Two-stage fuel reactor structure and technological process

A technology of fuel reactor and process flow, which is applied in the direction of granular/powdered fuel gasification, petroleum industry, and manufacture of combustible gas, etc. Problems such as residence time can be solved to achieve the effect of increasing the concentration and increasing the reduction reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

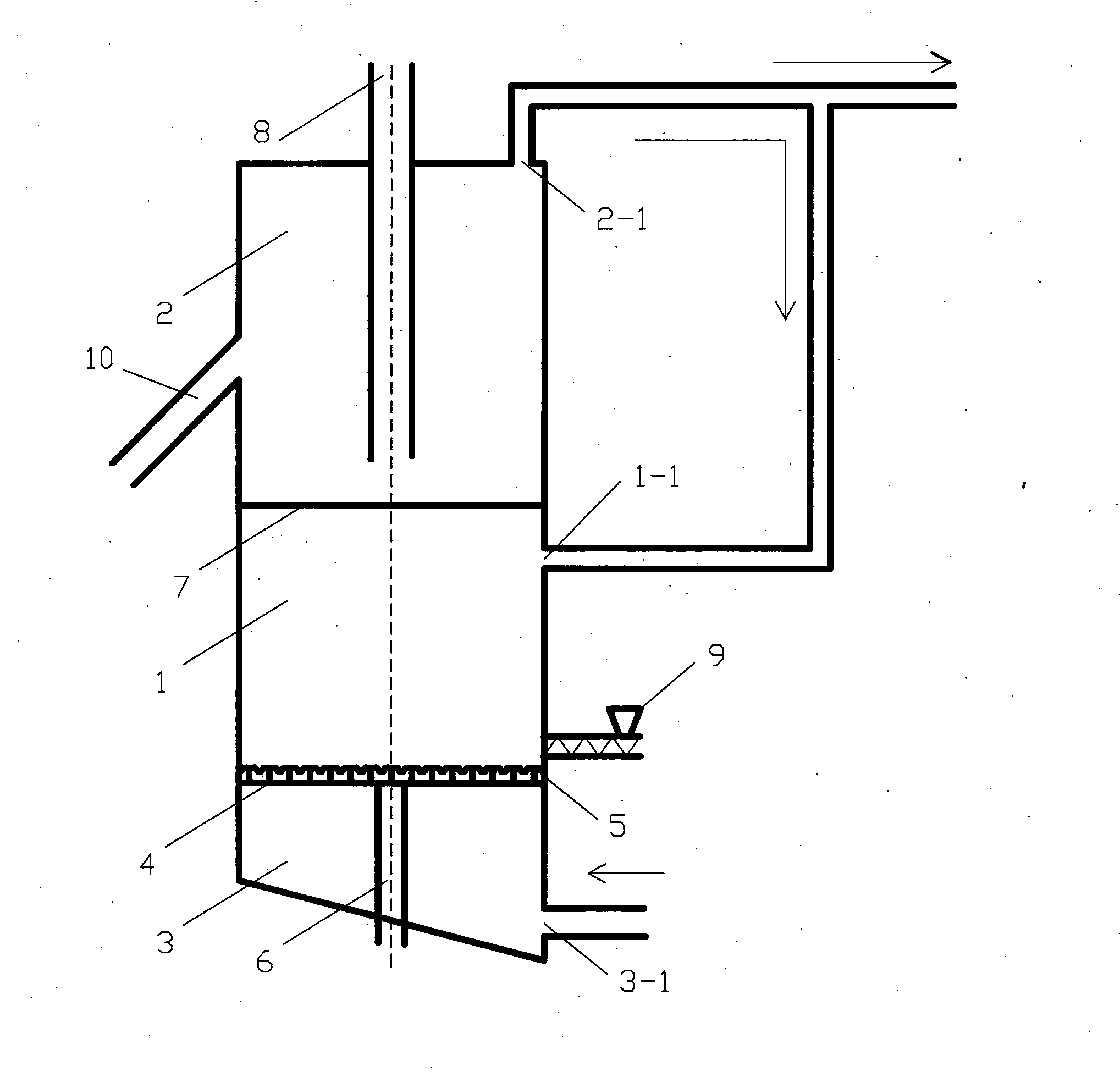

[0019] figure 1 Schematic diagram of the structure of the two-stage fuel reactor provided by the present invention, the structure of the two-stage fuel reactor consists of a gasification zone 1, a reduction zone 2, an air chamber 3, an air distribution plate 4, an air cap 5, and a slag discharge pipe 6 , grid net 7, feed pipe 8, screw feeder 9 and discharge pipe 10.

[0020] The internal space of the fuel reactor is divided into a lower gasification zone 1 and an upper reduction zone 2 by using a grid 7; an exhaust pipe is arranged at the upper end 2-1 of the reduction zone 2 to lead out the generated flue gas, and the exhaust pipe is provided with a tee. One of them is led back to the gasification zone gas inlet 1-1 as part of the gas supply to the reduction zone, and the other part is purified and condensed to obtain high-purit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com