Polymeric ferric sulfate water treatment agent and preparation method thereof

A technology for polymerizing sulfuric acid and treating chemicals, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc. It can solve the problem of high cost of using chemicals, and achieve the effects of protecting personnel and equipment safety, production safety, and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation steps of polyferric sulfate water treatment agent:

[0042] (1) Configure 1m 3 For the acidic aqueous solution of ferrous salt, the mass ratio of ferrous sulfate and sulfuric acid is controlled to be 1:0.45, and the mass fraction of ferrous sulfate to be configured is 20% ferrous salt aqueous solution (using 457.2kg of ferrous sulfate heptahydrate, 93% sulfuric acid 78.0kg).

[0043] (2) Pump the configured ferrous salt solution into the reaction tank.

[0044] (3) Introduce ozone-containing gas to make ozone and ferrous react in the reaction tank. Ozone gas comes from an ozone machine with a ventilation volume of 600Nm 3 / h, the ozone concentration is 90g / m 3 .

[0045] (4) After 0.5h and 1h of reaction, take samples and analyze them respectively. When the characteristics of the samples meet the production index, stop the ventilation, draw out the product, and end a round of reaction.

[0046] After 0.5h of reaction, 71% of ferrous ions were conve...

Embodiment 2

[0048] The differences between this implementation and Example 1 are:

[0049] Ferrous sulfate solution with a mass fraction of 15% is used as the ozone absorbing liquid, and the ventilation volume is 600Nm 3 / h, the ozone concentration is 80g / m 3 . After 1 h of reaction, all ferrous ions were converted into ferric ions. After the solution absorbs ozone gas, the concentration of ozone in the tail gas is 0.2mg / m 3 .

Embodiment 3

[0051] The differences between this implementation and Example 1 are:

[0052] Use ferrous sulfate solution with a mass fraction of 10% as the ozone absorbing liquid, and the air flow is 500Nm 3 / h, the ozone concentration is 60g / m 3 . After 1 h of reaction, all ferrous ions were converted into ferric ions. After the solution absorbs ozone gas, the concentration of ozone in the tail gas is 0.2mg / m 3 .

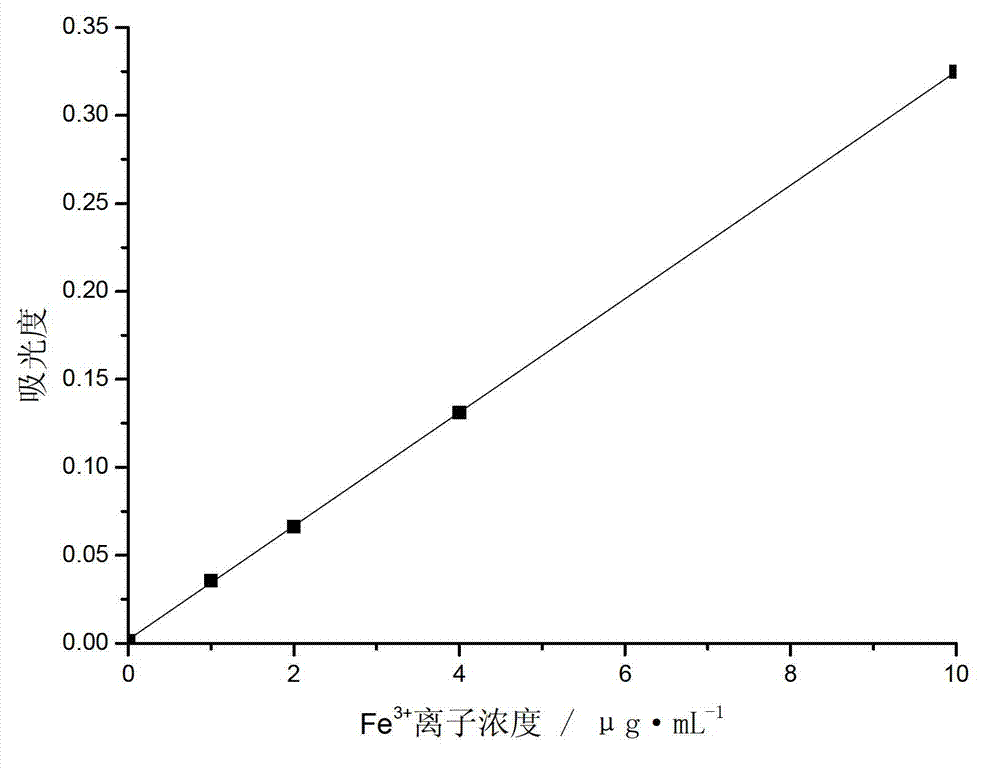

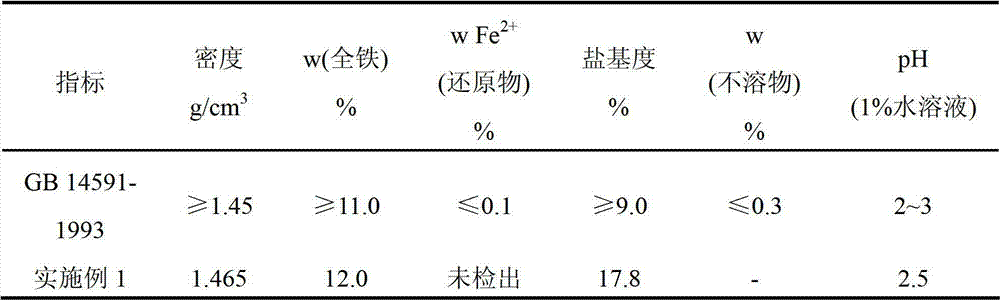

[0053] The polyferric sulfate prepared in Example 1 was compared with the commercially available product in terms of water treatment performance.

[0054] Each 10g sample was dissolved in 100ml water to make polyferric solution. Add the solution into landfill leachate with V=250mL, pH=5, COD 710mg / L, chroma 3000 times, and the concentration of polyiron in the leachate is 900mg / L. Stir at 200r / min for 3min, 60r / min for 10min, then let stand for 30min, take the supernatant to measure COD and chromaticity. The polyferric sulfate that this embodiment makes and commercially ava...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com