Upright type vertical conveying device for non-woven fabric drying and setting machine

A conveying device and non-woven fabric technology, applied in textiles and papermaking, equipment for drying fabrics, fabric surface trimming, etc., can solve problems such as abnormal production and tearing of cloth edges under force, and reduce the risk of tearing and clamping Good holding power and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

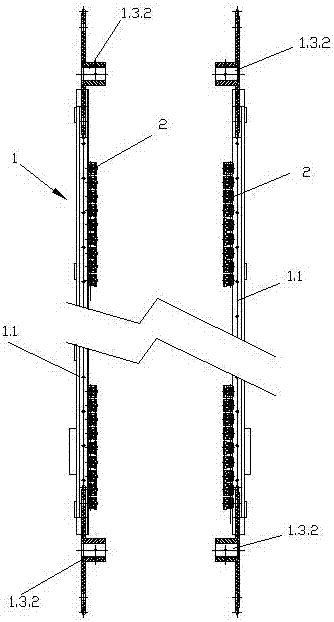

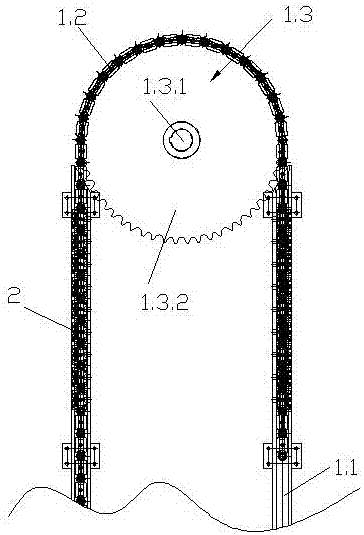

[0026] Embodiment 1: A vertical vertical conveying device for a non-woven fabric drying and setting machine, including two sets of symmetrical vertical conveying units 1 on the left and right, and the thin non-woven fabric is clamped between the two vertical conveying units 1 in a vertical state In between, the vertical conveying unit 1 includes two vertical guide rails 1.1 arranged at intervals in parallel, a closed-loop conveying chain 1.2 arranged in the two vertical guide rails 1.1, and a driving conveyor arranged above and below the two vertical guide rails 1.1. The chain driving device 1.3 driven clockwise by the chain 1.2 and the cloth clip 2 installed on each link 1.2.1 of the conveyor chain 1.2, the cloth clip 2 and the chain link 1.2.1 are vertically installed, and the two sides of the thin non-woven fabric Clamped on cloth clip 2. The chain driving device 1.3 comprises an upper and lower drive shaft 1.3.1, an upper and lower sprocket 1.3.2 installed on the upper and...

Embodiment 2

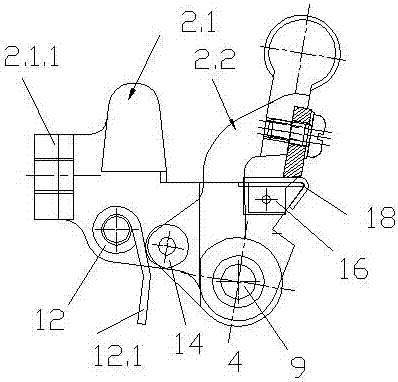

[0027] Embodiment 2: Referring to Embodiment 1, the cloth clip 2 includes a main body base 2.1 and a knife clip 2.2 hinged with the main body base 2.1. The main body base 2.1 includes a tail plate 2.1.1 at the left end and a knife table 2.1.2 at the right end And the front and rear two side plates 2.1.3 that are symmetrical between the tail plate 2.1.1 and the tool rest 2.1.2, the three are surrounded to form a hollow frame structure, and the front and rear two side plates 2.1.3 are provided with a Set of torsion spring holes 3, the right side of the torsion spring hole 3 is provided with a group of spindle holes 4, the knife clip 2.2 includes the hinged arm 2.2.1, the hinged hole 5 opened at the bottom of the left end of the hinged arm 2.2. .1 a group of lugs 6 located at the upper right end of the hinged hole 5, a knife edge platform 7 near the right end of the hinged arm 2.2.1, and a knife holder 8 at the right end of the hinged arm 2.2.1, the hinged hole 5 corresponds to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com