Method for improving electrochemical performance of zinc ferrite by doping nickel element and application

A technology of zinc ferrite and nickel elements, which is applied in the preparation process of advanced composite materials and the field of negative electrode composite materials for lithium-ion batteries, can solve the problems of large volume change, short cycle life, and low cycle stability, and achieve a simple synthesis method, Low self-discharge rate and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

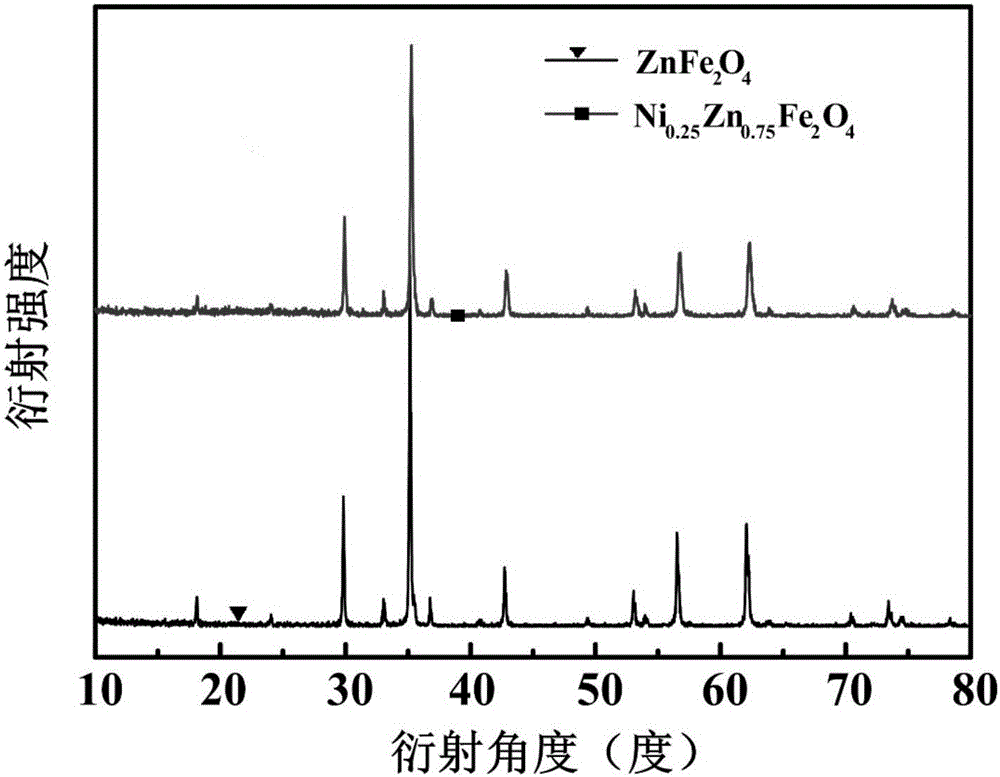

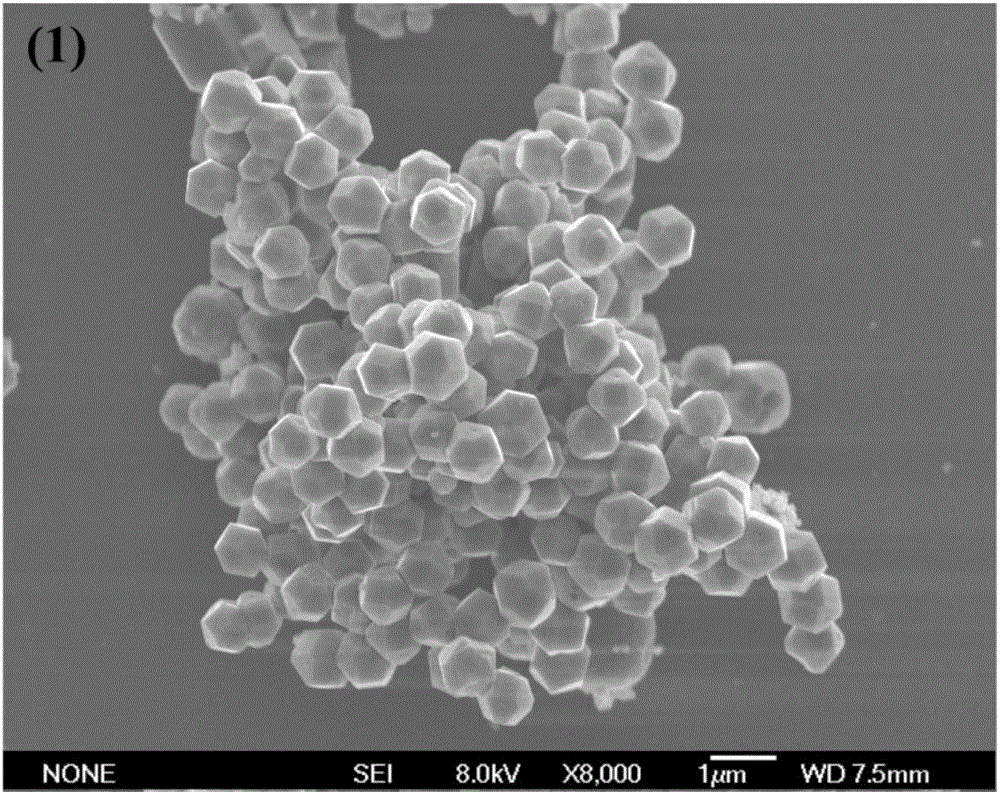

[0026] A method for improving the electrochemical performance of zinc ferrite by doping nickel elements, wherein a certain molar mass of nickel replaces a certain molar mass of zinc to form a ternary metal oxide, and the specific preparation steps are as follows:

