An in-situ control municipal sewage pipeline sulfur conversion system and its operation method

A technology for municipal sewage and pipelines, applied in chemical instruments and methods, water/sewage treatment, biological water/sewage treatment, etc., to achieve the effects of improving the reduction reaction rate, low cost, and increasing current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

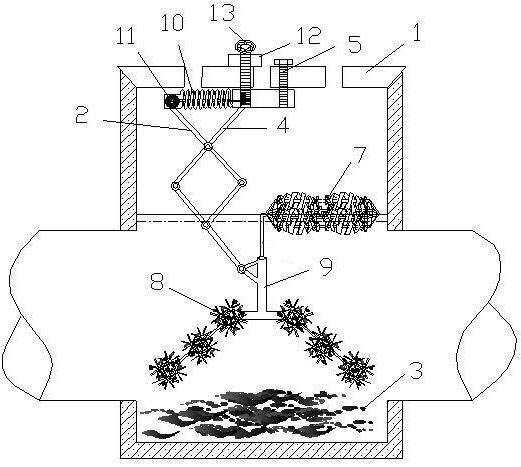

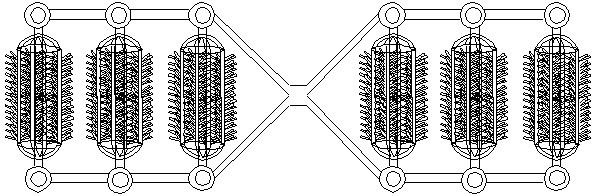

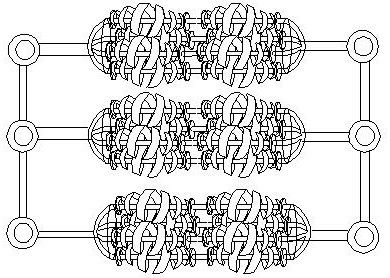

[0029] An in-situ control system for sulfur conversion of municipal sewage pipelines, comprising sewage manhole covers of municipal sewage pipelines, a microbial electrochemical system and a lift system, the upper end of the lift system is fixed on the sewage well cover 1, and the lower end is connected to the microbial electrochemical system. The lifting frame system includes an upper bracket 2, a telescopic module, a lower bracket 4, and a fixture 5. The telescopic module is fixed on the sewage well cover 1 through the fixture 5. The upper bracket 2 and the lower bracket 4 form an X shape, and the upper bracket 2 The upper ends of the lower bracket 4 are respectively fixed on both sides of the telescopic module, and the telescopic module shrinks to change the size of the X-shaped angle to complete the telescopic purpose and realize the change of the position of the microbial electrochemical system. The lower end of the upper support 2 is fixed on the lower support 4, and the ...

Embodiment 2

[0037] The above-mentioned operation method for in-situ regulation and control of the sulfur conversion system of the municipal sewage pipeline comprises the following steps: installing a sewage manhole cover, a lift system and a microbial electrochemical system, and the SO in the municipal sewage pipeline 4 2- Sewage is reduced to S by sulfate-reducing bacteria 3 in the sludge at the bottom of the pipeline 2- , and then oxidized to S 0 , while generating S 0 The anode is rapidly separated from the anode by hydraulic scouring; the cathode in the cathode group 7 placed at the junction of the sewage surface and the air receives electrons from the anode to reduce oxygen to water. During operation, maintenance and repairs are carried out for the microbial electrochemical system through the lift system. The invention samples the sewage in the system to monitor the concentration change of the sulfur conversion product and samples the gas above the sewage manhole cover 1 to measur...

Embodiment 3

[0039] Usually SO in sewage 4 2- The concentration fluctuation range is 20-200 mg / L. In order to investigate the value of the angle formed by the anode group and the pipeline, the sulfur conversion effect of the sewage pipeline is the best. 4 2- A set of control cases was made when the concentration was 150±5mg / L (that is, the angle between the anode group and the pipeline was 0°, 30°, 45°, 60°, and 90°). Except that the angle between the anode group and the pipeline was different, the rest The implementation steps and implementation content are the same as above.

[0040] From Figure 5 see that in SO 4 2- When the concentration is 150±5mg / L, when the anode group and the pipeline are at 0°, 30°, 45°, 60°, 90°, the S in the sulfur conversion product 0 The proportions in the sulfur form reached 67%, 70%, 83%, 68%, 60%, respectively, S 2- The proportions are 19%, 8%, 4%, 9%, and 14%. It can be seen that the setting of the anode group and the pipeline at 45° is more conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com