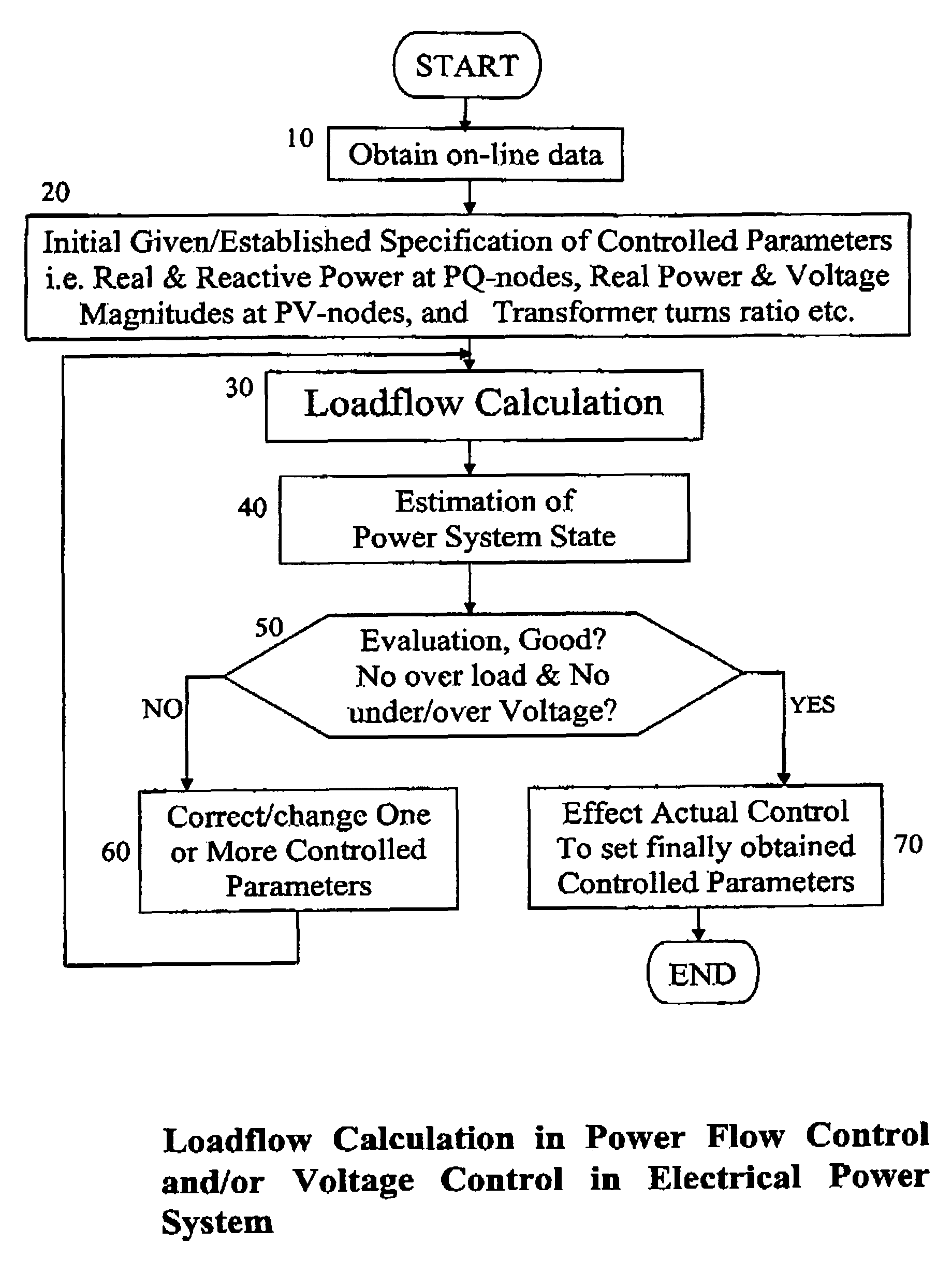

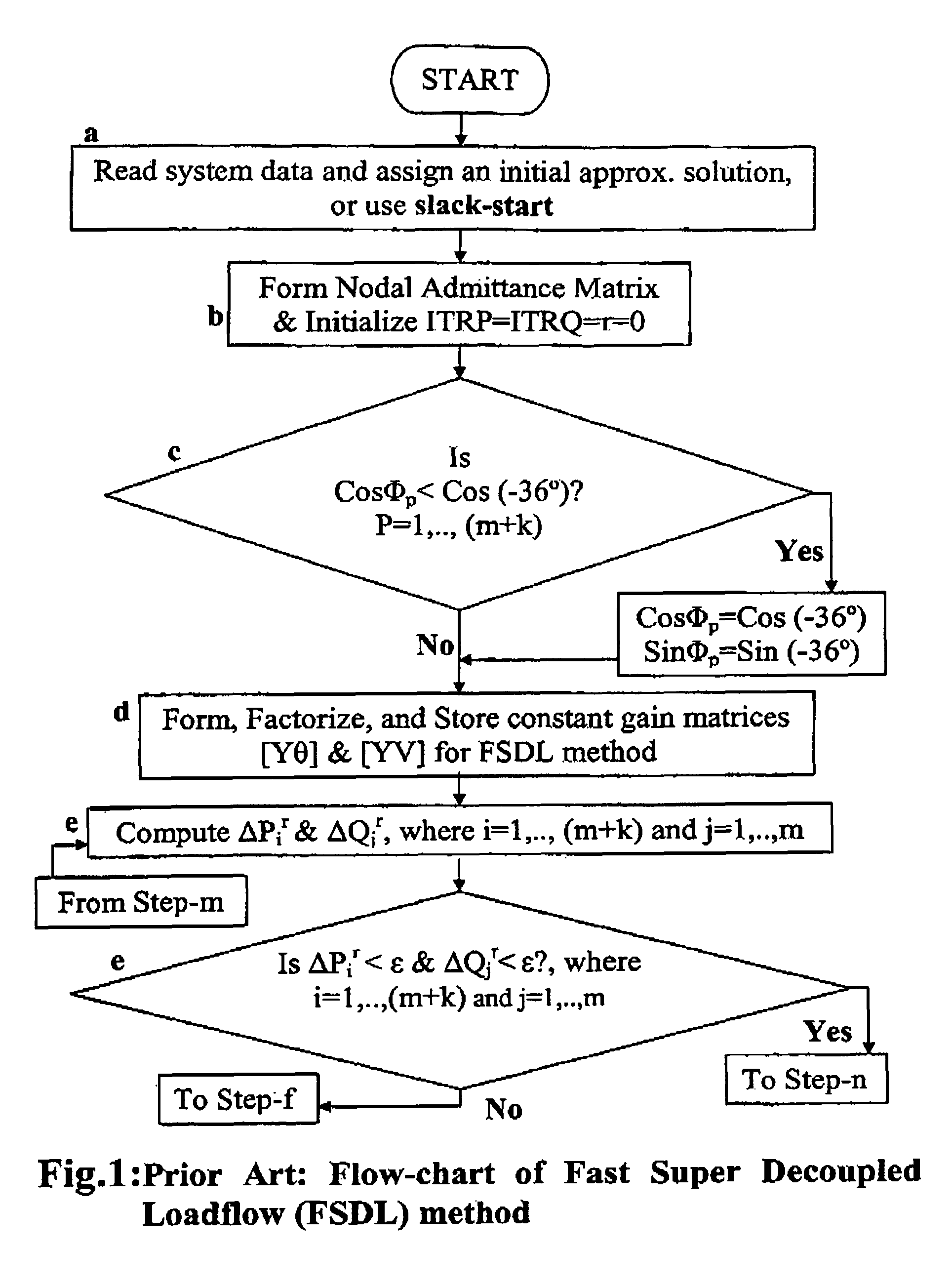

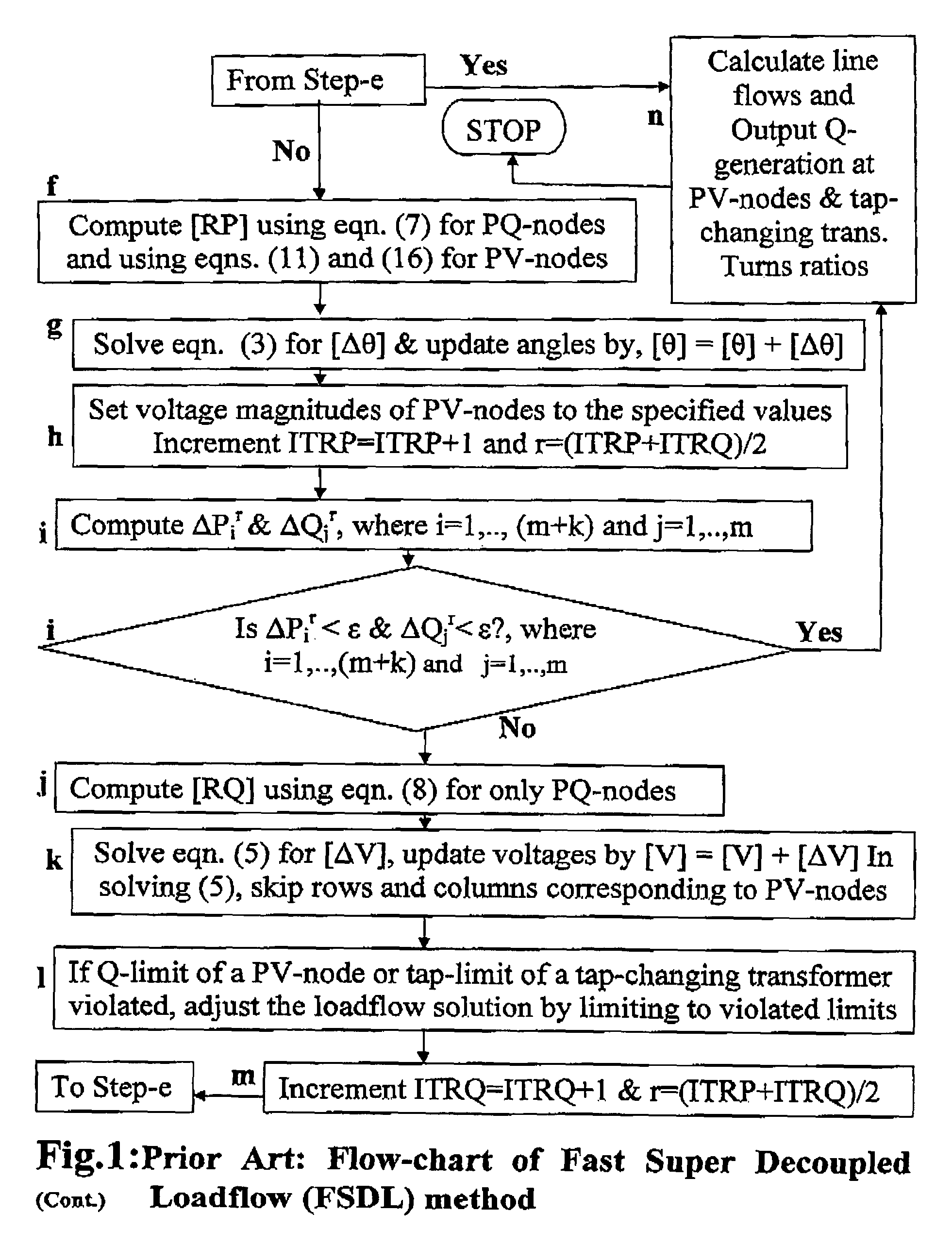

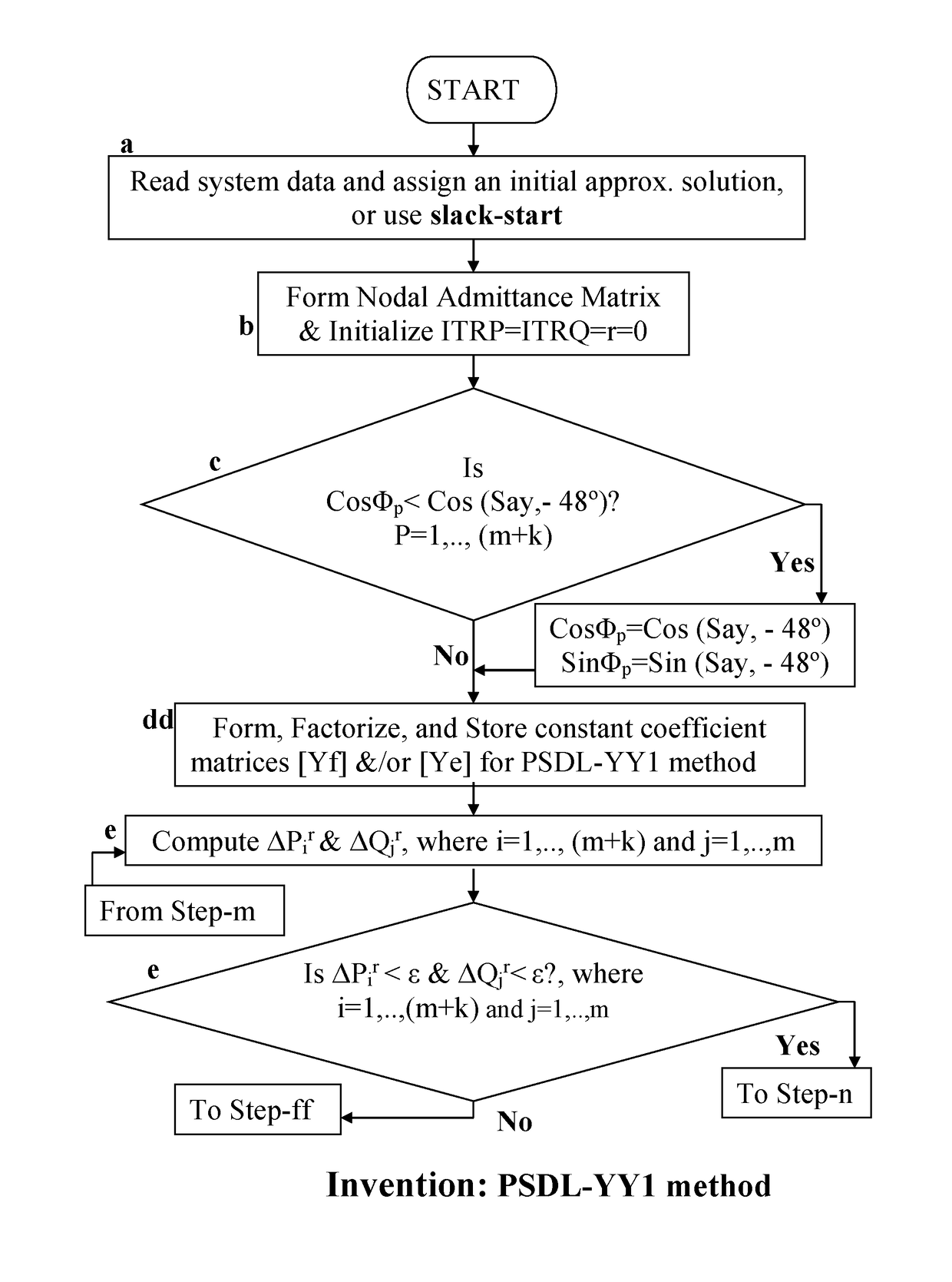

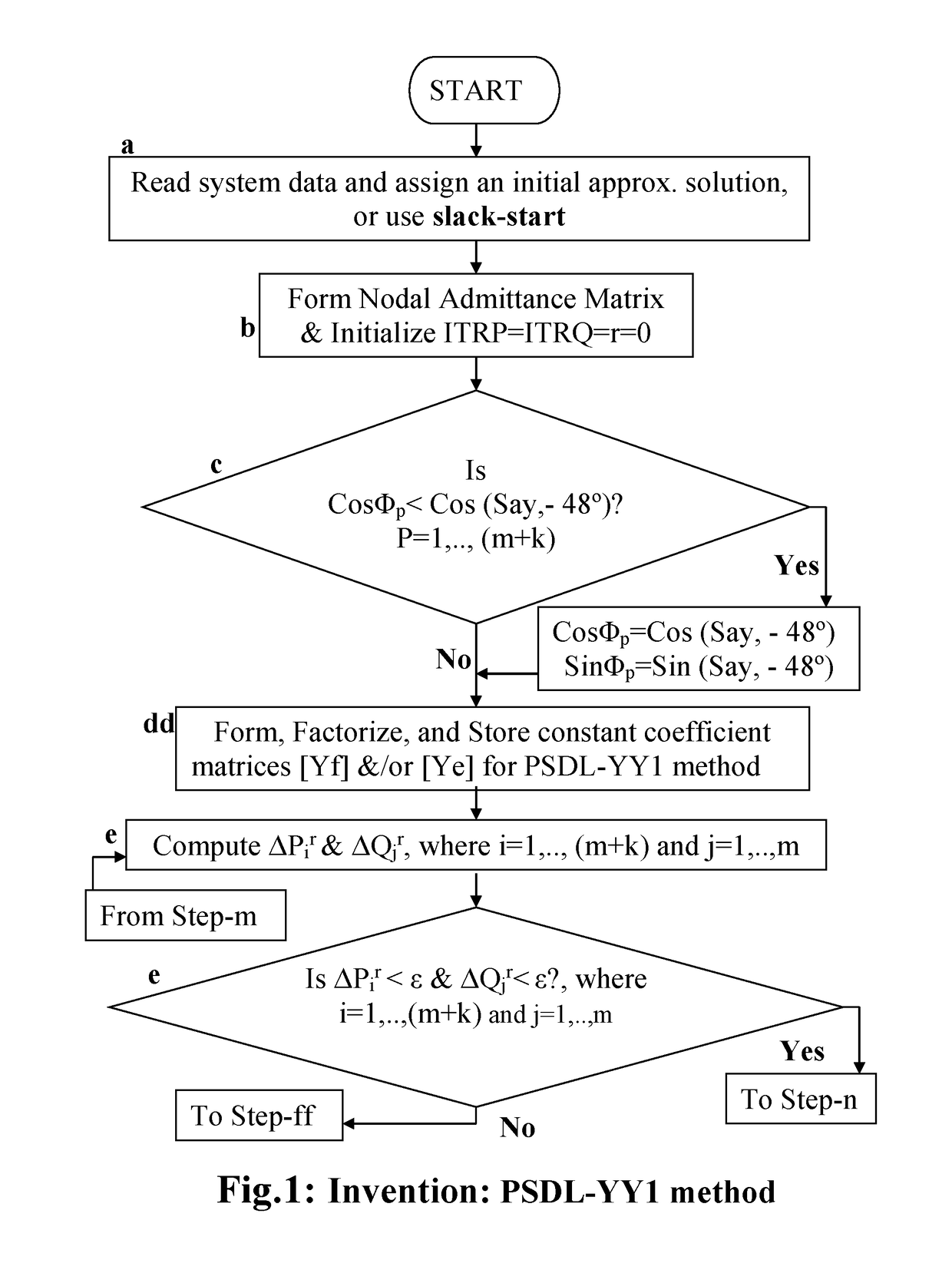

Method of super super decoupled loadflow computation for electrical power system

InactiveUS7769497B2Improve convergence and efficiencySize reduction requirementsLevel controlLoad balancing in dc networkNetwork variablePower flow

A method of performing loadflow calculations for controlling voltages and power flow in a power network by reading on-line data of given / specified / scheduled / set network variables / parameters and using control means, so that no component of the power network is overloaded as well as there is no over / under voltage at any nodes in the network following a small or large disturbances. The invented generalized Super Super Decoupled Loadflow (SSDL) calculation method is characterized in that 1) modified real power mismatch at any PQ-node-p is calculated as RPp=[ΔPp′+(Gpp′ / Bpp′)ΔQp′] / Vp2, which takes different form for different manifestation of the generalized version SSDL-X′X′ method, 2) transformed values of known / given / specified / scheduled / set quantities in the diagonal elements of the gain matrix [YV] of the Q-V sub-problem are present, and 3) transformation angles are restricted to maximum of −48° particularly for the most successful version SSDL-YY method, and these inventive loadflow calculation steps together yield some processing acceleration and consequent efficiency gains, and are each individually inventive. The other two Super Super Decoupled Loadflow methods: BGX′ version (SSDL-BGX′) and X′GpvX′ version (SSDL-X′GpvX′) are characterized in the use of simultaneous (1V, 1θ) iteration scheme thereby calculating mismatches only once in each iteration and consequent efficiency gain.

