A kind of electrode film and preparation method thereof

An electrode film and chemical method technology, applied in the field of electrode film and its preparation, can solve the problems of limiting the high current discharge performance of aluminum-air batteries, slow catalytic oxygen reduction reaction rate, poor battery high current discharge effect, etc., and achieve light weight. , low cost, stable discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] A method for preparing an electrode film, comprising:

[0064] Catalyst layer preparation steps: in Na 2 SO 4 Add anhydrous ethanol, carbon carrier and catalyst to the solution in turn, mix evenly and add PTFE dropwise, after the dropwise addition, ultrasonically disperse, continue stirring to obtain the catalytic layer solution; the molar concentration of the catalyst in the catalytic layer solution is 0.001-0.02mol / L: heating the catalytic layer solution in a water bath for demulsification, and suction filtration to obtain a catalytic layer paste; rolling the catalytic layer paste to obtain a catalytic layer;

[0065] With Ag + concentration increases, the Ag + When it is reduced, the concentration of silver generated is large, and it is easy to agglomerate. After agglomeration, the uniform dispersion of the generated silver on the carbon carrier is reduced, its specific surface area is reduced, the formation of effective three-phase reaction interface is also red...

Embodiment 1-3

[0072] The electrode film of embodiment 1-3 is prepared by the following method:

[0073] 1. Preparation of catalyst:

[0074] MnO 2 The preparation method of -Ag / C is: prepare the raw material according to the number of moles in Table 1, and then weigh the AgNO 3 and AgNO 3 2 times the weight of polyvinylpyrrolidone (PVP), mixed and dissolved in deionized water to prepare AgNO 3 A solution with a concentration of 0.01mol / L; then add activated carbon and stir well, add 0.1mol / L NaBH 4 solution, to NaBH 4 in solution with AgNO 3 Equal molar numbers, keep stirring and fully react, filter, wash, take the solid and place it in a vacuum at 40°C to dry to obtain a 40%wt Ag / C solution;

[0075] MnO 2 Co-grinding with Ag / C solution for 1h, ultrasonic oscillation for 10min, to obtain MnO 2 -Ag / C.

[0076] The composition mole number (mol) of catalyst among the table 1 embodiment 1-3

[0077] Element Example 1 Example 2 Example 3 MnO 2

0.012 0.013 ...

Embodiment 1-3

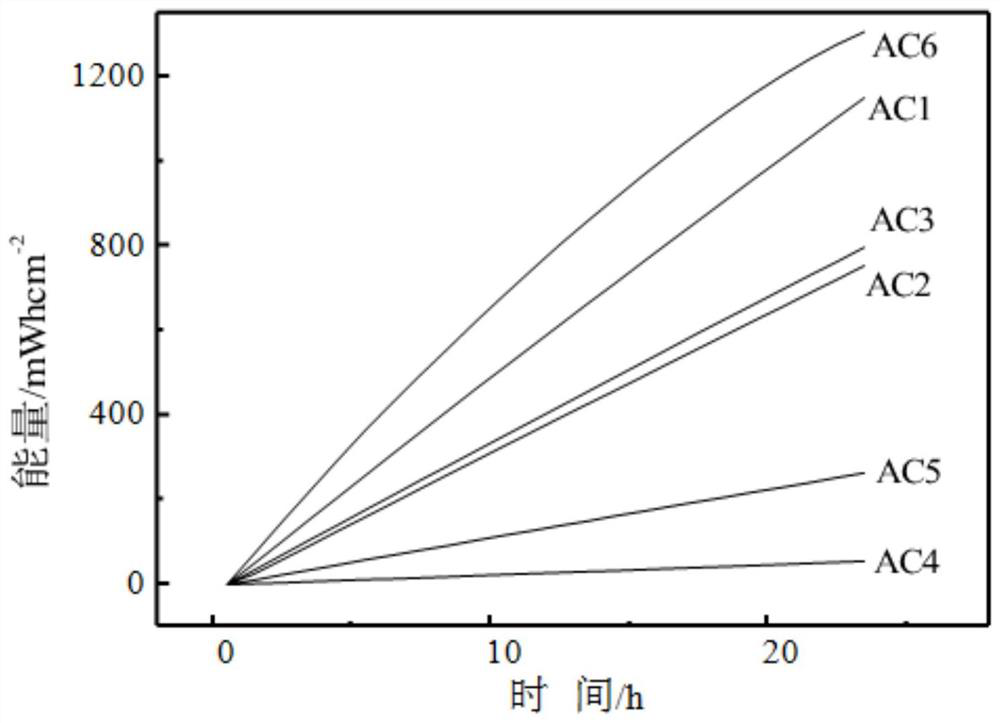

[0099] Embodiment 1-3 is detected:

[0100] Electrode film detection methods mainly include:

