Plating apparatus and method

a technology of plating apparatus and substrate, applied in the direction of liquid/solution decomposition chemical coating, coating, electrolysis components, etc., can solve the problems of large plating resolution and definition errors, affecting the stability of the substrate, so as to minimize the risks of damage in plating small, expensive substrates, and reduce the volume required for plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

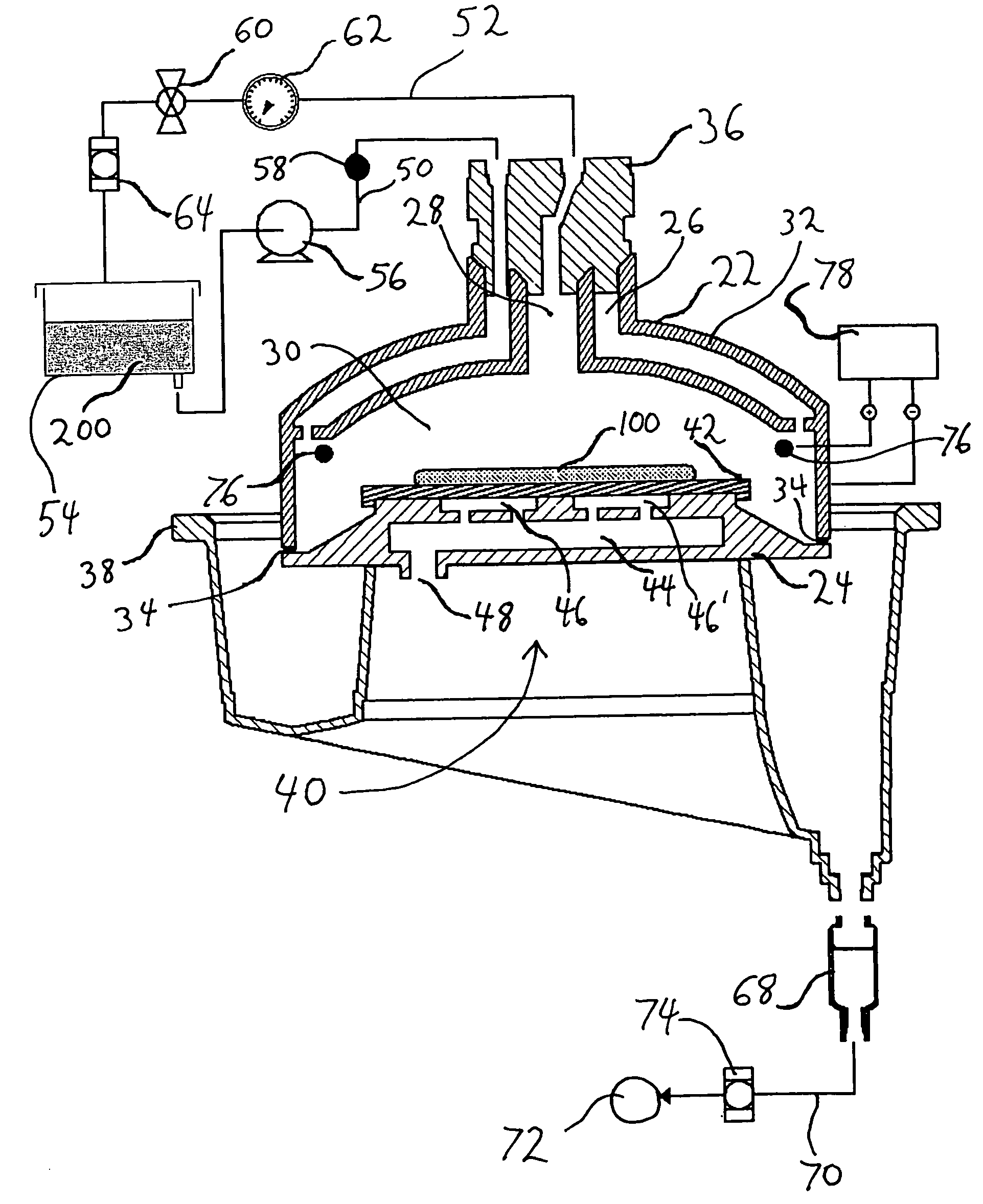

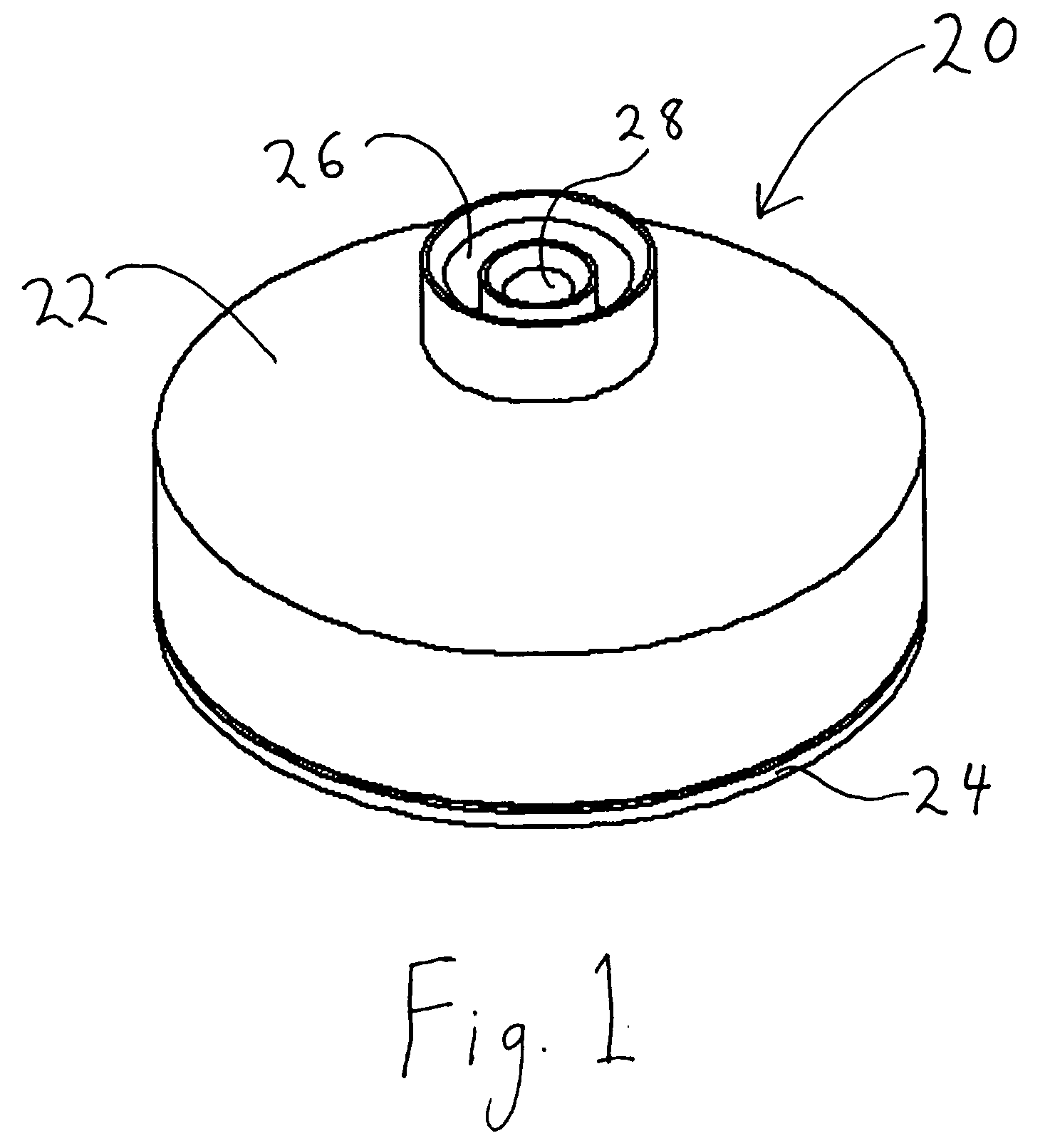

