Patents

Literature

35results about How to "Increase the rate of the reduction reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

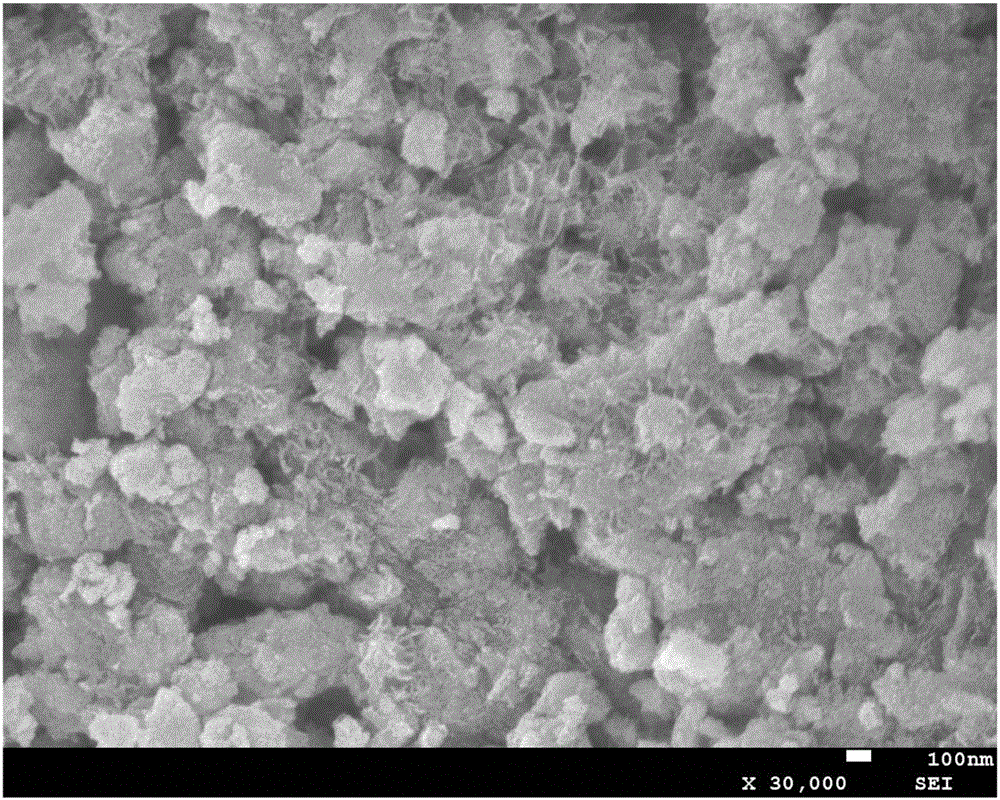

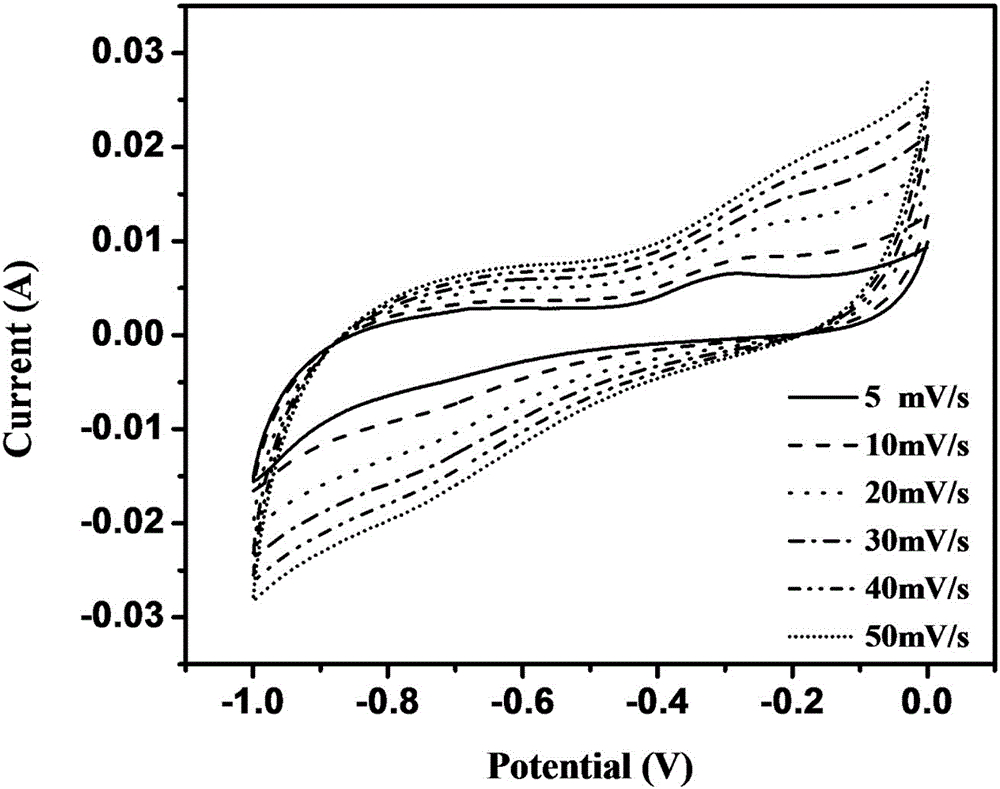

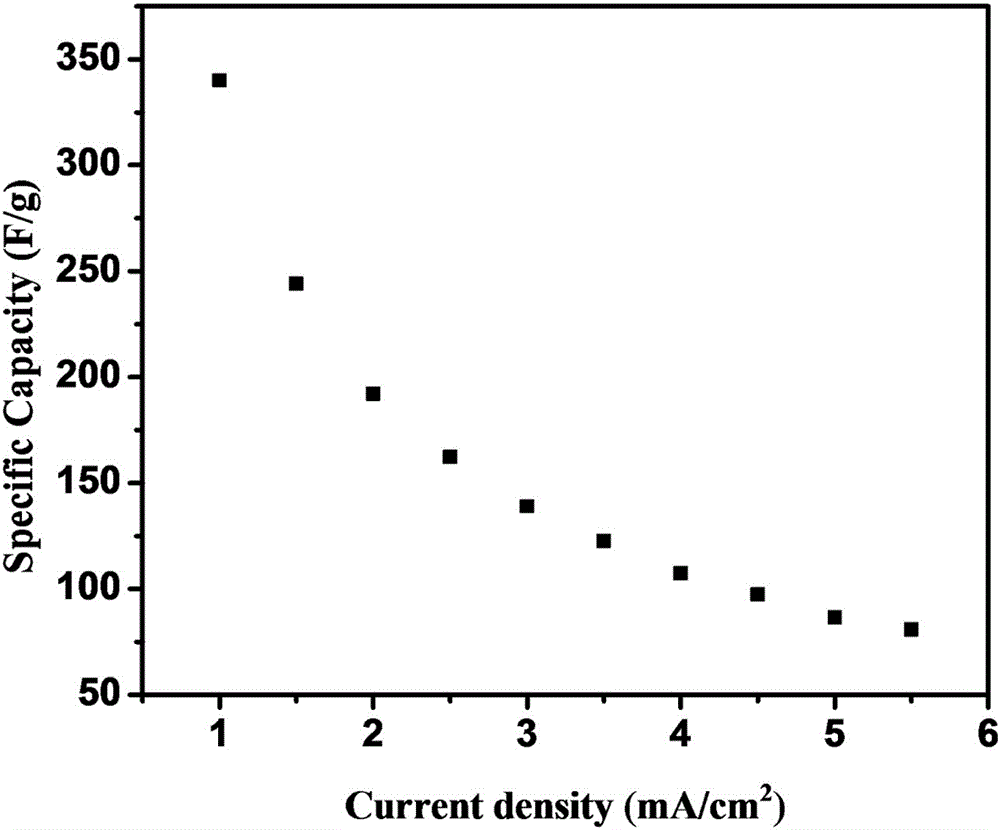

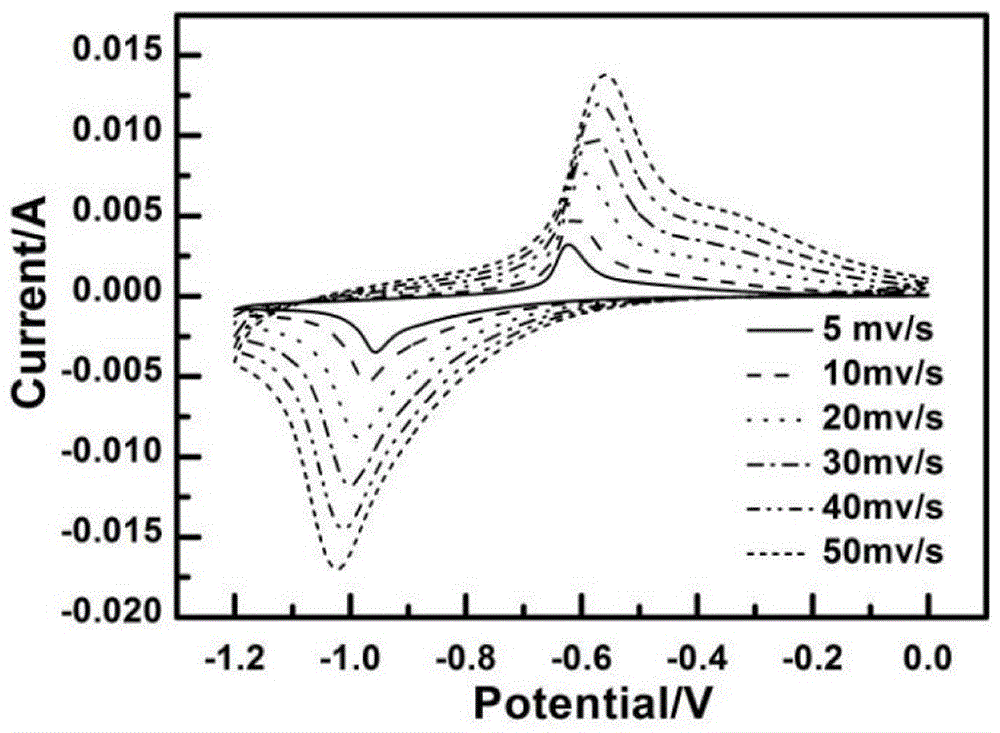

Vulcanized modification method for Ni-Fe LDH electrode material

InactiveCN106601500AIncrease capacityEasy transferHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceVulcanization

The invention discloses a vulcanized modification method for a Ni-Fe LDH electrode material. Urea is used as a precipitant and ferrous chloride is used as an iron source. Ni-Fe LDH grows on a nickel net substrate; and with a solvothermal method, vulcanization is carried out on the Ni-Fe LDH by using thiourea, sodium sulphide, or thioacetamide as a vulcanizing agent to obtain Ni-Fe LDH-S growing uniformly on the surface of the nickel net based on a cellular structure. Electrochemical performance evaluation is carried out on the Ni-Fe LDH-S in a 1M KOH electrolyte; and a potential window range is stabilized to be -1.1 to 0V. When constant-current charging and discharging are carried out in the potential window, the specific capacitance of the Ni-Fe LDH-S can reach 340 F / g, wherein the specific capacitance of the sample being Ni-Fe LDH without second-step vulcanization is only 45F / g. The result demonstrates that the specific capacity of the Ni-Fe LDH can be improved substantially.

Owner:CHINA THREE GORGES UNIV

Method for removing nitrate nitrogen in water body

InactiveCN103964550AHigh removal rateLarge specific surface areaWater/sewage treatment using germicide/oligodynamic-processPotassium borohydrideNitrate nitrogen

The invention provides a method for removing nitrate nitrogen in a water body, which comprises the following steps: 1, adding ferrous sulfate heptahydrate, polyethyleneglycol and graphene into deoxidized distilled water, mixing to prepare a suspension, then adding a potassium borohydride solution into the suspension, stirring, filtering, and washing to obtain graphene loaded nano iron; and 2, uniformly mixing the graphene loaded nano iron and a water body to be treated, and then performing constant-temperature oscillation treatment, thus ensuring that the removal rate of nitrate nitrogen in the water body is above 85%. According to the invention, the nitrate nitrogen in the water body is removed by using the graphene loaded nano iron, so that the method is simple in technical process, low in production cost and easy to realize popularization and application, maximally keeps the favorable characteristics of graphene and nano iron, and can efficiently and quickly remove the nitrate nitrogen in the water body, thereby obviously improving the nitrate nitrogen removal effect and having wide application value.

Owner:CHANGAN UNIV

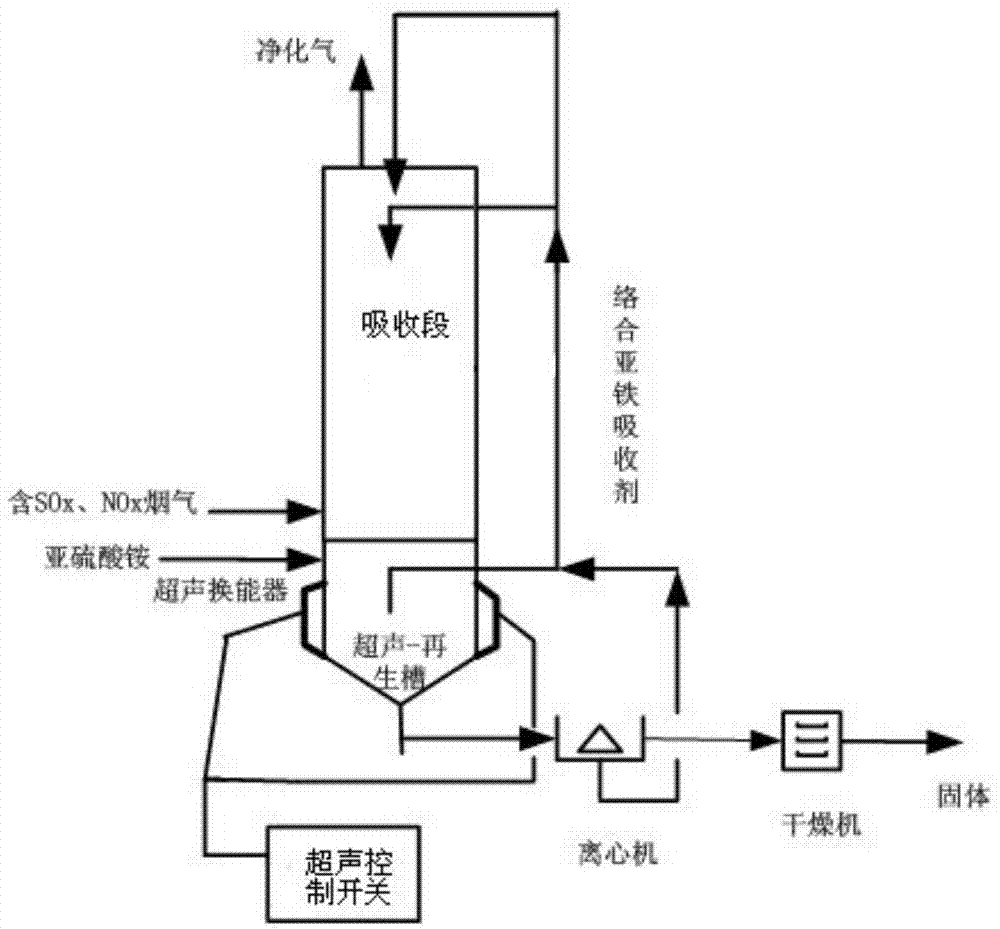

Integrated complex ferrous wet flue gas desulfurization and denitration method

ActiveCN103877831AIncrease contact areaImprove absorption efficiencyDispersed particle separationEthylene diamineReflux

The invention discloses an integrated complex ferrous wet flue gas desulfurization and denitration method which comprises the following steps: introducing flue gas into the bottom of an absorption section of an absorption device, and contacting the flue gas with a complex ferrous absorbent solution which is introduced into the absorption device and has the temperature of 30-60 DEG C on the absorption section in a reflux mode, wherein an ultrasonic regeneration tank is arranged at the bottom of the absorption device; and by taking complex ferrous as an absorbent, reducing the regenerated complex iron ions by adopting ultrasound-enhanced sulfite. Due to the addition of ammonium sulfite, Fe (III) EDTA (Ethylene Diamine Tetraacetic Acid) and Fe (II) EDTA (NO) can be reduced into Fe (II) EDTA, regeneration of the absorbent is promoted, byproducts subjected to desulfurization and denitration can be crystallized and recovered to serve as ammonium fertilizers, and resource utilization can be realized. The method is simple in process, high in absorption efficiency and complete in dust removal, the absorbent can be repeatedly utilized, the desulfurization rate is over 99 percent, and the denitration rate is over 97 percent.