Owner:PATEL SURESHCHANDRA B

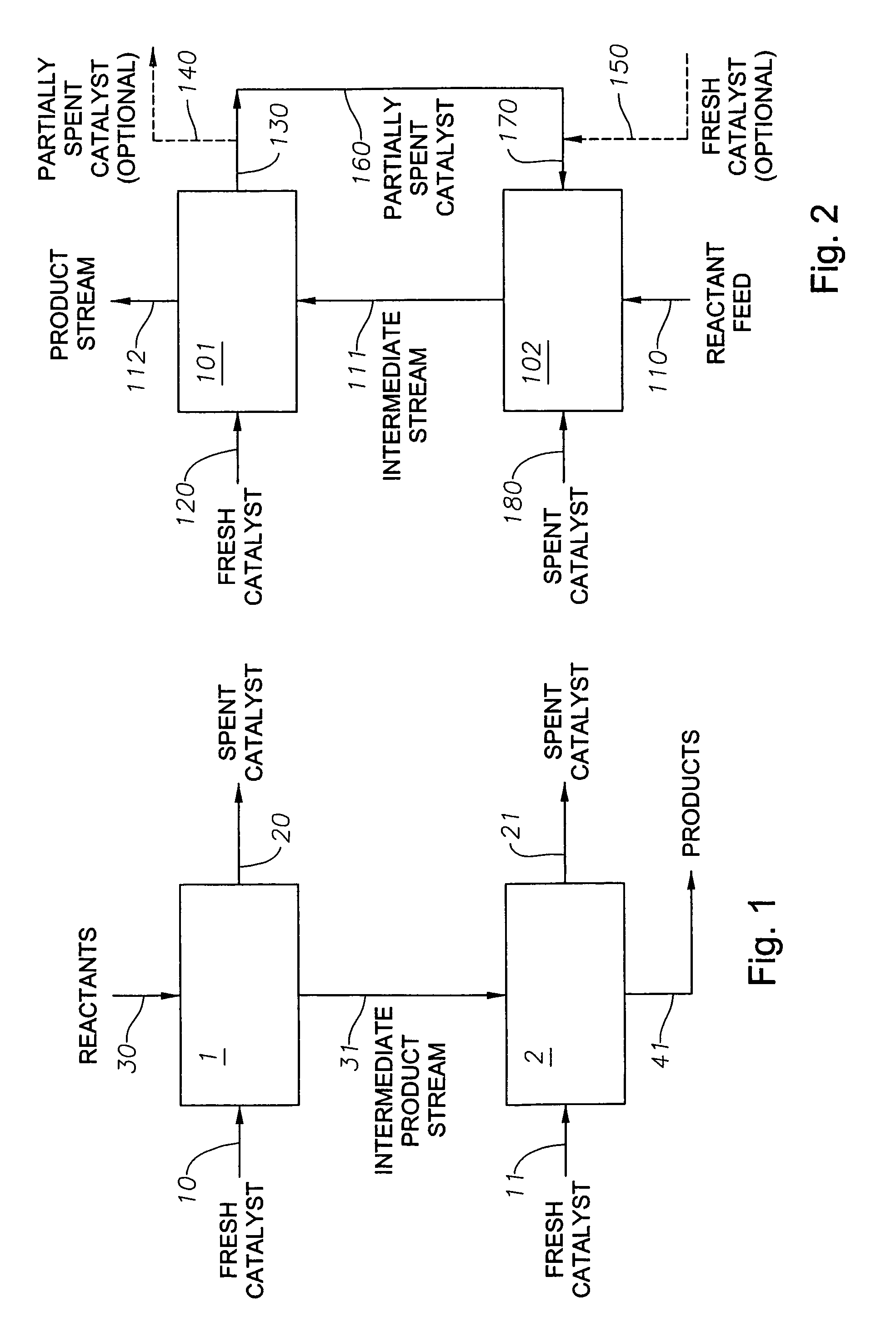

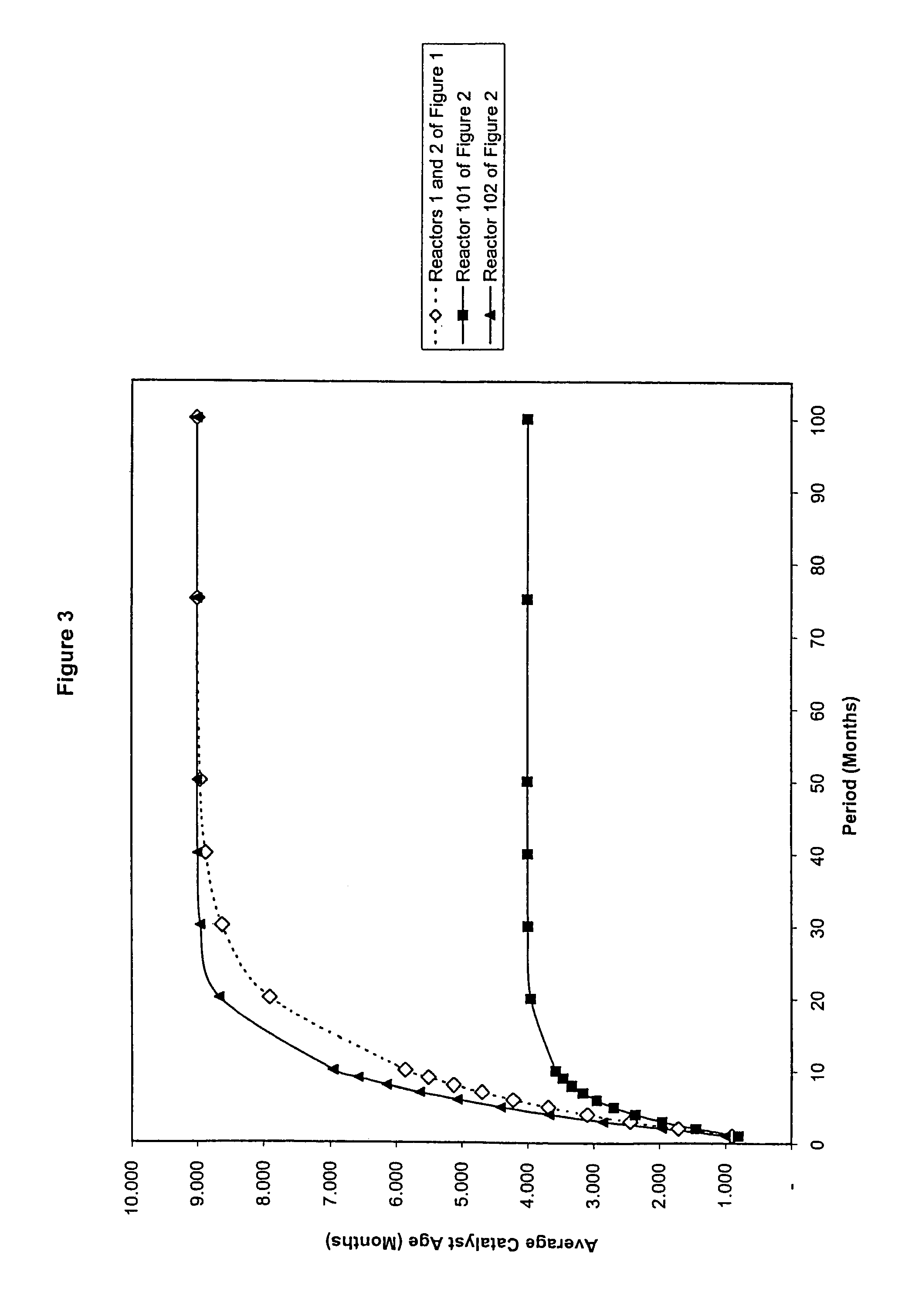

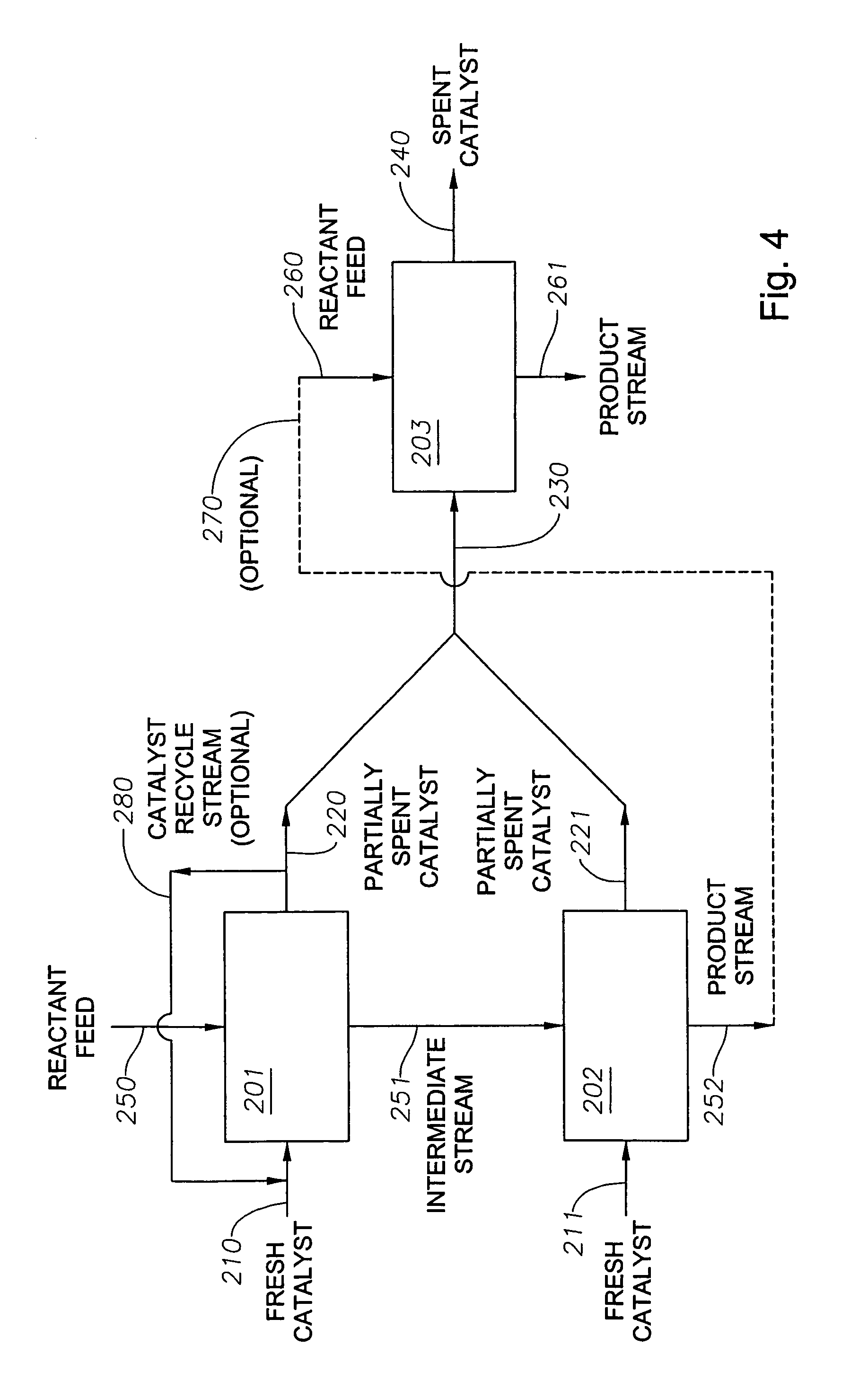

Method of removing and replacing catalyst in a multi-reactor cascade configuration

InactiveUS7033488B2Reduce frequencyGood removal effectTreatment with plural serial cracking stages onlyCatalytic crackingProduction rateReactor system

A defined catalyst withdrawal and replacement program for optimizing the productivity and the economics of catalyst consumption in a multi-reactor system is disclosed. Catalyst cost is reduced by minimizing removal of the newest catalyst and maximizing removal of older catalyst to achieve an overall reduction of catalyst age in the multi-reactor system.