[0027] (1) Dissolve 0.15 mmol of nickel nitrate hexahydrate, 0.85 mmol of zinc nitrate hexahydrate, 1.5 mmol of ferrous sulfate heptahydrate, 2.5 mmol of urea and 1.7 mmol of ammonium fluoride in 25 milliliters of deionized water to form a uniform The mixed solution is then transferred to a stainless steel reaction kettle, and subjected to hydrothermal reaction for 20 hours at 180 degrees Celsius;

[0028] (2) cooling and centrifuging the turbid solution prepared in step (1), and cleaning three times with deionized water and alcohol;

[0029] (3) After drying the sample prepared in step (2) in an oven for 24 hours, the powder sample is fully ground in a mortar, mixed evenly, placed in a porcelain boat, and placed in...

Embodiment 2

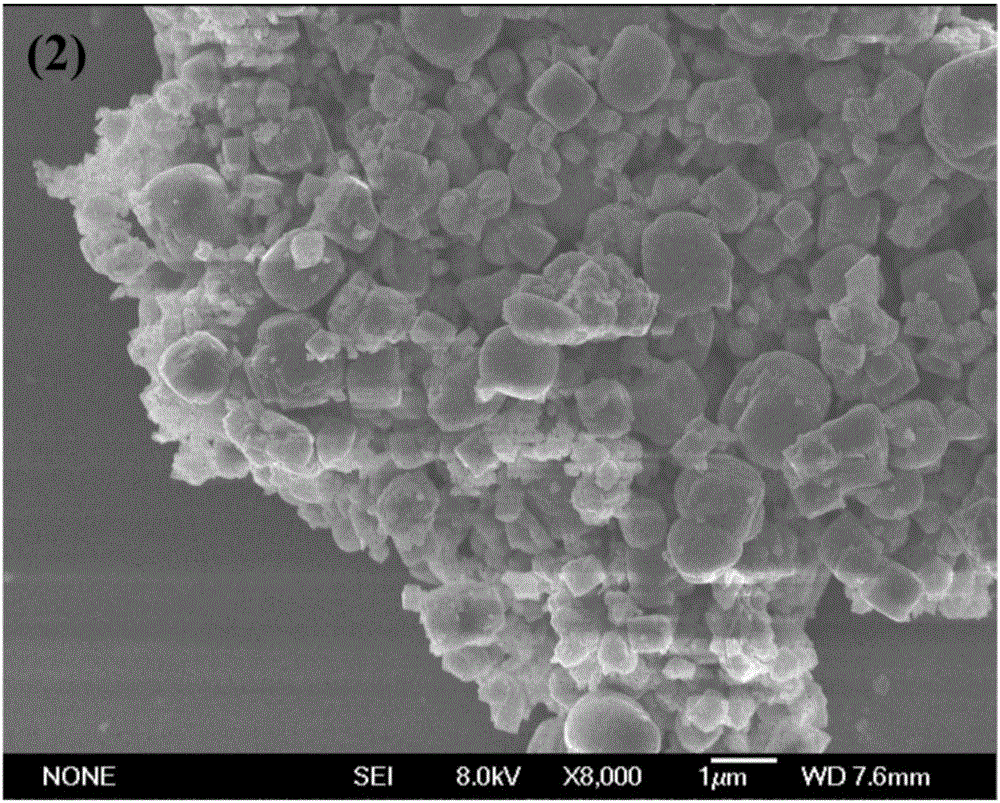

[0031] A method for improving the electrochemical performance of zinc ferrite by doping nickel elements, wherein a certain molar mass of nickel replaces a certain molar mass of zinc to form a ternary metal oxide, and the specific preparation steps are as follows:

[0032] (1) Dissolve 0.25 mmol of nickel nitrate hexahydrate, 0.75 mmol of zinc nitrate hexahydrate, 2 mmol of ferrous sulfate heptahydrate, 5 mmol of urea and 2 mmol of ammonium fluoride in 35 milliliters of deionized water to form a uniform The mixed solution is then transferred to a stainless steel reactor, and subjected to hydrothermal reaction at 200 degrees Celsius for 24 hours;

[0033] (2) cooling and centrifuging the turbid solution prepared in step (1), and cleaning three times with deionized water and alcohol;

[0034] (3) After drying the sample prepared in step (2) in an oven for 24 hours, the powder sample is fully ground in a mortar, mixed evenly, placed in a porcelain boat, and placed in a tube furnac...

Embodiment 3

[0036] A method for improving the electrochemical performance of zinc ferrite by doping nickel elements, wherein a certain molar mass of nickel replaces a certain molar mass of zinc to form a ternary metal oxide, and the specific preparation steps are as follows:

[0037] (1) Dissolve 0.35 mmol of nickel nitrate hexahydrate, 0.65 mmol of zinc nitrate hexahydrate, 1.8 mmol of ferrous sulfate heptahydrate, 3 mmol of urea and 2.5 mmol of ammonium fluoride in 45 milliliters of deionized water to form a uniform The mixed solution is then transferred to a stainless steel reactor, and subjected to hydrothermal reaction for 28 hours at 220 degrees Celsius;

[0038] (2) cooling and centrifuging the turbid solution prepared in step (1), and cleaning three times with deionized water and alcohol;

[0039] (3) After drying the sample prepared in step (2) in an oven for 24 hours, the powder sample is fully ground in a mortar, mixed evenly, placed in a porcelain boat, and placed in a tube fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com