Method for removing nitrate nitrogen in water body

A technology of nitrate nitrogen and water body, applied in the field of environmental chemistry, can solve the problem of removing nitrate nitrogen, which has not been reported, and achieves the effects of protecting excellent characteristics, rapidly removing, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method for removing nitrate nitrogen in the water body in this embodiment is:

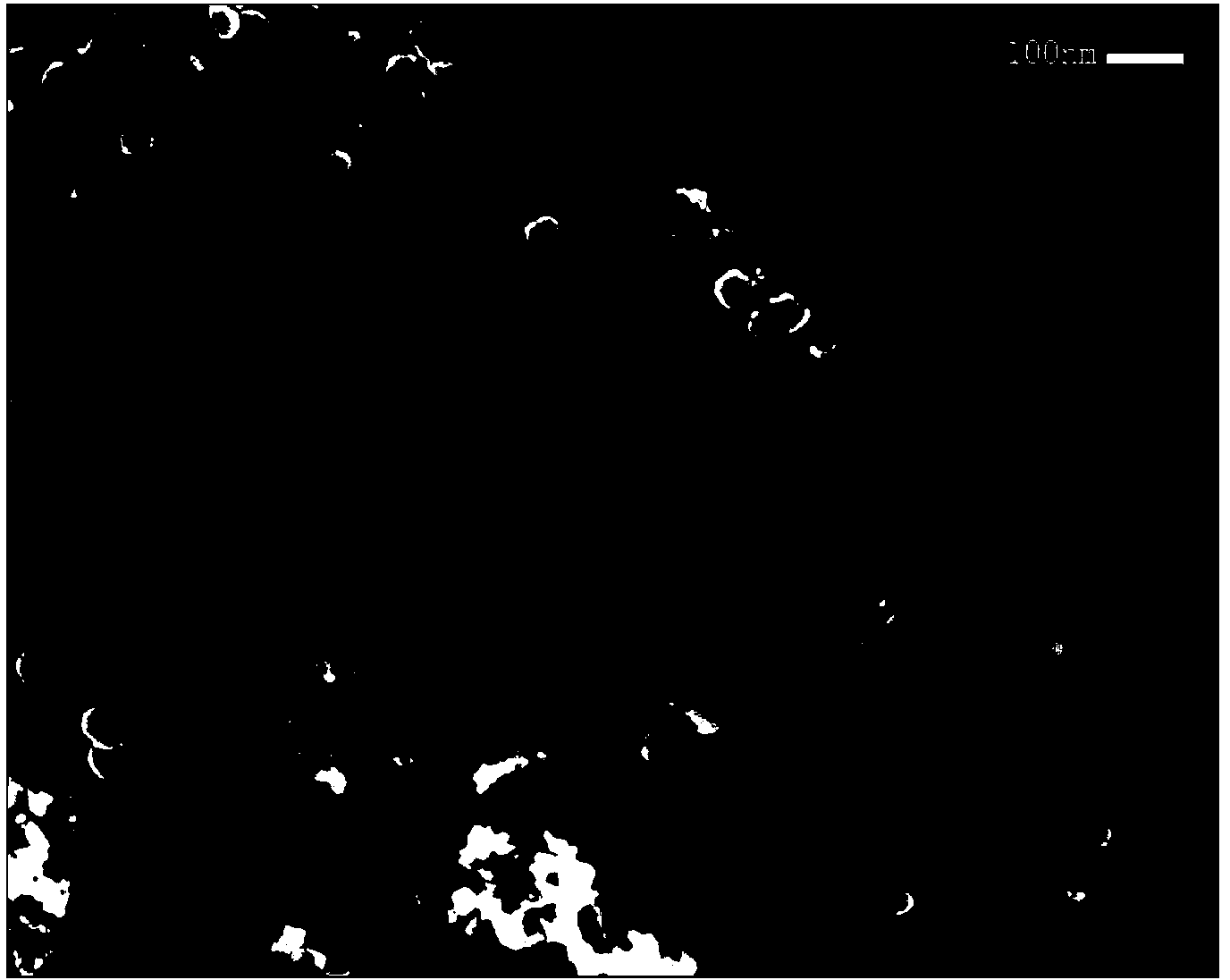

[0028] Step 1. Preparation of graphene-loaded nano-iron: Under the protection of nitrogen atmosphere, 0.75g of ferrous sulfate heptahydrate and 0.015g of polyethylene glycol-4000 were completely dissolved in 100mL of deoxygenated distilled water, and then 0.75g of graphene was added and mixed evenly Obtain the suspension, then slowly add 20mL of potassium borohydride solution with a concentration of 1.0mol / L dropwise to the suspension under the condition of nitrogen protection and a stirring rate of 200r / min, and control the rate of addition of the potassium borohydride solution After the dropwise addition, continue to stir at a stirring rate of 120r / min for 20min, then filter under the protection of a nitrogen atmosphere, wash three times with deoxygenated distilled water, and then wash three times with absolute ethanol to obtain graphene-loaded nano Iron, stored in a desiccator protect...

