Ternary nanocomposite Au/RGO-TiO2 nanotube array as well as preparation method and application thereof

A technology of nanocomposite materials and nanotube arrays, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of inability to make full use of natural sunlight, inability to form nanotube structures, and insufficient specific surface area, etc., to achieve Excellent photocatalytic efficiency and repeated recycling efficiency, improved photoelectric conversion efficiency, increased specific surface area and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (l) Grind the surface of the base material and clean it for later use;

[0021] (2) Preparation of inorganic electrolyte: the electrolyte is composed of sodium fluoride and sodium bisulfate solution with a mass percentage of HF of 0.5-3%;

[0022] (3) Under 25-100V DC voltage, using pure titanium or titanium alloy as the anode and platinum sheet as the cathode, electrolytically prepare titanium oxide nanotubes in the electrolyte;

[0023] (4) Calcinate the titanium oxide nanotube array prepared above under aerobic conditions at 400°C-500°C for 4-6h to crystallize it into TiO 2 array of nanotubes.

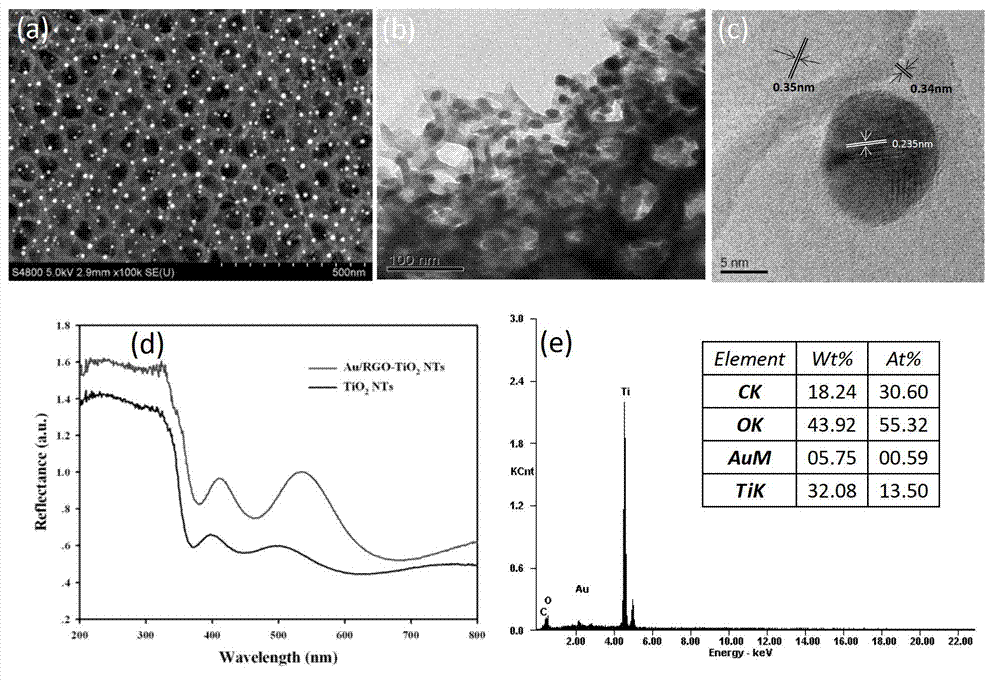

[0024] (5) Preparation of Au / RGO co-modified titania nanotube arrays:

[0025] The graphite oxide suspension (10mL 0.5mg mL -1 ) and chloroauric acid solution (1mL 5mmol / L) were magnetically stirred for ten minutes under ice-water bath conditions until the solution was uniformly mixed, and then the above TiO 2 Nanotube arrays were placed in a mixed solution of graphite ox...

