Iron and nitrogen co-doped carbon oxygen reduction catalyst and preparation method thereof

A catalyst and co-doping technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as hindering the widespread commercialization of fuel cell technology, high price of platinum-based catalysts, and deterioration of nanoparticle performance, and accelerate the oxygen reduction reaction. The effect of speed, process optimization, rich pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]An iron-nitrogen co-doped carbon-oxygen reduction catalyst, which uses a mixture of iron nitrate nonahydrate, guanidine hydrochloride and Ketjen black nano-carbon black particles as a precursor to prepare iron and nitrogen co-doped carbon-oxygen by high-temperature pyrolysis Catalyst reduction comprises the steps of:

[0039] (1) Dissolve 0.2g of Ketjen Black nano-carbon black particles as a carbon carrier in 50ml of organic solvent ethanol, ultrasonically dissolve and disperse evenly, add ferric nitrate under stirring conditions, mix thoroughly to obtain a mixed solution, and then transfer to the reaction kettle , the reaction kettle was placed at room temperature and stirred for 24 hours, vacuum filtered and repeatedly washed with organic solvent ethanol, then dried, mixed and ground after adding nitrogen source guanidine hydrochloride to obtain a pyrolysis precursor; wherein, the concentration of ferric nitrate in the solution was 0.1mol·L -1 , the amount of guanidin...

Embodiment 2

[0043] This example is an iron and nitrogen co-doped carbon-oxygen reduction catalyst, which adopts a preparation process similar to that of Example 1, except that the reaction temperature is increased to 900° C. during the process of pyrolyzing the precursor.