Owner:JIANGHAN UNIVERSITY

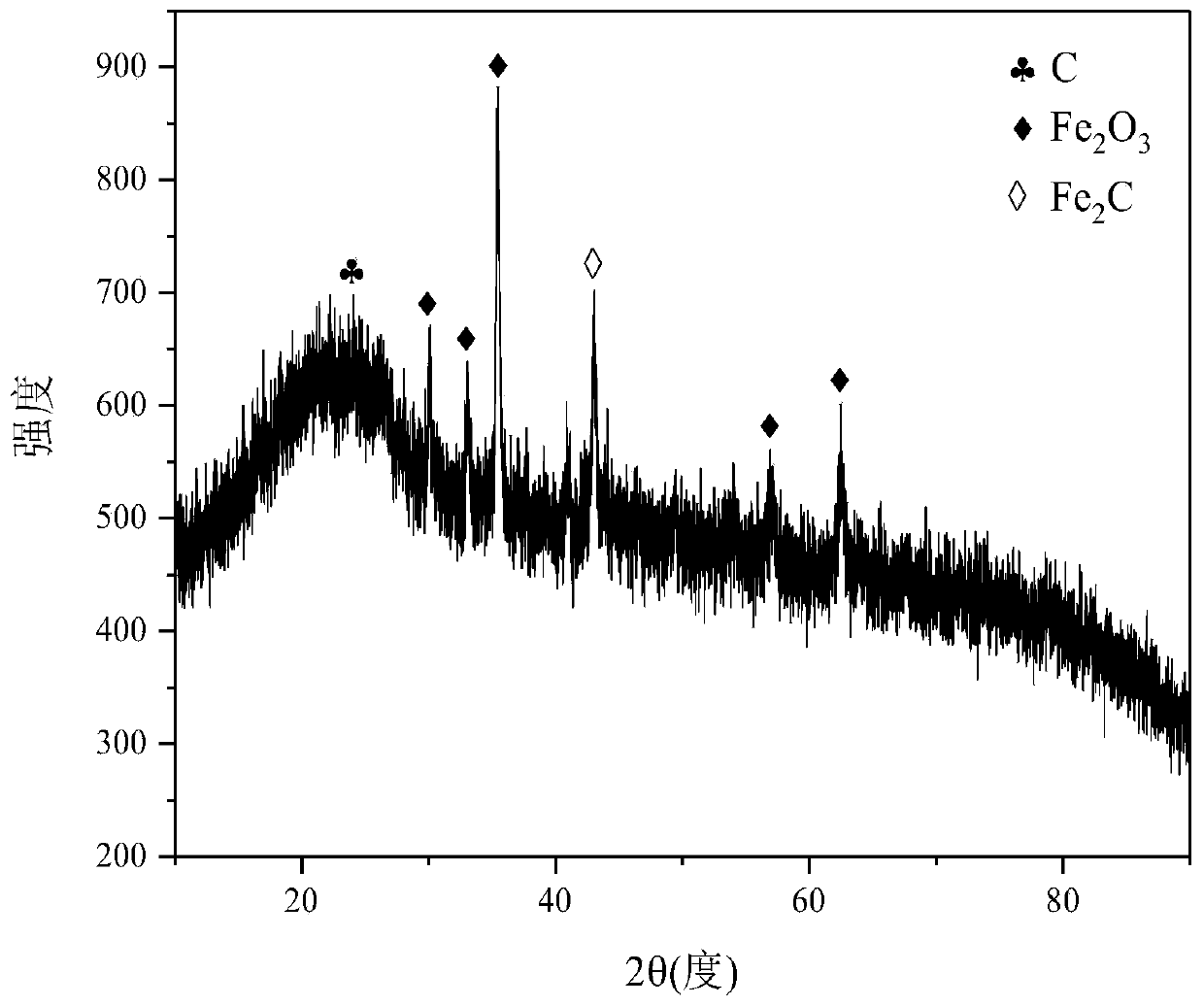

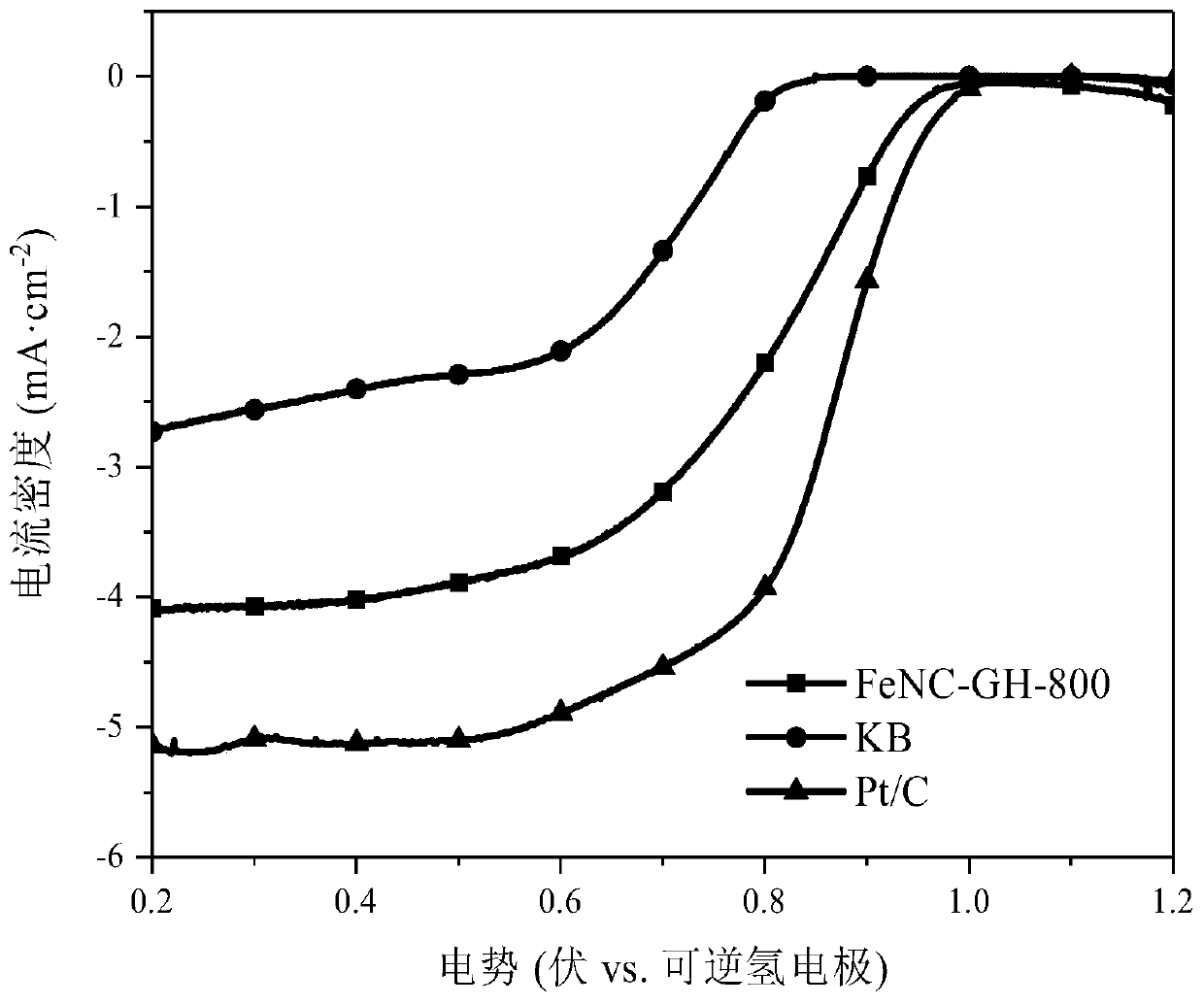

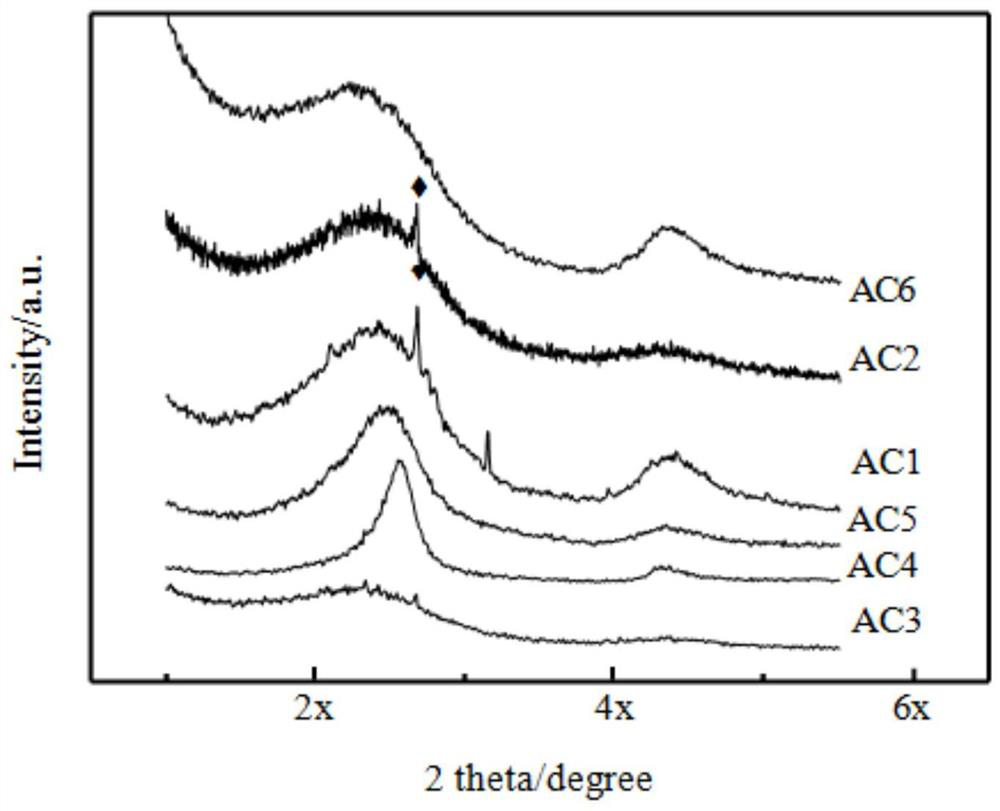

Iron and nitrogen co-doped carbon oxygen reduction catalyst and preparation method thereof

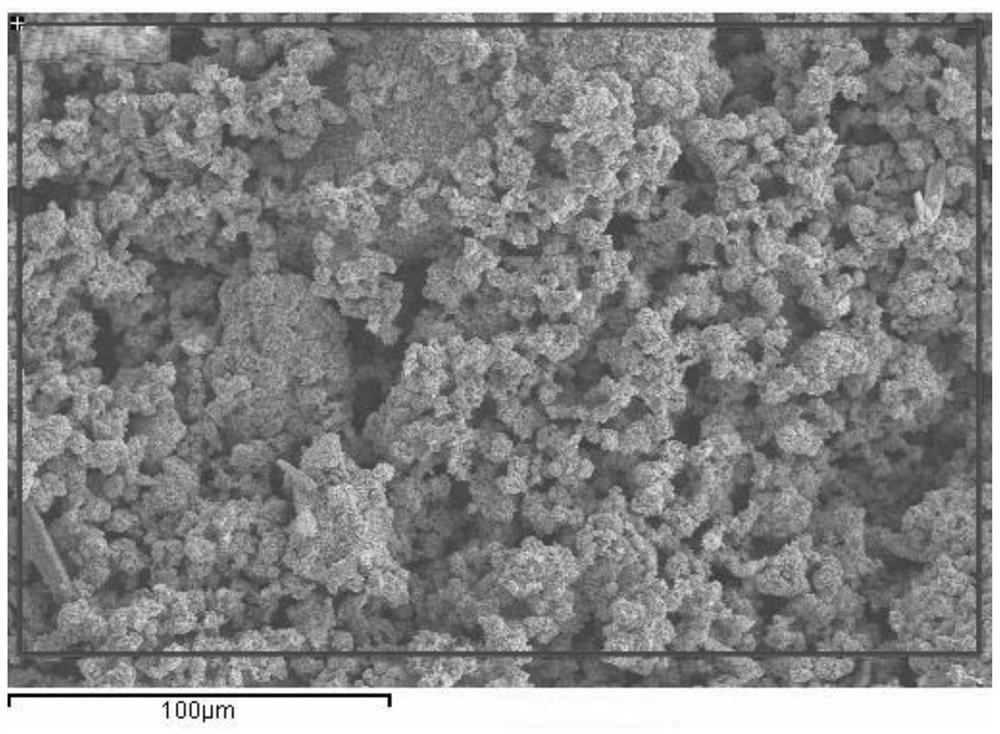

ActiveCN110534752AAperture adjustableShape is easy to controlCell electrodesUltrasonic dispersionOxidation reduction

The invention relates to an iron and nitrogen co-doped carbon oxygen reduction catalyst. The preparation method comprises steps: a carbon carrier is dissolved in an organic solvent, ultrasonic dispersion for being uniform is carried out, soluble iron salt is added under a stirring condition, and after uniform mixing, a mixed solution is obtained; the mixed solution is transferred to a reaction kettle, a reaction is carried out under the stirring condition, the reaction solution after the reaction is subjected to solid-liquid separation, washing and drying to obtain a solid material, the solidmaterial and a nitrogen source are mixed and grinded, and a pyrolysis precursor is obtained; and the pyrolysis precursor is roasted in an inert atmosphere to obtain the iron and nitrogen co-doped carbon oxygen reduction catalyst, wherein the carbon carrier is Ketjen black nano carbon black particles. Compared with the prior art, the method has the advantages of high oxidation reduction catalytic activity, good electrochemical stability, simple and controllable preparation method, short period, rich raw material reserves, low cost, capability of realizing large-scale production and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Chrome-molybdenum metal self reduction pellet and preparation and direct steel liquid alloying methods thereof

The invention relates to alloy steel smelting, and particularly relates to a chrome-molybdenum metal self reduction pellet and preparation and direct steel liquid alloying methods thereof. The pellet comprises the following components according to mass percentage: 40-65 percent of high-carbon ferrochrome powder, 15-40 percent of molybdic oxide powder, 5-15 percent of a reductant and 3-5 percent of a flux. The self reduction pellet product is added to a ladle during electric furnace or convertor tapping, under the action of high-temperature molten steel and a pellet inner reductant, metal elements in the pellet are effectively reduced, as a result, the molten steel is directly alloyed; the self reduction pellet product is applied in alloy steel including stainless steel, wear resistant steel and the like, which contain elements Cr and Mo, and not only is the procedure for the production of ferro molybdenum saved, but also the elements Cr and Mo can be added at one time, so that the cost of adding alloy elements is lowered, the smelting cycle is shortened, meanwhile, the use range of high-carbon ferrochrome is widened, and furthermore, the problem that the element Mo is difficult to add and settle and great in volatilization during the steel smelting is solved.

