Graphene with composite pore structure, preparation method thereof and application in super capacitor

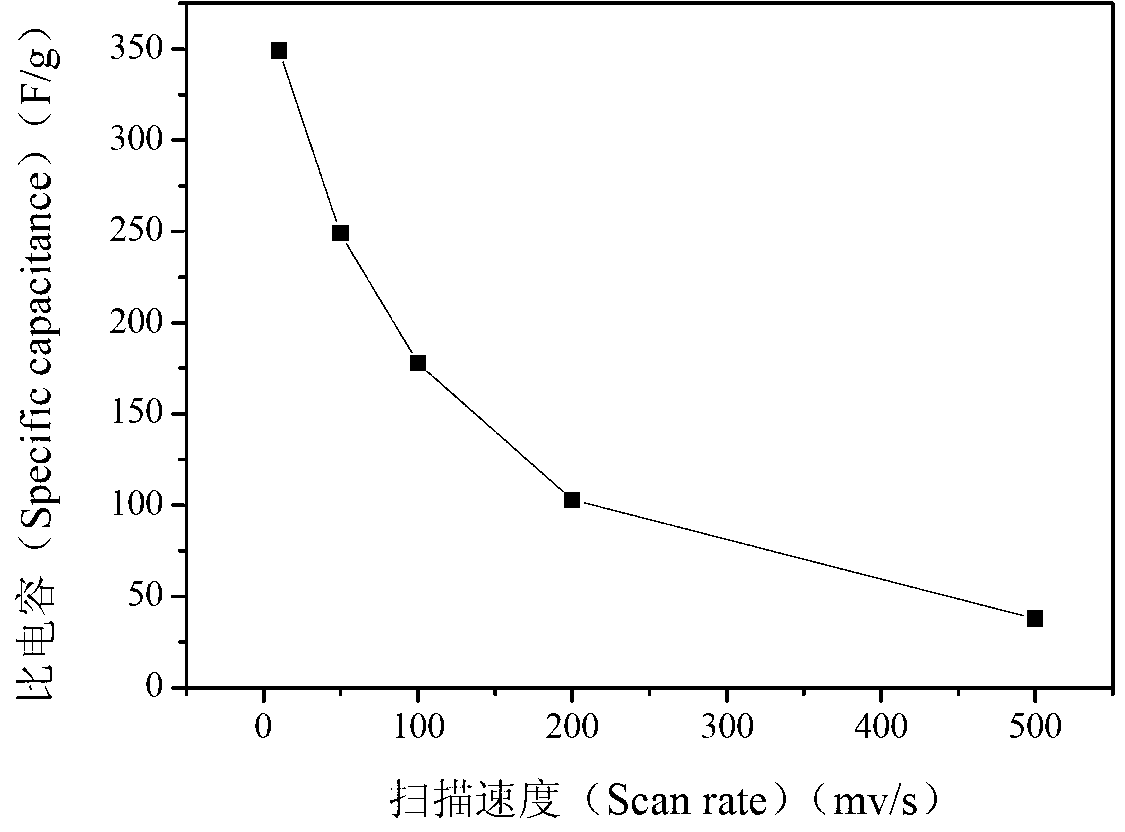

A composite hole and graphene technology, applied to graphene with a composite pore structure, in the field of its preparation, can solve the problems of low specific capacitance and low effective specific surface area, achieve high specific capacitance, improve effective specific surface area, The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

