An environmentally friendly and efficient veneer drying device

A drying device and veneer technology, applied in drying, drying machine, drying gas arrangement and other directions, can solve the problems of warping and low energy consumption, and achieve the avoidance of warping, good appearance and good drying effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

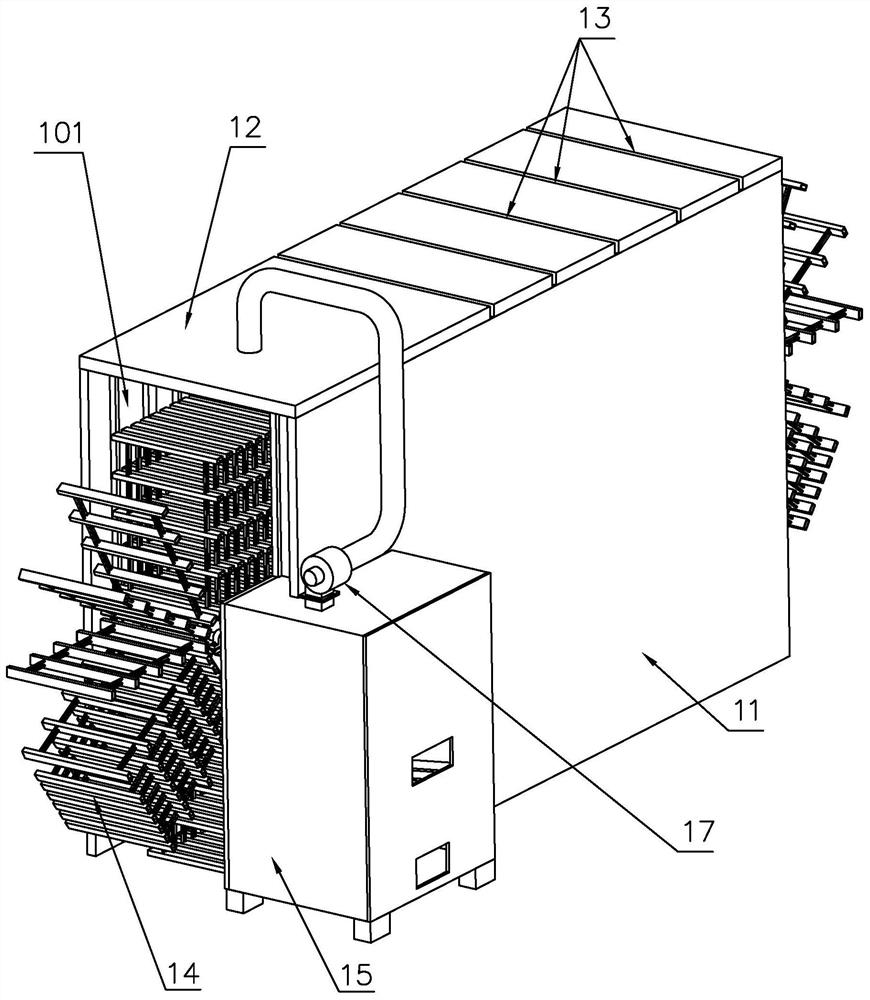

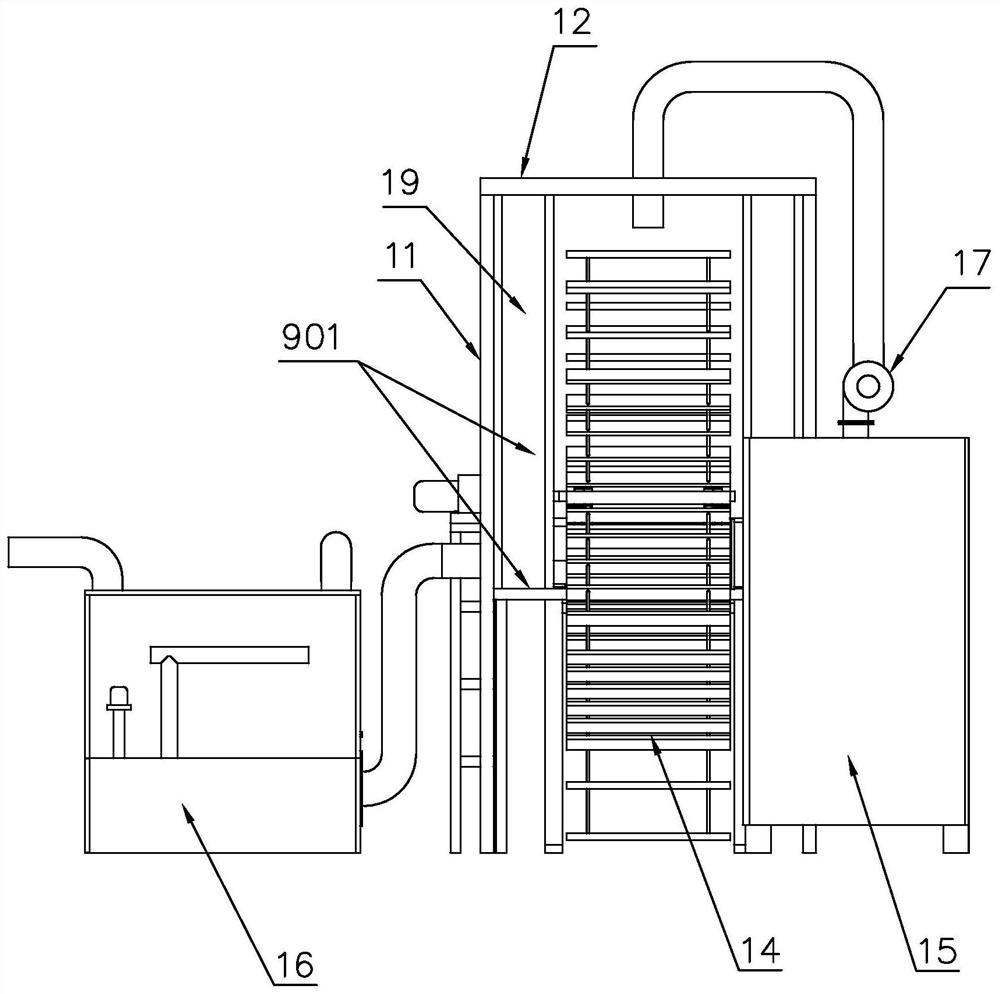

[0037] An environmentally friendly and efficient veneer drying device, comprising a board inlet 101, a board outlet 102, a rack 10, a thermal insulation box 11, a top cover 12, a moisture outlet 13, a conveying mechanism 14, a blowing device 19, and a fire channel 20 , flue gas duct 22, flue 23; the frame 10 is mainly composed of channel steel, square steel, angle steel, I-beam, steel plate, and the frame 10 is used to carry the conveying mechanism 14, the blowing device 19, the fire channel 20, The flue gas duct 22 and the flue 23; the outer side of the frame 10 is provided with a thermal insulation box 11, the upper part of the thermal insulation box 11 is provided with a top cover 12, and a number of moisture outlets 13 are provided on the top cover 12 near the outlet 102 ;

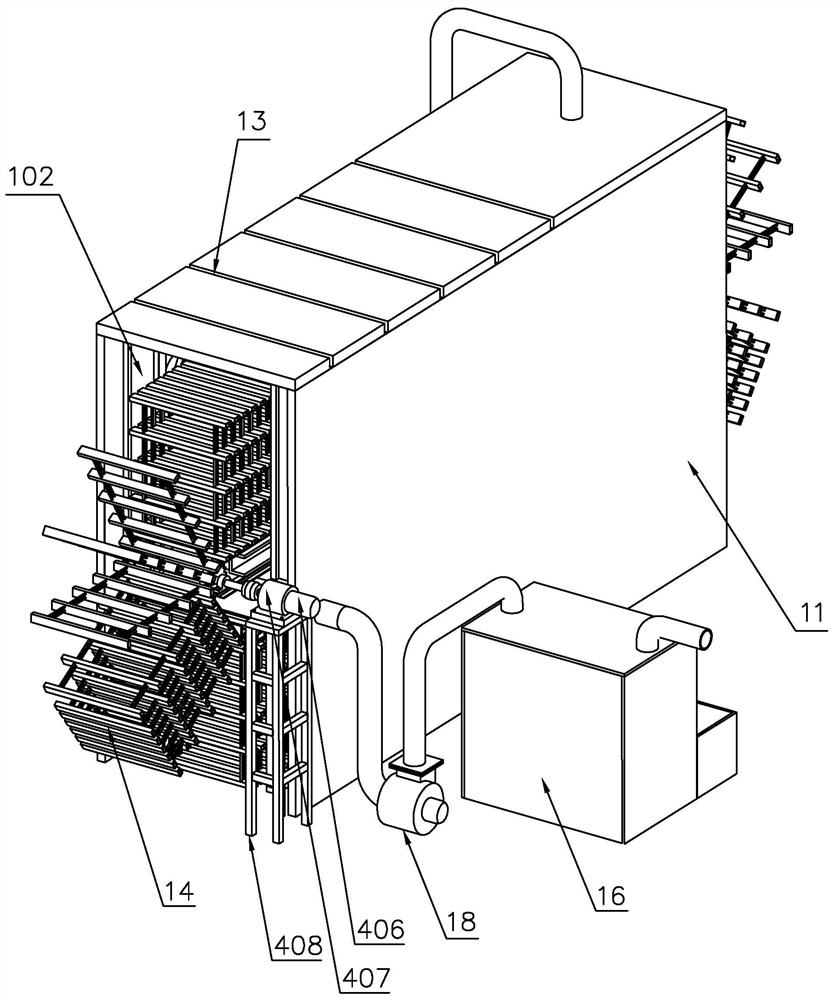

[0038] The transmission mechanism 14 includes a transmission shaft 400, a clamping arm 401, a support pad 402, a chain 403, a sprocket 404, a roller 405, a motor 406, a reducer 407, and a motor fixing ...

Embodiment 2

[0041] The difference from Embodiment 1 is that a chain bracket 409 is provided at the bottom of the upper transmission chain 403 in the transmission group to prevent the chain 403 from bearing the veneer 9 from falling due to gravity, and the transmission resistance of the chain 403 is large, which affects the stable operation of the transmission mechanism 14; A chain hanger 410 is provided on one side of the transmission chain 403 in the middle and lower part of the transmission group to prevent the chain 403 from falling due to its own gravity during the transmission process, which affects the stable operation of the transmission mechanism 14 .

[0042] The ventilation pipe 4011 in the clamping arm 401 is a square pipe or a round pipe, the veneer is clamped by the ventilation pipe 4011, and the hot air can flow in the opposite direction through the ventilation pipe 4011 in the clamping arm 401, so that the veneer 9 effective drying.

Embodiment 3

[0044] The difference from Embodiment 1 is that a plurality of support bars 4014 are provided on the ventilation pipe 4011 in the clamping arm 401, so that the clamping arm 401 can dry multiple veneers on the same horizontal plane, and the supporting bars 4014 assist The clamping arm lifts a plurality of veneers to increase the number of veneers to be dried, thereby improving the efficiency of veneer drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com