A kind of preparation method of molybdenum dioxide

A technology of molybdenum dioxide and molybdenum trioxide, which is applied in the field of powder metallurgy, can solve the problems of high danger and potential safety hazards, and achieve the effects of reducing production costs, high safety, and saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

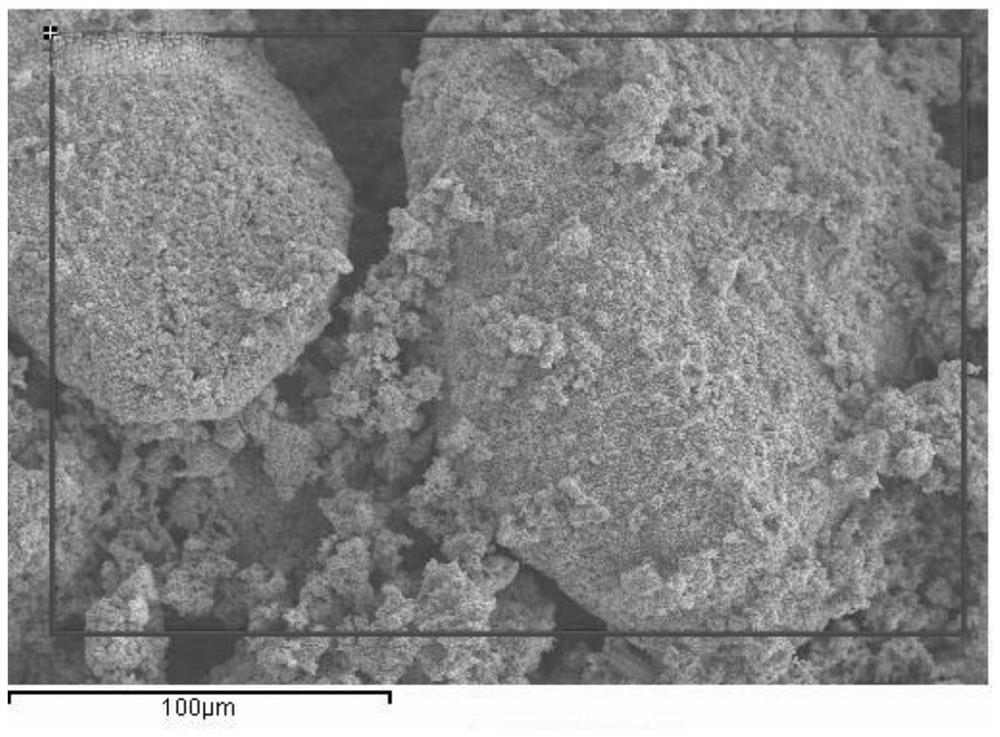

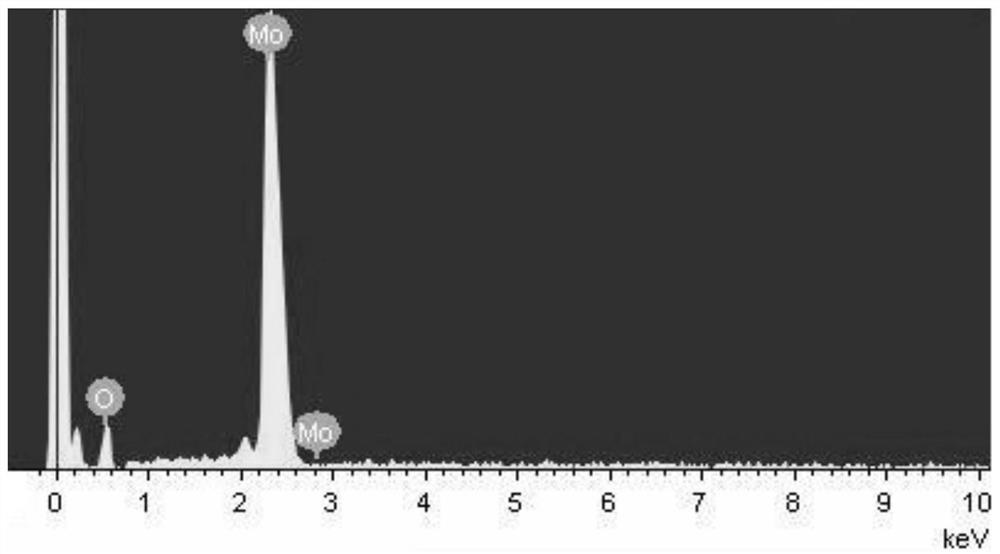

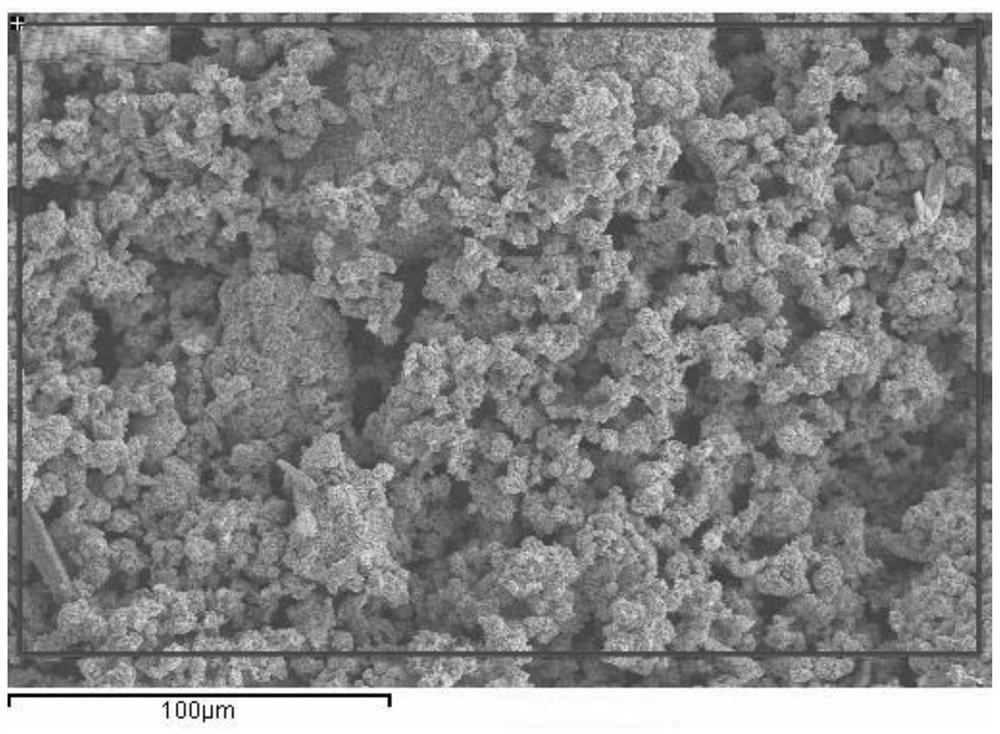

Image

Examples

Embodiment 1

[0030] The method of the present embodiment comprises the following steps:

[0031] Step 1. Fully mix 3.01g of molybdenum trioxide and 1g of molybdenum powder and grind them evenly to obtain a mixed powder; the particle size of the molybdenum powder is 0.4 μm;

[0032] Step 2. Put the mixed powder obtained in step 1 into the high temperature resistant boat of the reaction tube, then evacuate to a vacuum degree of 0.8 MPa in the reaction tube, and then pass in argon gas to replace the gas in the reaction tube and fill the reaction tube The diameter of the reaction tube is 50 mm, and the length is 1000 mm; the thickness of the mixed powder loaded into the high temperature boat is 5 mm, and the replacement time of the gas in the argon replacement reaction tube is 10 min;

[0033] Step 3. Heat the mixed powder in the high-temperature resistant boat mentioned in step 2 to 600°C for 2 hours and continue to feed argon gas. After the heating reaction is completed, brown molybdenum dio...

Embodiment 2

[0040] The method of the present embodiment comprises the following steps:

[0041] Step 1, fully mixing 3.05g of molybdenum trioxide and 1g of molybdenum powder and grinding them evenly to obtain a mixed powder; the particle size of the molybdenum powder is 0.7 μm;