Owner:JIANGSU UNIV

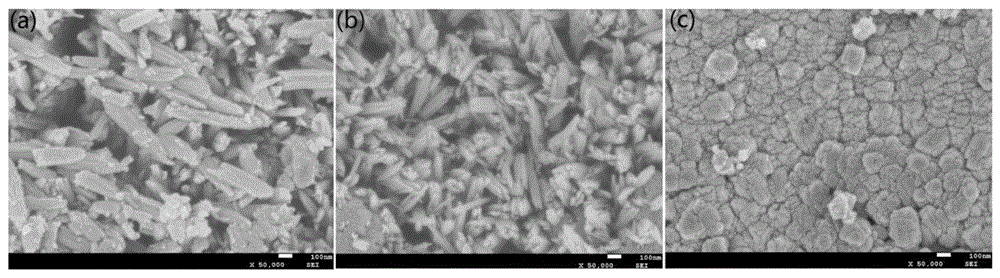

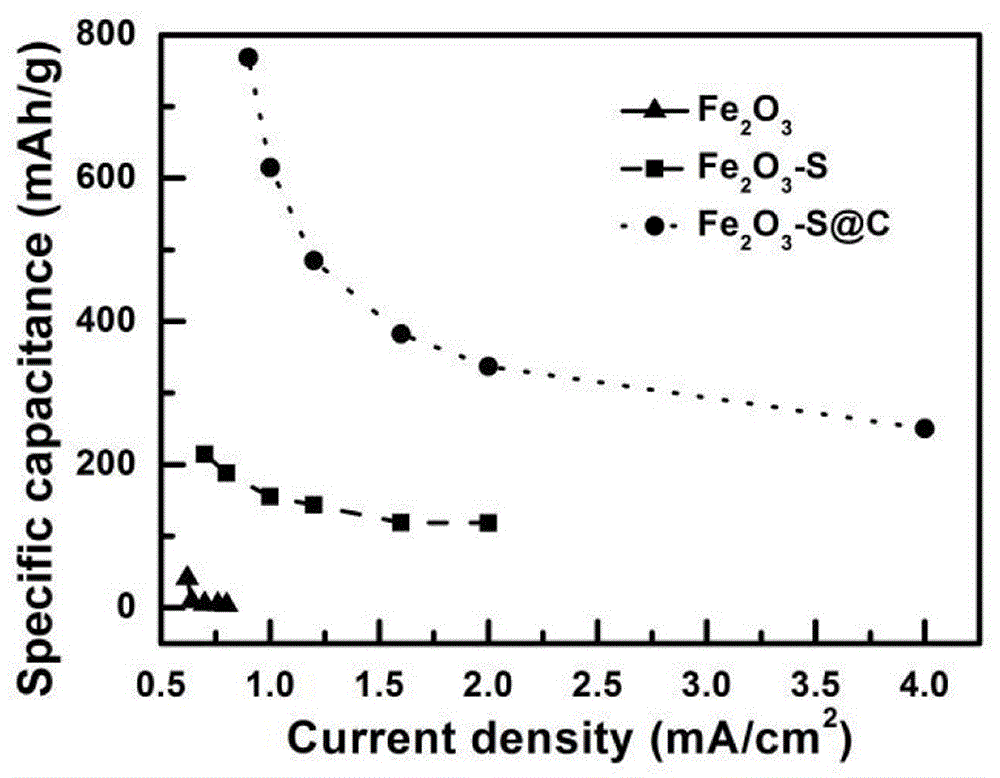

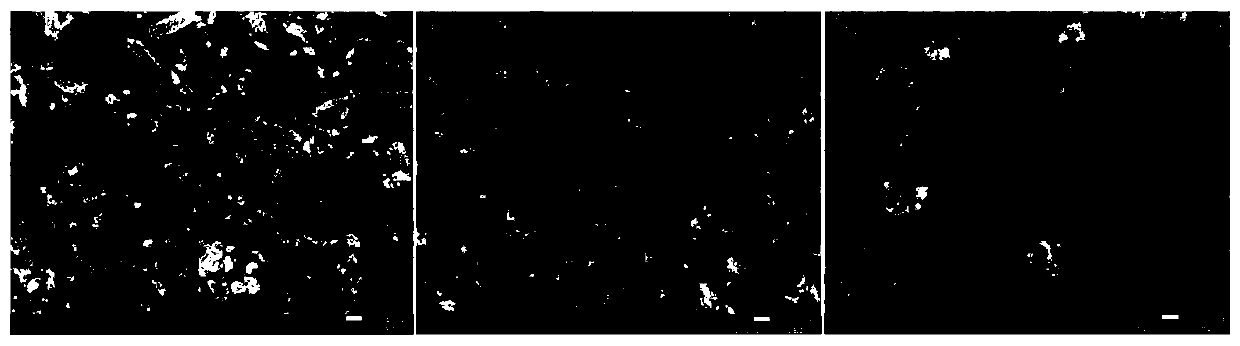

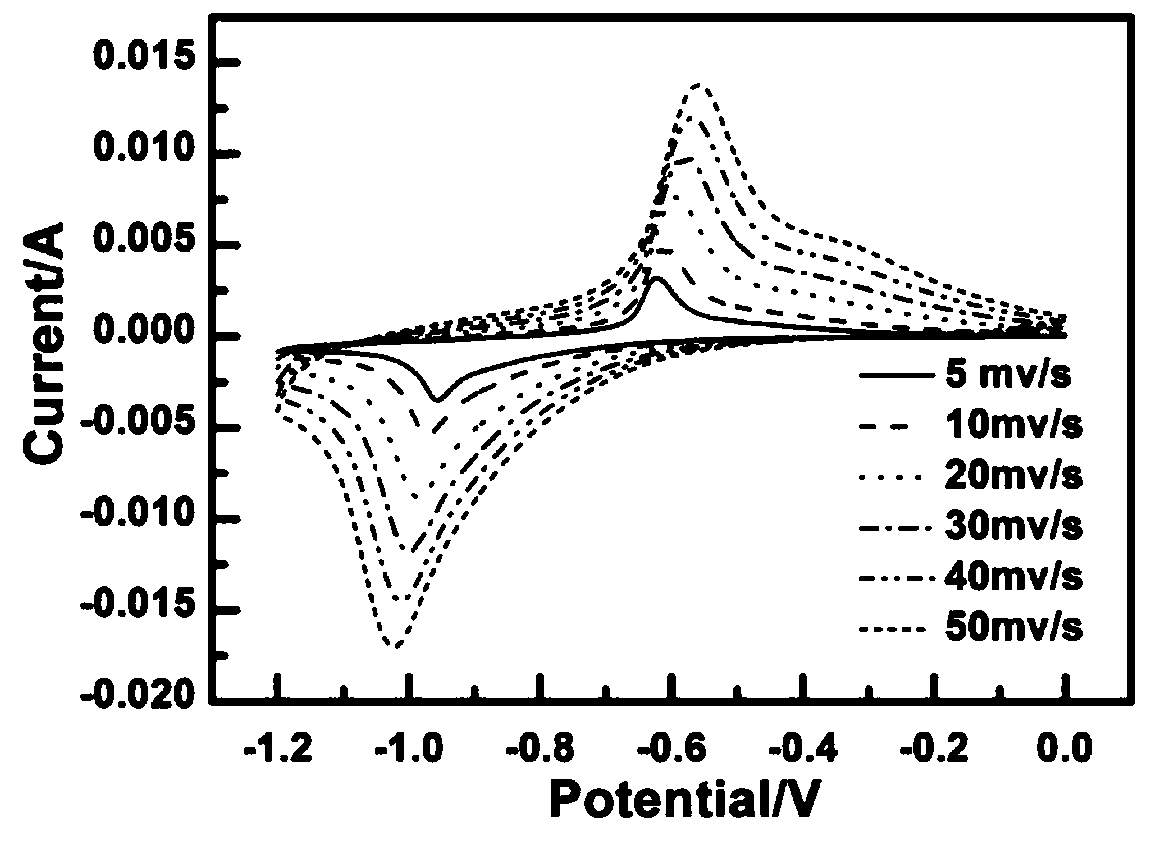

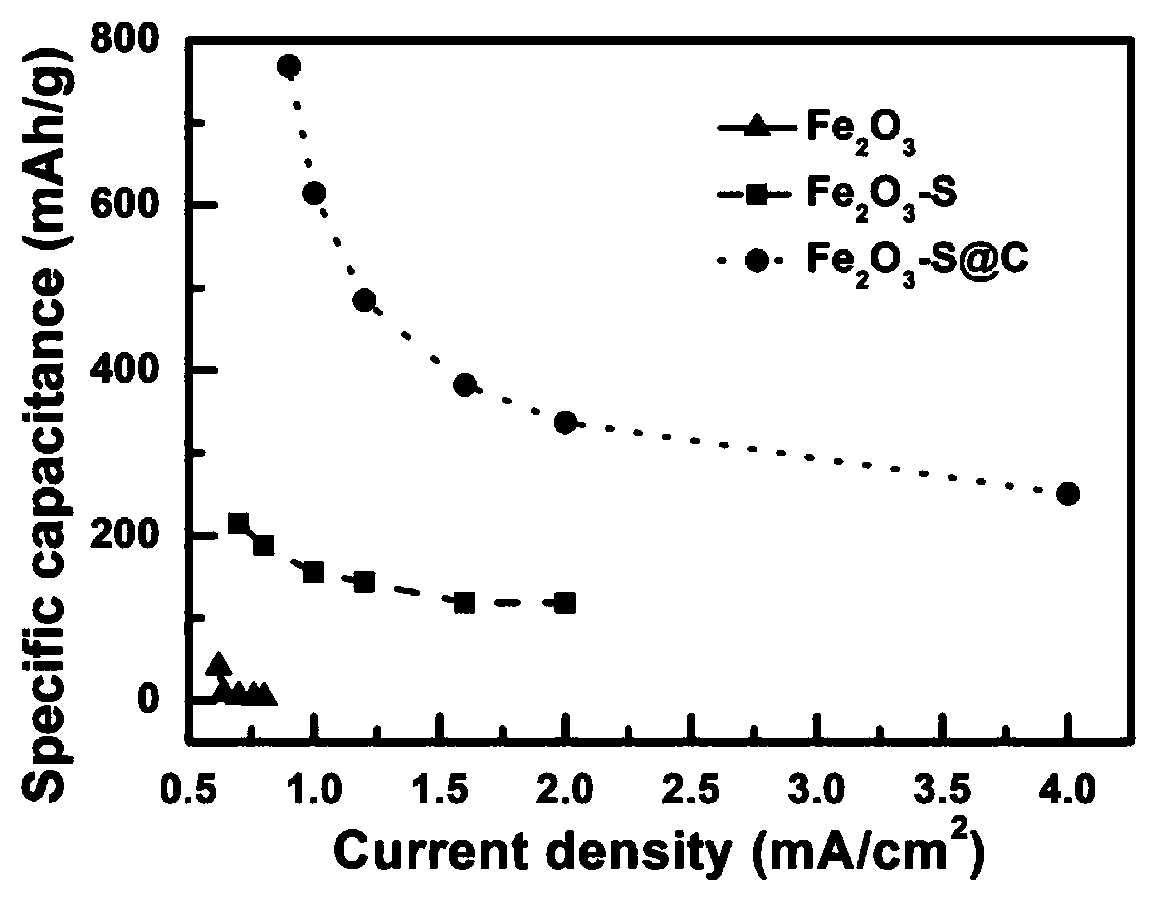

Method for preparing Fe2O3 nano-rod array electrodes by means of in-situ vulcanization and carbon coating and application of Fe2O3 nano-rod array electrodes

ActiveCN106848301AIncrease capacityImprove cycle stabilityAlkaline accumulatorsCell electrodesCarbon coatingVulcanization

The invention discloses a method for preparing Fe2O3 nano-rod array electrodes by means of in-situ vulcanization and carbon coating and application of the Fe2O3 nano-rod array electrodes. The method includes sintering titanium sheets, iron chloride and sodium sulfate by a hydrothermal synthesis process to obtain nano-rod-shaped Fe2O3 arrays; vulcanizing iron sesquioxide by the aid of thiourea or thioacetamide by solvothermal process to obtain Fe2O3-S; carrying out carbon coating on the Fe2O3-S by plasma-enhanced chemical vapor deposition process to obtain Fe2O3-S@C. The titanium sheets are used as a substrate, the iron chloride is used as an iron source, and the sodium sulfate is used as a precipitator. The thiourea or the thioacetamide is used as a vulcanizing agent. The method and the application have the advantages that the maximum capacity of original Fe2O3 electrodes in 1M KOH electrolyte is only 13.67 mAh / g, can be improved to reach 214.3 mAh / g after the Fe2O3 electrodes are vulcanized, and can reach 768.3 mAh / g after carbon coating optimization is carried out on the Fe2O3 electrodes; the capacity retention rate of the Fe2O3-S is only 7.95% after the Fe2O3-S is cycled by 100 times, and the capacity retention rate of the Fe2O3-S@C can reach 92.13%.

Owner:CHINA THREE GORGES UNIV

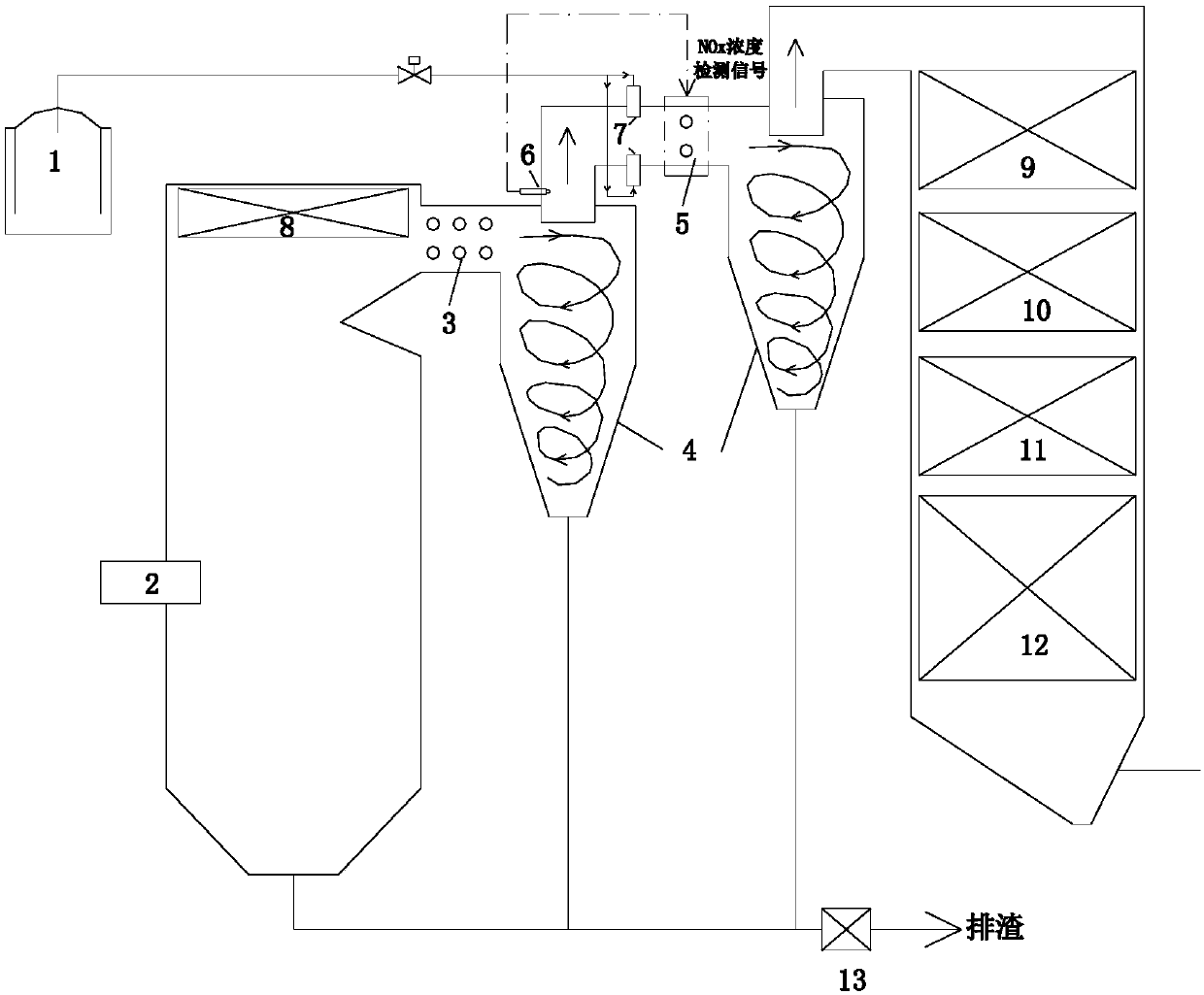

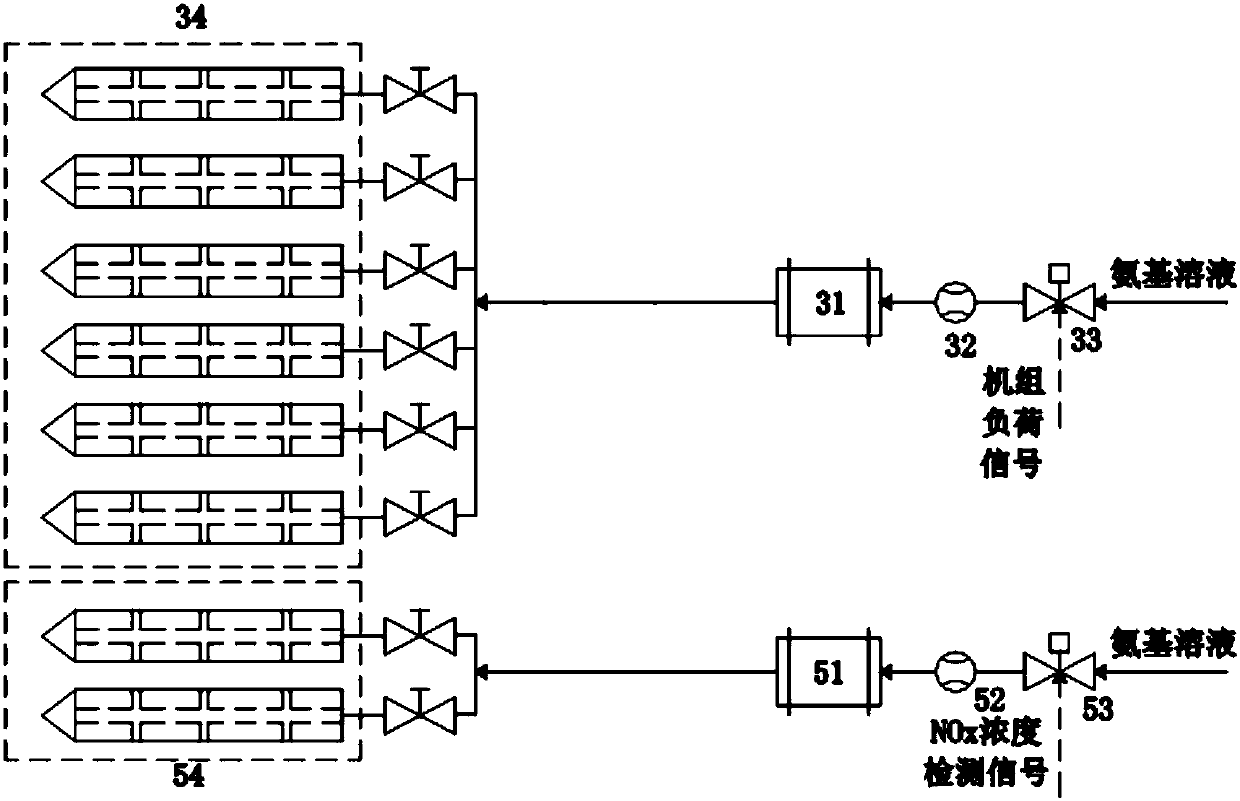

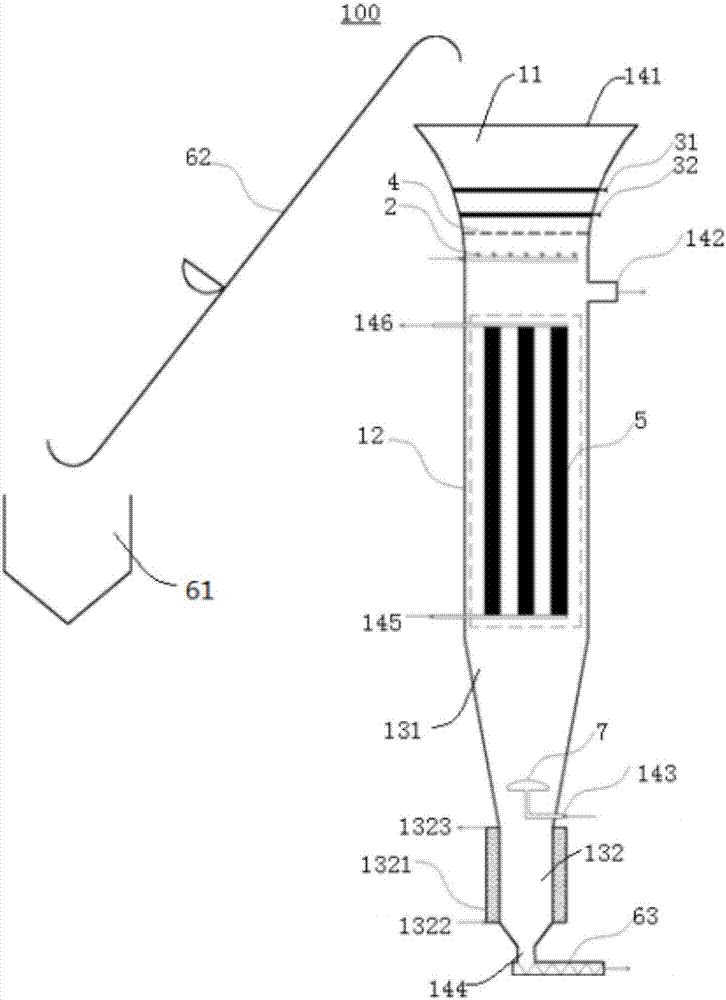

Two-stage selective non-catalytic reduction (SNCR) denitrification system and two-stage SNCR denitrification method

PendingCN107551783AEmission reductionReduce escapeDispersed particle separationIncinerator apparatusCycloneFlue gas

The invention provides a two-stage selective non-catalytic reduction (SNCR) denitrification system and a two-stage SNCR denitrification method. The system and the method can effectively prolong the residence time of a reductant in a furnace, enhance a mixing effect of the reductant and flue gas, and promote a reduction reaction to be rapidly carried out at a low-temperature section, thereby greatly improving the denitrification efficiency of SNCR and having considerable economic and environmental benefits. The system comprises a boiler; two stages of cyclone separators are arranged on a horizontal flue behind a furnace arch of the boiler in a way of series connection; a first stage SNCR denitrification reactor and a second stage SNCR denitrification reactor are respectively arranged in front of the two stages of cyclone separators; an outlet end of the later cyclone separator is connected with an exit flue; the first stage denitrification reactor is internally provided with a pluralityof main spray guns, and the main spray guns are evenly arranged on the cross section of the horizontal flue in multiple layers; the second stage denitrification reactor is internally provided with ammonia supplement spray guns, and the ammonia supplement spray guns are arranged along the cross section of the horizontal flue.

Owner:CHINA HUANENG GRP CO LTD +1

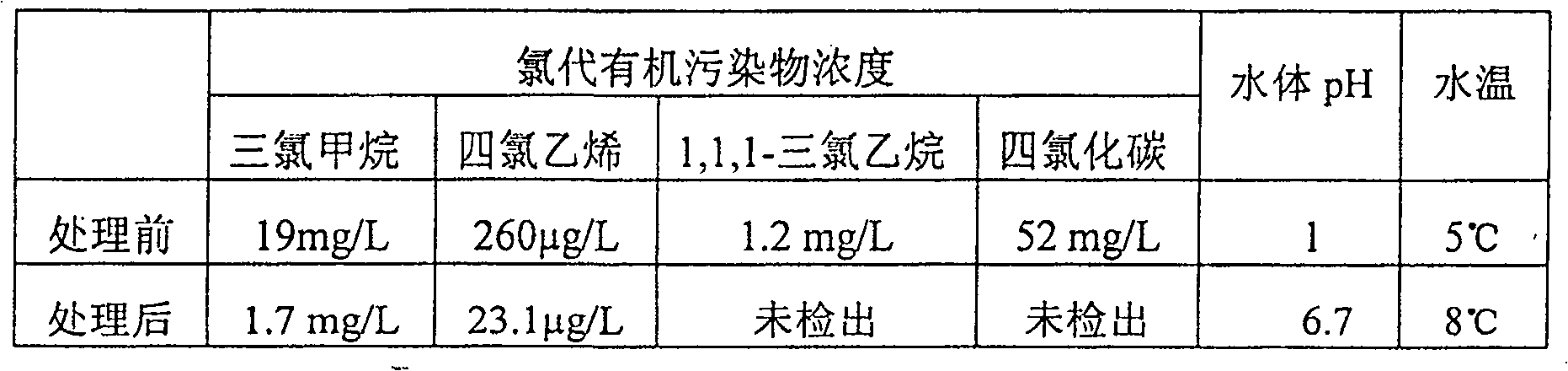

Method for reducing chlorine-containing organic substance in dechlorination treatment water by surface modified catalytic iron

InactiveCN101085690AImprove reducibilityIncrease reaction rateWater/sewage treatment by electrochemical methodsWater/sewage treatment by reductionCopper platingDissolution

The invention provides a method for treating chlorine- containing organic substance, relating to chlorine- removing from chlorine- containing organic substance in water technique. The surface of iron used for water treatment is catalyzed through chemical copper plating to increase the reduction effect of iron, then modifies the surface of plated copper by using surface active agent to change the hydrophilicity and lipophilicity of iron surface and increase the dissolution and adsorption of organic substance on the iron surface, and improve the transmission condition of organic substance to iron surface and the reaction speed. The invention is characterized by simple device, convenient management, low cost and low energy consumption.