Embodiment 2

[0033] Step 1. Preparation of graphene-loaded nano-iron: Under the protection of nitrogen atmosphere, 0.75g of ferrous sulfate heptahydrate and 0.015g of polyethylene glycol-4000 were completely dissolved in 100mL of deoxygenated distilled water, and then 0.375g of graphene was added and mixed evenly Obtain the suspension, then slowly add 20mL of potassium borohydride solution with a concentration of 1.0mol / L dropwise to the suspension under the condition of nitrogen protection and a stirring rate of 240r / min, and control the rate of addition of the potassium borohydride solution 1.2mL / min, continue stirring with 240r / min for 20min after the dropwise addition, then filter, wash three times with deoxygenated distilled water, and then wash three times with absolute ethanol to obtain graphene-loaded nano-iron, which is stored in nitrogen In a protected desiccator; the mass ratio of graphene and nano-iron in the graphene-loaded nano-iron is 2.5:1;

[0034] Step 2. Use graphene-loa...

Embodiment 3

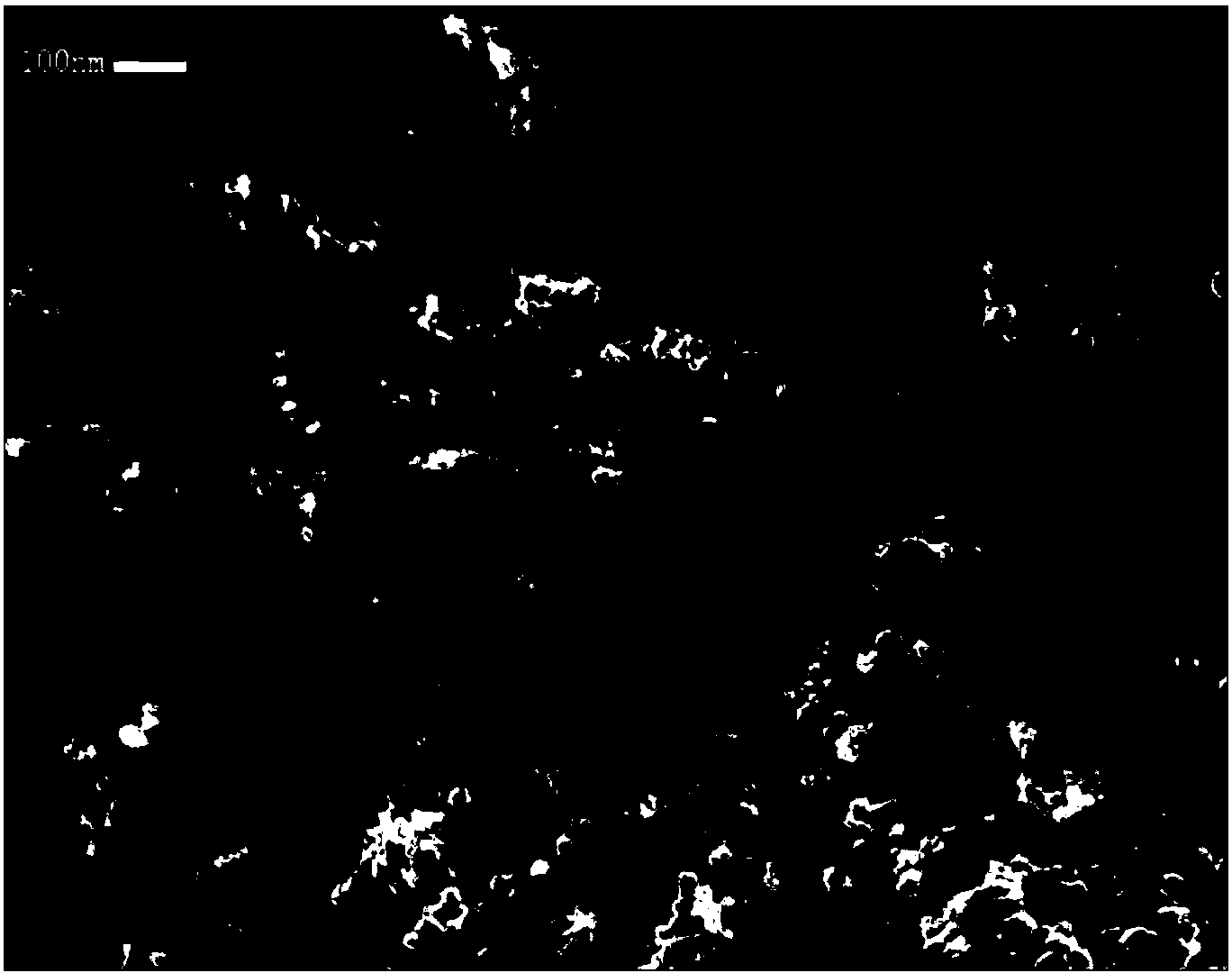

[0037] Step 1. Preparation of graphene-loaded nano-iron: Under the protection of nitrogen atmosphere, 0.75g of ferrous sulfate heptahydrate and 0.015g of polyethylene glycol-4000 were completely dissolved in 100mL of deoxygenated distilled water, and then 1.125g of graphene was added and mixed evenly Obtain the suspension, then slowly add 20mL of potassium borohydride solution with a concentration of 1.0mol / L dropwise to the suspension under the condition of nitrogen protection and a stirring rate of 200r / min, and control the rate of addition of the potassium borohydride solution 1.0mL / min, continue to stir at a stirring rate of 120r / min for 20min after the dropwise addition, then filter, wash three times with deoxygenated distilled water, and then wash three times with absolute ethanol to obtain graphene-loaded nano-iron, which is stored in a nitrogen In a protected desiccator; the mass ratio of graphene and nano-iron in the graphene-loaded nano-iron is 7.5:1;

[0038] Step 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com