Vulcanized modification method for Ni-Fe LDH electrode material

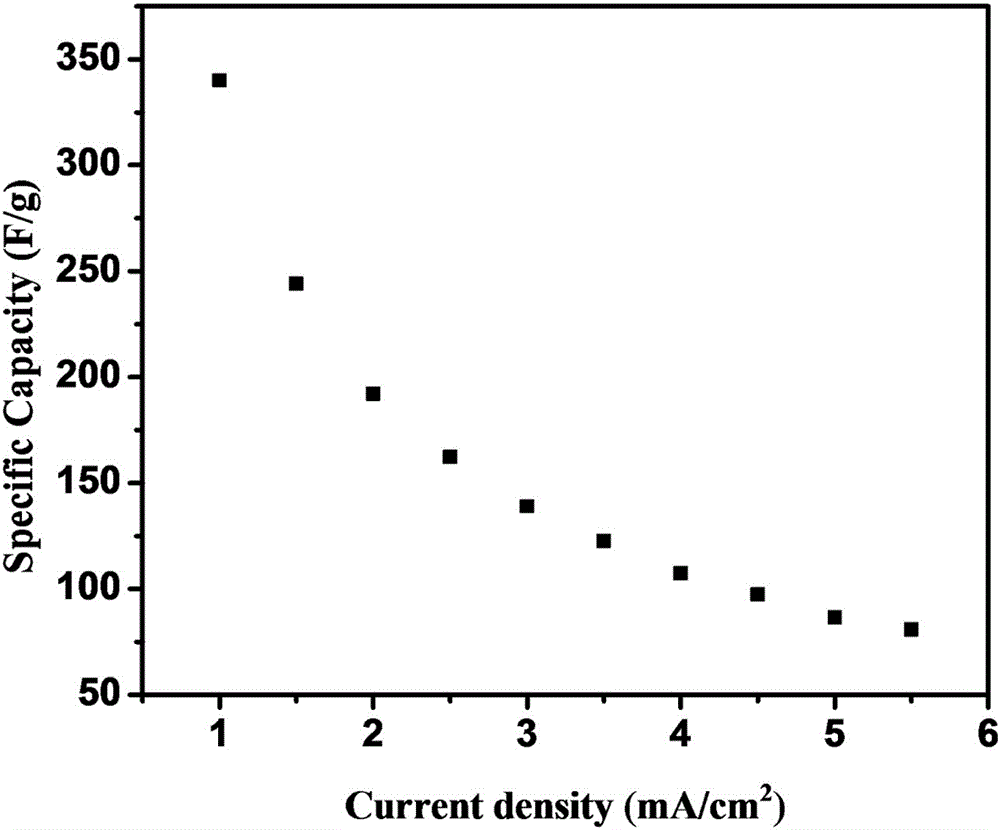

An electrode material and modification technology, applied in the field of vulcanization modification of Ni-FeLDH electrode materials, can solve the problem of low capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The concrete preparation method step of the present invention to Ni-Fe LDH vulcanization modification:

[0019] (1) Weigh ferrous chloride and nickel nitrate respectively according to the molar ratio of 1:1, and dissolve them in a mixed solvent of deionized water and ethylene glycol with a volume ratio of 2:3. A clear solution was obtained. Under magnetic stirring, add 10 times the urea of nickel nitrate molar weight, under magnetic stirring, it is dissolved in ethylene glycol, in the mixed solution of ferrous chloride and nickel nitrate;

[0020] (2) Put the solution obtained in step (1) into a 50ml polytetrafluoroethylene lining, then put the nickel mesh into the polytetrafluoroethylene lining, then put the lining into a stainless steel hydrothermal kettle, seal it and put it Put it into a constant temperature drying oven at 85°C, and heat it at a constant temperature for 6h;

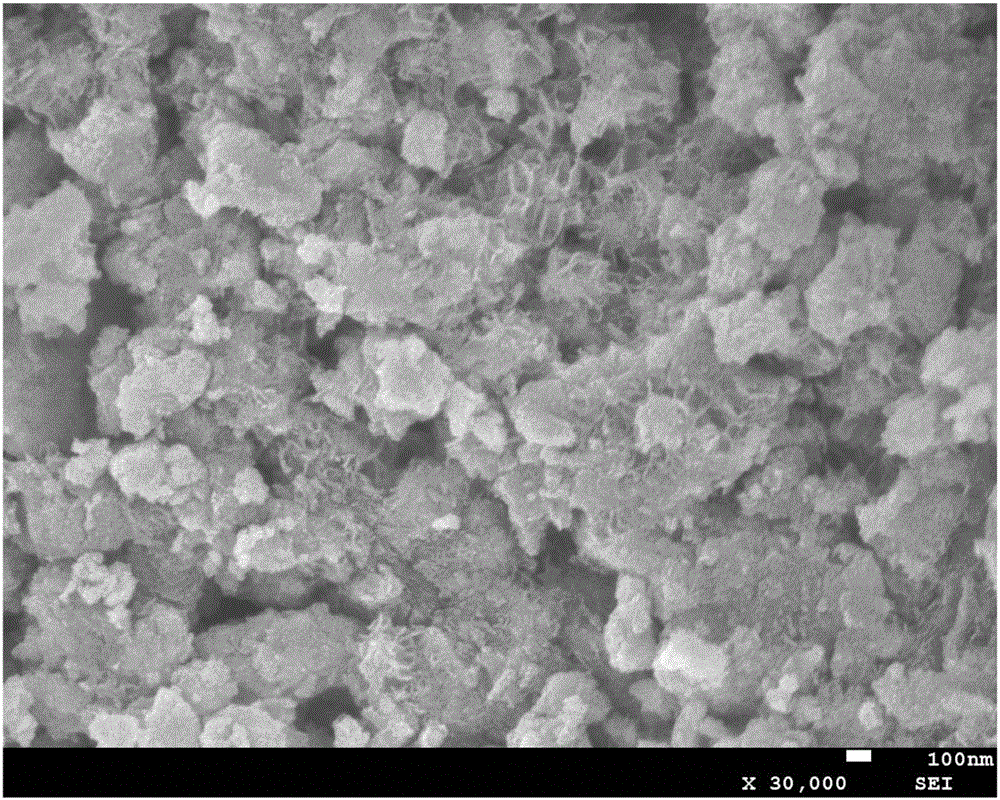

[0021] (3) Take out the nickel mesh, rinse the surface of the nickel mesh repeatedly wi...

Embodiment 1

[0028] Step 1: Dissolve 1mmol of ferric chloride and 1mmol of nickel nitrate into a mixed solvent of 20mL of deionized water and ethylene glycol (V / V=2 / 3) at the same time, and obtain a transparent solution under the action of ultrasound. Then, under magnetic stirring, add 10mmoL of urea into the solution, and after it is completely dissolved, pour the solution into a 50mL polytetrafluoroethylene liner, put the nickel mesh into the polytetrafluoroethylene liner containing the solution, Seal it with a stainless steel jacket, put it in a constant temperature drying oven at 85°C, and keep it warm for 6 hours. After the reaction kettle drops to room temperature, take out the nickel mesh, rinse the surface of the nickel mesh repeatedly with deionized water, and dry it under natural conditions.

[0029] Step 2: Add 0.5mmol thiourea to 50mL ethylene glycol, stir until fully dissolved, then pour the prepared solution into the reactor, put the sample from the previous step into the reac...

Embodiment 2

[0032] Compared with Example 1, except that the temperature (160° C.) in the second step is different, the others are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com