Owner:TONGJI UNIV

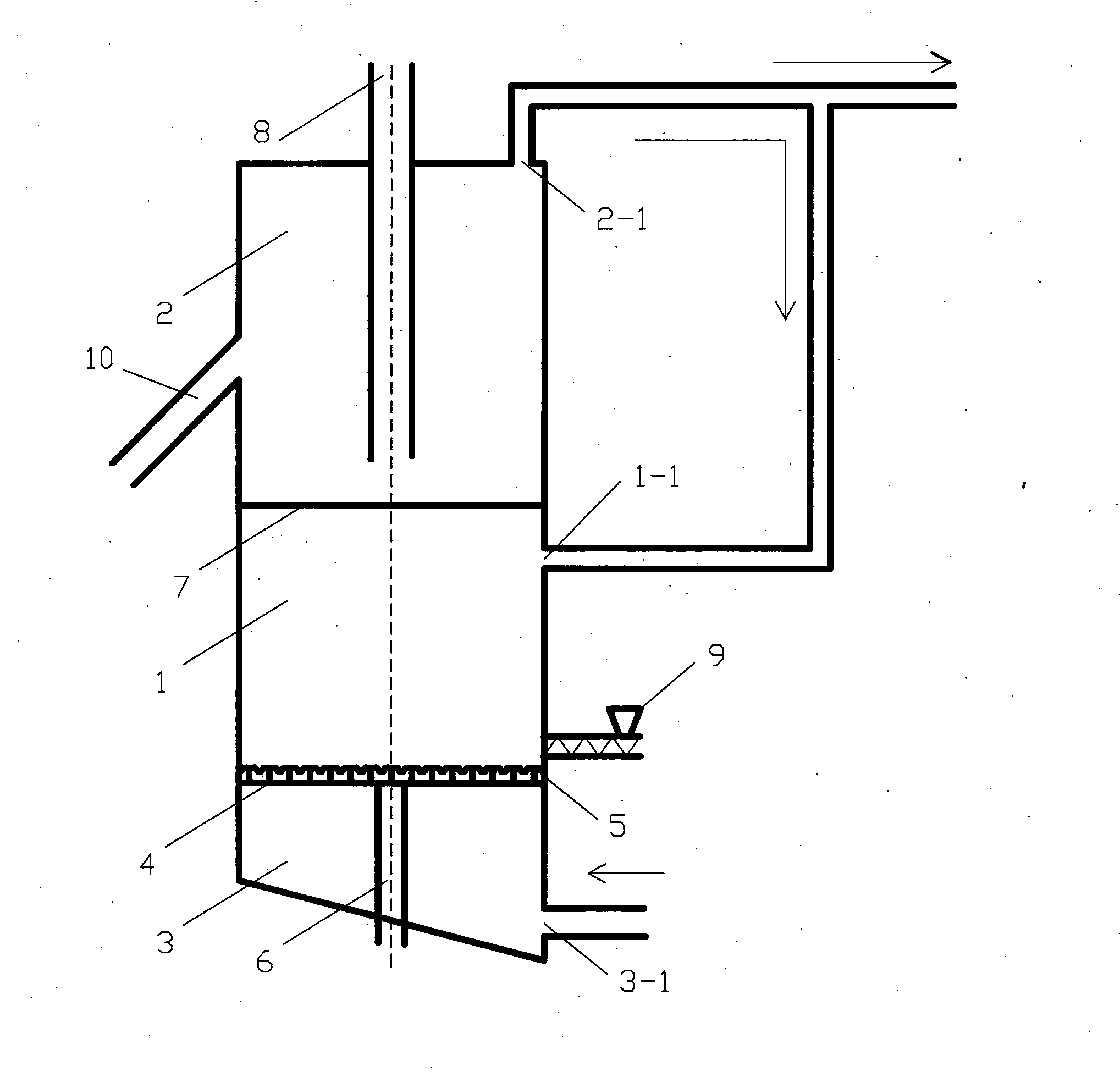

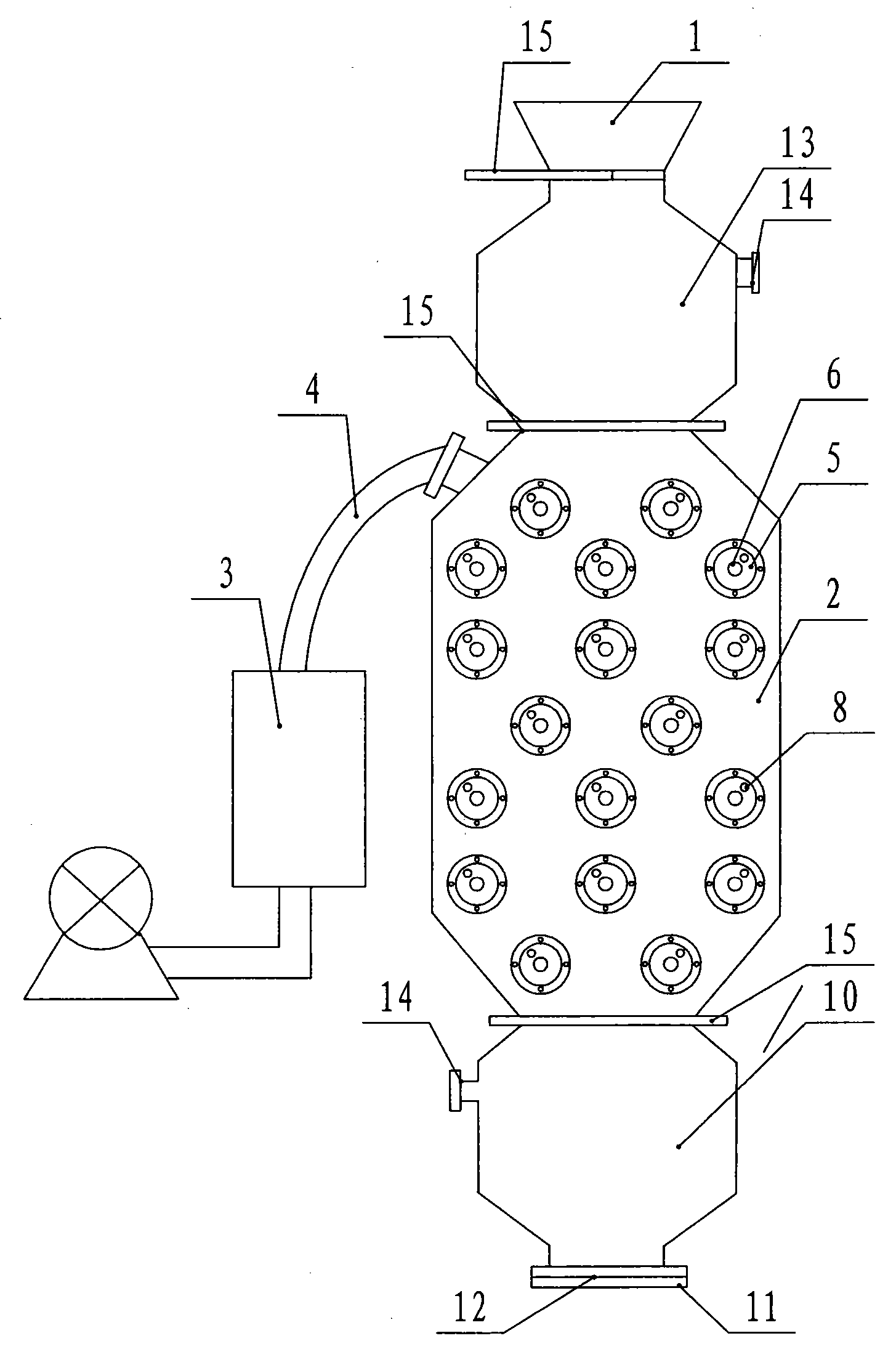

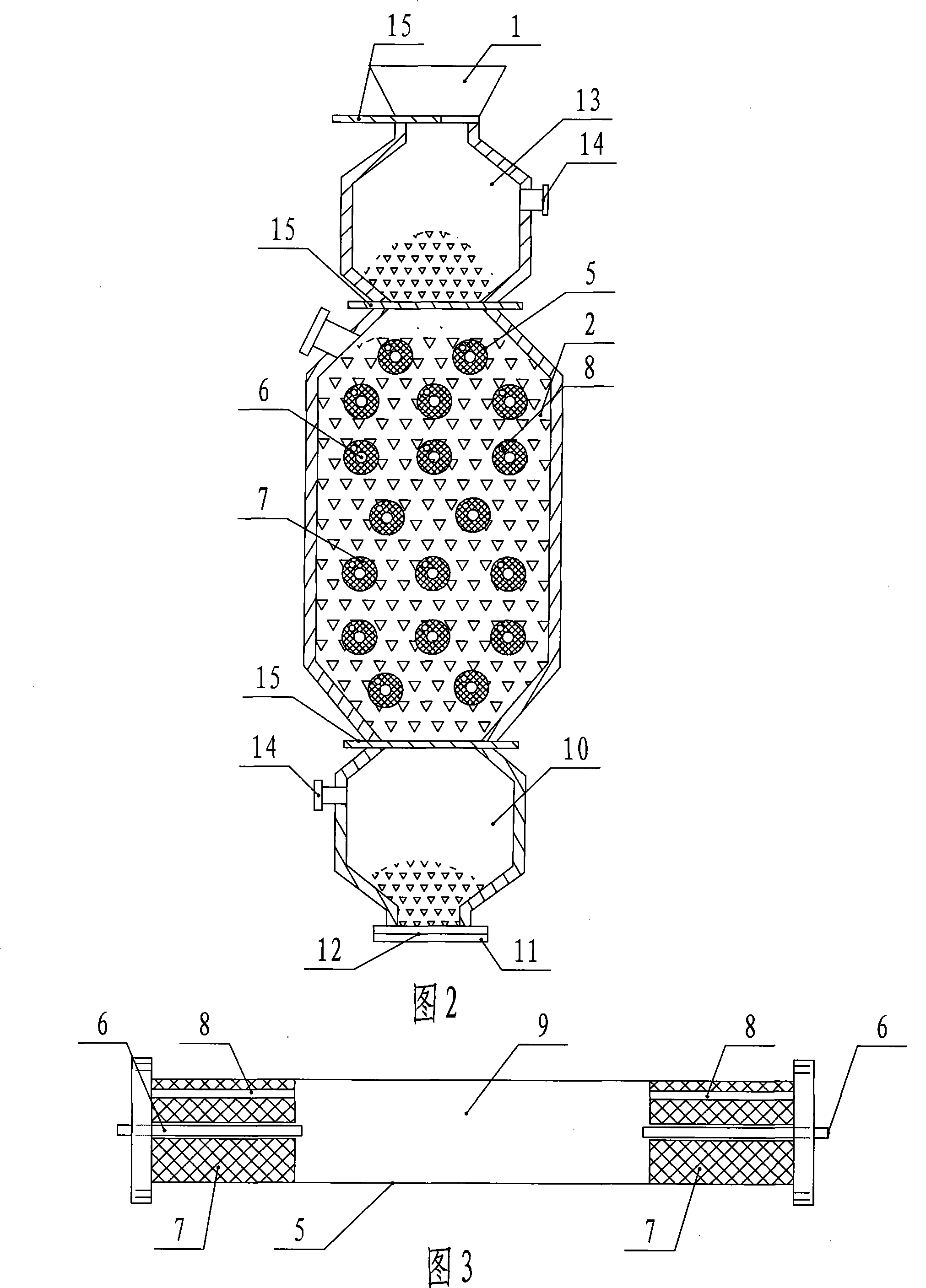

Two-stage fuel reactor structure and technological process

InactiveCN103756733AIncrease the rate of the reduction reactionAvoid carryingGranular/pulverulent flues gasificationReaction rateFlue gas

The invention provides a two-stage fuel reactor structure. The two-stage fuel reactor structure comprises a fuel reactor cavity, wherein a grid net divides the fuel reactor cavity into a lower gasification zone and an upper reduction zone; a tee joint is arranged in an exhaust pipeline of an upper end of the reduction zone; one way of the tee joint is led back to a gas inlet of the gasification zone; an air distribution plate is arranged in the gasification zone; a hood is arranged on the air distribution plate; an air chamber is arranged below the air distribution plate; a slagging pipe passes through the air chamber to be connected with the lower end of the gasification zone; a screw feeder is connected with the side wall surface of the gasification zone; a feed pipe and a discharge pipe are arranged at the upper end and on the side of the reduction zone respectively. The invention also provides a technological process of the two-stage fuel reactor structure. The device provided by the invention has the beneficial effects that the gasification and oxygen carrier reduction processes of solid fuel are separated, so that the reduction reaction rate of the oxygen carrier is effectively increased and is matched with oxidation reaction of the oxygen carrier; the solid fuel is not in contact with the oxygen carrier, thus preventing the oxygen carrier from carrying ashes, unburnt carbon and other impurities, and simultaneously increasing the concentration of CO2 in the flue gas.

Owner:SHANGHAI BOILER WORKS

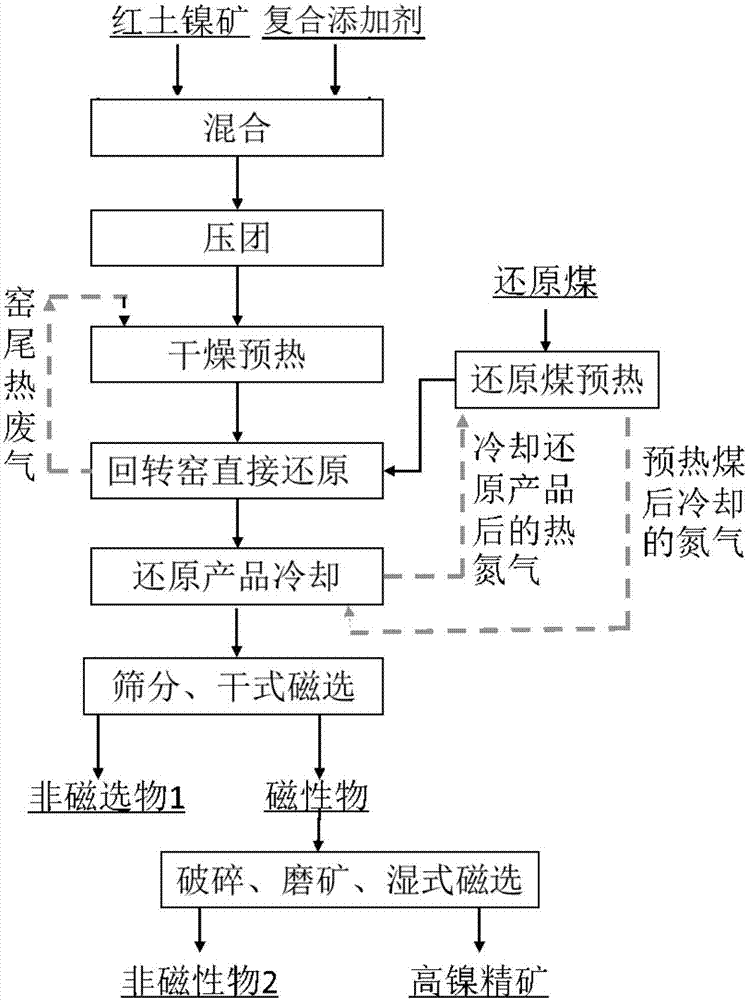

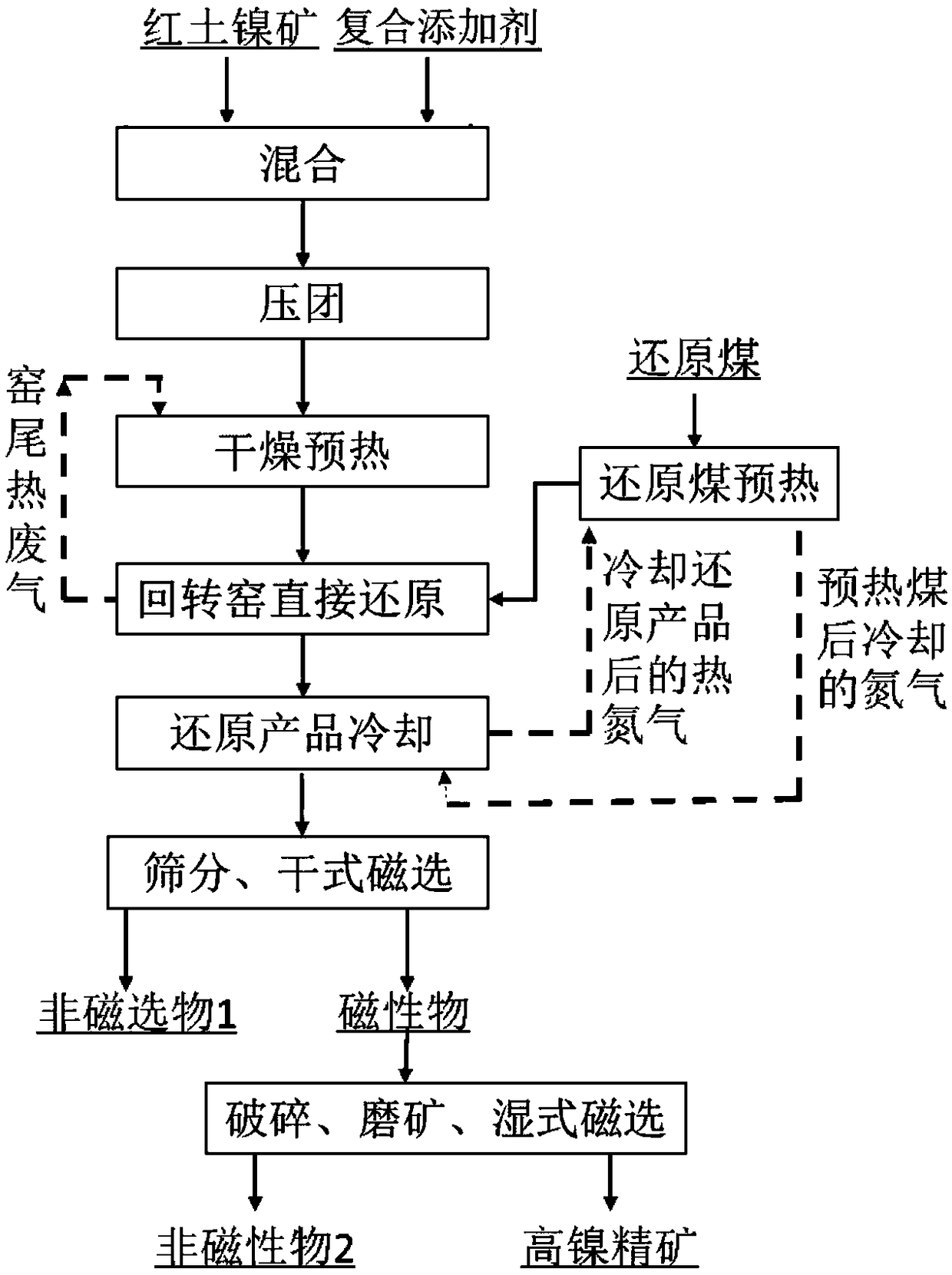

Rapid reduction process of rotary kiln for laterite nickel ore

The invention discloses a rapid reduction process of a rotary kiln for laterite nickel ore. The rapid reduction process of the rotary kiln for the laterite nickel ore includes the following steps that laterite nickel ore and a composite adding agent are mixed and then are pressed into block masses, and the composite adding agent comprises pulverized coal and limestone; the block masses are dried and pre-heated, and then enter the rotary kiln, reduction coal is added in, and reduction is performed under the reduction atmosphere so that reduced products can be obtained; the reduced products are cooled, screened and magnetically separated so that magnetic products can be obtained; and the magnetic products are crushed, subjected to ore grinding and magnetically separated, and high-nickel concentrate is obtained. According to the rapid reduction process of the rotary kiln for the laterite nickel ore, the low grade laterite nickel ore serves as raw materials, three manners that fuel is matched in the block masses, the block masses are preheated in a vertical furnace and coal is fed through hot air are developed to guarantee that the laterite nickel ore block masses are contained in the kiln while being hot, high temperature rapid reduction of the whole kiln is achieved, and therefore the rotary kiln temperature is lowered, the reduction time is shortened, and the high-nickel concentrate is effectively manufactured from the low grade laterite nickel ore.

