Grinding type air drying device for tea polyphenol processing

An air-drying device and crushing technology, which is applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of unfavorable drying and affecting the drying efficiency, and achieve the effect of sufficient and effective drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

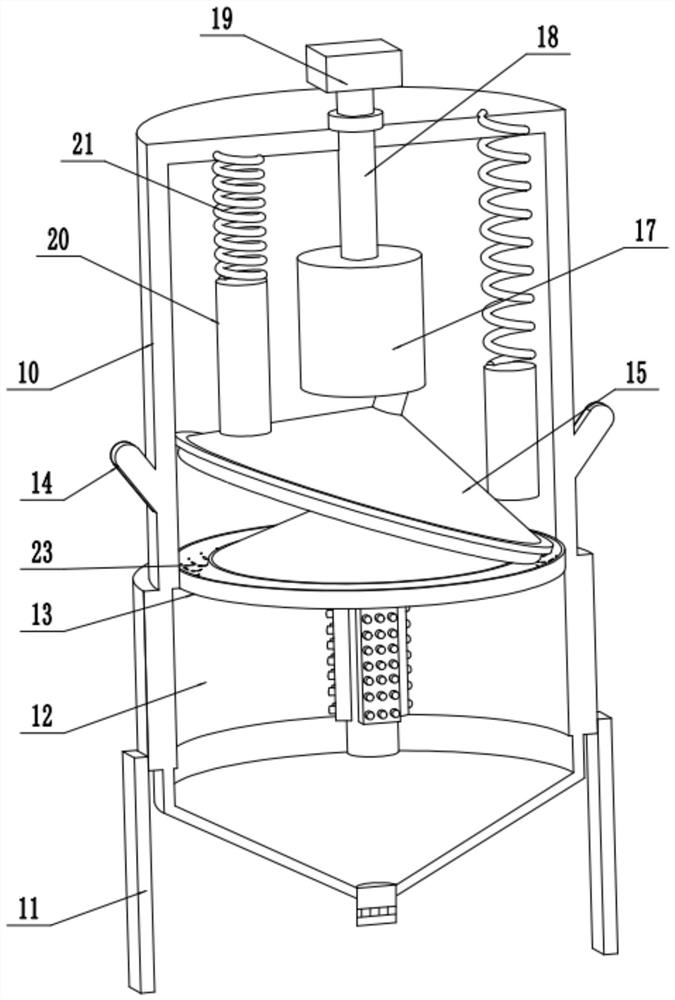

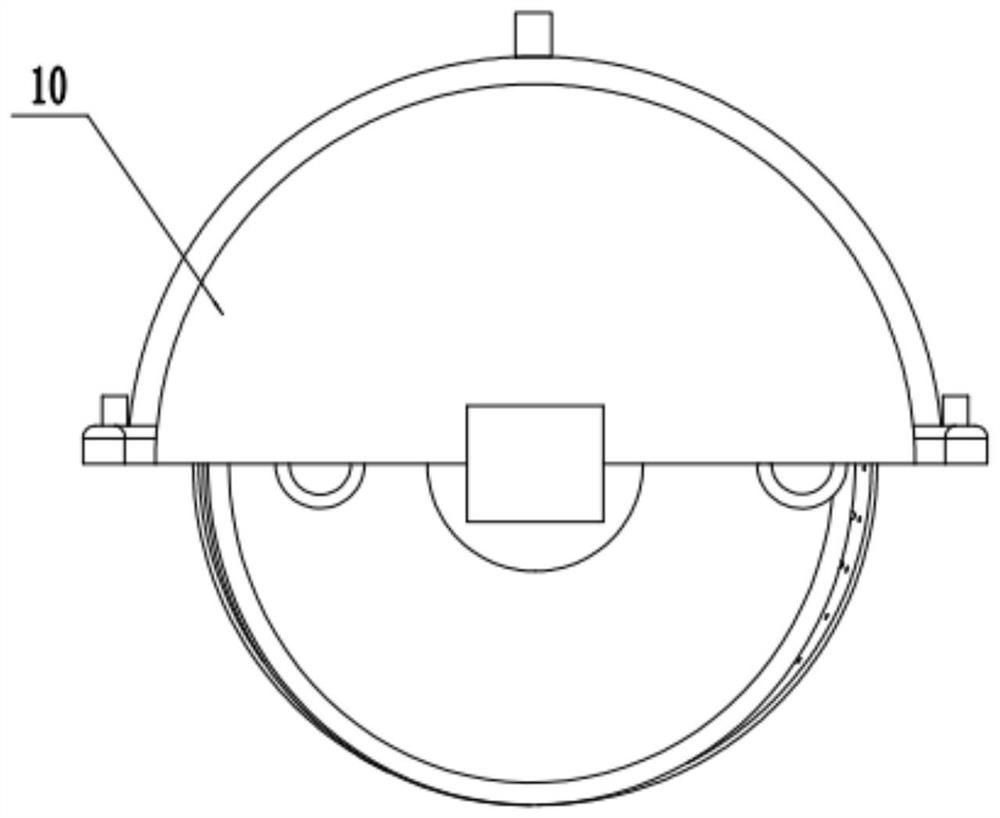

[0020]SeeFigure 1-5A crushing air drying device for tea polyphenol processing, including housings 10, bracket 11, air drying chamber 12, feed port 14, discharge hole 33; two sets of brackets 11 of the left and right side walls of the casing 10 However, the left and right front and rear side surfaces of the housing 10 communicate with four groups of inclined feed port 14, the internal fixation of the housing 10 at the bottom of the feed port 14 is fixedly mounted with a set of tapered structural mills 13, the The bottom outer ring of the mill 13 is opened with a curved structure, and a uniformly distributed filter hole 23 is opened in the mill, and the tea polyphenol is directly input to the mill. . The top end of the milling disk 13 has a set of rotating grooves 30, and the internal rolling connection of the rotation groove 30 has a set of balls 31, and the upper side of the ball 31 is fixedly connected has a set of tapered rolling disks 15, rolling disk 15. The bottom is located at...