[0042] Step 2. Put the mixed powder obtained in step 1 into the high-temperature-resistant boat of the reaction tube, then evacuate until the vacuum degree in the reaction tube is 0.85MPa, and then pass in argon gas to replace the gas in the reaction tube and fill the reaction tube. The diameter of the reaction tube is 56mm, and the length is 1100mm; the thickness of the mixed powder loaded into the high temperature boat is 7mm, and the replacement time of the gas in the argon replacement reaction tube is 15min;

[0043] Step 3. Heat the mixed powder in the high temperature resistant boat described in step 2 to 630°C for 3 hours and continue to feed argon gas. After the heating reaction is completed, brown molybd...

Embodiment 3

[0050] The method of the present embodiment comprises the following steps:

[0051] Step 1, fully mixing 3.1g of molybdenum trioxide and 1g of molybdenum powder and grinding them evenly to obtain a mixed powder; the particle size of the molybdenum powder is 1 μm;

[0052] Step 2. Put the mixed powder obtained in step 1 into the high-temperature-resistant boat of the reaction tube, then evacuate until the vacuum degree in the reaction tube is 0.9MPa, and then pass in argon gas to replace the gas in the reaction tube and fill the reaction tube. The diameter of the reaction tube is 60mm, and the length is 1200mm; the thickness of the mixed powder loaded into the high temperature boat is 10mm, and the replacement time of the gas in the argon replacement reaction tube is 20min;

[0053] Step 3. Heat the mixed powder in the high-temperature resistant boat mentioned in step 2 to 650°C for 4 hours and continue to feed argon gas. After the heating reaction is completed, tan molybdenum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com