Owner:CENT SOUTH UNIV

Chromium-molybdenum metal self-reducing pellets and method for preparing and directly alloying molten steel

The invention relates to alloy steel smelting, and particularly relates to a chrome-molybdenum metal self reduction pellet and preparation and direct steel liquid alloying methods thereof. The pellet comprises the following components according to mass percentage: 40-65 percent of high-carbon ferrochrome powder, 15-40 percent of molybdic oxide powder, 5-15 percent of a reductant and 3-5 percent of a flux. The self reduction pellet product is added to a ladle during electric furnace or convertor tapping, under the action of high-temperature molten steel and a pellet inner reductant, metal elements in the pellet are effectively reduced, as a result, the molten steel is directly alloyed; the self reduction pellet product is applied in alloy steel including stainless steel, wear resistant steel and the like, which contain elements Cr and Mo, and not only is the procedure for the production of ferro molybdenum saved, but also the elements Cr and Mo can be added at one time, so that the cost of adding alloy elements is lowered, the smelting cycle is shortened, meanwhile, the use range of high-carbon ferrochrome is widened, and furthermore, the problem that the element Mo is difficult to add and settle and great in volatilization during the steel smelting is solved.

Owner:JIANGSU UNIV

Preparation method and application of Fe2O3 nanorod array electrode in-situ vulcanization and carbon coating

ActiveCN106848301BIncrease capacityImprove cycle stabilityAlkaline accumulatorsCell electrodesElectrolytic agentCarbon coating

The invention discloses a method for preparing Fe2O3 nano-rod array electrodes by means of in-situ vulcanization and carbon coating and application of the Fe2O3 nano-rod array electrodes. The method includes sintering titanium sheets, iron chloride and sodium sulfate by a hydrothermal synthesis process to obtain nano-rod-shaped Fe2O3 arrays; vulcanizing iron sesquioxide by the aid of thiourea or thioacetamide by solvothermal process to obtain Fe2O3-S; carrying out carbon coating on the Fe2O3-S by plasma-enhanced chemical vapor deposition process to obtain Fe2O3-S@C. The titanium sheets are used as a substrate, the iron chloride is used as an iron source, and the sodium sulfate is used as a precipitator. The thiourea or the thioacetamide is used as a vulcanizing agent. The method and the application have the advantages that the maximum capacity of original Fe2O3 electrodes in 1M KOH electrolyte is only 13.67 mAh / g, can be improved to reach 214.3 mAh / g after the Fe2O3 electrodes are vulcanized, and can reach 768.3 mAh / g after carbon coating optimization is carried out on the Fe2O3 electrodes; the capacity retention rate of the Fe2O3-S is only 7.95% after the Fe2O3-S is cycled by 100 times, and the capacity retention rate of the Fe2O3-S@C can reach 92.13%.

Owner:CHINA THREE GORGES UNIV

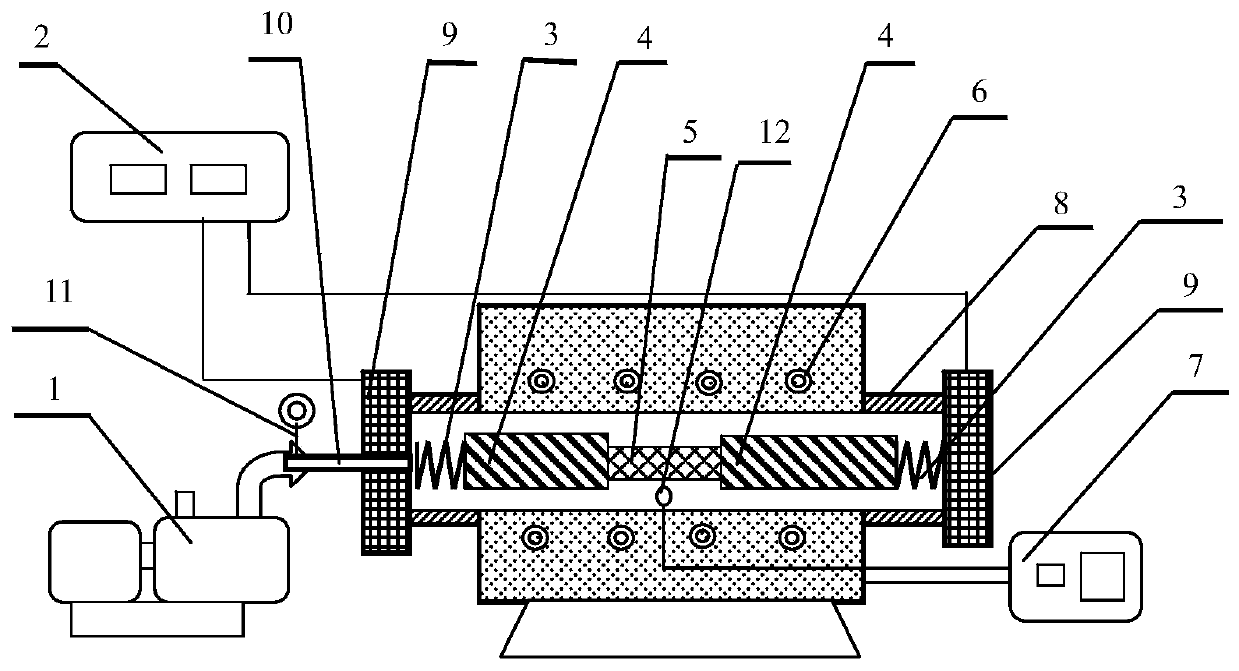

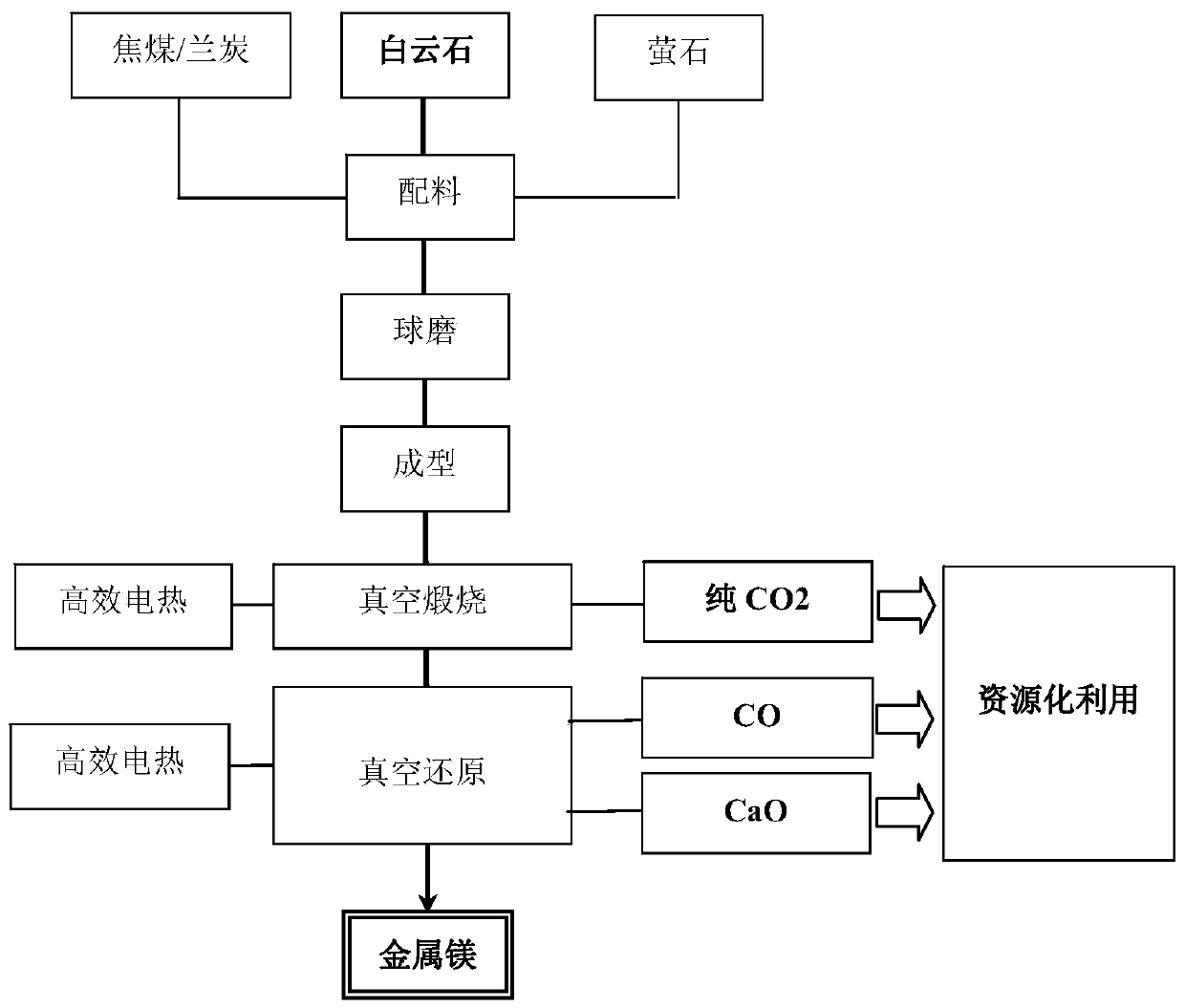

Metal magnesium carbon thermal reduction process and device

The invention discloses a metal magnesium carbon thermal reduction process and device. The process comprises the following steps that a magnesium-containing raw material, a carbon-containing reducingagent and a catalyst are used as raw materials, the raw materials are subjected to uniform mixing and forming, under certain temperature and vacuum degree conditions, current is directly conducted atthe two ends of a formed sample, and the current is controlled to carry out power-on reduction reaction, and the cooling is carried out to obtain the metal magnesium after the reaction is finished. The device comprises a reactor, a positive electrode, a negative electrode, a position buffer and a sealing cover, wherein the reactor is used for performing a metal magnesium reduction reaction, the positive electrode and the negative electrode are used for directly applying current to the reaction raw material formed parts, the position buffer is used for regulating the positive and negative electrodes, and the sealing cover is used for sealing the reactor. The process and device overcome the series of problems such as high reduction temperature, long reduction time, reversible reaction and the like of an existing carbon thermal method metal magnesium, the temperature of the reduction device can be greatly reduced, the metal magnesium can be initially reduced at room temperature, the reduction speed of the metal magnesium is greatly improved, and the process is green and environmentally friendly.

Owner:CHANGAN UNIV

Method for removing chromium and nickel in acid washing waste liquor

InactiveCN107416959AIncrease contact areaIncrease reduction and adsorption capacityIron oxides/hydroxidesWater contaminantsChemistryHeavy metals

The invention relates to a method for removing chromium and nickel in acid washing waste liquor. The method is implemented as follows: a removal process is specifically divided into the following two steps: adding a proper amount of iron powder into the acid washing waste liquor, performing reaction for a period of time at proper temperature and stirring speed, filtering and separating the acid washing waste liquor and the iron powder, adding a proper amount of nano-iron into the acid washing waste liquor, performing reaction for a period of time at proper temperature and stirring speed, and filtering and separating the acid washing waste liquor and the nano-iron. The acid washing waste liquor from which heavy metals are removed is consistent with the national standard HG / T4200-2011 about a raw material ferrous chloride for polyferric chloride, and can be used for preparing an iron-based coagulant. The method provided by the invention is simple, fast, low in cost and energy consumption and environment-friendly, and has a good removal effect on chromium and nickel ions with a relatively high concentration, a broad application prospect and high industrial application value.

Owner:TONGJI UNIV

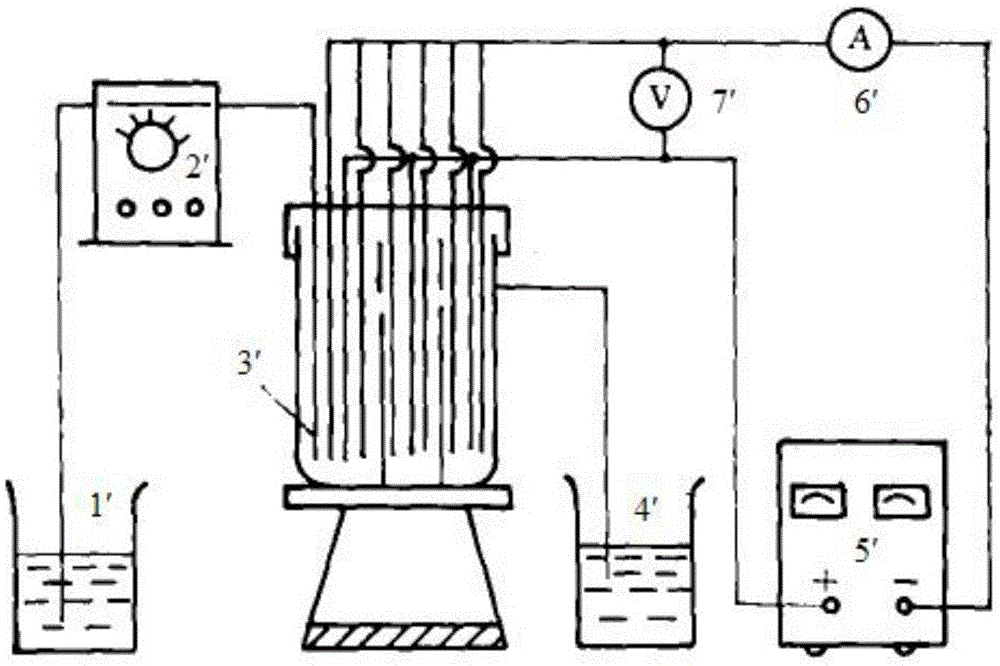

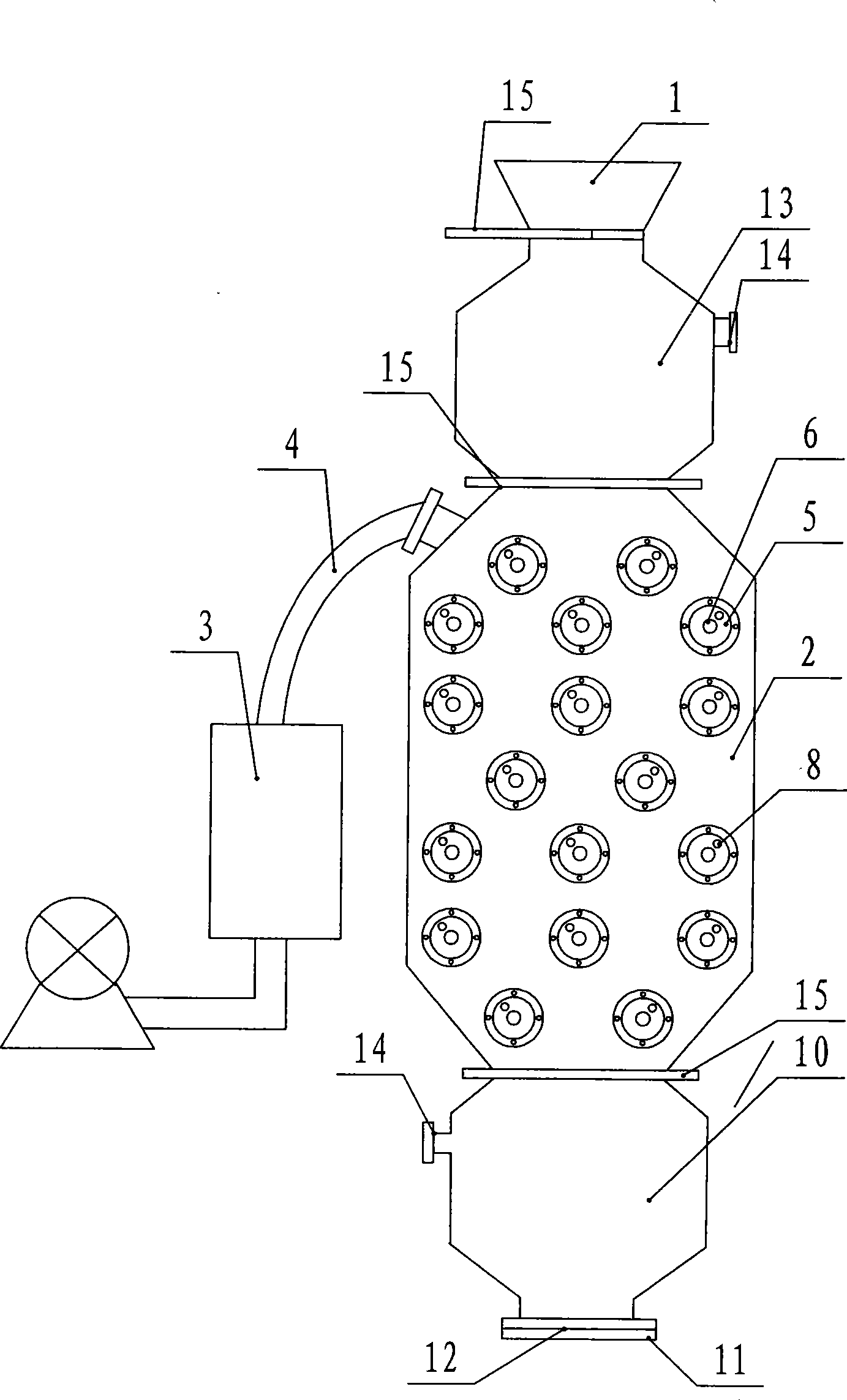

A device for preparing tetravalent uranium by electrolytic reduction

ActiveCN103695956BIncreased surface area ratioIncrease the rate of the reduction reactionCellsBarrel ShapedTitanium

The invention relates to an electrolytic device and provides a device for preparing tetravalent uranium by electrolytic reduction to solve the problems of low tetravalent uranium yield of an existing diaphragm-free electrolysis device and complicated equipment, high cost and the like of a diaphragm electrolysis device. The device comprises an electrolytic tank body with an insulated inner wall, an anodic platinized and titanized rod and a cathodic titanium net, wherein the cathodic titanium net is barrel-shaped, the anodic platinized and titanized rod is arranged on the axial line of the barrel-shaped cathodic titanium net, and the surface area ratio of the cathodic titanium net to the anodic platinized and titanized rod is (10 to 1) to (20 to 1). The device for preparing tetravalent uranium by electrolytic reduction is simple in structure, high in tetravalent uranium yield and more convenient to operate and repair, overcomes the defect of low tetravalent uranium yield of the existing diaphragm-free electrolysis device and solves the problems of complicated equipment, high cost and the like of the diaphragm electrolysis device; the tetravalent uranium yield is more than 90% during a static electrolytic process.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Zirconium oxide carrier catalyst based on ternary copper-based microspheres and preparation method thereof

InactiveCN107824191AImprove catalytic performanceEasy to prepareOrganic compound preparationCatalyst activation/preparationCopper saltCopper oxide