Embodiment 2

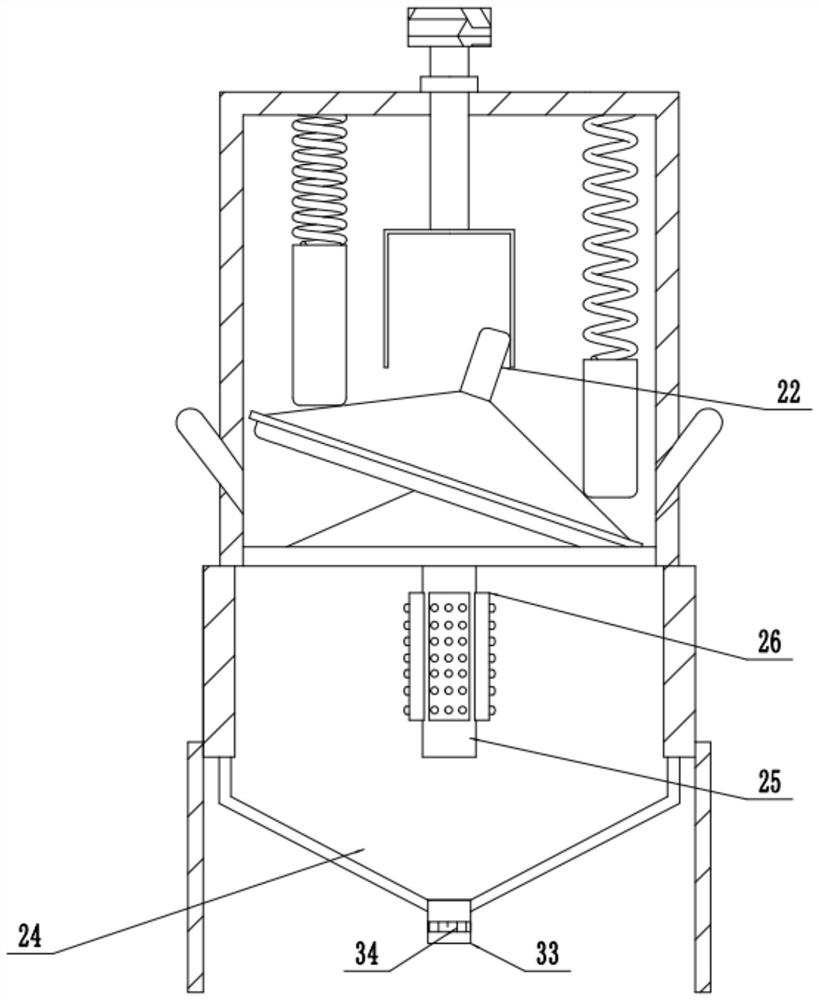

[0023]On the basis of the first example, the top rotation of the turning cylinder 25 is rotatable with a set of servo motor 28 fixed to the top of the mill, and rotates by activating the servo motor 28 driving the rotating cartridge 25, thereby passing through the row The heat gas rotation released by the air hole is uniformly released to the inside of the air drying chamber 12, thereby performing a comprehensive drying treatment in the air-dried chamber 12.

[0024]The working principle of the present invention is: When used, the tea polyphenol to be dried in the feed port 14 is input to the mill groove on the feed port 14, and then operates through the servo motor, drive the rotational cavity 17 to rotate. Then, in the limit of the limit lever 22 and the pressure of the left and right two sets of embossed rod 20, the rolling disk 15 is rotated on the top of the mill 13, and then scrolls in the mill 13 by the protrusions at the bottom of the rolling disk 15. Further, the tea polypheno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com