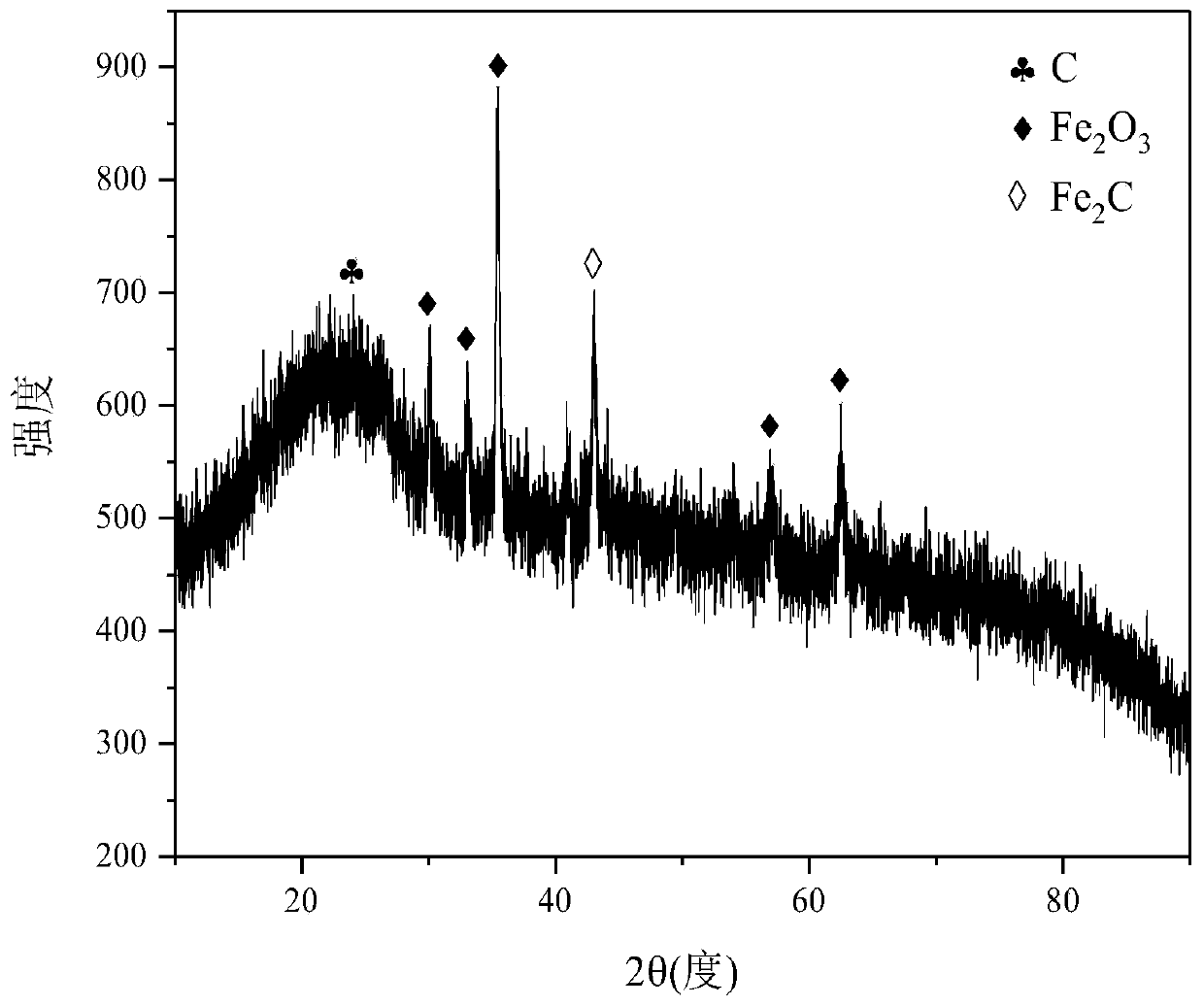

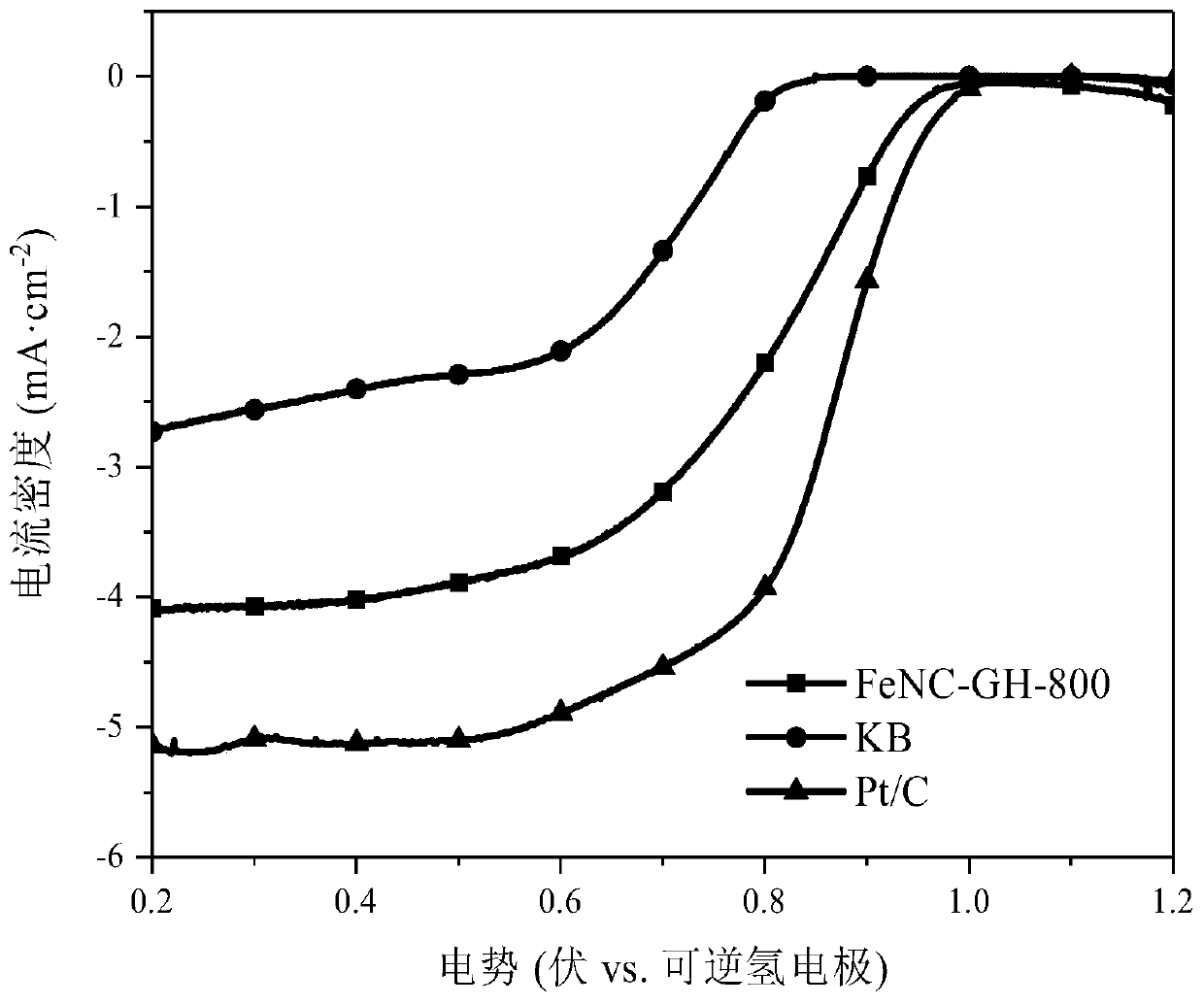

[0044] Characterize the structure of the catalyst to obtain its XRD pattern, such as Figure 4 as shown, Figure 4 It shows that the prepared catalyst contains a lot of Fe 3 C; Further test the oxygen reduction performance of the catalyst prepared by pyrolysis carbonization, such as Figure 5 Shown, show that this catalyst has the electrocatalytic activity that is better than commercial Ketjen black nano-carbon black particle, half-wave potential exceeds 114mV; Close to the electrocatalytic activity of commercial Pt / C catalyst, half-wave potential differs 54mV, compares embodiment 1 decreased by 1mV, and the electrochemical stability is better than commercial 20%Pt / C.

Embodiment 3

[0046] This example is an iron and nitrogen co-doped carbon-oxygen reduction catalyst. The preparation process of this catalyst is similar to that of Example 1, except that the reaction temperature drops to 700° C. during the process of pyrolyzing the precursor.

[0047] Characterize the structure of the catalyst to obtain its XRD pattern, such as Image 6 As shown, the iron and nitrogen co-doped carbon catalysts prepared by pyrolytic carbonization exhibited a large amount of Fe 2 The map structure of the C active site; further test the oxygen reduction performance of the catalyst prepared by pyrolysis carbonization, such as Figure 7 As shown, it is shown that the catalyst has electrocatalytic activity superior to commercial Ketjen black nano-carbon black particles, and the half-wave potential exceeds 45mV; it has an electrocatalytic activity close to that of commercial 20% Pt / C, and the half-wave potential difference is 123mV, compared with Example 1 drops 70mV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com