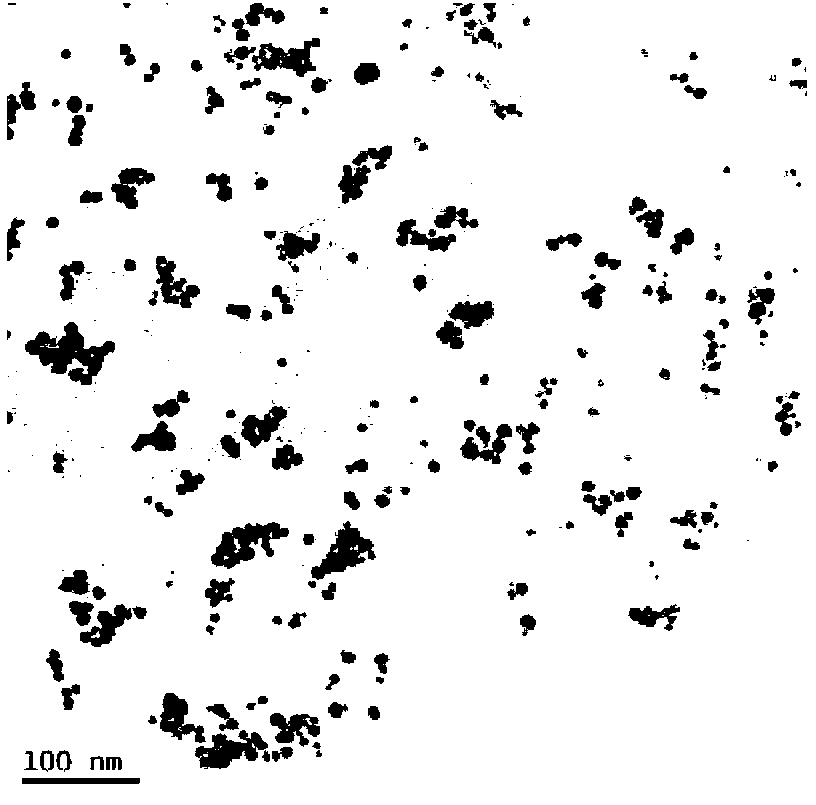

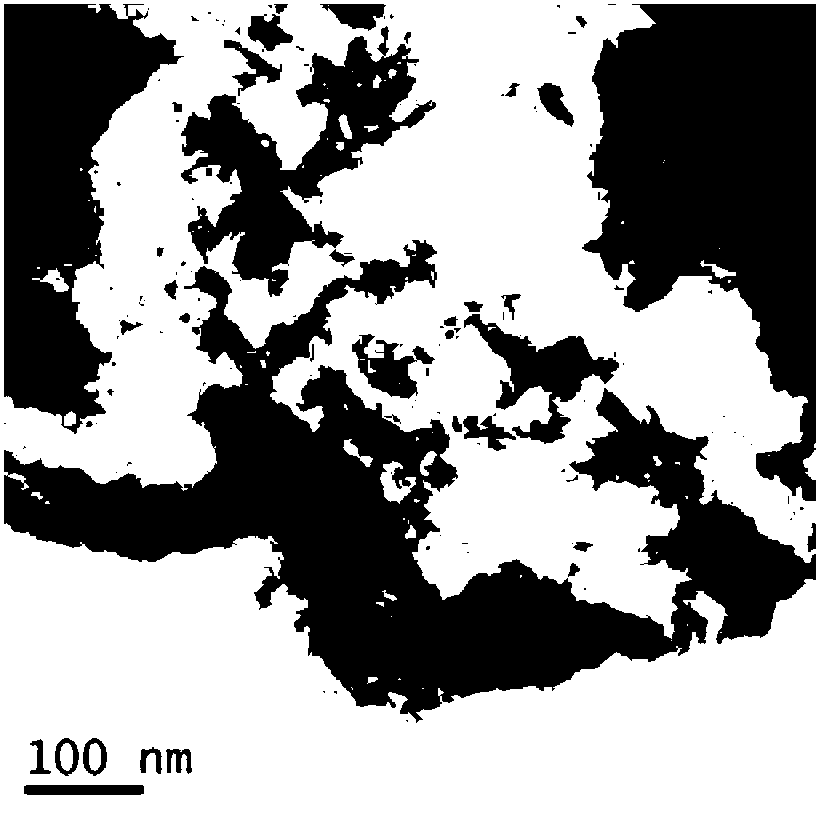

[0037] In this embodiment, the graphene sheet structure having a compound pore structure includes both micropores and macropores, the diameter of the micropores is 0.1 nm˜10 nm, and the diameter of the macropores is 50 nm˜100 nm.

[0038] The above-mentioned preparation method of graphene with composite pore structure is as follows:

[0039] (1) After ultrasonically mixing 40ml of the aqueous dispersion containing 100mg of graphene oxide and 160ml of the aqueous dispersion containing 6mg of zinc oxide nanoparticles (average particle size 4nm), they were heated at 90°C for 5 hours under electromagnetic stirring to make Zinc oxide nanoparticles are uniformly dispersed on the surface of graphene oxide to obtain a dispersion liquid of zinc oxide nanoparticles composite graphene oxide;

[0040] (2) Place the dispersion of zinc oxide nanoparticles and graphene oxide under a 24W ultraviolet lamp, and light it for 12 hours under electromagnetic stirring;

[0041] (3) Add 2.1ml of hyd...

Embodiment 2

[0048] In this embodiment, the graphene sheet structure having a compound pore structure is the same as that of the graphene sheet structure having a compound pore structure in Example 1.

[0049] The above-mentioned preparation method of graphene with composite pore structure is as follows:

[0050] (1) Ultrasonically mix 40ml of N-methylpyrrolidone phase dispersion containing 100mg graphene oxide with 200ml of N-methylpyrrolidone phase dispersion containing 25mg of zinc oxide nanoparticles (average particle size 4nm) Heating at 90°C for 5 hours, so that the zinc oxide nanoparticles are evenly dispersed on the surface of graphene oxide, and a dispersion liquid of zinc oxide nanoparticles composite graphene oxide is obtained;

[0051] (2) Place the dispersion of zinc oxide nanoparticles and graphene oxide under a 24W ultraviolet lamp, and light it for 35 hours under electromagnetic stirring;

[0052] (3) Add 10ml of hydrochloric acid with a mass fraction of 0.37% to the dispe...

Embodiment 3

[0059] In this embodiment, the graphene sheet structure having a compound pore structure is the same as that of the graphene sheet structure having a compound pore structure in Example 1.

[0060] The above-mentioned preparation method of graphene with composite pore structure is as follows:

[0061] (1) After ultrasonically mixing 40ml of N-methylpyrrolidone phase dispersion containing 100mg graphene oxide and 160ml of N-methylpyrrolidone phase dispersion containing 12.5mg of zinc oxide nanoparticles (average particle size 4nm), the Stirring and heating at 90° C. for 5 hours, so that the zinc oxide nanoparticles are uniformly dispersed on the surface of graphene oxide, and a dispersion liquid of zinc oxide nanoparticles composite graphene oxide is obtained;

[0062] (2) Place the dispersion of zinc oxide nanoparticles and graphene oxide under a 24W ultraviolet lamp, and light it for 35 hours under electromagnetic stirring;

[0063] (3) Add 10ml of hydrochloric acid with a ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com