Embodiment 2

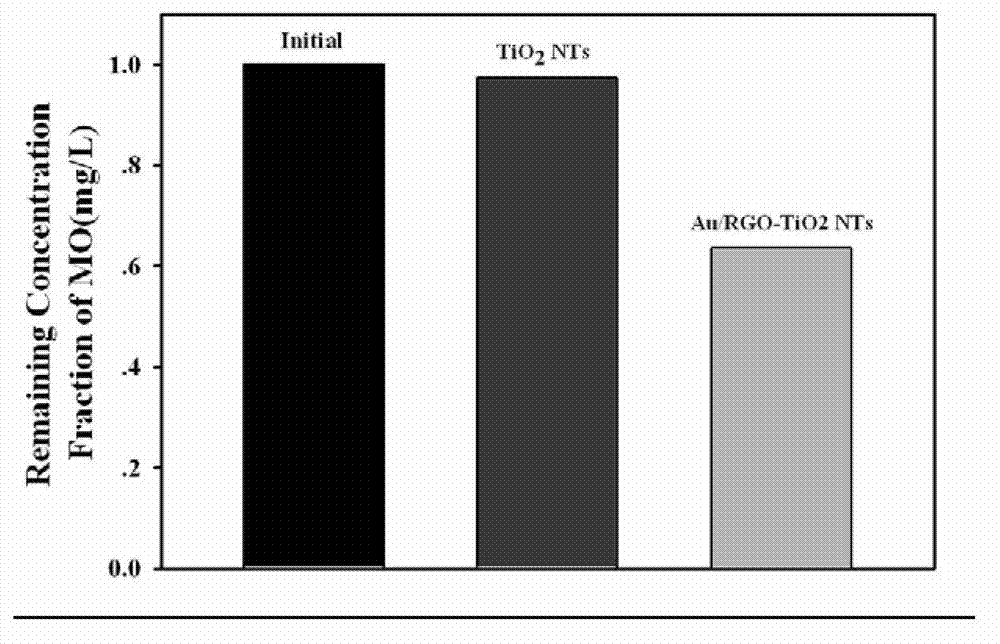

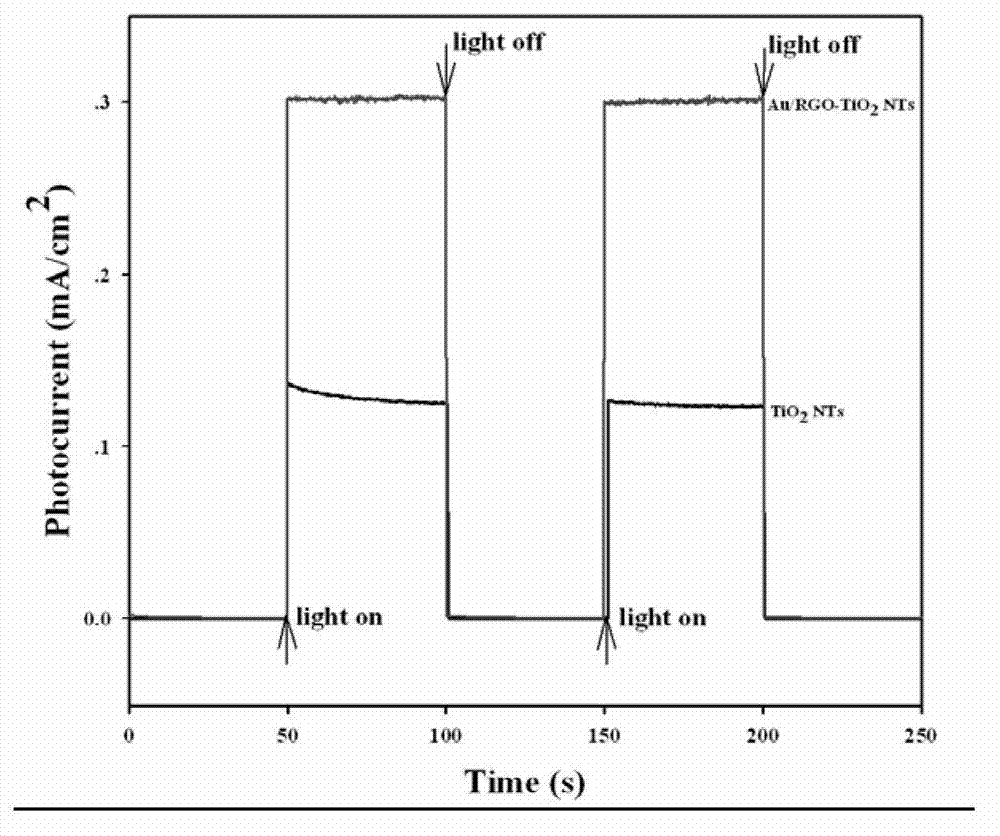

[0027] Au / RGO-TiO 2 Photocatalytic degradation performance and stability of nanotube arrays for methyl orange

[0028] The inventors used TiO 2 Nanotube arrays and TiO modified with Au and graphene 2 Nanotube arrays were used to degrade 20mg / L simulated methyl orange (Methyl Orange, MO) wastewater. Implementation steps:

[0029] (1) Au / RGO-TiO with an effective electrode area of 3cm×3cm 2 The composite nanotube array electrode was immersed in 40mL simulated methyl orange wastewater with a concentration of 20mg / L;

[0030] (2) Use a Xe lamp with a light source of 500W (100mW / cm 2 ), simulating sunlight to photocatalytically degrade it;

[0031] (3) After regular sampling, use a UV-visible spectrophotometer to monitor the changes in the concentration of methyl orange in the solution;

[0032] (4) Control experiment on unmodified TiO 2 On the nanotube array, the steps are the same as above.

[0033] (5) Material stability test: take Au / RGO-TiO with an effective area of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com