Mineral powder reduction system

A mineral powder and original segment technology, applied in the field of mineral powder reduction system, can solve problems such as hindering normal operation, energy consumption, water consumption, and low reduction speed, so as to improve utilization rate and system heat utilization rate, and reduce energy consumption and operating costs, and the effect of accelerating the reduction reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

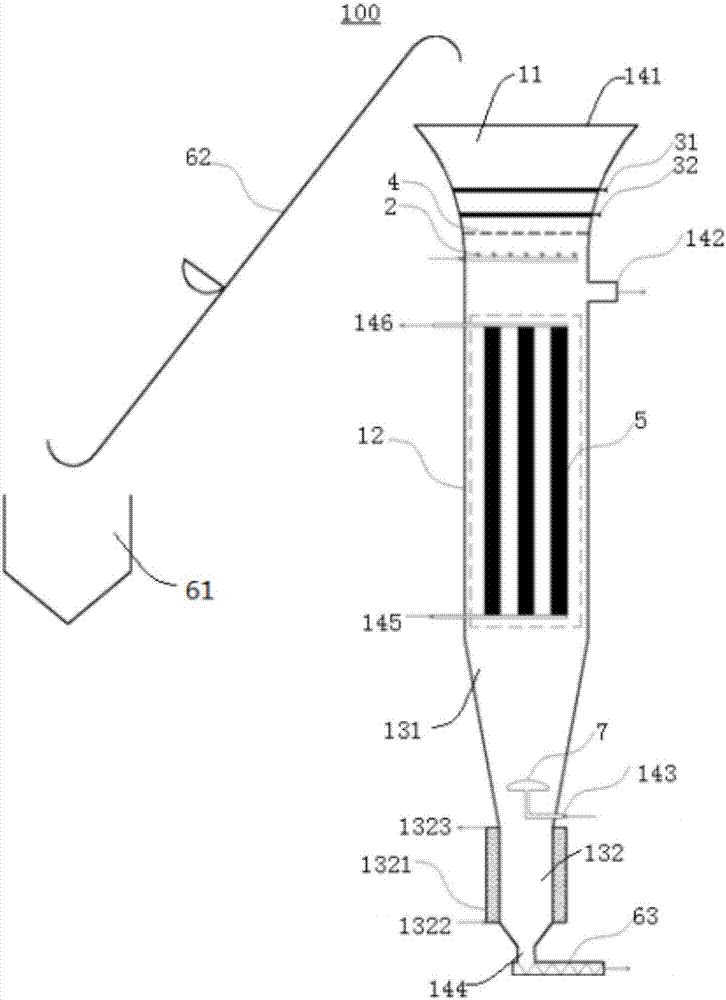

Embodiment 1

[0086] Material: Iron grade of iron ore concentrate is 65%, and the proportion of iron ore powder particle size less than 0.074mm is not less than 80%;

[0087] The volume fraction of CO in the reducing gas is 80%, and the volume fraction of H2 is 15%.

[0088] Reaction conditions: The temperature of the radiation tube in the reaction zone of the iron ore powder regenerative rapid reduction device is set at 950°C.

[0089] Steps in the restore method:

[0090] Iron ore concentrate is added to reactor 1 from feed port 141;

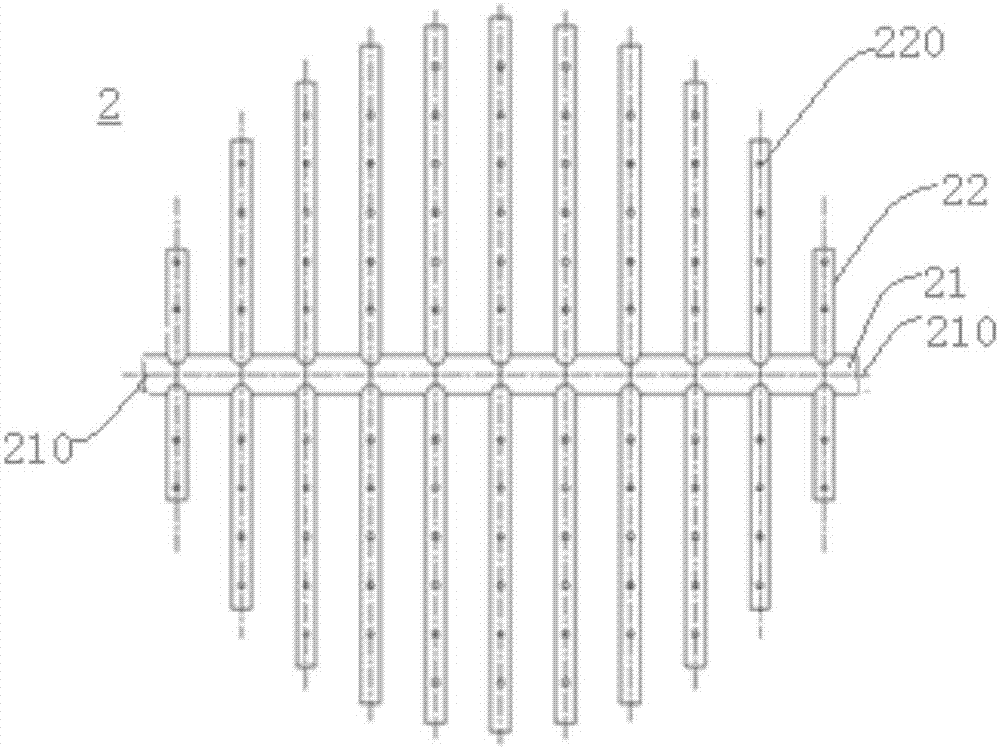

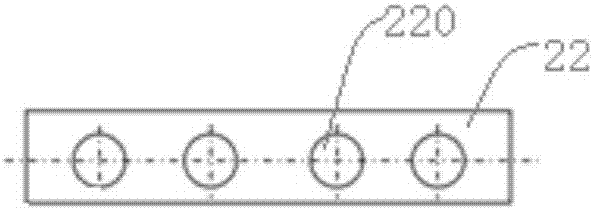

[0091] Pass the inert gas into the gas distributor 2;

[0092] The normal temperature reducing gas is introduced from the bottom of the iron ore powder regenerative rapid reduction device, and the reduction reaction is carried out with the iron concentrate;

[0093] The reducing gas is heated by the regenerative radiant tube 5 during the ascent process, exchanges heat with the falling iron ore powder and undergoes a reduction reaction, and the reduction ...

Embodiment 2

[0097] Material: the iron grade of the iron concentrate is 65%, the proportion of ore powder particles with a particle size of less than 1 mm is not less than 80%; the volume fraction of CO in the reducing gas is 60%, and the volume fraction of H2 is 30%;

[0098] Reaction conditions: The temperature of the radiation tube in the reaction zone of the iron ore powder regenerative rapid reduction device is set at 950°C.

[0099] Steps in the restore method:

[0100] Iron ore concentrate is added to reactor 1 from feed port 141;

[0101] Pass the inert gas into the gas distributor 2;

[0102] The normal temperature reducing gas is introduced from the bottom of the iron ore powder regenerative rapid reduction device, and the reduction reaction is carried out with the iron concentrate;

[0103] The reducing gas is heated by the regenerative radiant tube 5 during the ascent process, exchanges heat with the falling iron ore powder and undergoes a reduction reaction, and the reductio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com