Method and device for automatic control of thermal state in chamber-type drying chamber for block wet billets

An automatic control device and chamber-type drying chamber technology, which is applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of waste of energy, low degree of automation, and economic loss of enterprises, and achieve the reduction of human resources and product quality. Good, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

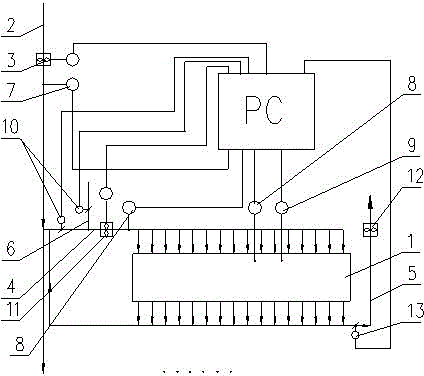

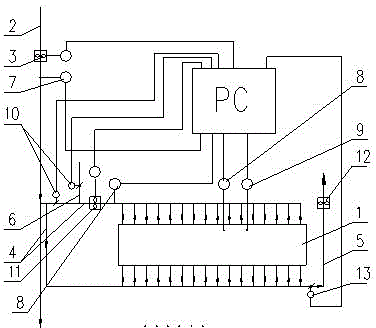

[0015] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0016] Embodiment of the present invention: The method for automatically controlling the thermal state of a bulk wet green chamber drying chamber of the present invention can be directly implemented in an existing sintered brick factory equipped with a block wet green chamber drying chamber 1. , the waste heat of flue gas discharged from the sintering kiln in the sintering brick factory is used as the drying energy of the chamber type drying chamber. The hot air of the exhausted flue gas waste heat is sent to the hot air conveying branch pipe 4, and the hot air is sent into the block wet blank drying chamber 1 through the hot air conveying branch pipe 4, and then the block wet blank drying chamber 1 is discharged. The gas is discharged into the exhaust pipe 5, one end of the exhaust pipe 5 is communicated with the air inlet end of the hot air conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com