Owner:CONOCO INC

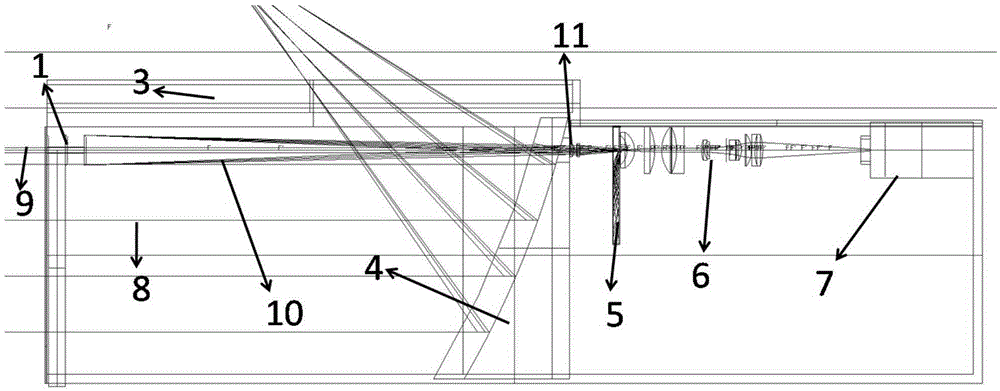

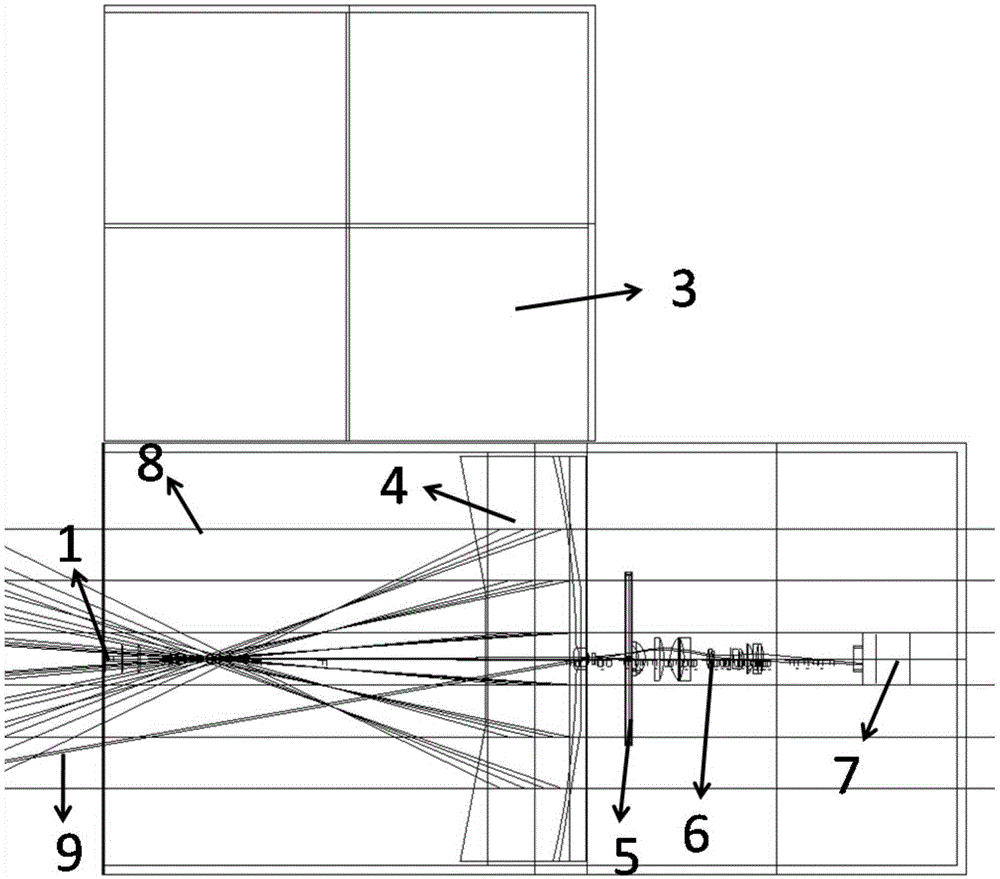

Semi-open type full circumferential coronagraph apparatus with large field of view

InactiveCN105388617ALower performance requirementsSize reduction requirementsOptical elementsSemi openOptical axis

The invention relates to a semi-open type full circumferential coronagraph apparatus with a large field of view. The coronagraph apparatus comprises in sequence from left to right: an outer shielding body, an outer window, a heat collecting lens, an inner shielding body, an inner shielding body light-absorbing groove, an imaging system and a CCD camera. The outer shielding body and the inner shielding body are disposed on the optical axis of an optical path. The inner shielding body is positioned in an imaging position where the outer shielding body passes through an object lens unit. The coronagraph apparatus, as a whole, is of a semi-open square structure, and is reduced in size and weight. The heat collecting lens is a reflector with a square centrally-recessed structure, and the recessed surface of the centrally-recessed structure faces one side of the outer window. The heat collecting lens is arranged in an inclined manner. The lower end of the heat collecting lens goes toward one side of the outer window relative to the upper end of the heat collecting lens. Incident sun direct light is focused by the heat collecting lens outside the semi-open square structure, so the influence of scattered stray light on the surface of the heat collecting lens is reduced.

Owner:SHANDONG UNIV +1

Methods of Patel Loadflow Computation for Electrical Power System

InactiveUS20180048151A1Improve convergence and efficiencySize reduction requirementsPower network operation systems integrationSimulator controlElectric power systemAlgebraic equation

Owner:PATEL SURESHCHANDRA B

Methods of Patel Loadflow Computation for Electrical Power System

InactiveUS20190296548A1Fast convergenceImprove efficiencyDesign optimisation/simulationComplex mathematical operationsElectricity systemAlgebraic equation

