Fe/Mn composite oxide, preparation method and application thereof

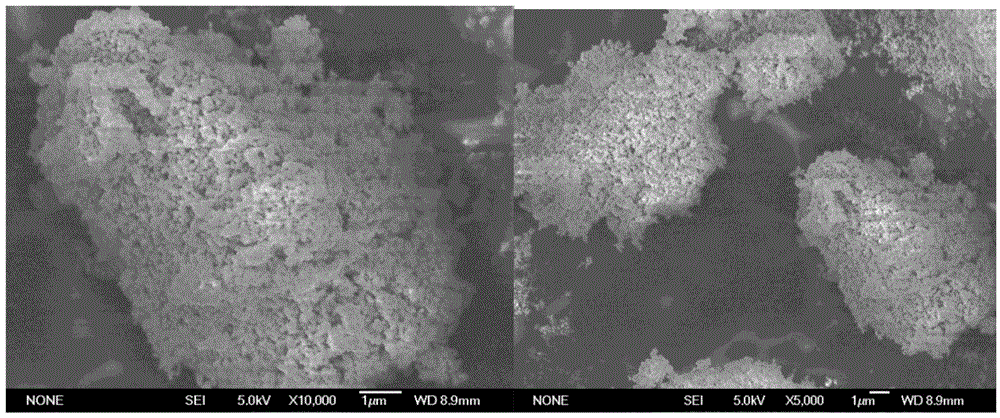

A composite oxide, iron-manganese technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problem that the properties of iron-manganese composite oxides are unstable, the oxidation process takes a long time, and it is not suitable for preparing compounds. and other problems, to achieve the effect of low cost, regular shape and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

