Battery grade high-purity manganese sulfate monohydrate and preparation method thereof

A manganese sulfate, battery-grade technology, applied in the direction of manganese sulfate, etc., can solve the problems of inconvenient production and corrosion effects of equipment, and achieve the effects of reducing corrosion effects, low economic cost, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

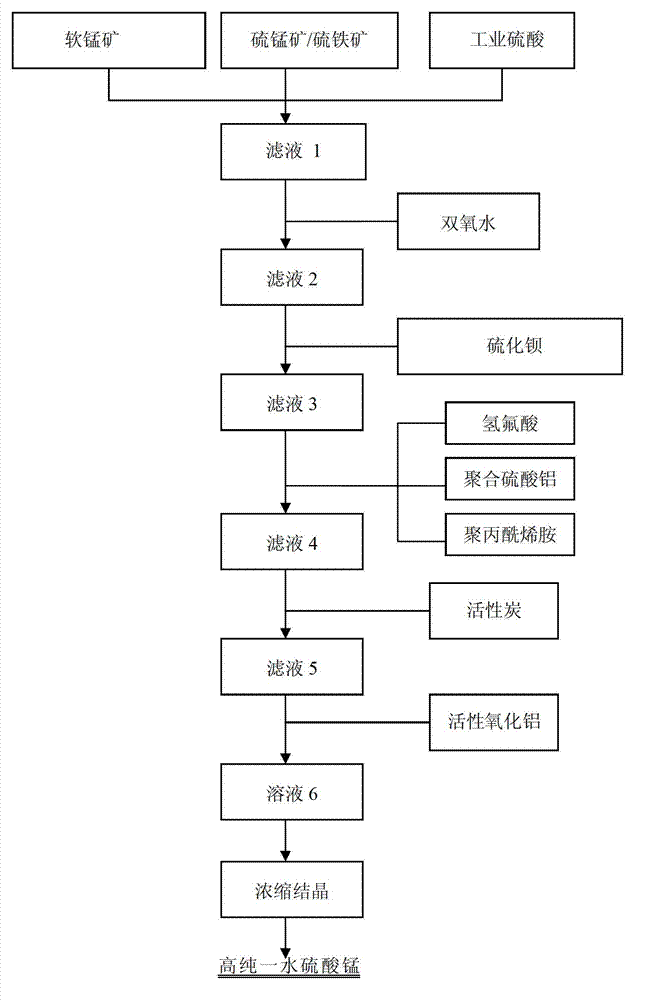

[0041] The preparation method of battery grade high-purity manganese sulfate monohydrate of the present invention comprises the following steps, and its process flow chart is as follows figure 1 shown.

[0042] (1) Weigh 600g of pyrolusite containing 25% manganese, 200g of pyrolusite, and 4.0L of water, stir evenly, slowly add 200ml of industrial sulfuric acid, heat up to 100°C within 30min, react for 4h, pH is 2, slowly add 40g of CaCO 3 , the pH at the end of the reaction is 4, and the manganese sulfate filtrate 1 is obtained by filtration;

[0043] (2) Add 2ml of hydrogen peroxide to filtrate 1, control the temperature at 50°C, oxidize and hydrolyze for 2 hours, stand and filter to obtain filtrate 2;

[0044] (3) Weigh 5g of BaS, dissolve in 50ml of distilled water, boil and filter to obtain BaS hydrolysis filtrate, add this BaS hydrolysis filtrate to filtrate 2, control the temperature at 50°C, stir for 2 hours, and obtain filtrate 3 by filtration;

[0045] (4) Add 8ml o...

Embodiment 2

[0051] The preparation method of battery grade high-purity manganese sulfate monohydrate of the present invention comprises the following steps, and its process flow chart is as follows figure 1 shown.

[0052] (1) Weigh 640g of pyrolusite containing 25% manganese, 160g of pyrite, and 4.5L of water, stir evenly, slowly add 220ml of industrial sulfuric acid, heat up to 90°C within 35min, react for 6h, pH is 2.5, slowly add 50g of CaCO 3 , the pH at the end of the reaction is 4.5, and the manganese sulfate filtrate 1 is obtained by filtration;

[0053] (2) Add 6ml of hydrogen peroxide to the filtrate 1, control the temperature at 60°C, oxidize and hydrolyze for 2 hours, stand and filter to obtain the filtrate 2;

[0054] (3) Weigh 4g of BaS, dissolve in 60ml of distilled water, boil and filter to obtain the BaS hydrolysis filtrate, add the BaS hydrolysis filtrate to the filtrate 2 at a temperature of 45°C, stir for 1 hour, and filter to obtain the filtrate 3;

[0055] (4) Add ...

Embodiment 3

[0061] The preparation method of battery grade high-purity manganese sulfate monohydrate of the present invention comprises the following steps, and its process flow chart is as follows figure 1 shown.

[0062] (1) Weigh 1000g of pyrolusite containing 18% manganese, 200g of pyrolusite, and 4.5L of water, stir evenly, slowly add 280ml of industrial sulfuric acid, heat up to 95°C within 30min, react for 5h, pH is 2.2, slowly add 80g of CaCO 3 , the pH at the end of the reaction is 4, and the manganese sulfate filtrate 1 is obtained by filtration;

[0063] (2) Add 10ml of hydrogen peroxide to filtrate 1, control the temperature at 70°C, oxidize and hydrolyze for 1 hour, stand and filter to obtain filtrate 2;

[0064] (3) Weigh 5g of BaS, dissolve it in 60ml of distilled water, boil and filter to obtain the BaS hydrolysis filtrate, add the BaS hydrolysis filtrate to the filtrate 2, control the temperature at 30°C, stir for 1.5h, and filter to obtain the filtrate 3;

[0065] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com