Owner:PATEL SURESHCHANDRA B

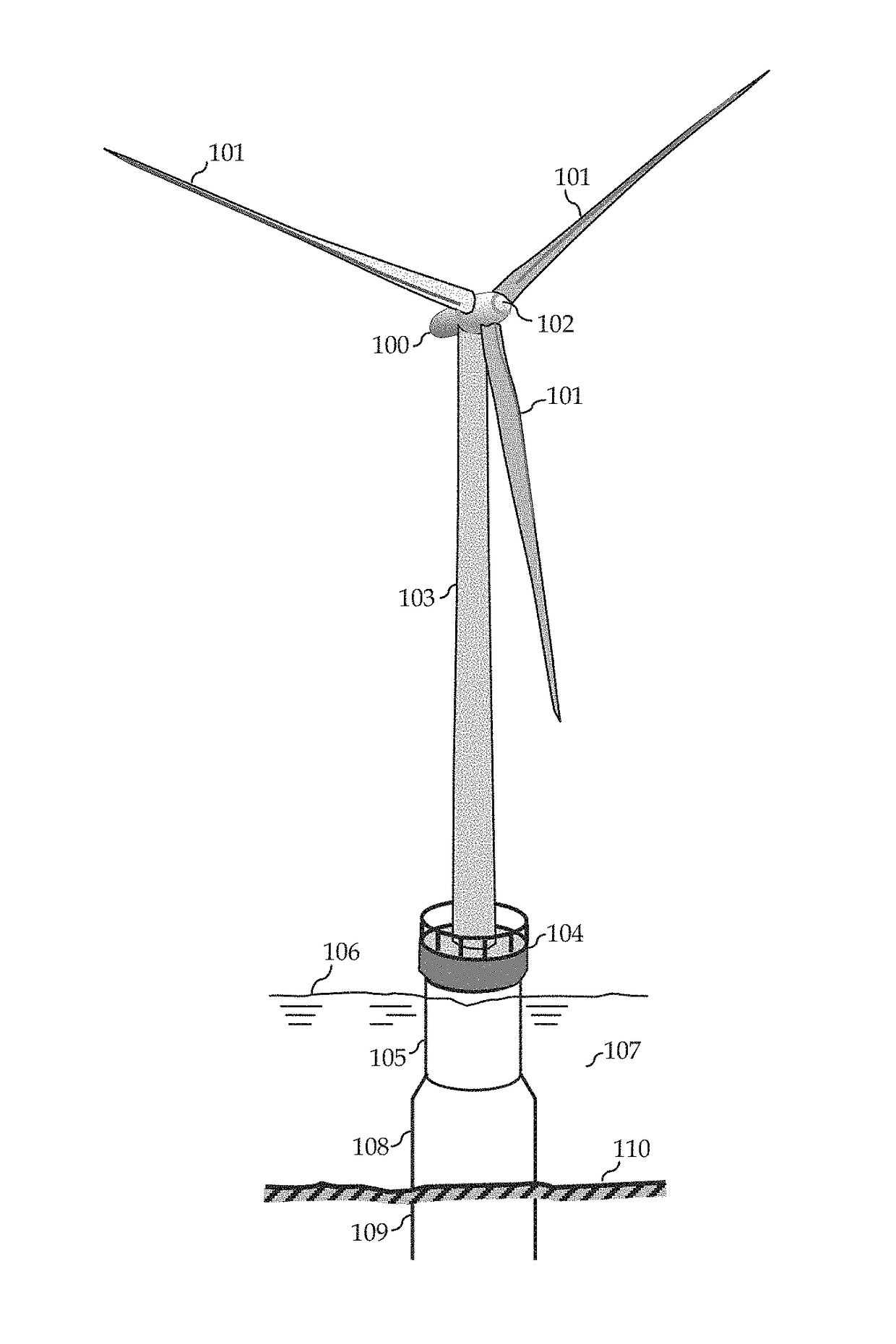

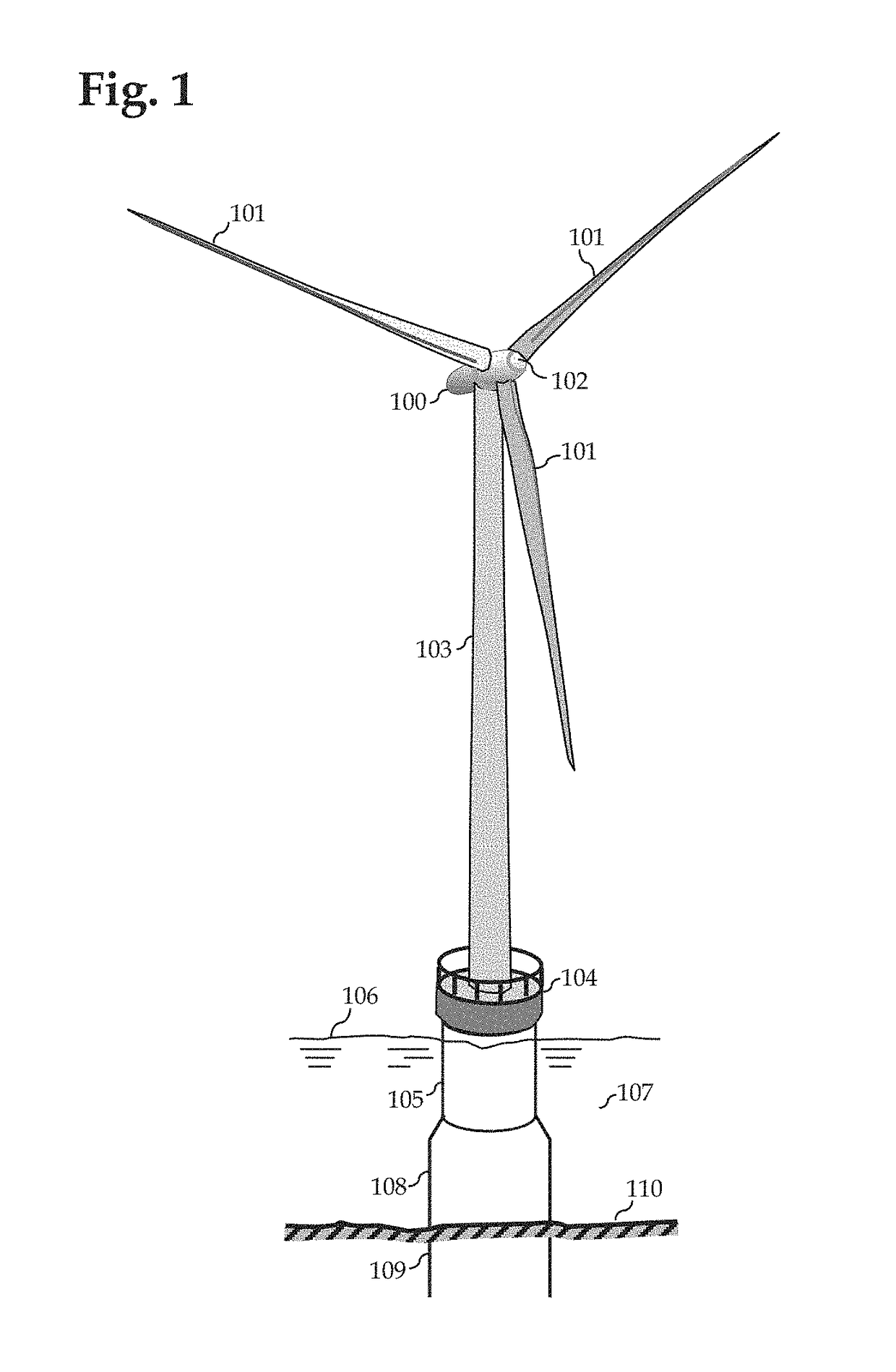

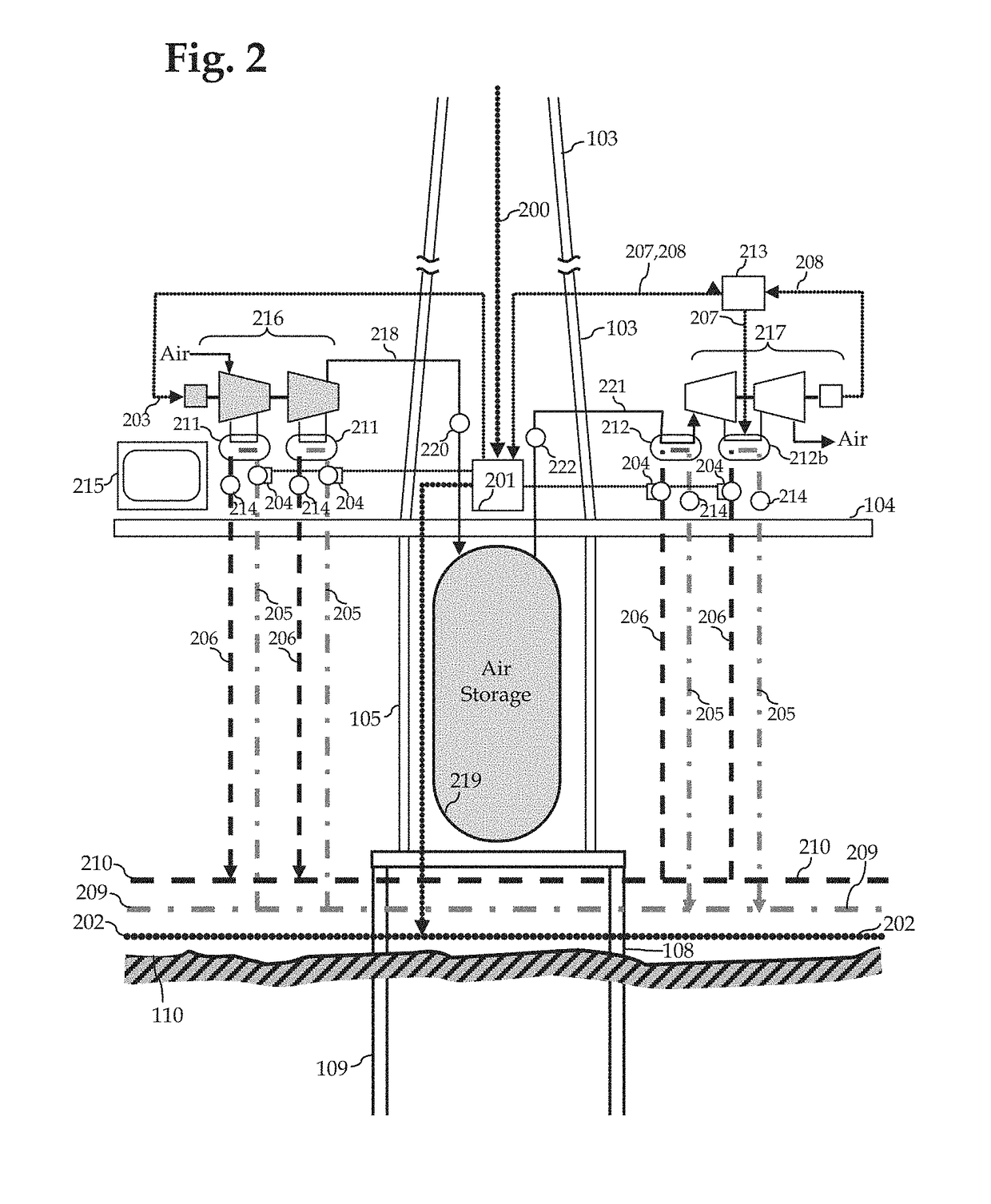

Distributed compressed air energy storage with heat network

PendingUS20180238304A1Reduce temperatureImprove process capacity and efficiencyArtificial islandsWind motor controlAutomotive engineeringCapacity factor

A method and system of distributed Compressed Air Energy Storage with thermal energy interchange network of cooling and heating circuits and dynamically scheduled power production, energy storage and power generation from storage, of integrated individual power resources to enhance system thermal efficiency and capacity factor.

Owner:UMEZ ERONINI ERONINI IHEANYI

A formwork system

ActiveUS20170254072A1SpacingShorten the connection distanceWallsAuxillary members of forms/shuttering/falseworksEngineeringBuilding construction

The present invention provides a system 10 for construction of formwork where a settable compound is pourable into a cavity in the formwork and retained by the formwork to set to form a completed structure. The formwork comprises structural panels 12, 14 connected by adjustable connectors 34 for varying the spacing between the panels.

