Integrated complex ferrous wet flue gas desulfurization and denitration method

A wet desulfurization and flue gas purification technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as inability to meet economic needs, complex procedures, multiple spaces and materials, and achieve thorough dust removal and process Simple and effective to improve the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

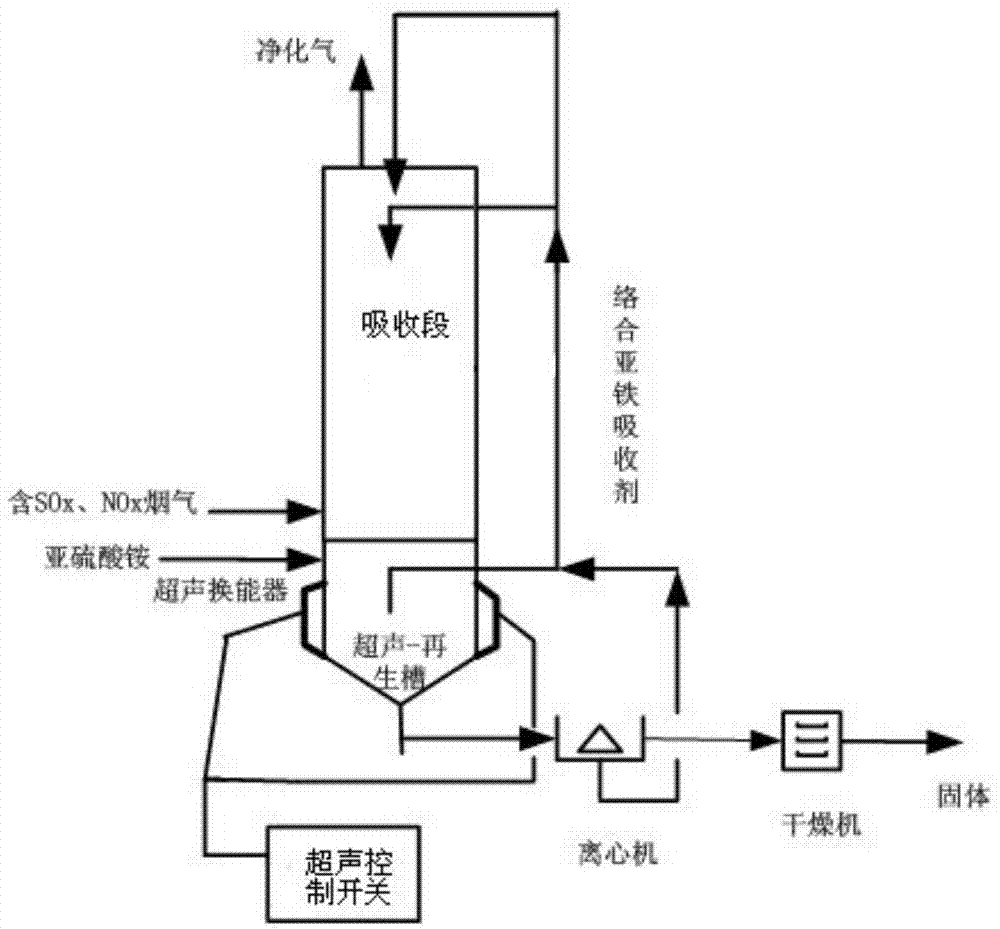

[0028] A method for the integration of complexed ferrous flue gas wet desulfurization and denitrification, such as figure 1 shown, including the following steps:

[0029] 1) Pass the flue gas containing sulfur oxides and nitrogen oxides at a temperature of 100°C into the bottom of the absorption section of the absorption device, and the SO in the flue gas 2 The concentration is 1200-1400ppmv, the NO concentration is 500-800ppmv, the oxygen concentration is 2% (volume fraction), and the flue gas is in countercurrent contact with the complexed ferrous absorbent solution that enters the absorption device at a temperature of 30°C in the absorption section. The complexed ferrous absorbent is sprayed downward from the upper end of the absorption section by atomization. The volume ratio of the flue gas to the complexed ferrous absorbent is 50:1. The absorbent is HEDTA-Fe solution with a pH of 5.5. Concentration 0.1mol / L;

[0030] 2) The flue gas is discharged from the top of the ab...

Embodiment 2

[0035] A method for the integration of complexed ferrous flue gas wet desulfurization and denitrification, such as figure 1 shown, including the following steps:

[0036] 1) Pass the flue gas containing sulfur oxides and nitrogen oxides at a temperature of 40°C into the bottom of the absorption section of the absorption device, and the SO in the flue gas 2 The concentration is 1400-2000ppmv, the NO concentration is 500-800ppmv, the oxygen volume fraction is 3%, and the flue gas is in countercurrent contact with the complexed ferrous absorbent solution that enters the absorption device at a temperature of 60°C in the absorption section. The ferrous absorbent is sprayed downward from the upper end of the absorption section by atomization. The volume ratio of the flue gas to the complexed ferrous absorbent is 700:1. The absorbent is EDTA-Fe solution with a pH of 7.5 and a total iron concentration of 0.5. mol / L;

[0037] 2) The flue gas is discharged from the top of the absorpti...

Embodiment 3

[0042] A method for the integration of complexed ferrous flue gas wet desulfurization and denitrification, such as figure 1 shown, including the following steps:

[0043] 1) Pass the flue gas containing sulfur oxides and nitrogen oxides at a temperature of 50°C into the bottom of the absorption section of the absorption device, and the SO in the flue gas 2 The concentration is 1600-2400ppmv, the NO concentration is 500-800ppmv, the oxygen volume fraction is 5%, and the flue gas is in countercurrent contact with the complexed ferrous absorbent which enters the absorption device at a temperature of 35°C in the absorption section. The iron absorbent is sprayed downward from the upper end of the absorption section by atomization. The volume ratio of flue gas to complexed ferrous absorbent is 200:1. The absorbent is NTA-Fe solution with a pH of 6 and the total iron concentration is 0.3mol. / L;

[0044] 2) The flue gas is discharged from the top of the absorption device after bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com