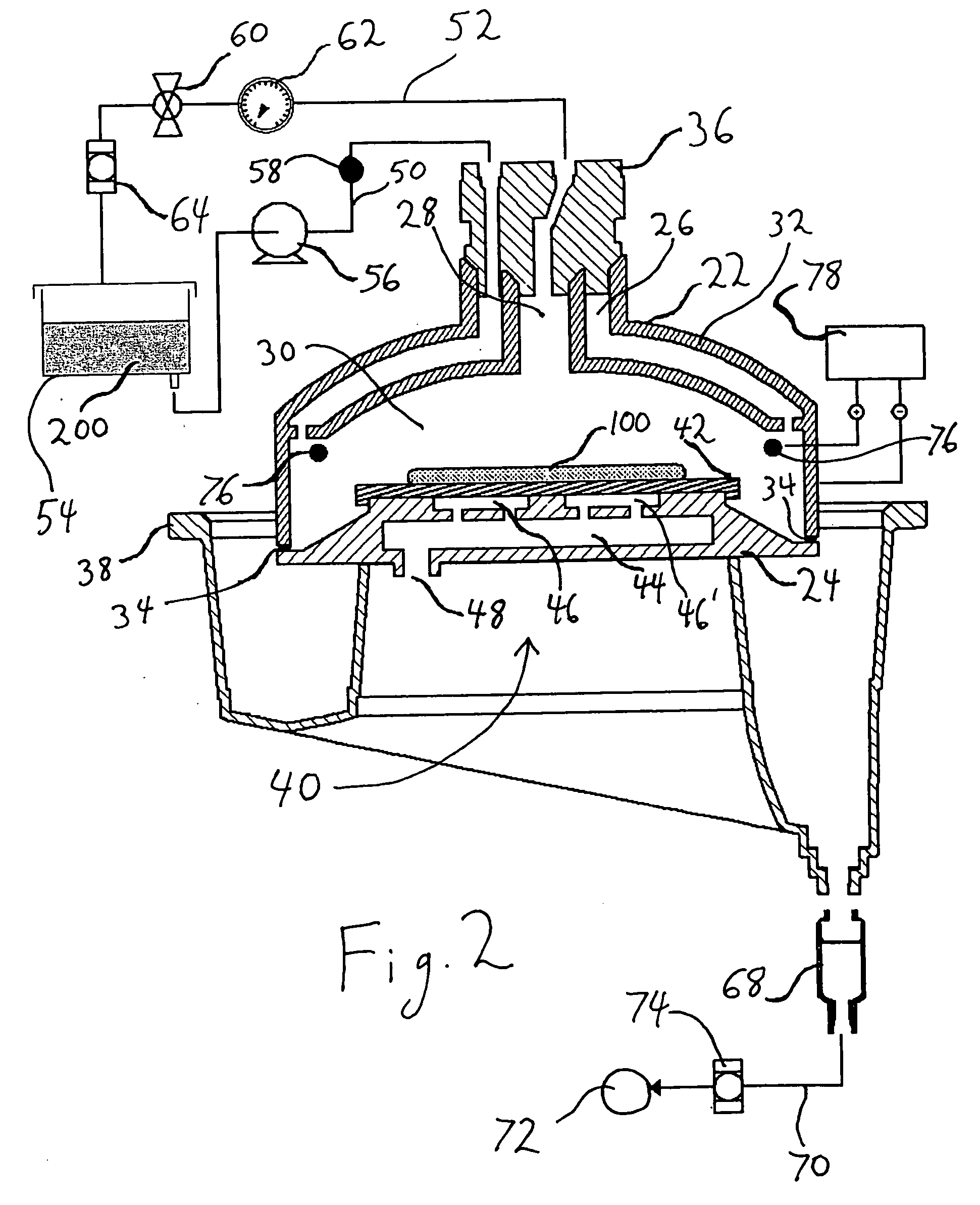

[0071] The preferred embodiment of the present invention comprises a metal plating (i.e., metal deposition) apparatus and method. The apparatus comprises a vessel or other enclosure to contain a substrate to be plated while the substrate is subjected to one or more plating processes and / or materials and fluids. Such processes include the electrolytic and electroless (i.e., autocatalytic) deposition of metal(s). As used herein, “substrate” is defined as any object comprising a surface onto which metal deposition is to occur, including, but not limited to, a semiconductor wafer. The present invention provides for the plating of a substrate in a single vessel without the need to transfer the substrate to other vessels for exposure to other plating fluids or process steps. As used herein, a “plating fluid” is any fluid to which a substrate is exposed during a plating process including, but not limited to, chemical solutions, rinsing solutions, and metal solutions. In the preferred embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com