The invention provides a zirconium oxide carrier catalyst based on ternary copper-based microspheres and a preparation method thereof. The zirconium oxide carrier catalyst based on the ternary copper-based microspheres comprises a lamellar tetragonal ZrO2 carrier based on the ternary copper-based microspheres. The preparation method comprises the following steps: uniformly stirring and mixing a copper salt solution and a zirconium salt solution, slowly dropwise adding an alkaline solution, adding a co-catalyst, standing, aging, washing, suction filtering, drying, grinding into powder, roasting, and cooling to obtain copper oxide / zirconium oxide precursor; and adding the copper oxide / zirconium oxide precursor into the alkaline solution, stirring, heating in a water bath to a medium temperature, slowly dropwise adding hydrazine hydrate and glucose, performing the reduction reaction, after the reaction is ended, rapidly adding icy water for cooling, washing, suction filtering, vacuum drying, thus obtaining the zirconium oxide carrier catalyst based on the ternary copper-based microspheres. The preparation method is simple and high in efficiency, the change of Cu<2+> to Cu<+> to Cu<0>can be controlled, the reduction degree is controllable, a ratio of the Cu<0> and Cu<+> is increased, and the activity of the catalyst is high.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

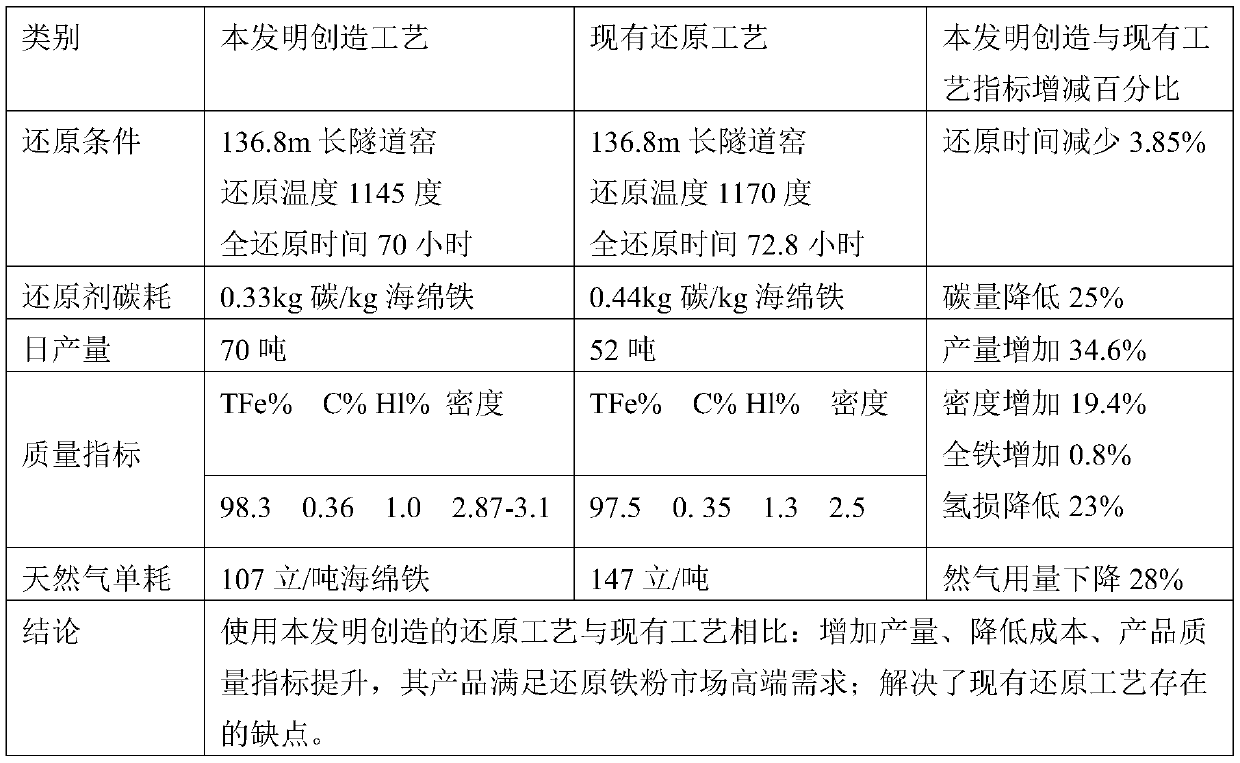

Preparation method of sponge iron

InactiveCN111321264AShorten the diffusion pathIncrease production capacityFluidised-bed furnacesTunnel kilnCarbide silicon

The invention discloses a preparation method of sponge iron. The preparation method comprises the following steps that step one, a raw material is prepared; step two, a reducing agent is prepared; andstep three, the technological process is carried out, specifically, (1), 42 columns of silicon carbide tank bodies are stacked on a vehicle surface; (2), a cylinder mould is placed at the center position of the silicon carbide tank bodies; (3), gaps between the cylinder mould and the silicon carbide tank bodies are filled with the reducing agent prepared in the step 2; (4), the cylinder mould isfilled with a prepared raw material, and a silicon carbide tank body opening is sealed; (5), a tunnel kiln is reduction is carried out; and (6), a product is subjected to drawing and cooling processing to form terminal product sponge iron powder. Compared with the prior art, the preparation method of the sponge iron has the advantages that the yield is increased, the cost is reduced, the product quality index is improved, and the product meets the high-end requirement of a reduced iron powder market; and the defects existing in a reduction technology are overcome.

Owner:北票新正粉末冶金有限公司

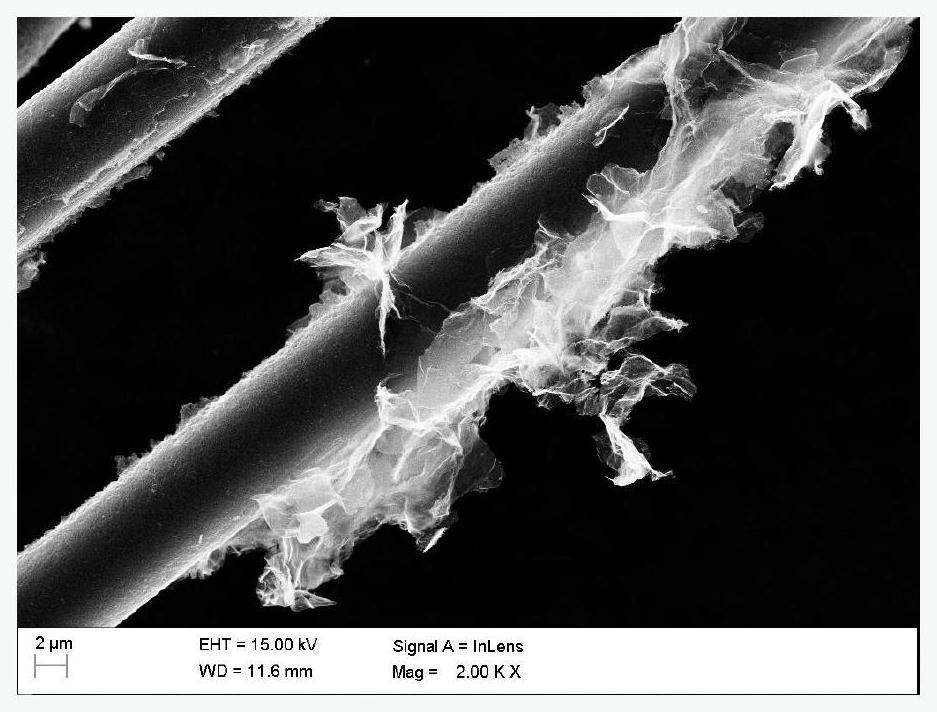

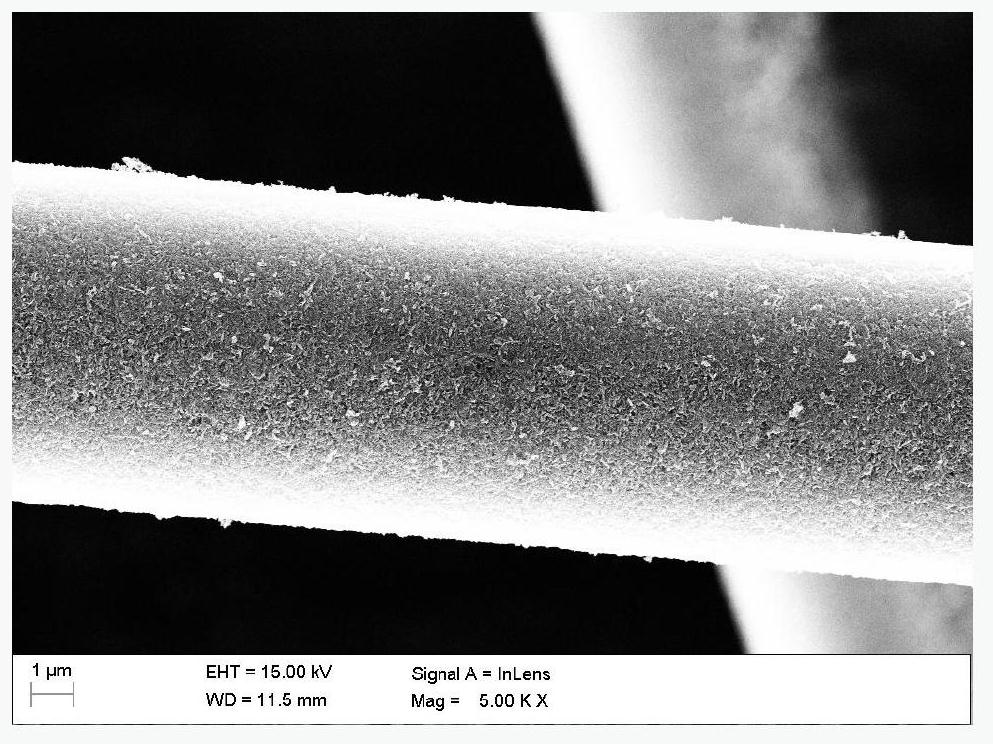

Modified carbon brush electrode and preparation method thereof

ActiveCN111613802AIncrease output powerLarge specific surface areaCell electrodesBiochemical fuel cellsFiberPtru catalyst

The invention belongs to the technical field of microbial fuel cells. The invention relates to a modified carbon brush electrode and a preparation method thereof. The modified carbon brush electrode comprises an anode and a cathode; the preparation process comprises the following steps of: enabling the carbon brush to besubjected to acid treatment; introducingoxygen-containing functional groups into the surface of the carbon brush; using a hydrothermal synthesis method to grow iron oxide nanoparticles on the surface of the carbon brush in situ; immersing the carbon brush with the iron oxide grown on the surface into an ethanol mixed solution containing a conductive polymer monomer; sequentially adding deionized water or a solution containing a nano carbon material and hydrochloric acid, reacting iron oxide on the surface of the carbon brush with acid to generate Fe<3+>, and inducing a conductive polymer monomer near the carbon fiber to be subjected to in-situ polymerization reaction toform a conductive polymer film or a conductive polymer film containing a nano carbon material, thereby obtaining a modified carbon brush anode; and further calcining the modified carbon brush anode in an inert atmosphere to obtain the in-situ growth nitrogen-doped or iron-nitrogen-doped oxygen reduction reaction catalyst carbon brush cathode.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Efficient smelting method of silicon-manganese alloy

ActiveCN112921177AHigh recovery rateHigh melting pointProcess efficiency improvementSmelting processFlue gas

The invention provides an efficient smelting method of silicon-manganese alloy. The efficient smelting method comprises the following steps: adding raw materials including water-washing residues, silicon-manganese alloy residues, prebatching being prepared from smelting dust caused by dust removal of smelting flue gas, manganese ores and the like into a submerged-arc furnace and performing smelting so that waste residues produced in a smelting process of a part of silicon-manganese alloy are effectively treated on one hand, and the dried water-washing residues and silicon-manganese alloy residues are beneficial for improving the thermodynamics conditions of the submerged-arc furnace in a smelting process on the other hand, and thus, the smelting efficiency is improved. The water-washing residues and the smelting dust contain a large amount of calcium oxide and magnesium oxide, so that regulation demands on alkalinity in the submerged-arc furnace can be met, the dried water-washing residues, the silicon-manganese alloy residues and the smelting dust contain a large amount of silicon and manganese, and the recycling ratios of the silicon and the manganese are obviously increased after re-smelting. Meanwhile, the the dried water-washing residues and the smelting dust has higher smelting point, by coordinating with addition of aluminum oxide, the furnace residue smelting point can be effectively increased, and thus, the furnace temperature is improved, and reduction reaction velocity in the submerged-arc furnace is quickened.

Owner:平罗县阳光焦化有限公司

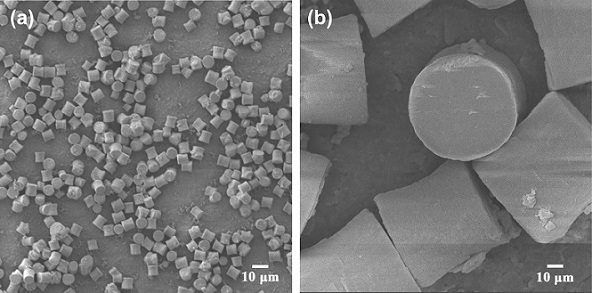

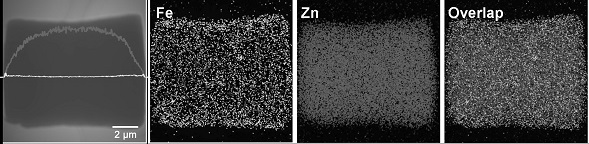

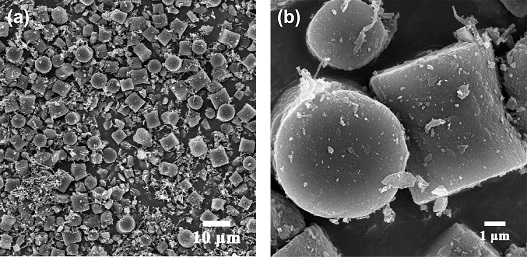

A kind of iron, nitrogen co-doped carbon oxygen reduction catalyst and its preparation method and application

The invention relates to an iron and nitrogen co-doped carbon oxygen reduction catalyst and its preparation method and application. A Fe / Zn bimetallic ZIF with element gradient distribution is prepared, and it is used as a precursor for pyrolysis and carbonization to prepare iron, Nitrogen co-doped carbon oxygen reduction catalyst to improve the utilization of active sites, optimize the pore structure, and then enhance the catalytic activity. The iron and nitrogen co-doped carbon oxygen reduction catalyst prepared by the invention can efficiently catalyze the oxygen reduction reaction, and exhibit better oxygen reduction catalytic activity and electrochemical stability than commercial Pt / C. The preparation method is simple and controllable, the cycle is short, and the raw material reserves are abundant, the cost is low, and large-scale production can be realized.

Owner:BEIJING UNIV OF CHEM TECH

Method for reducing chlorine-containing organic substance in dechlorination treatment water by surface modified catalytic iron

InactiveCN100564278CImprove reducibilityIncrease reaction rateWater/sewage treatment by electrochemical methodsWater/sewage treatment by reductionCopper platingReaction rate

Owner:TONGJI UNIV

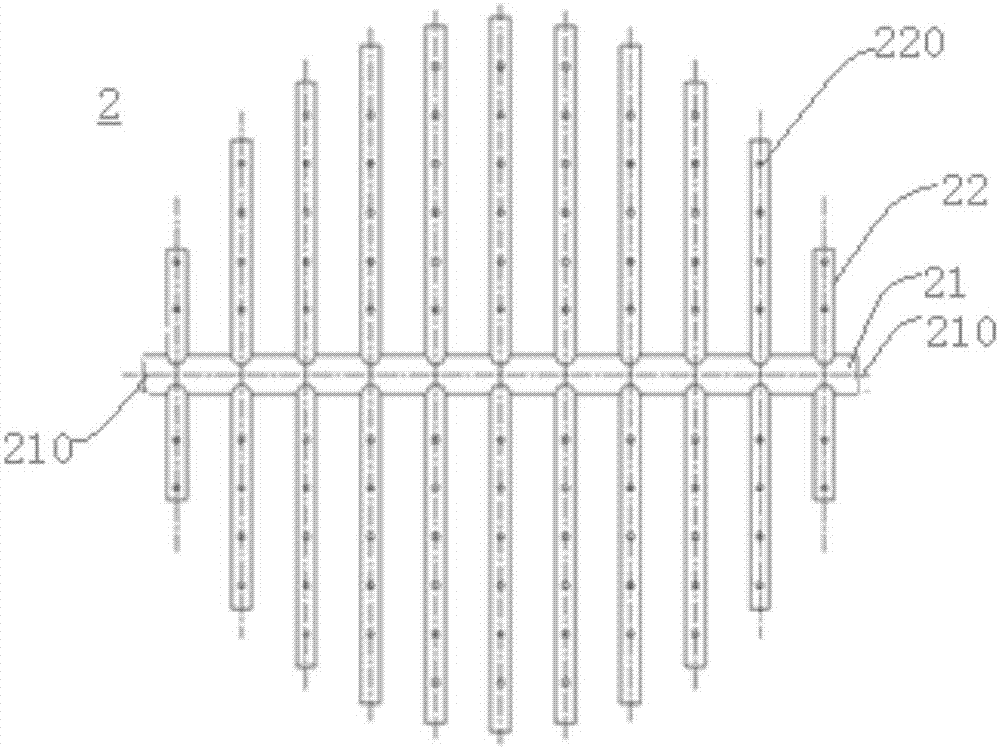

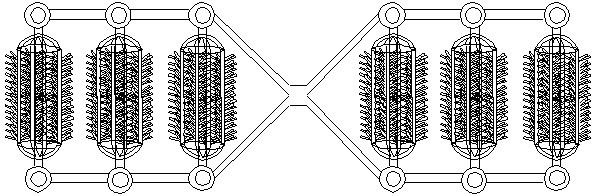

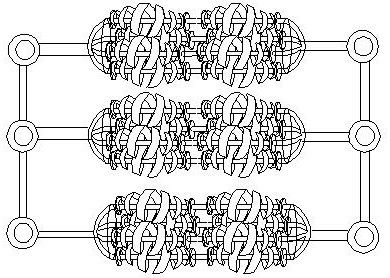

Mineral powder reduction system

PendingCN107227390AIncrease contact areaSpeed up the reduction reactionRetort furnacesSlagExhaust gas

The invention discloses a mineral powder reduction system, which includes: a reactor, a heating device and a gas distributor. The reactor includes a feed section, a reduction section and a cooling section. The reduction section is located below the feed section and communicates with the feed section. , the cooling section is located below the reduction section and communicates with the reduction section, the top of the feed section is provided with a feed port, the bottom of the cooling section is provided with a discharge port, and the side wall of the reactor is provided with a reduction tail gas outlet and a reduction gas inlet The heating device is arranged in the reduction section to provide heat for the reduction reaction in the reduction section; the gas distributor is arranged in the feed section, and the gas distributor has a gas inlet and an upwardly facing gas outlet, and the gas inlet and the gas outlet are connected. The gas distributor is configured to blow off the falling mineral powder in the feeding section so that the mineral powder falls into the reducing section in a dispersed manner. According to the ore powder reduction system of the embodiment of the present invention, the ore powder can be fully dispersed by the gas distributor, thereby increasing the contact area between the ore powder and the reducing gas.