Owner:TWINWALL ICF

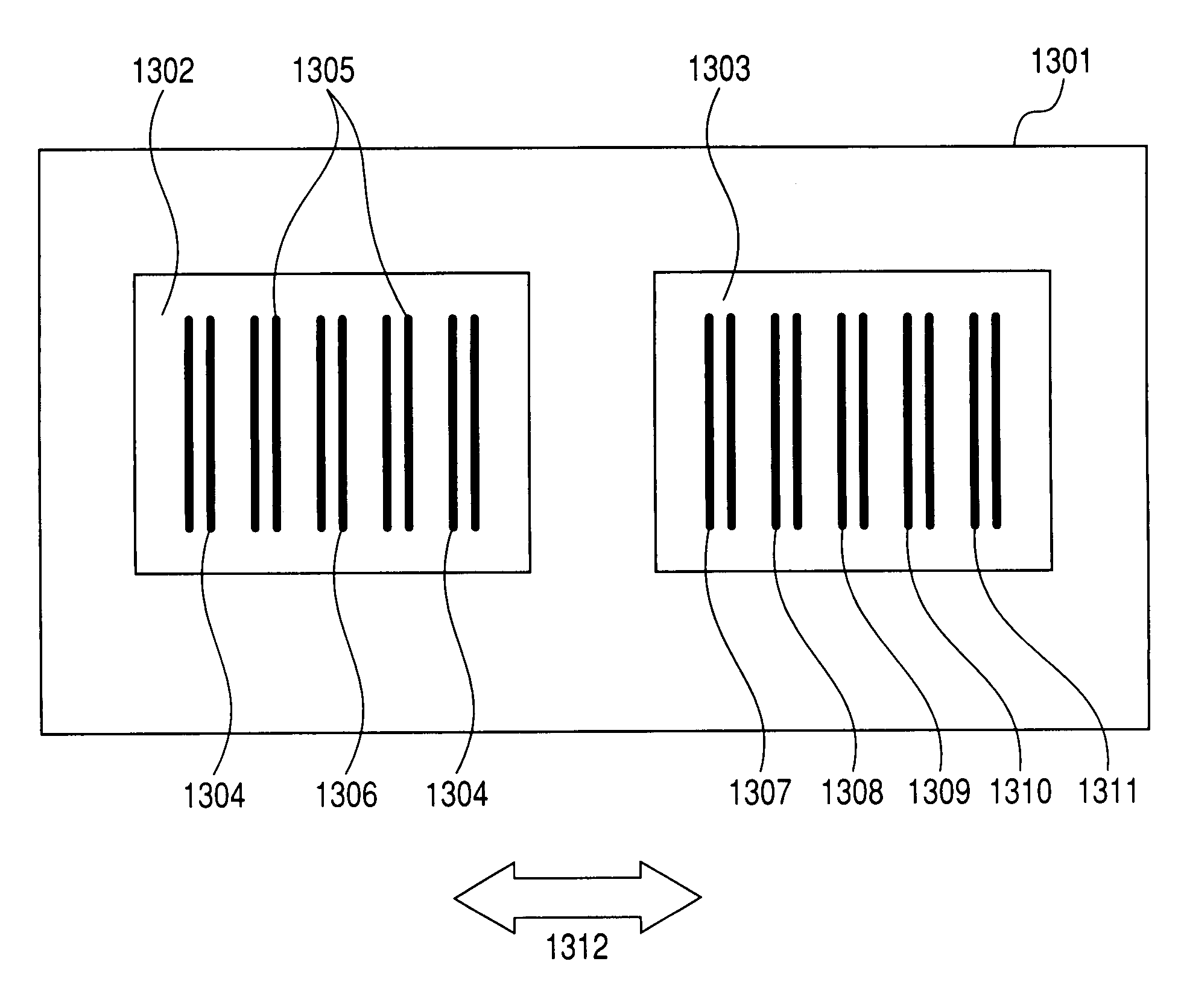

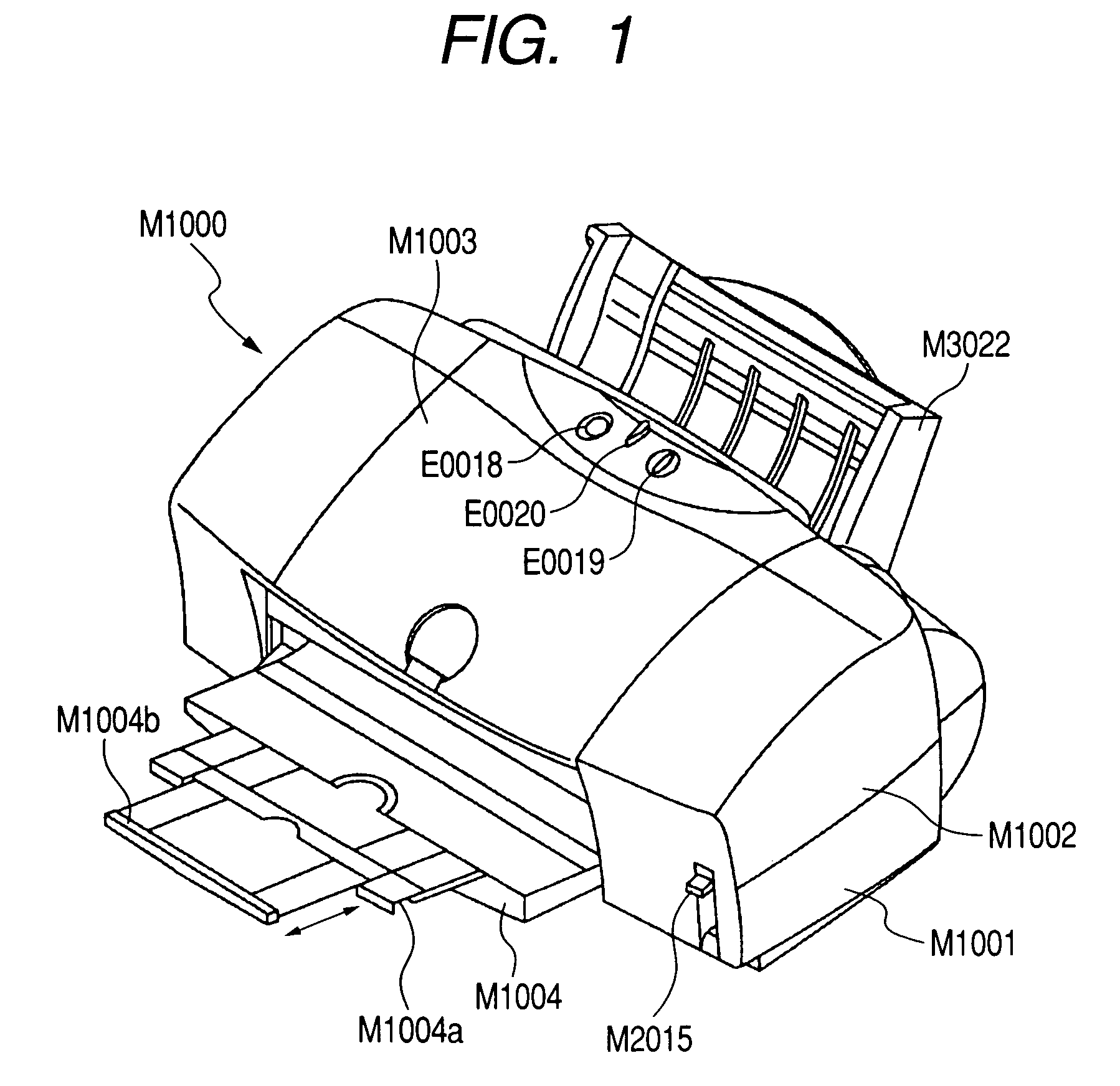

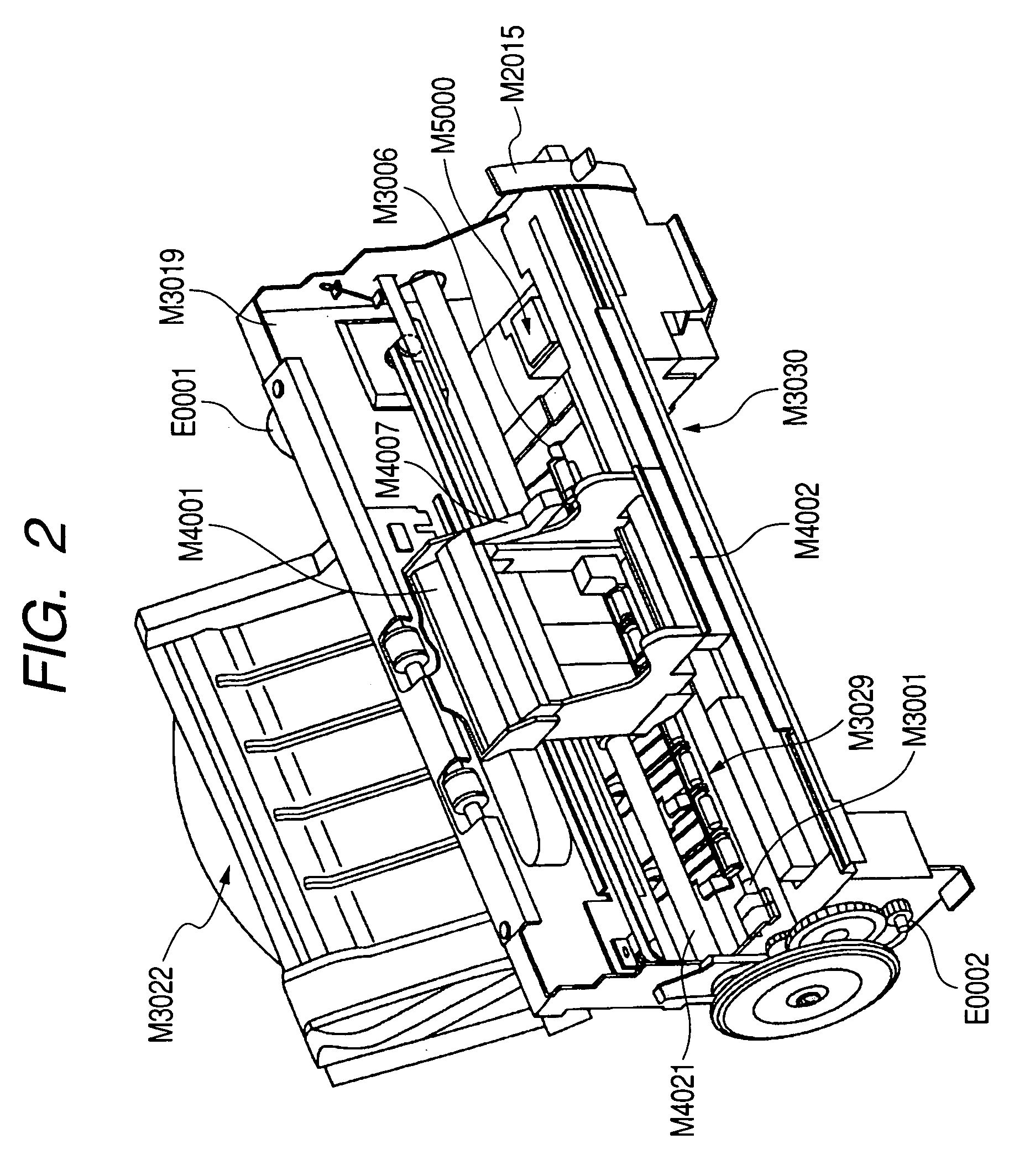

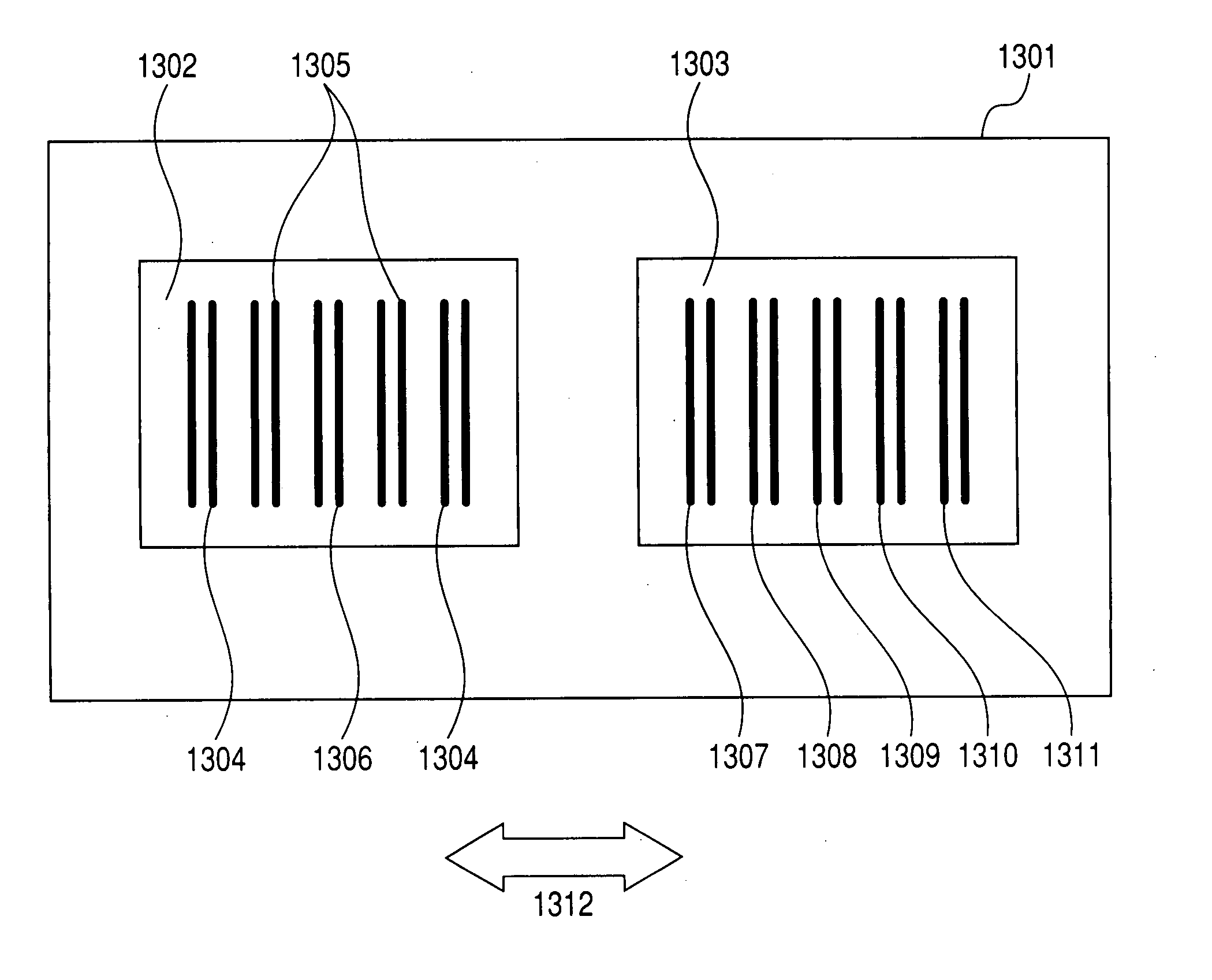

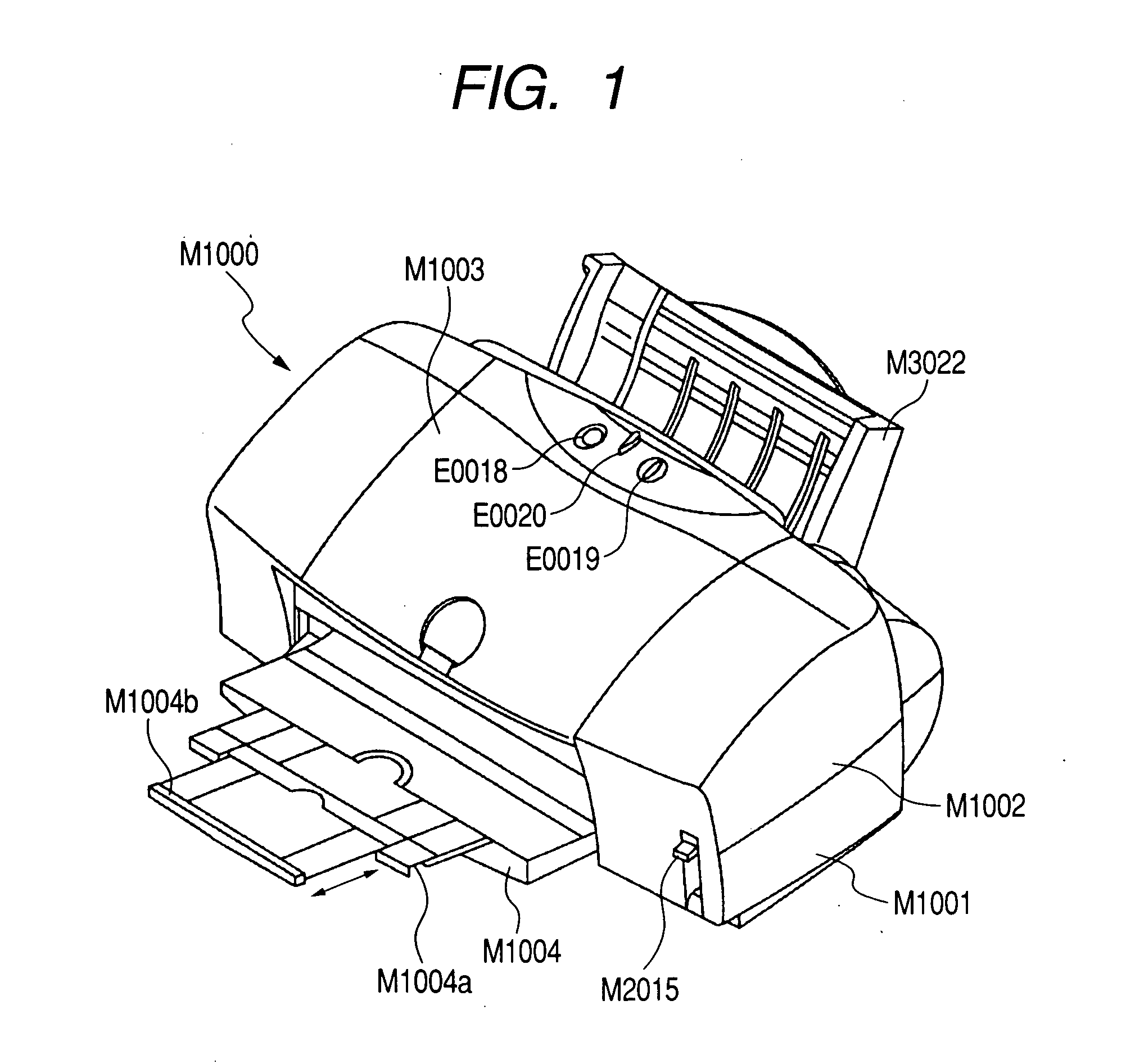

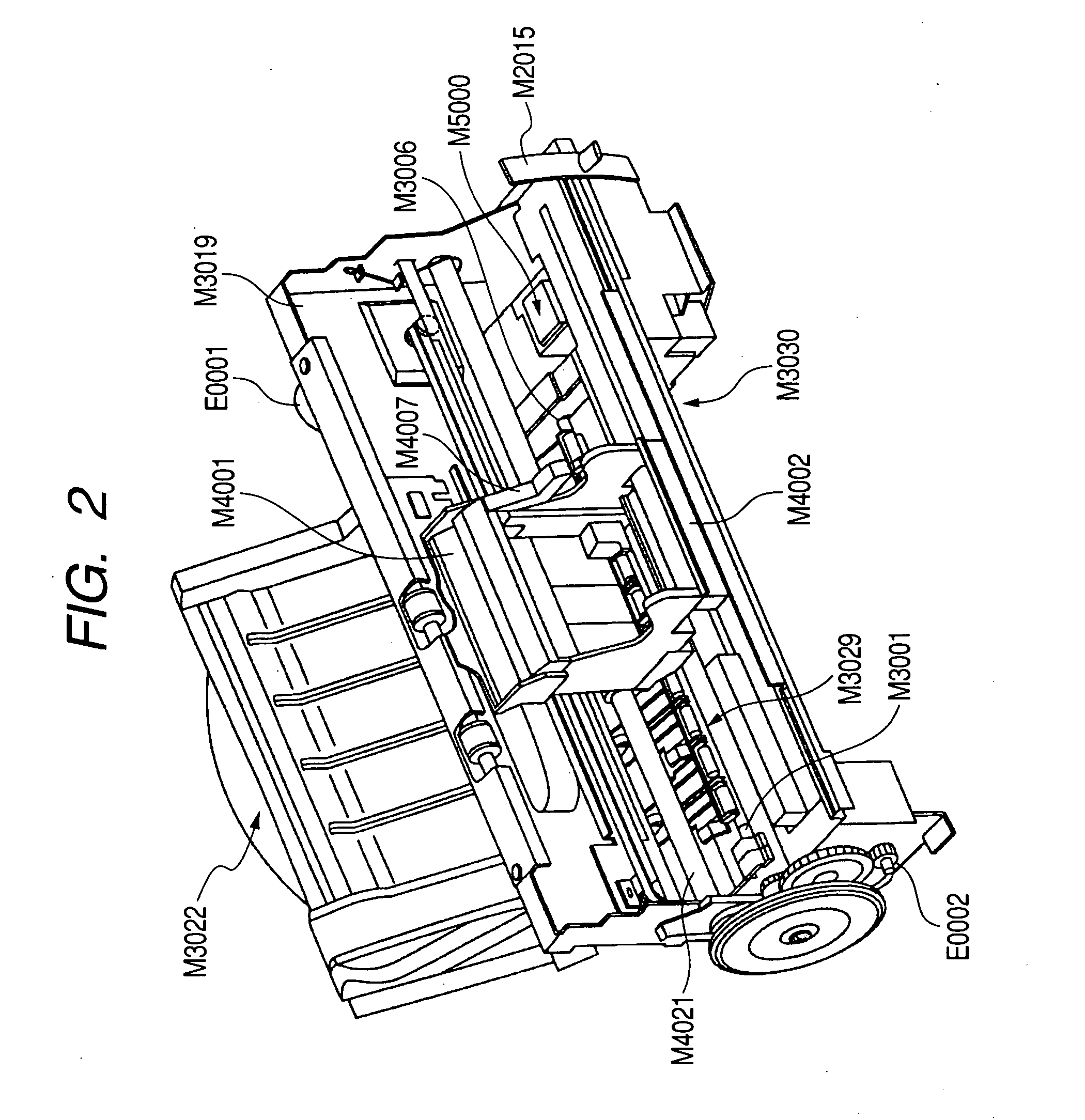

Ink jet recording apparatus

An ink ejection nozzle constituting section for performing printing with a high image quality and an ink ejection nozzle constituting section for performing full-color printing at a high speed are separately disposed in one ink jet head. A recovery system is capable of performing suction recovery only in each of the nozzle constituting sections, and the suction recovery optimized for each constituting section is carried out. Accordingly, an increase in size of a recording apparatus can be restrained, and total ink consumption can be suppressed at the time of maintenance.

Owner:CANON KK

Ink jet recording apparatus

An ink ejection nozzle constituting section characterized for performing printing with a high image quality, and an ink ejection nozzle constituting section characterized for performing full-color printing at a high speed are separately disposed in one ink jet head to constitute a recovery system capable of performing suction recovery only in each of the constituting sections, and the suction recovery optimized for each constituting section is carried out. Accordingly, the size enlargement of a recording apparatus can be restrained, and total ink consumption can be suppressed at the time of maintenance.

Owner:CANON KK

Device for radiation therapy under image monitoring

InactiveUS8788016B2Size reduction requirementsEasy and cheap to realizeMagnetic measurementsDiagnostic recording/measuringResonanceLight beam

A device for radiation therapy implemented with image monitoring has a magnetic resonance device and an exposure device. The magnetic resonance device has a magnet and primarily serves for image monitoring an examination object of a patient in an examination volume of the magnetic resonance device. The exposure is fashioned to be static and serves to expose the examination subject in the examination volume with therapeutic beams. The patient (and therefore the examination subject) are supported by a patient positioning device such that the examination subject can be moved relative to the magnetic resonance device and the exposure device around at least one rotation axis.

