Modified carbon brush electrode and preparation method thereof

A modified carbon and carbon brush technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve problems such as low output power and limit practical applications, and achieve increased output power, improved electron transfer efficiency, and improved cathode oxygen reduction reaction speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

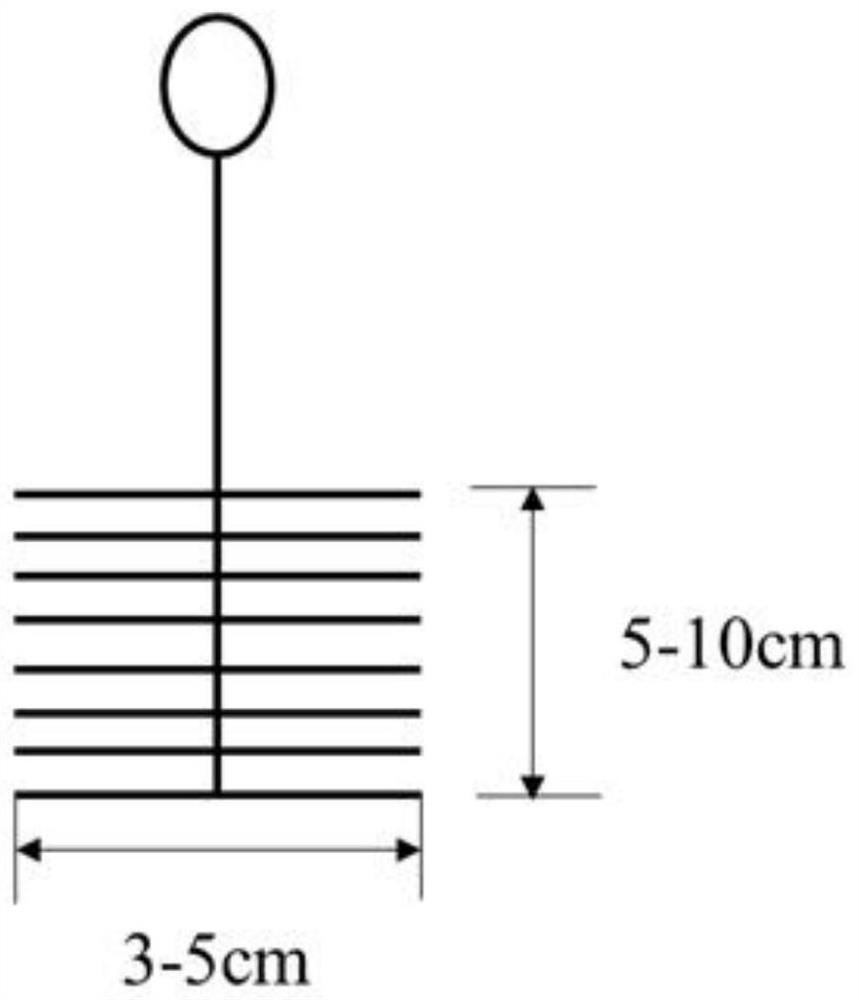

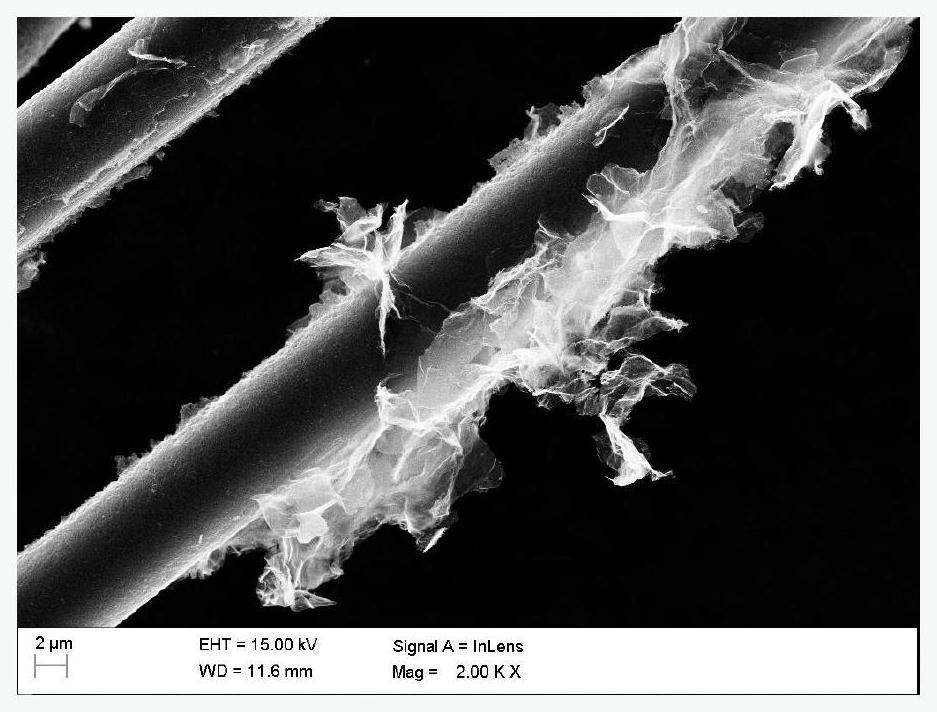

[0029] The process of the preparation method of the conductive polymer modified carbon fiber brush anode involved in this embodiment includes three steps of carbon brush acid treatment, iron oxide modified carbon brush, and conductive polymer film modified carbon brush:

[0030] (1) Carbon brush acid treatment: Soak the carbon fiber in a mixed acid with a volume ratio of concentrated sulfuric acid and concentrated nitric acid of 1:3, and treat it in a water bath at a temperature of 80°C for 2-4 hours to obtain a surface modified with oxygen-containing functional groups. Carbon brush

[0031] (2) Iron oxide modified carbon brush: The carbon brush obtained in step (1) is soaked in a mixed aqueous solution of ferric nitrate and sodium sulfate in a weight ratio of 1:1 for 2-4 hours to form Fe on the surface of the carbon brush. 3+ Transfer the carbon brush and the mixed aqueous solution to the reactor, react for 1-4h at a temperature of 120℃, take it out after natural cooling, clean it ...

Embodiment 2

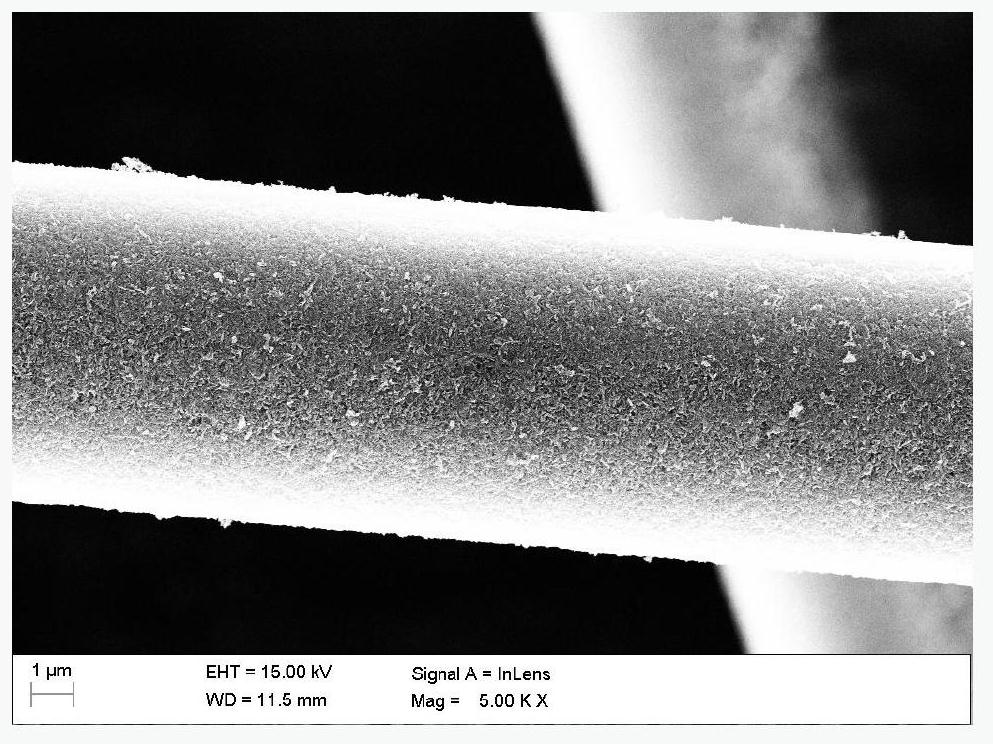

[0034] The process of the preparation method of the graphene oxide / conductive polymer modified carbon fiber brush anode involved in this embodiment includes carbon brush acid treatment, iron oxide modified carbon brush, preparation of graphene oxide aqueous solution and graphene oxide / conductive polymer film modification There are four steps in carbon brushing:

[0035] (1) Carbon brush acid treatment: Soak the carbon fiber in a mixed acid with a volume ratio of 1:3 concentrated sulfuric acid and concentrated nitric acid, and treat it in a water bath at a temperature of 80°C for 2-4 hours to obtain a modified surface with oxygen-containing functional groups. Carbon brushes;

[0036] (2) Iron oxide modified carbon brush: The carbon brush obtained in step (1) is soaked in a mixed aqueous solution of ferric nitrate and sodium sulfate at a mass ratio of 1:1 for 2-4 hours to form Fe on the surface of the carbon brush. 3+ Transfer the carbon brush and the mixed aqueous solution to the re...

Embodiment 3

[0040] The process of the preparation method of in-situ growth of nitrogen-doped oxygen reduction reaction catalyst modified carbon brush cathode involved in this embodiment includes carbon brush acid treatment, iron oxide modified carbon brush, conductive polymer film modified carbon brush, and high-temperature carbonization modification There are four steps in carbon brushing:

[0041] (1) Carbon brush acid treatment: Soak the carbon fiber in a mixed acid with a volume ratio of 1:3 concentrated sulfuric acid and concentrated nitric acid, and treat it in a water bath at a temperature of 80°C for 2-4 hours to obtain a modified surface with oxygen-containing functional groups. Carbon brushes;

[0042] (2) Iron oxide modified carbon brush: The carbon brush obtained in step (1) is immersed in a mixed aqueous solution of ferric nitrate and sodium sulfate in a weight ratio of 1:1 for 2-4 hours to form Fe on the surface of the carbon brush. 3+ Transfer the carbon brush and the mixed aque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com