Bed type drier

A dryer and drying sieve technology, applied in the direction of dryers, drying, hearth type furnaces, etc., can solve the problems of increasing the number of workers, increasing production costs, small heating area, etc., to achieve increased drying The effect of increasing the quantity, increasing the area and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

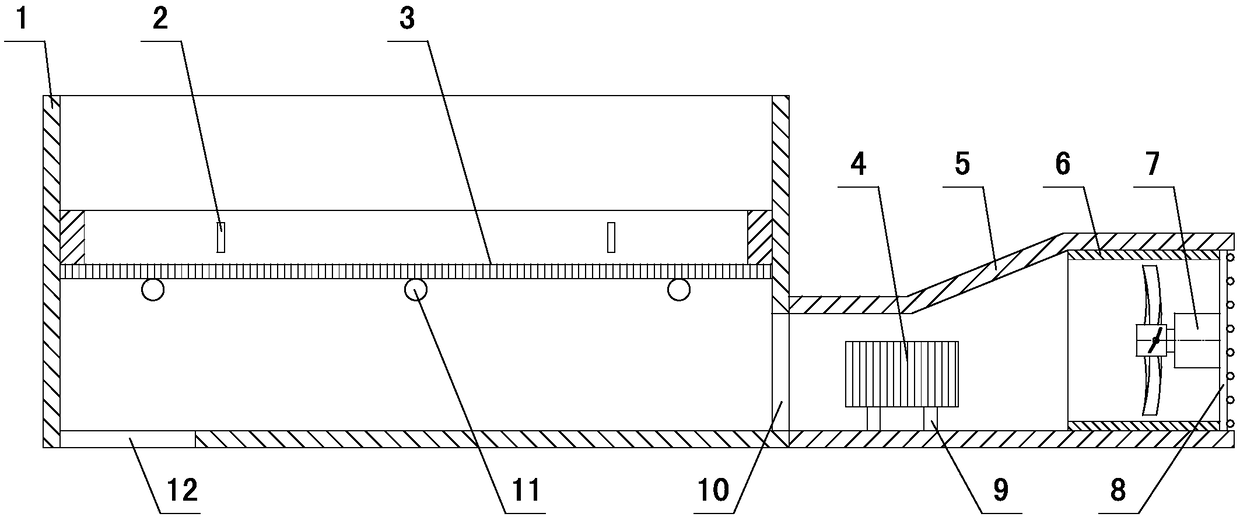

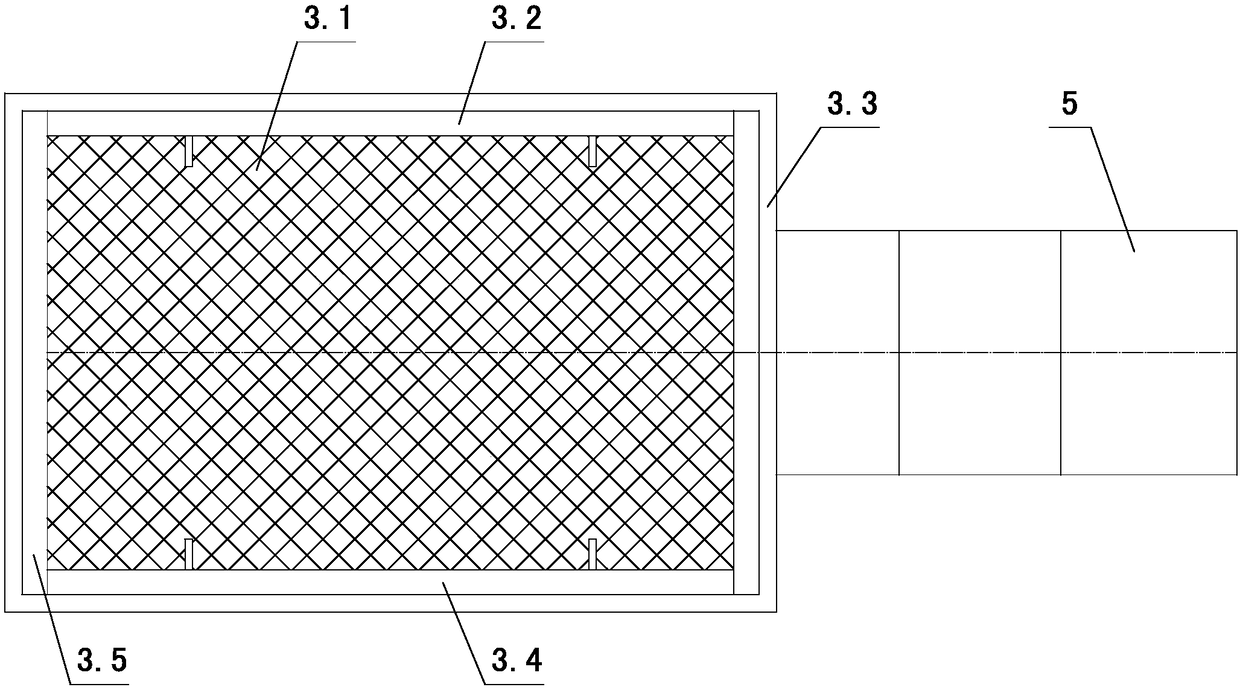

[0018] Such as figure 1 As shown, the bed dryer includes a box body 1 arranged horizontally, several positioning pins 11 are installed vertically on the front side plate of the box body 1, and a plurality of positioning pins 11 are vertically worn on the rear side plate of the box body 1. Several positioning pins 11 are provided with a drying screen 3 in the casing 1, and the drying screen 3 is arranged on the positioning pins 11, and the first through hole 10 is opened on the right side plate of the casing 1, and the drying screen 3 is arranged on the right side plate of the casing 1. The right side of the heat supply box 5 is provided with a heat supply box 5; the left side of the heat supply box 5 is an air outlet, and its right side is an air inlet; the air outlet of the heat supply box 5 is connected on the first through hole 10; A screen plate 8 is vertically arranged on the air inlet, and a dryer 4 is arranged in the heat supply box 5 , and a blower 7 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com