Owner:SHENWU TECH GRP CO LTD

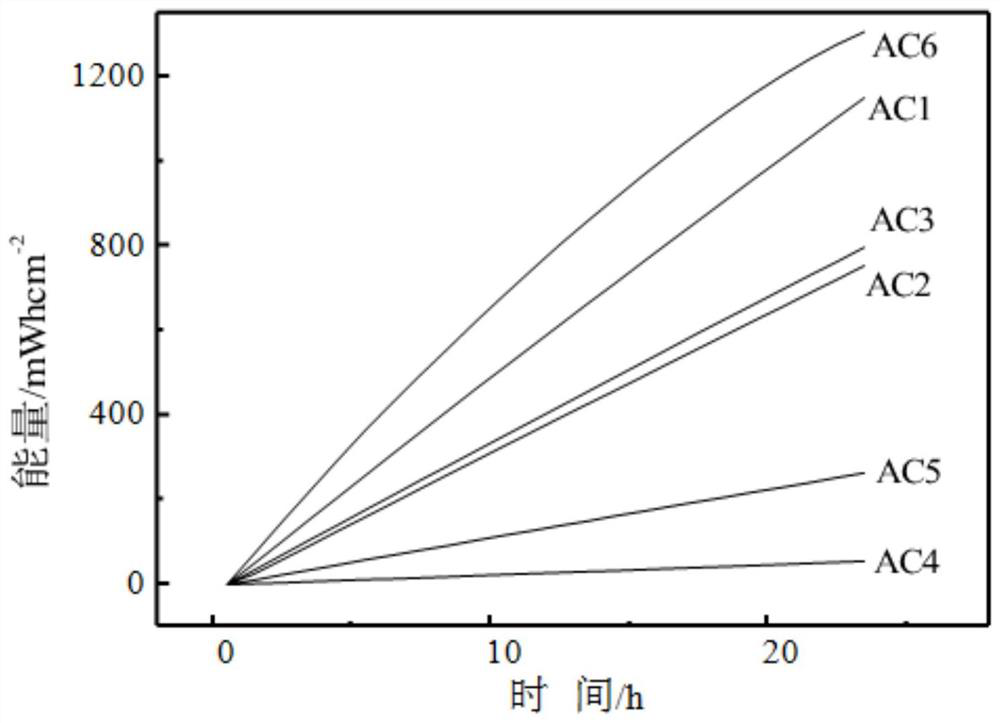

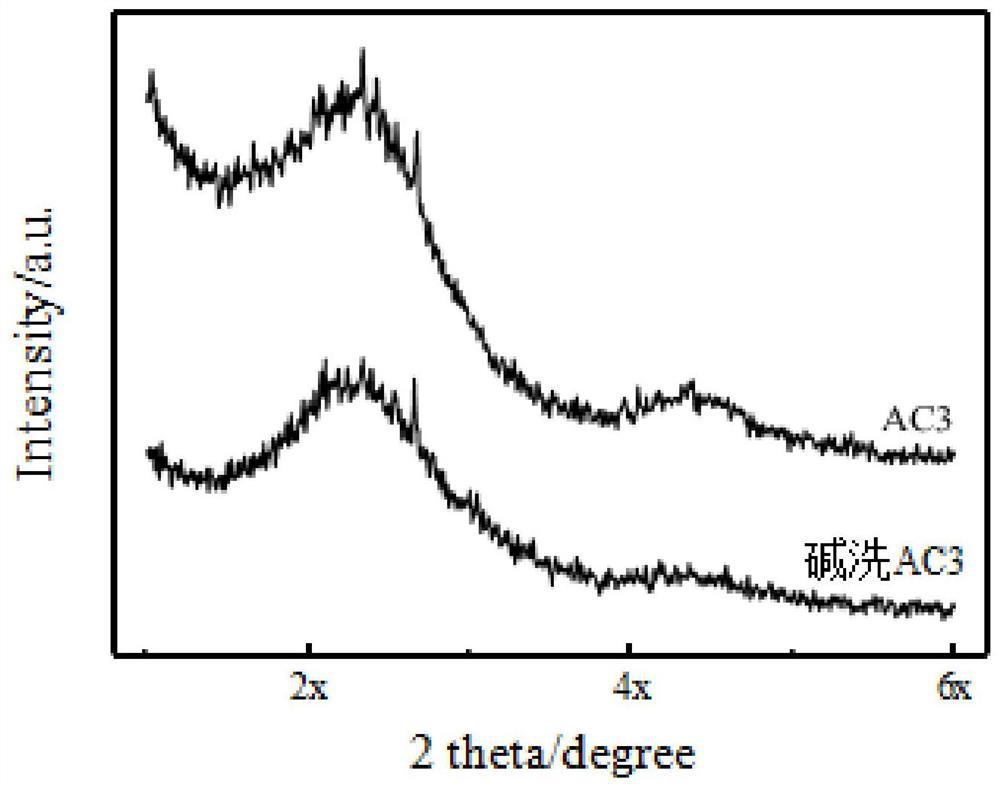

A kind of electrode film and preparation method thereof

ActiveCN110112511BIncrease the rate of the reduction reactionHigh catalytic activityFuel and primary cellsCell electrodesPtru catalystBattery cell

The invention discloses an electrode film and a preparation method thereof. The electrode film comprises a catalytic layer, a current collecting layer and a waterproof gas permeable layer, wherein thecatalytic layer, the current collecting layer and the waterproof gas permeable layer are superposed. The catalytic layer comprises a carbon carrier and a catalyst. The carbon carrier comprises an alkali-washed chemically active carbon and Vulcan XC72R carbon black. The mass ratio of chemically active carbon to Vulcan XC72R carbon black is (3 to 10):1. The catalyst is MnO2-Ag / C. The preparation method of the electrode film comprises the steps that catalytic layer preparation: the carbon carrier, a pore forming agent, the catalyst and a binder are added in a solvent, and a catalytic layer solution is acquired after ultrasonic dispersion; the catalyst layer solution is heated in a water bath to break the emulsion, and suction filtration is performed to acquire catalytic layer paste; the catalytic layer paste is rolled to acquire the catalytic layer; pressing: the acquired catalytic layer, the waterproof gas permeable layer and the current collecting layer are laminated to acquire an electrode film; and the electrode film is used in an aluminum-air battery to improve the rate of catalytic oxygen reduction reaction, so that the aluminum-air battery provides steady power.

Owner:中科(广州)能源科技开发有限公司

Rapid reduction process of laterite nickel ore rotary kiln

Owner:CENT SOUTH UNIV

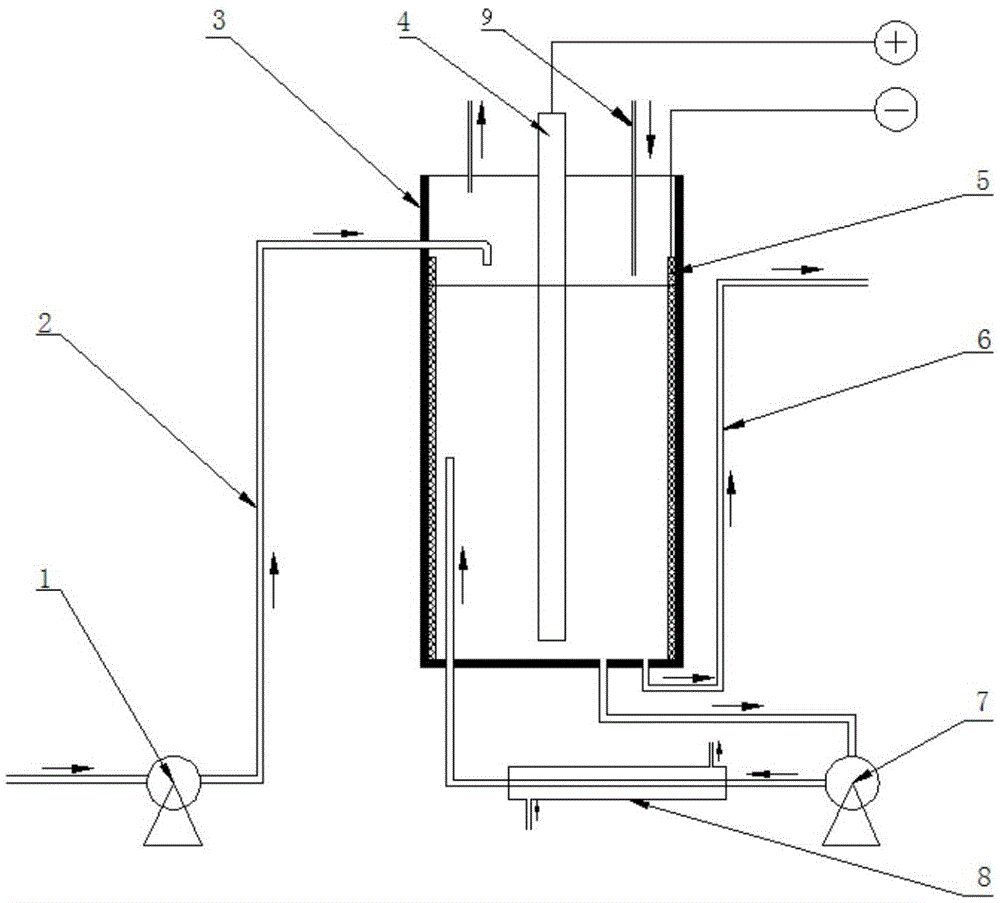

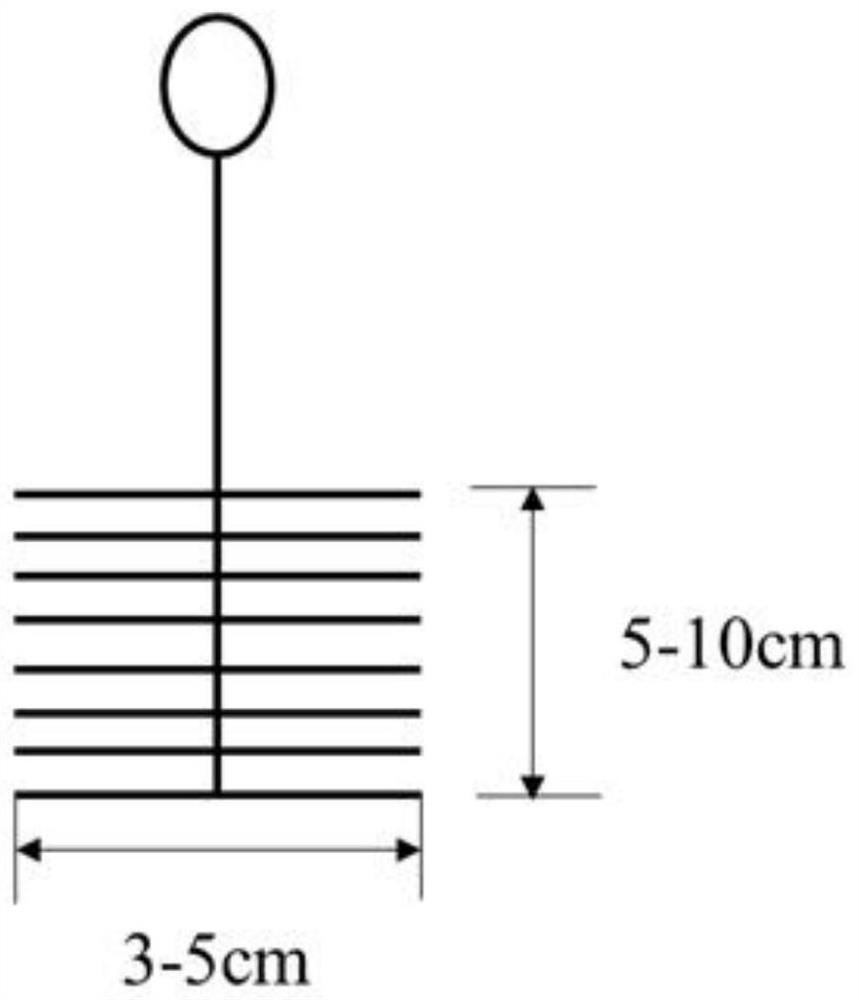

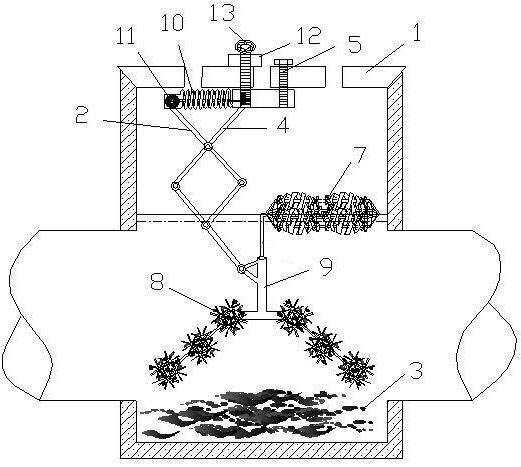

An in-situ control municipal sewage pipeline sulfur conversion system and its operation method

ActiveCN107459127BIncrease dissolved oxygen concentrationAccelerates the reaction rate of reduction to waterTreatment by combined electrochemical biological processesWater contaminantsMunicipal sewageElectrochemistry

The invention relates to a sulfur conversion system regulated and controlled in situ for a municipal sewage pipeline and a running method of the sulfur conversion system. The system comprises a sewage well lid of the municipal sewage pipeline, a microbial electrochemical system and a lifting rack system, wherein the upper end of the lifting rack system is fixed on the sewage well lid while the lower end of the lifting rack system is connected to the microbial electrochemical system; the lifting rack system comprises an upper support, a retractable module, a lower support and a fixing object; the retractable module is fixed on the sewage well lid through the fixing object; the upper support and the lower support form an X; the upper end of the upper support and the upper end of the lower support are separately fixed on two sides of the retractable module; the lower end of the upper support is fixed on the lower support; the lower end of the lower support is connected with the microbial electrochemical system; the electrochemical system comprises a cathode group, an anode group, a wire and a retractable sleeve; the cathode group is connected with the anode group by the wire with the retractable sleeve in a sleeving manner; the retractable sleeve is connected with the lower end of the lower support; and the anode group is positioned at the bottom of the sewage pipeline. The system is simple in structure, good in sulfur conversion effect and pollution-free to the environment.

Owner:YANCHENG INST OF TECH

Endogenous heat type hemicontinuous reduction furnace for producing magnesium, calcium and strontium

Owner:张元友

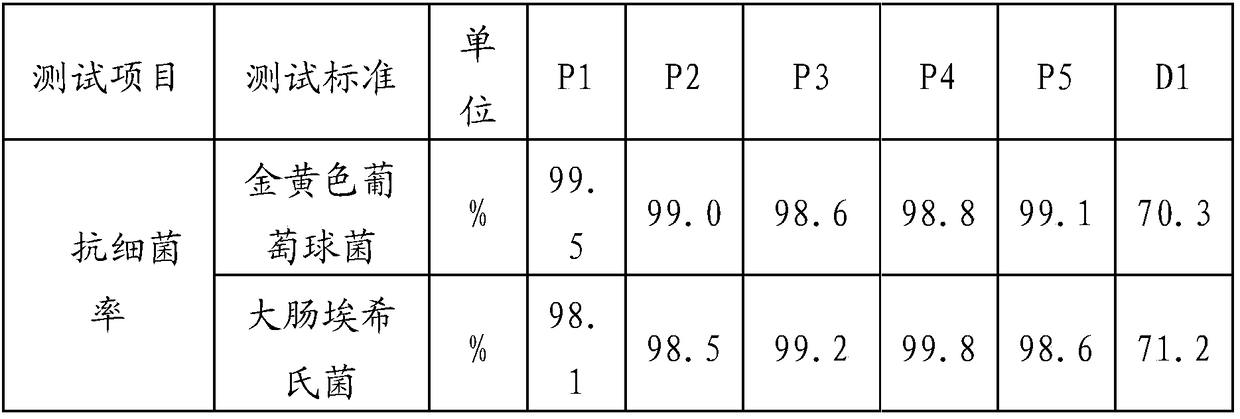

Antibacterial PP composite material and preparation method thereof

InactiveCN109294062AIncrease temperatureIncrease the rate of the reduction reactionChemistryAntimicrobial

The invention relates to an antibacterial PP composite material and a preparation method thereof. The antibacterial PP composite material comprises the following components in parts by weight: 80 parts-100 parts of PP; 4 parts-6 parts of an antibacterial agent; and 0.1 parts-0.5 parts of an antioxidant; The antibacterial agent is the glucose / nano-Cu antibacterial agent, which is characterized in that due to the existence of a hydroxyl group and an amino group in the glucose molecule, a cage molecule having a similar network structure is formed by hydrogen bond, the compact crystal structure isformed to form the steric hindrance effect, and the surfaces of the nano Cu particles are separated to produce the stereoscopic protection effect, the contact between the nano-Cu particles is prevented, the agglomeration probability of the nano-Cu particles is reduced; so that the antibacterial property of the PP composite material can be better improved, which has great significance.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

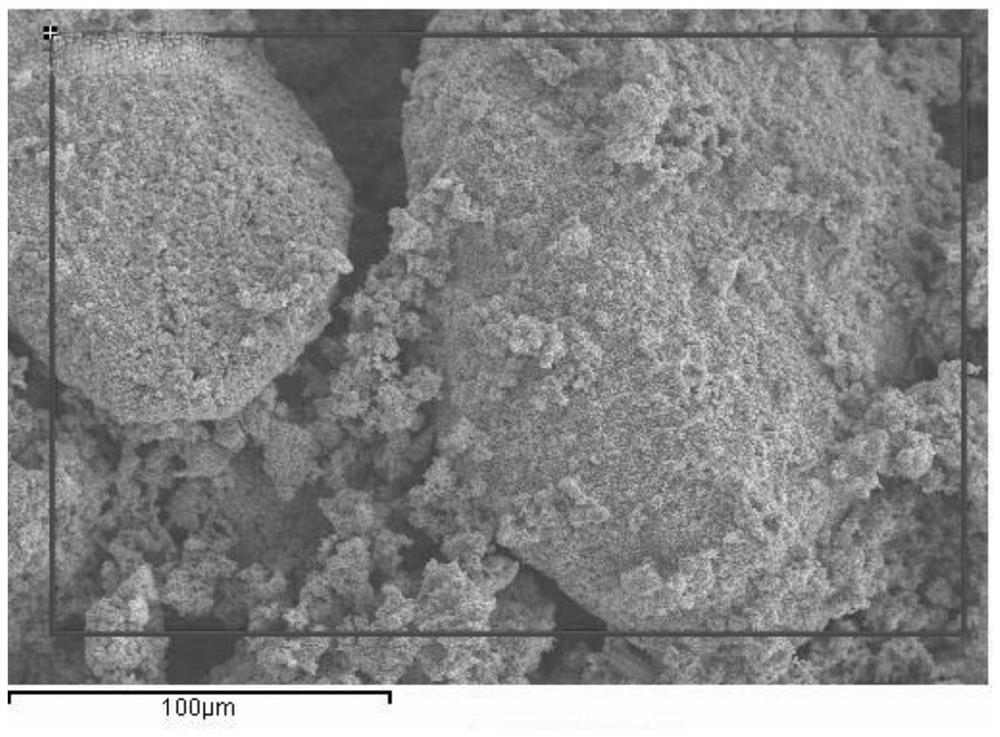

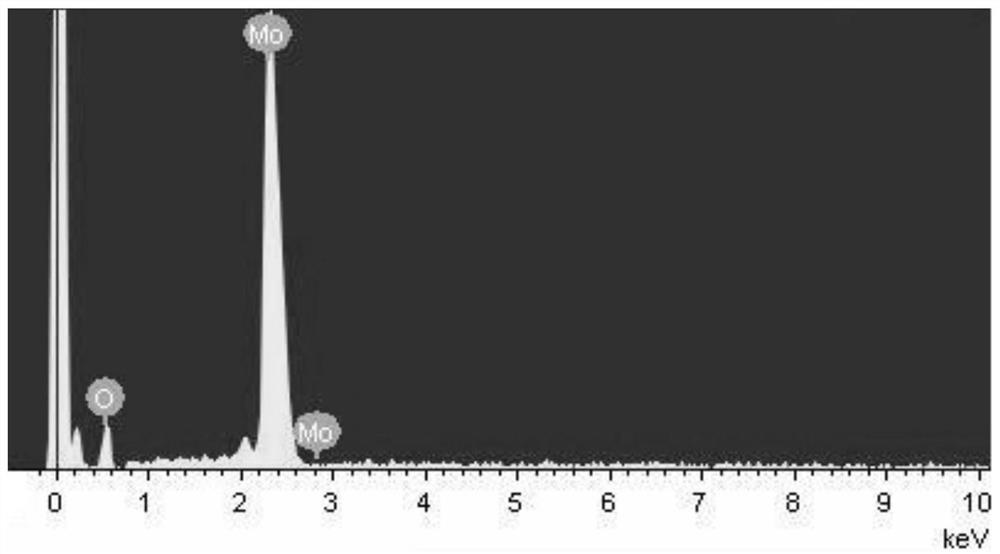

A kind of preparation method of molybdenum dioxide

ActiveCN109399721BImprove securityPrevent restoreMolybdenum oxides/hydroxidesPhysical chemistryMolybdenum trioxide

