Drying bracket and drying device for impeller casting plaster mold

A drying device and gypsum molding technology, which are applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problems of affecting the surface quality, increasing the cost, and complicated manufacturing methods of impeller cores, and improving the drying yield and saving. The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing, the present invention is described in detail:

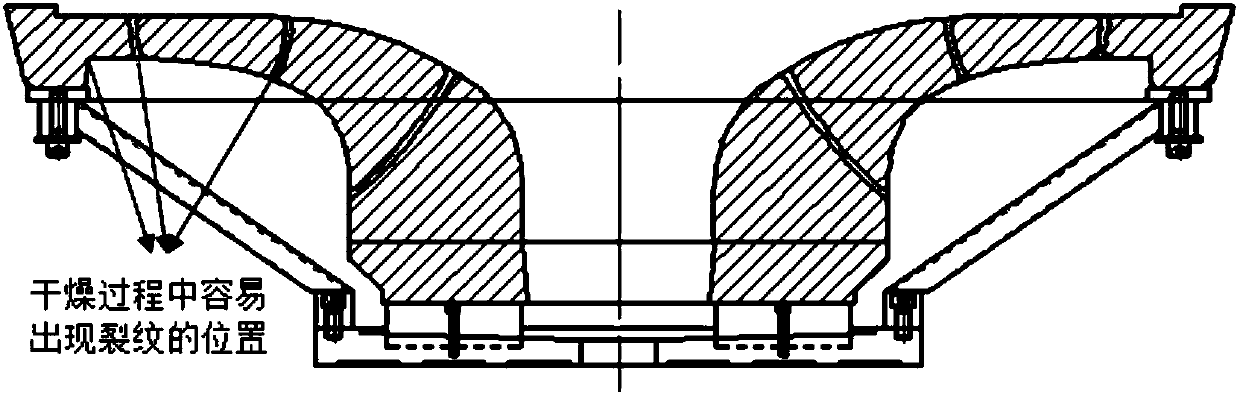

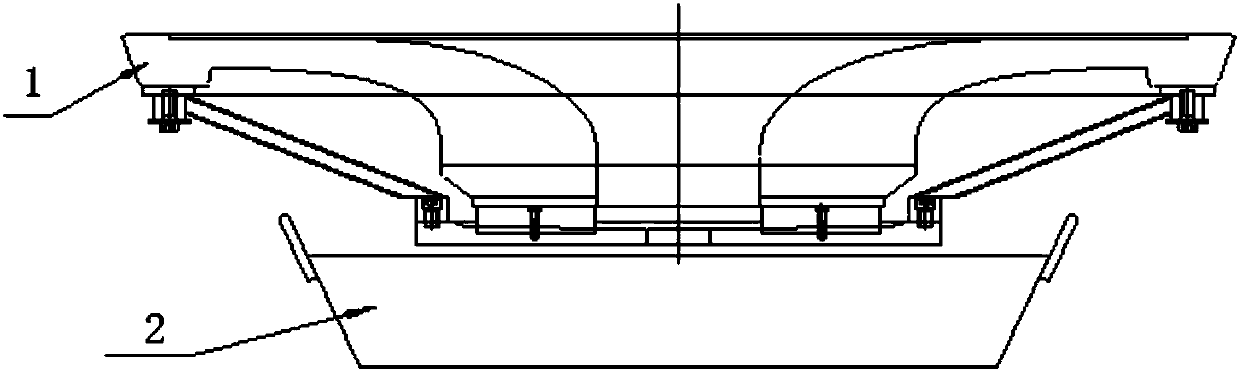

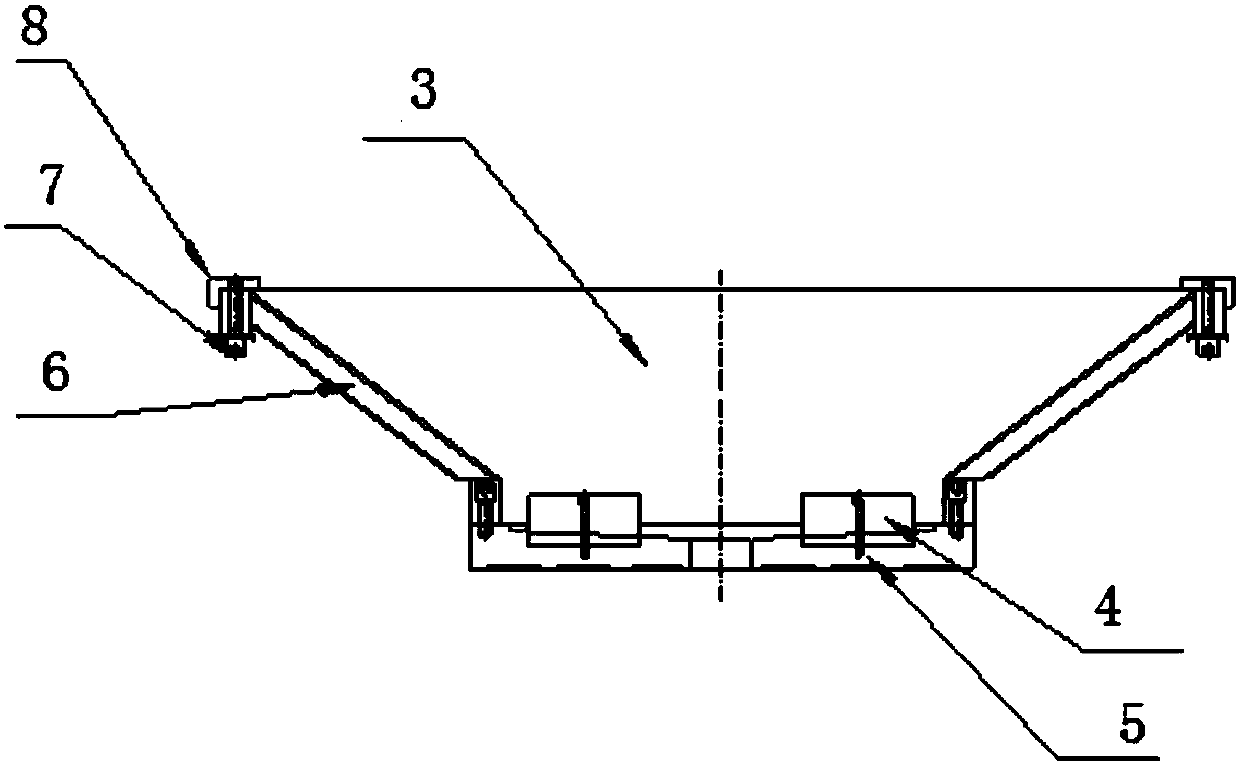

[0042] As the drying bracket described in the background art is relatively simple, it is easy to cause damage to the plaster type and affect the surface quality. However, the manufacturing method of the impeller core is complicated, the cost is high, and it is easy to be lost in the drying process. figure 1 Cracks appear at the locations shown (eg figure 1 shown), if there are cracks in the drying, the cost will be greatly increased, and the quality of the impeller will be seriously affected; for this reason, the present invention proposes a new drying bracket, which includes a chassis, and is installed on the chassis There is a circle of conical baffles connected to it. The top surface of the chassis is a slope that is high around and low in the middle. The low-melting-point alloy in the gypsum core melts and flows along it to the chassis, and flows out from the center hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com