A method for microwave-assisted extraction of metal minerals

A metal mineral and microwave-assisted technology, which is applied in the direction of improving process efficiency and reducing gas emissions, can solve the problems of long reduction and leaching time, cumbersome operation process, and high input cost, and achieve short reduction and leaching time and convenient operation , The effect of low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

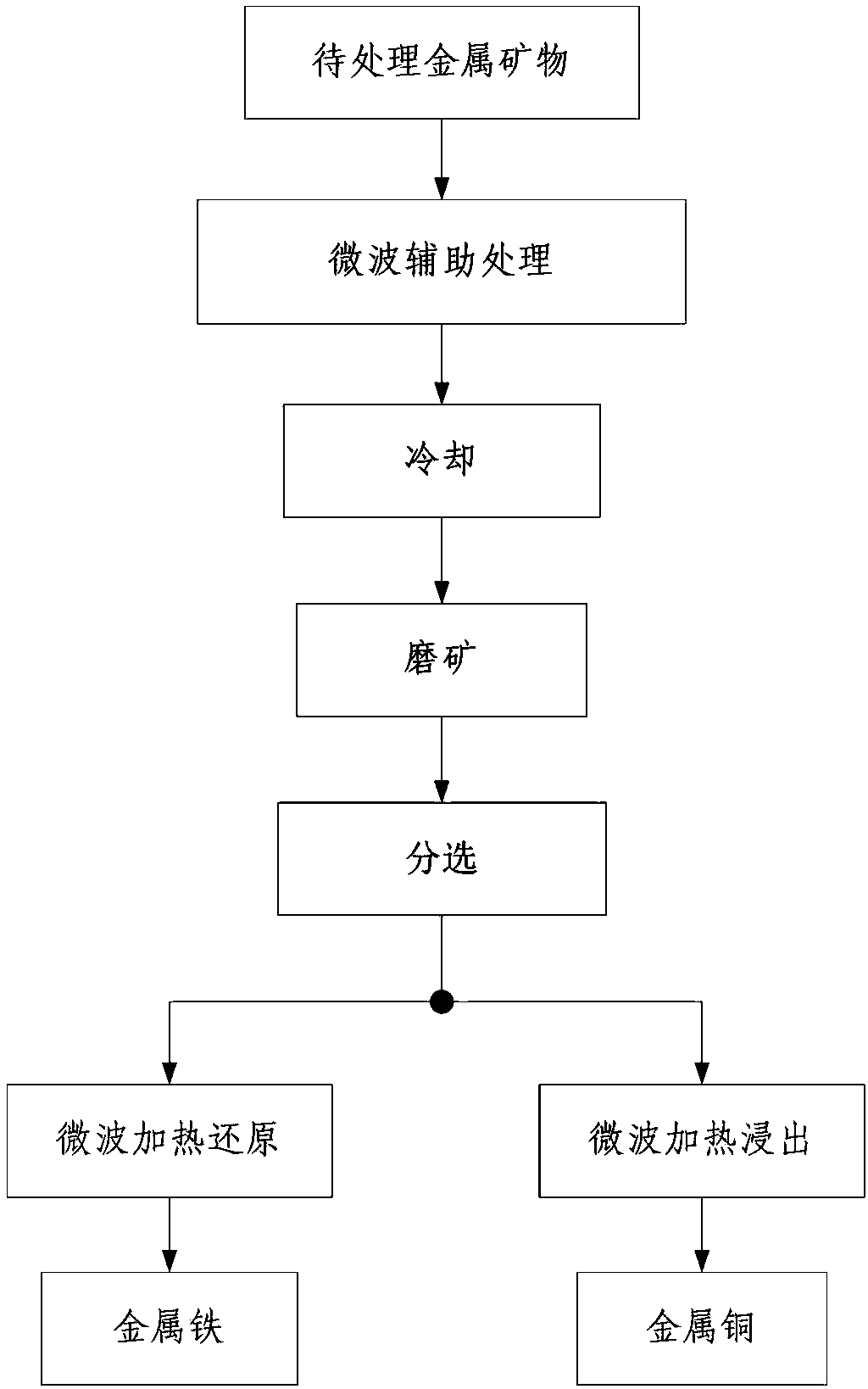

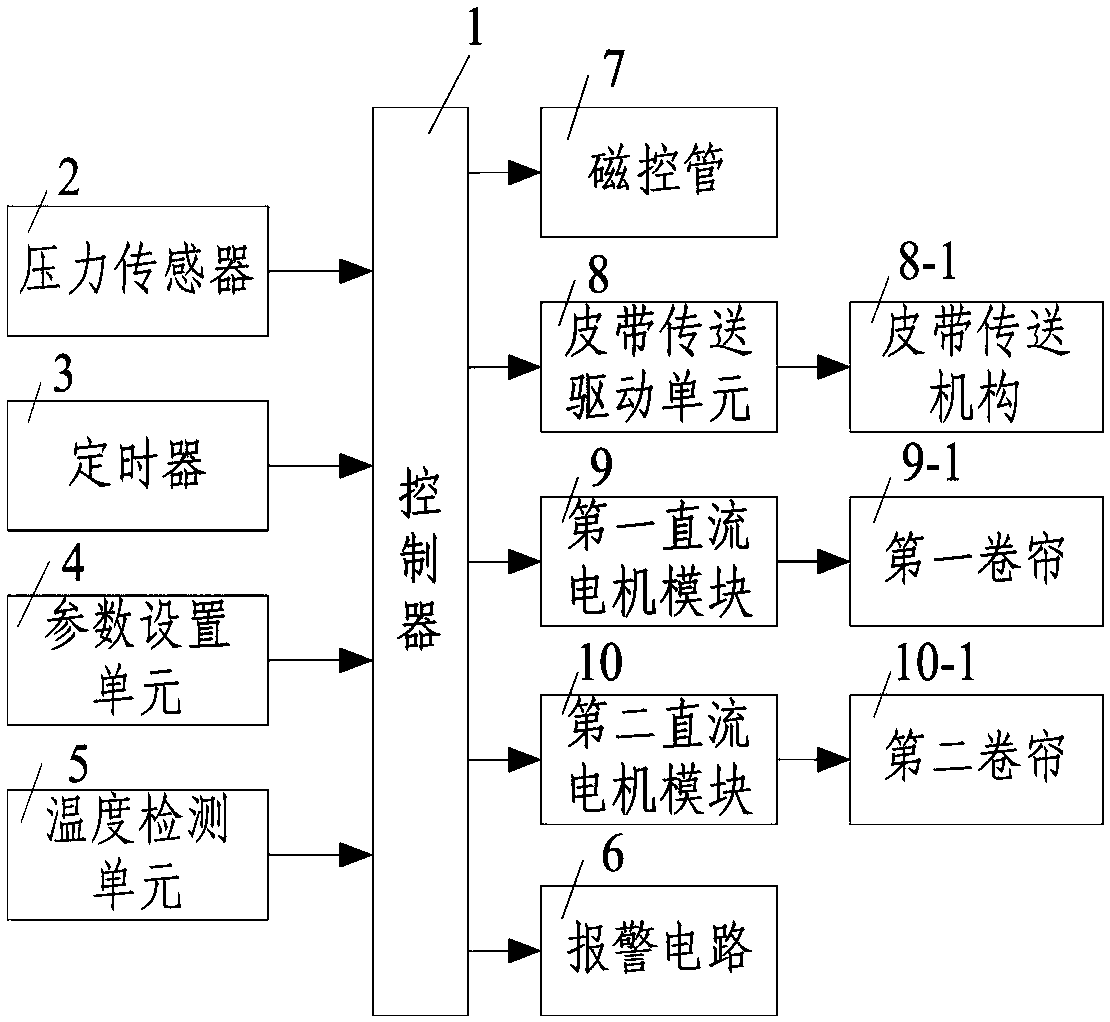

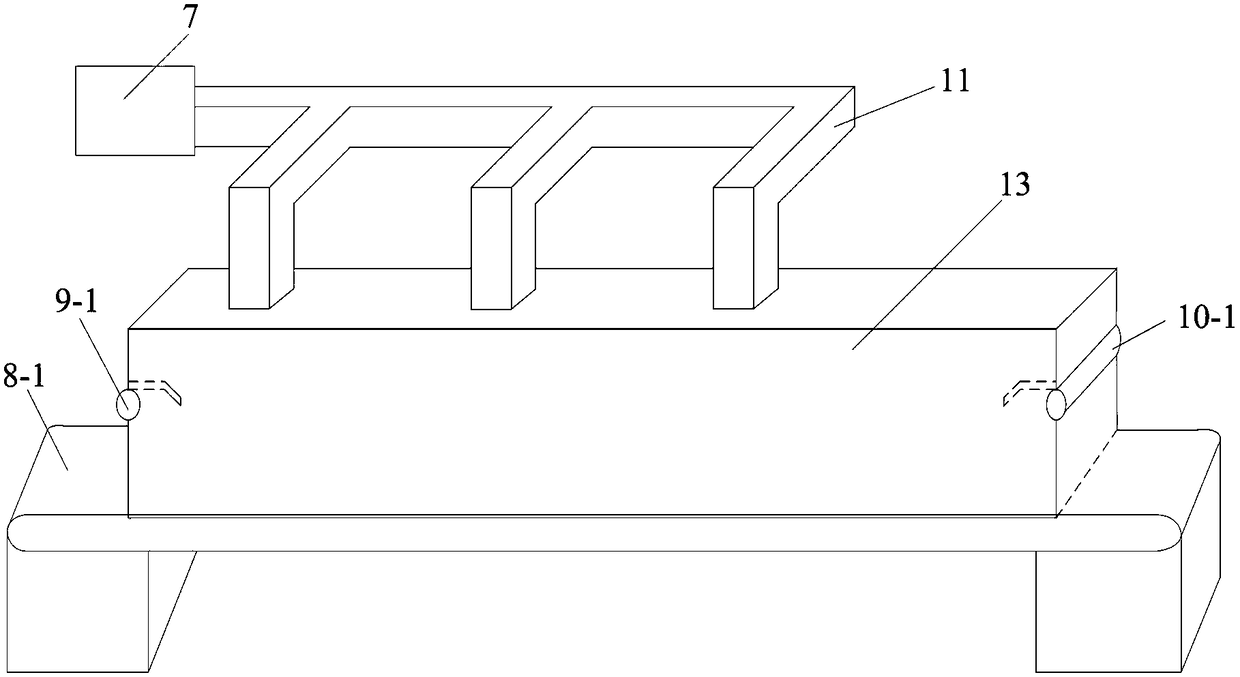

[0044] Such as figure 1 , figure 2 with image 3 As shown, this embodiment includes the following steps:

[0045] Step 1. Microwave-assisted treatment: put the magnetite on the belt transmission mechanism 8-1, the controller 1 drives the belt transmission mechanism 8-1 to rotate through the belt transmission drive unit 8, and transports the magnetite to the microwave processing device for further processing. Microwave assisted processing. Using microwaves to radiate magnetite, the temperature rise rate of useful minerals in magnetite is greater than that of gangue minerals in magnetite, including quartz and calcite, so