Owner:JINDUICHENG MOLYBDENUM CO LTD

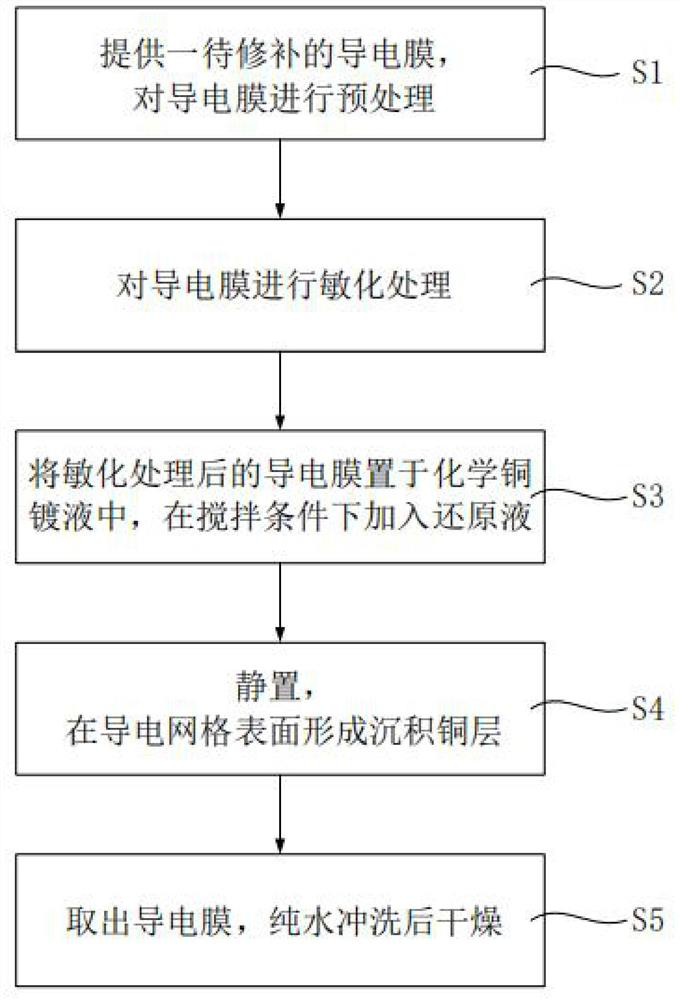

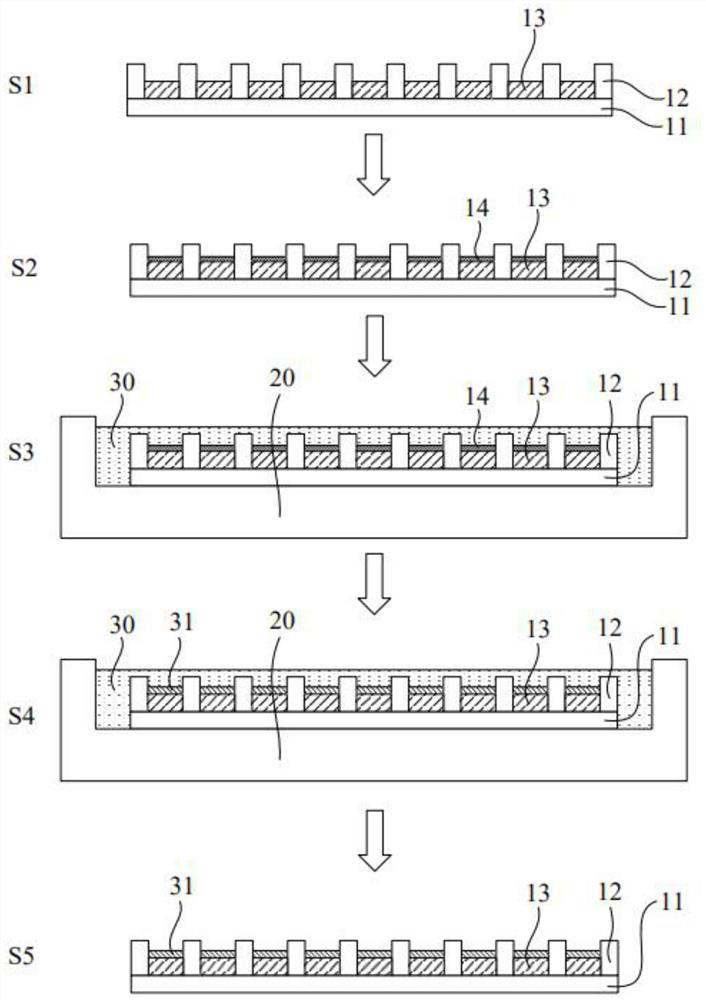

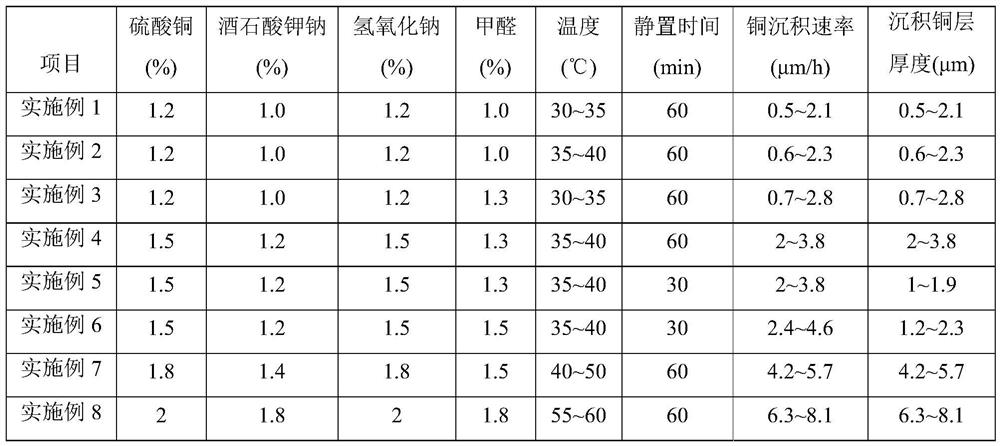

Conductive film repairing method

PendingCN113151813AIncrease success rateImprove efficiencyLiquid/solution decomposition chemical coatingElectrically conductiveCopper plating

The invention relates to a conductive film repairing method which comprises the following steps of providing a conductive film to be repaired, wherein the conductive film comprises a base film, a structural layer and a conductive mesh, the structural layer and the conductive mesh are located on the base film; the structural layer is provided with a pattern groove, and the conductive mesh is formed by filling the pattern groove with a metal material; carrying out sensitization treatment on the conductive film; placing the conductive film subjected to sensitization treatment in a chemical copper plating solution; adding a reducing solution under a stirring condition; and carrying out standing, so that a deposited copper layer is formed on the surface of the conductive mesh, and the deposited copper layer is further filled in gaps with poor circuit breaking in the conductive mesh. According to the conductive film repairing method provided by the invention, sensitization and chemical copper plating are carried out on the surface of the conductive film, silver or gold in the conductive mesh plays a catalytic role in the process, a high reduction reaction rate exists nearby the conductive mesh, batch repairing can be carried out on the poor circuit breaking of the conductive mesh, the success rate is high, the efficiency is high, and automatic repairing can be achieved.

Owner:SUZHOU WEIYEDA TOUCH TECH +1

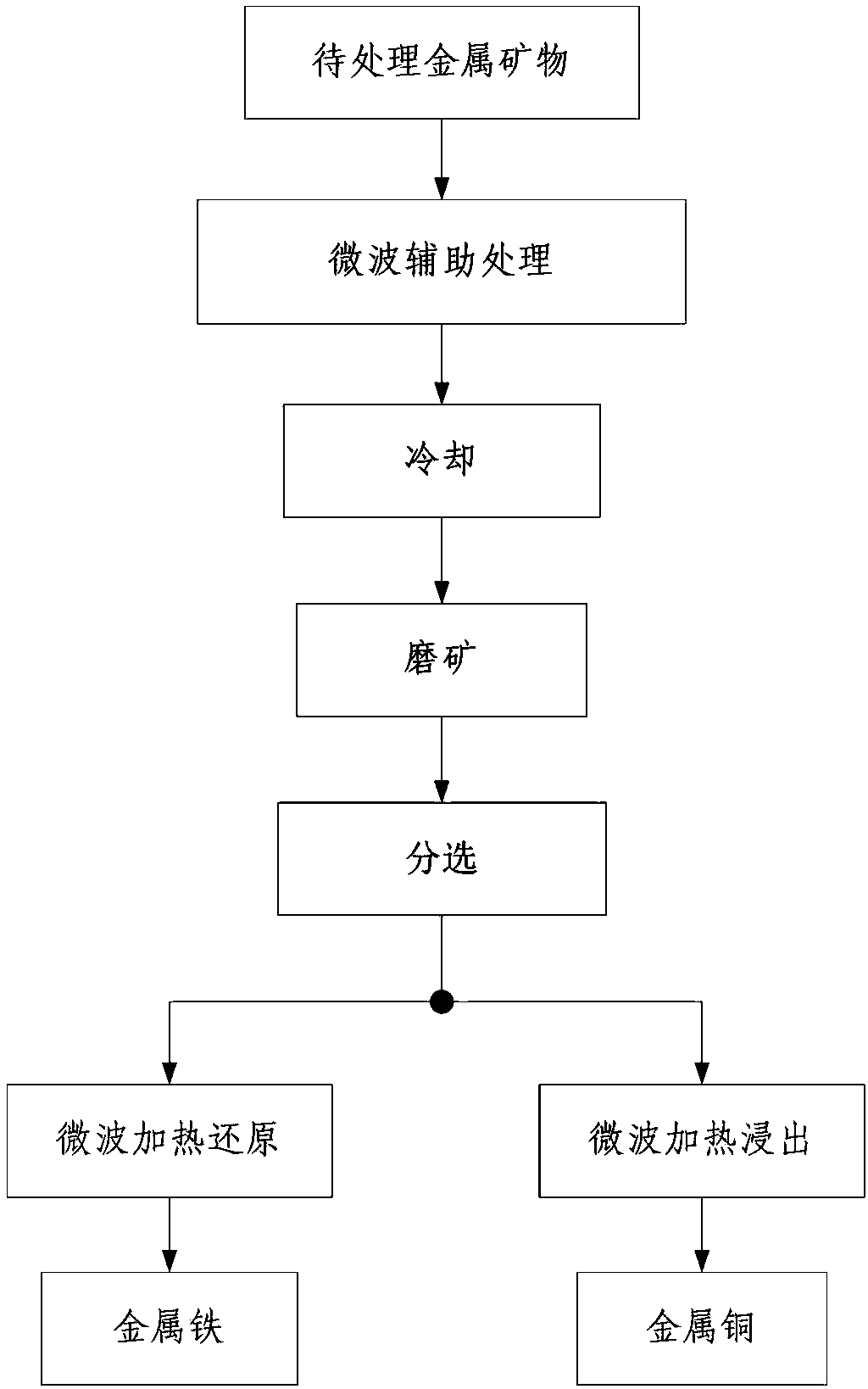

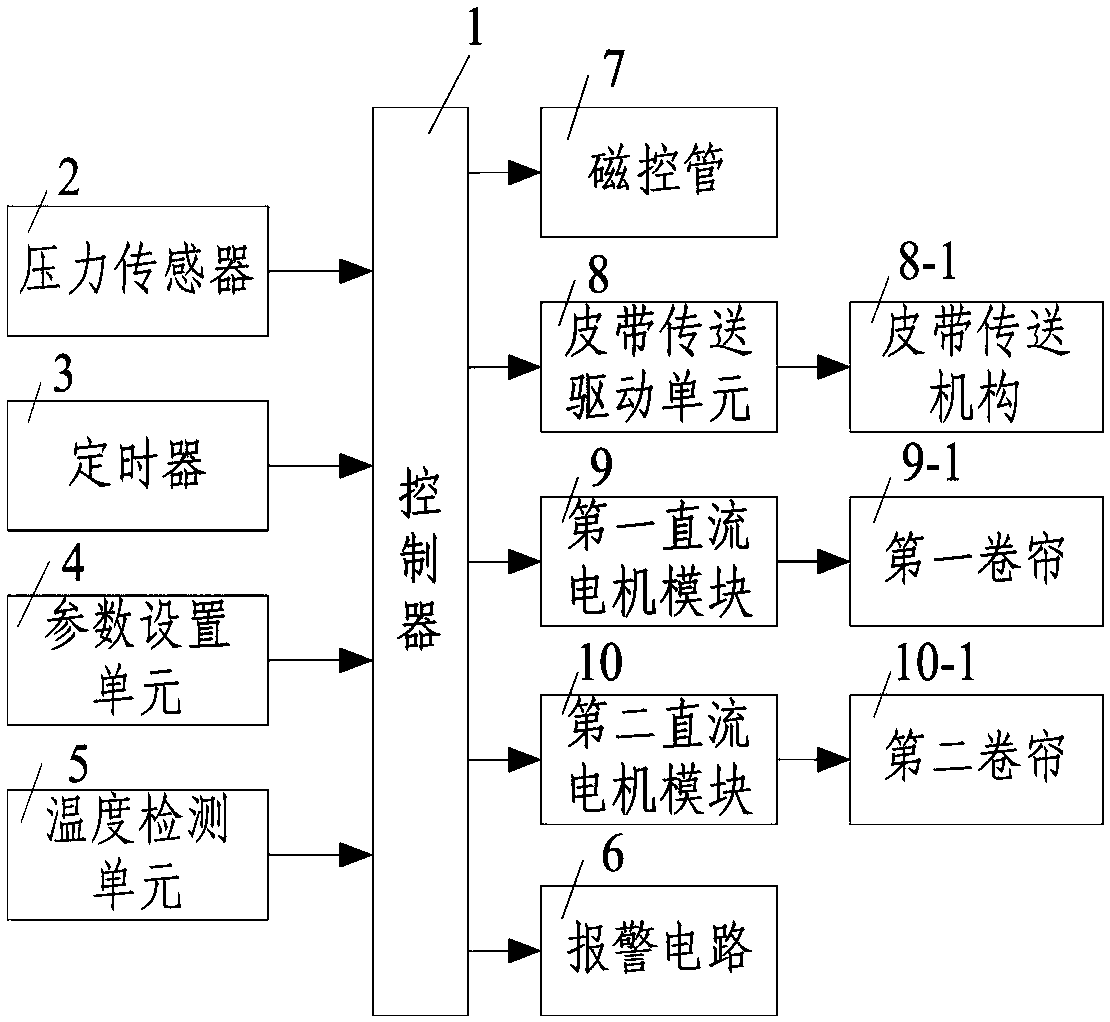

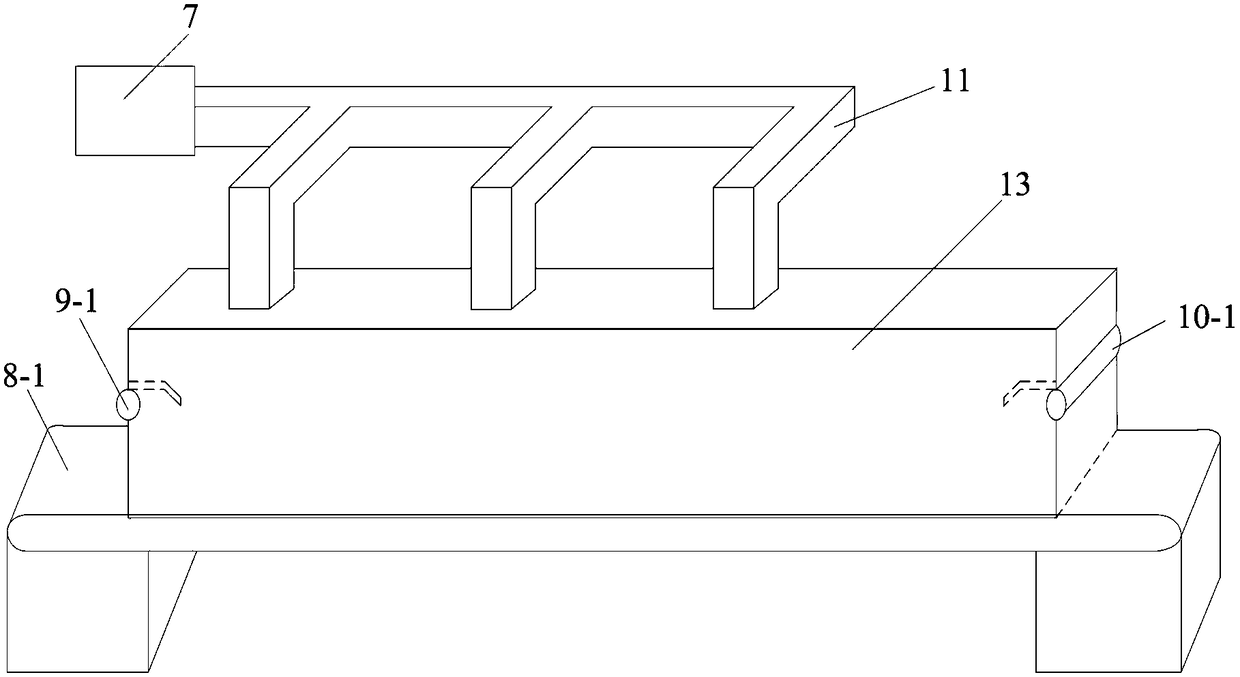

A method for microwave-assisted extraction of metal minerals

InactiveCN106148677BThe method steps are simpleLow input costProcess efficiency improvementGas emission reductionReduction rateWorkload

The invention discloses a method for microwave-assisted extraction of metal minerals. The method includes the first step of microwave-assisted treatment, the second step of cooling, the third step of ore grinding, the fourth step of separation and the fifth step of metal mineral extraction. The method is simple in step, low in input cost and convenient to achieve, the ore grinding workload is reduced, metal mineral extraction can be simply, conveniently and rapidly completed, efficiency is high, the needed reduction and leaching time is short, the reduction rate and the leaching rate of metal are high, energy conservation and environment friendliness are achieved, the using effect is good, and the problems that in a traditional extraction method, the input cost is large, the operation process is complex, energy consumption is large, the reduction and leaching time are long, and the environment is polluted can be effectively solved.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com