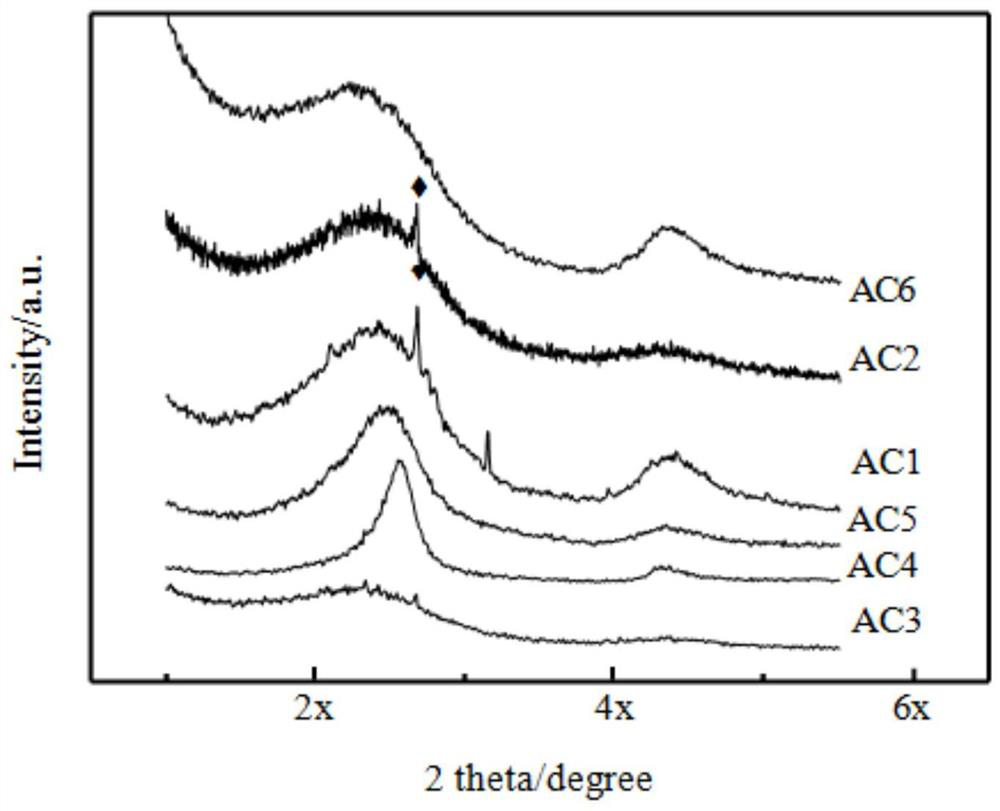

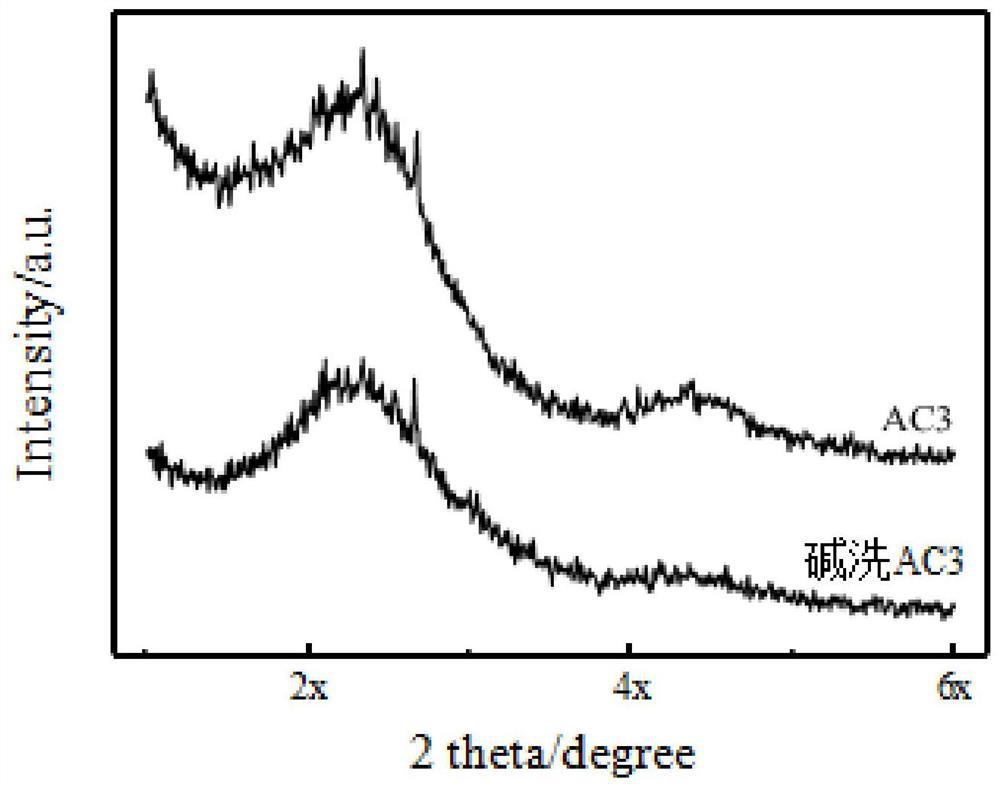

[0101] 1) XRD physical characterization:

[0102] X-ray diffraction test (XRD) is X-ray diffraction of materials, which will produce a discontinuous scattering image. A series of diffraction peaks of different intensities appear at different diffraction angles. The position, intensity and shape of the peaks can be analyzed. Parameters such as material phase composition, lattice constant, crystallinity and grain size were obtained.

[0103] After the sample is carefully ground, the tablet is tested in an X-ray diffractometer; CuKα target, graphite monochromator, scanning speed: 9° / min, scanning angle range: 10°-80°, sampling interval: 0.03°.

[0104] 2) Potentiodynamic polarization curve test:

[0105] Determining the relationship curve between electrode potential and current density is the basic method to study electrochemical kinetics, and these curves are called polarization cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com