useful minerals in magnetite absorb microwave energy and heat at a higher temperature, while magnetite Gangue minerals in iron ore absorb less microwave energy and lower temperature, so that a local temperature difference is formed between useful minerals and gangue minerals, resulting in cracks between useful minerals and gangue minerals, increasing the mon...

Embodiment 2

[0063] In this example, the difference from Example 1 is that the heating time of the microwave-assisted treatment in step 1 is 18 minutes, and the microwave power is 8 kW. In step 5, the magnetite powder to be processed is 2.8 kg, the temperature for microwave heating and reduction is 1100° C., and the time for microwave heating and reduction is 55 minutes. In this embodiment, the remaining steps and process parameters are the same as in Embodiment 1.

[0064] The properties of extracting metallic iron from the magnetite in this example by the traditional method and the present method are shown in Table 2.

[0065] Table 2

[0066]

[0067] As can be seen from Table 2, utilizing the traditional method, the reduction time is 85min, and the reduction rate is 88.7%, and the reduction time utilizing the embodiment of the present invention 2 to extract metallic iron from the magnetite powder is 55min (30min less than the traditional method time) , and the reduction rate of meta...

Embodiment 3

[0069] In this example, the difference from Example 1 is that the heating time of the microwave-assisted treatment in step 1 is 25 minutes, and the microwave power is 10 kW. In step 5, the magnetite powder to be processed is 3.2 kg, the temperature for microwave heating and reduction is 1180° C., and the time for microwave heating and reduction is 60 minutes. In this embodiment, the remaining steps and process parameters are the same as in Embodiment 1.

[0070] The performances of extracting metallic iron from the magnetite of this example by the traditional method and the present method are shown in Table 3.

[0071] table 3

[0072]

[0073]

[0074] As can be seen from Table 3, utilizing the traditional method, the reduction time is 95min, and the reduction rate is 88.6%, and the reduction time utilizing the embodiment of the present invention 3 to extract metallic iron from the magnetite powder is 60min (35min less than the traditional method time) , and the reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com