Owner:SIEMENS HEALTHCARE GMBH

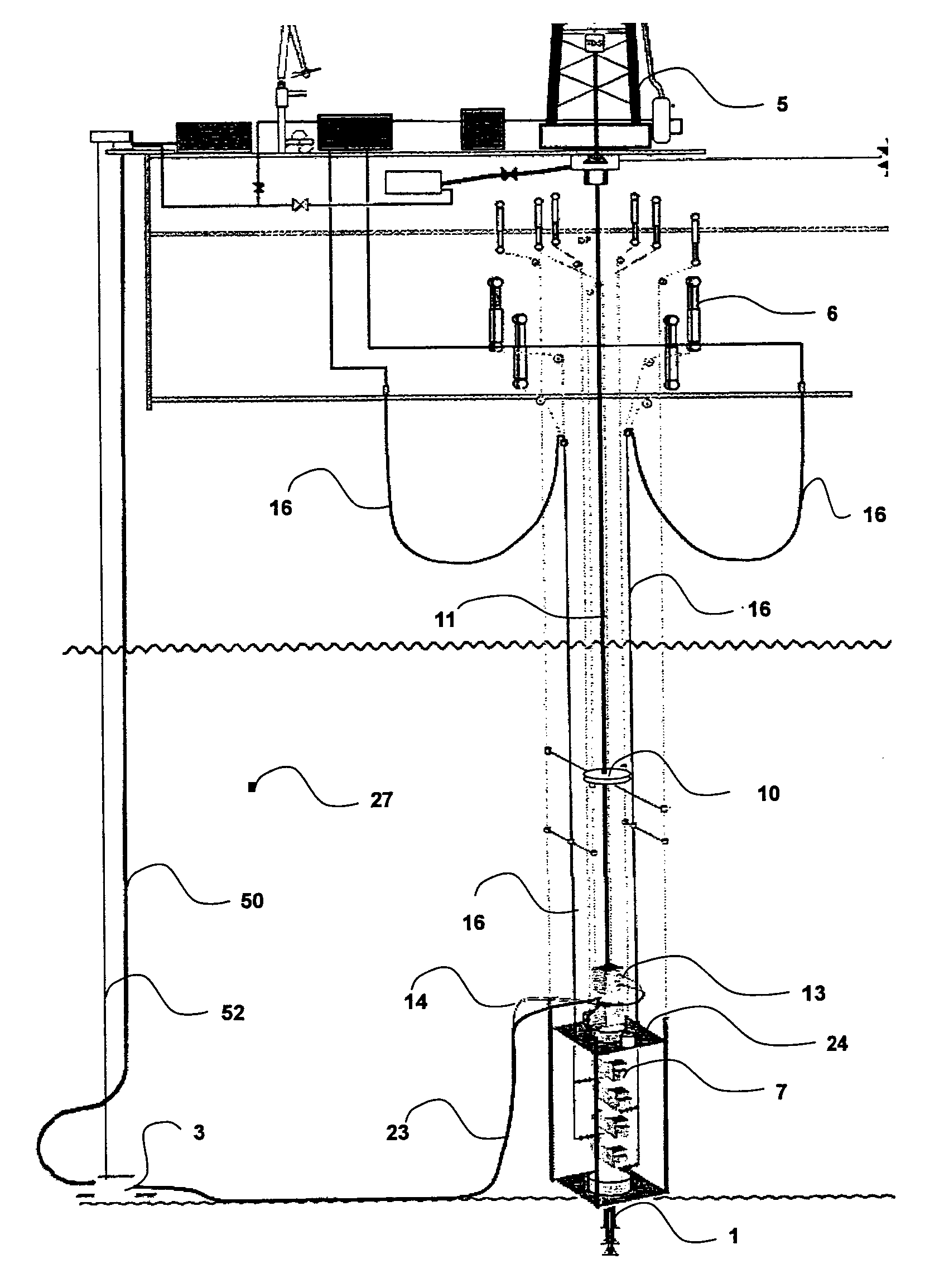

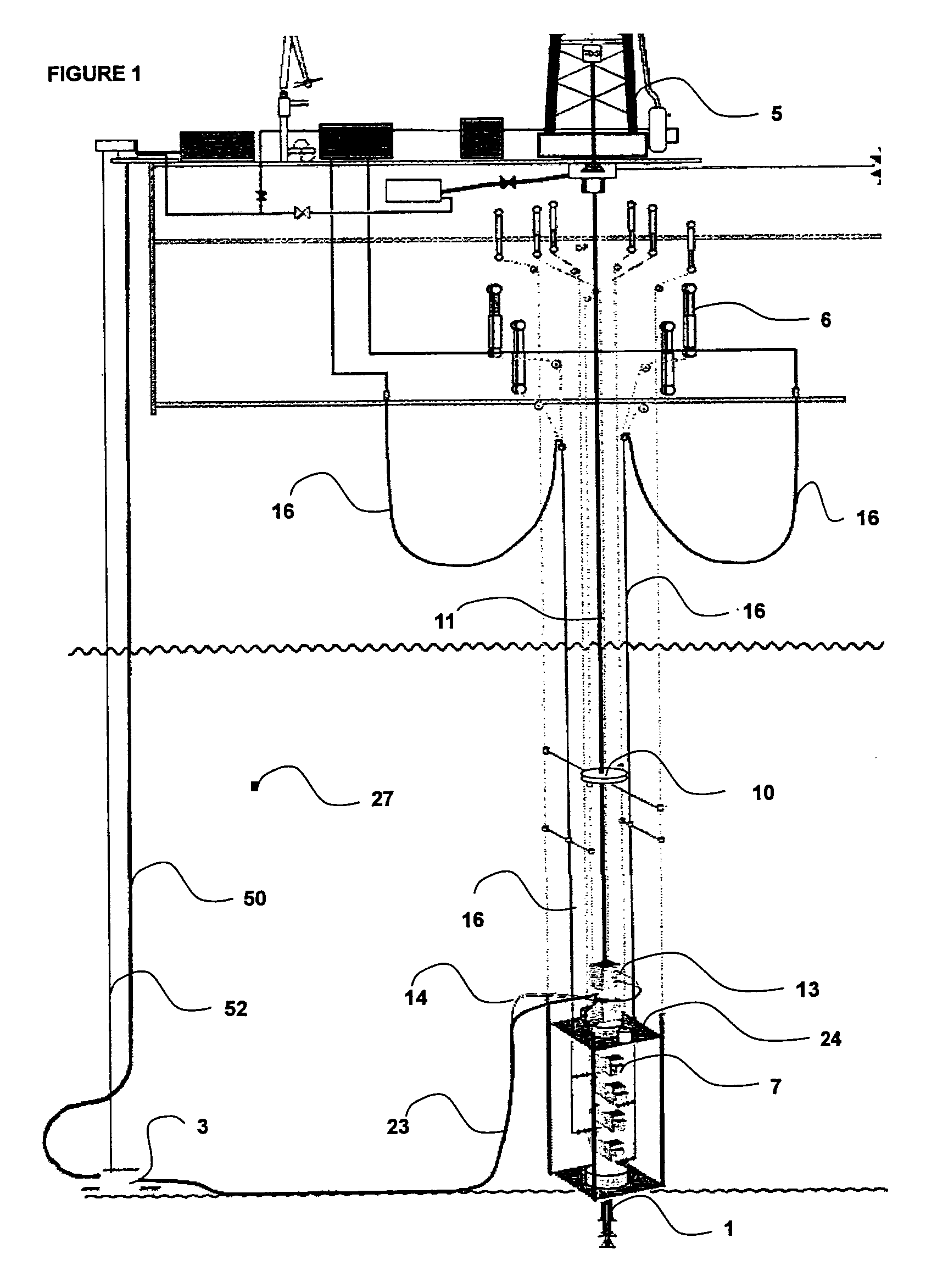

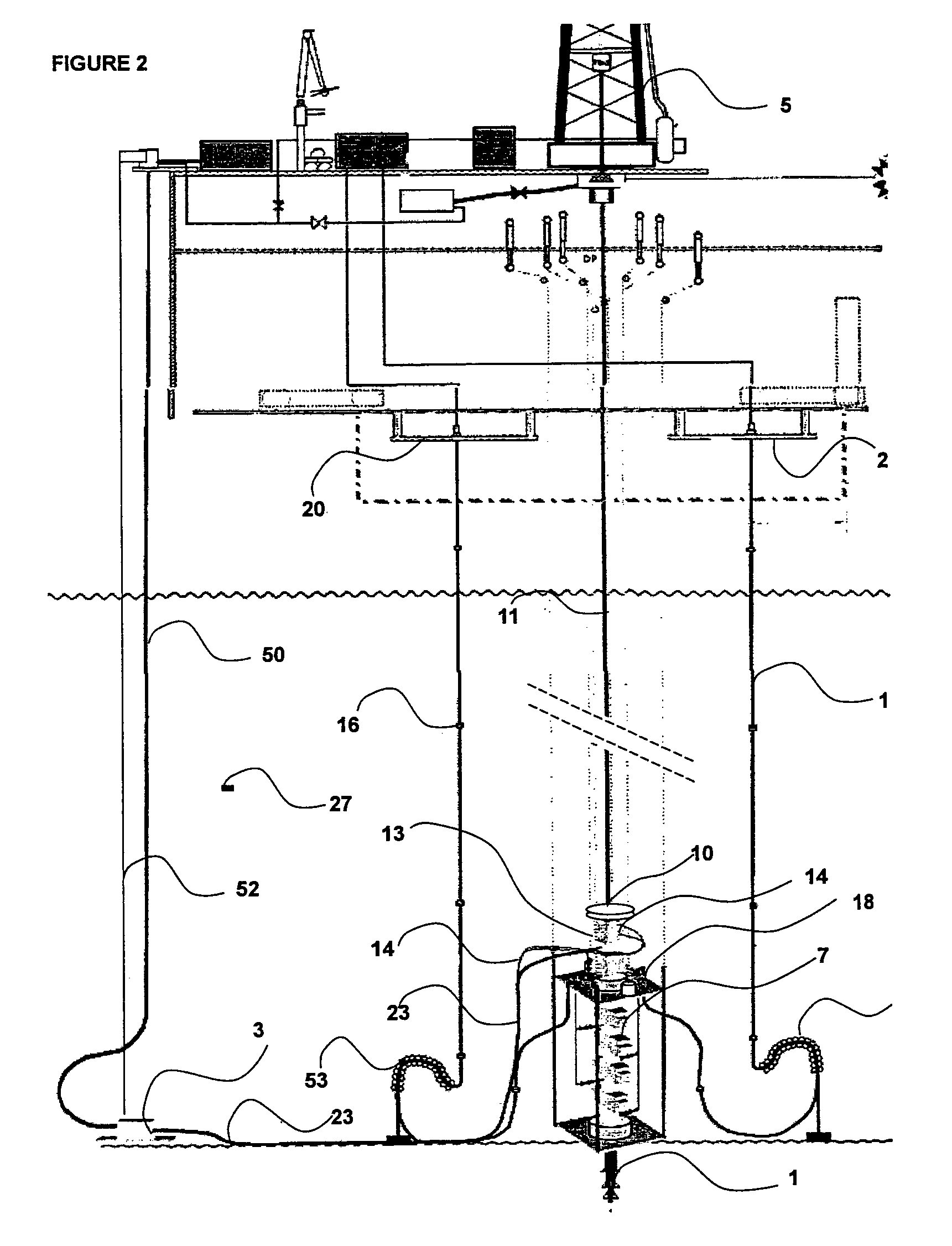

Riserless, pollutionless drilling system

ActiveUS9062498B2Reduce riskAvoid excessive heightUnderwater drillingFlushingWell drillingEngineering

Owner:ENHANCED DRILLING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com