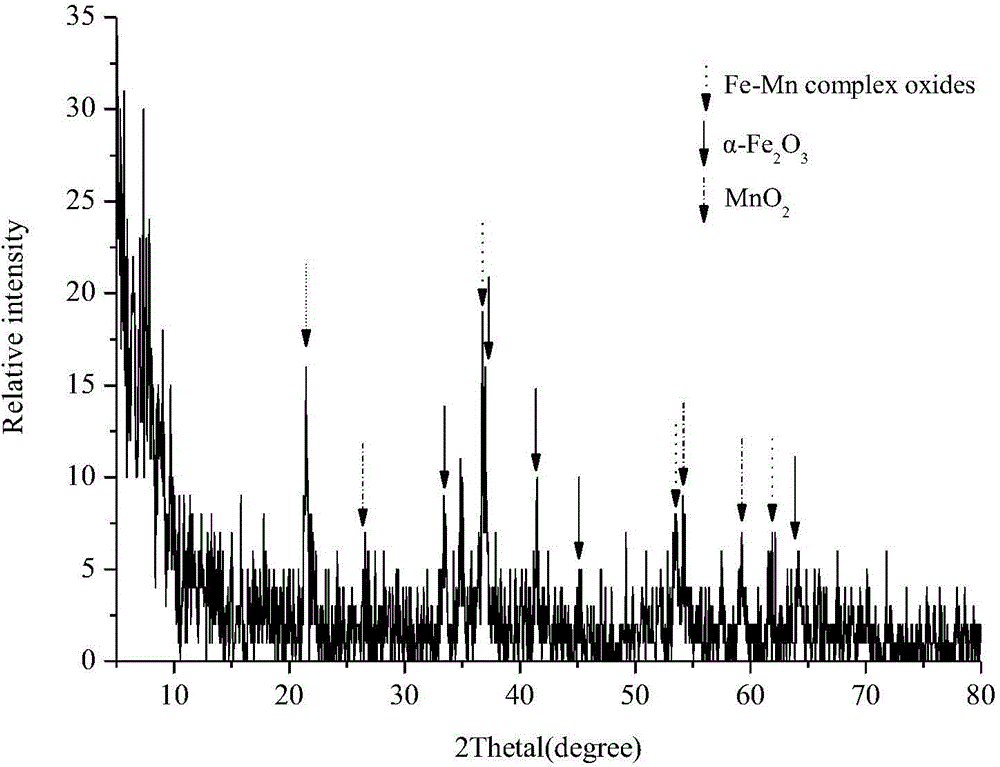

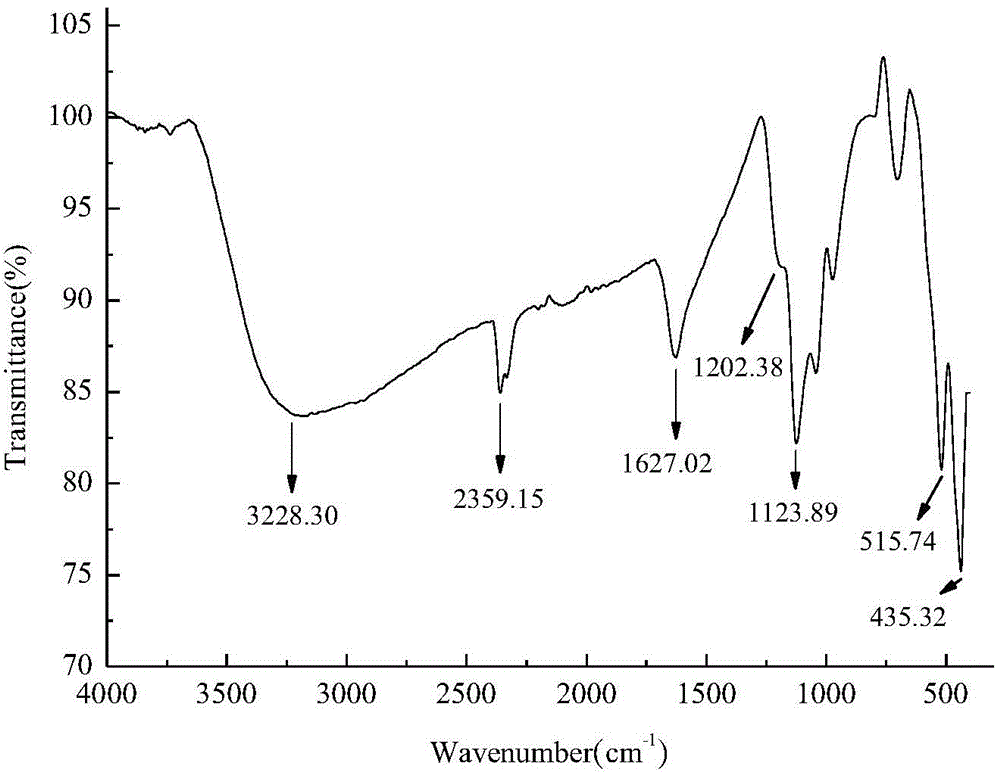

[0034] Embodiment 1: the preparation of iron-manganese composite oxide

[0035] The specific preparation method is as follows:

[0036] (1) Take a certain quality of potassium permanganate (KMnO 4 ) and ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) were ultrasonically dissolved in 100mL twice distilled water (the ratio of the amount of iron to manganese substance was 3:1), and after returning to 25°C, the KMnO 4 The solution was transferred to a 250mL round-bottomed flask added with a magnet, and stirred on a temperature-controlled magnetic stirrer;

[0037] (2) FeSO 4·7H 2 The O solution was transferred to a 100mL constant pressure dropping funnel, and was added dropwise to the KMnO at a rate of 1d / s. 4 solution, a brownish red suspension was obtained. During the reaction process, the pH of the solution was adjusted to 3.0-4.0 with 1 mol / L dilute hydrochloric acid solution continuously. At room temperature, the reaction continued for 1 h;

[0038] (3) Transfer the br...

Embodiment 2

[0058] Embodiment 2: The adsorption test of iron-manganese composite oxide to chromium in water

[0059] 1. The effect of the addition amount of iron-manganese composite oxide on the adsorption of Cr(VI)

[0060] Under the condition of a certain concentration of adsorbate, the amount of adsorbent input will directly affect the adsorption efficiency, and for a certain amount of adsorbent, the amount of adsorbate in the solution will directly affect the degree to which the adsorption site of the adsorbent is utilized. , so the effect of the amount of adsorbent added on the adsorption performance has received greater attention from researchers. This experiment will investigate the effect of five gradients of adsorbent dosages of 1.0, 2.0, 3.0, 4.0, and 5.0 g / L on the adsorption performance of iron-manganese composite oxides. The specific test operation is as follows:

[0061] At room temperature at 25°C, take 5 conical flasks with stoppers, add 0.05, 0.10, 0.15, 0.20, 0.25 g of...

Embodiment 3

[0084] Example 3: Cost accounting

[0085] (1) Raw material cost: ferrous sulfate 400 yuan / ton; potassium permanganate 10,000 yuan / ton;

[0086] According to experiments, the mass ratio of ferrous sulfate and potassium permanganate is 5:1, so the raw material cost is:

[0087] 1 ton of ferrous sulfate is 400 yuan, 200kg of potassium permanganate is 2,000 yuan, a total of 2,400 yuan;

[0088] These raw materials can produce 1 ton of adsorbent, that is, the cost of 1 ton of adsorbent is 2400 yuan.

[0089] (2) 1g of adsorbent treats 2.5L wastewater, 1kg treats 2500L (2.5m 3 ), 1 ton handles 2500m 3 2400 yuan to process 2500m 3 of water, that is, 0.96 yuan to treat 1m 3 waste water.

[0090] (3) In the prior art, the commonly used chemical method is used to process 1kg Cr 6+ See Table 1 for the dosage and cost of the medicines.

[0091] Table 1 Commonly used chemical methods to treat 1kg Cr 6+ Drug dosage and cost comparison

[0092]

[0093]The data in Table 1 are q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com