Preparation method of thermoplastic polyurethane nanofiber membrane

A thermoplastic polyurethane and nanofiber membrane technology, which is applied in fiber treatment, fabric drying equipment, heating/cooling fabric, etc., can solve the problems of not having high moisture permeability and inability to block liquids, etc., to improve membrane quality and production efficiency , good deposition performance and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

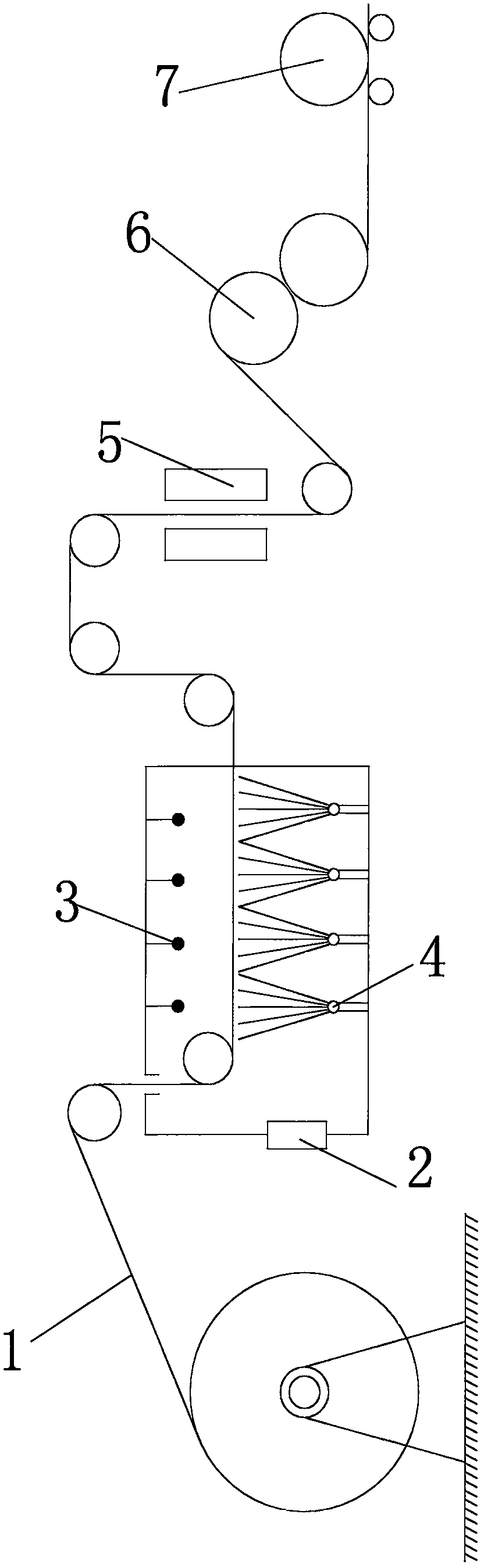

[0022] like figure 1 As shown, the preparation of a thermoplastic polyurethane nanofiber film, the rolled base fabric 1 moves forward with the rotating wheel, and the tension wheel stretches the base fabric 1 straight into the high-voltage power field 2, and the high-voltage power field 2 is equipped with two The two electrodes are collecting electrode 3 and spinning electrode 4 respectively. The spinning solution is sprayed from spinning electrode 4 and sprayed to collecting electrode 3. When the base cloth 1 passes through the high-voltage power field 2, the spinning solution is deposited on it. The cloth 1 continues to move forward, enters the heating device 5 for drying, and then enters the heat setting equipment 6 after drying. After the base cloth 1 comes out, it is gradually cooled by the air, and finally enters the winding equipment 7 to obtain a thermoplastic polyurethane nanofiber film. .

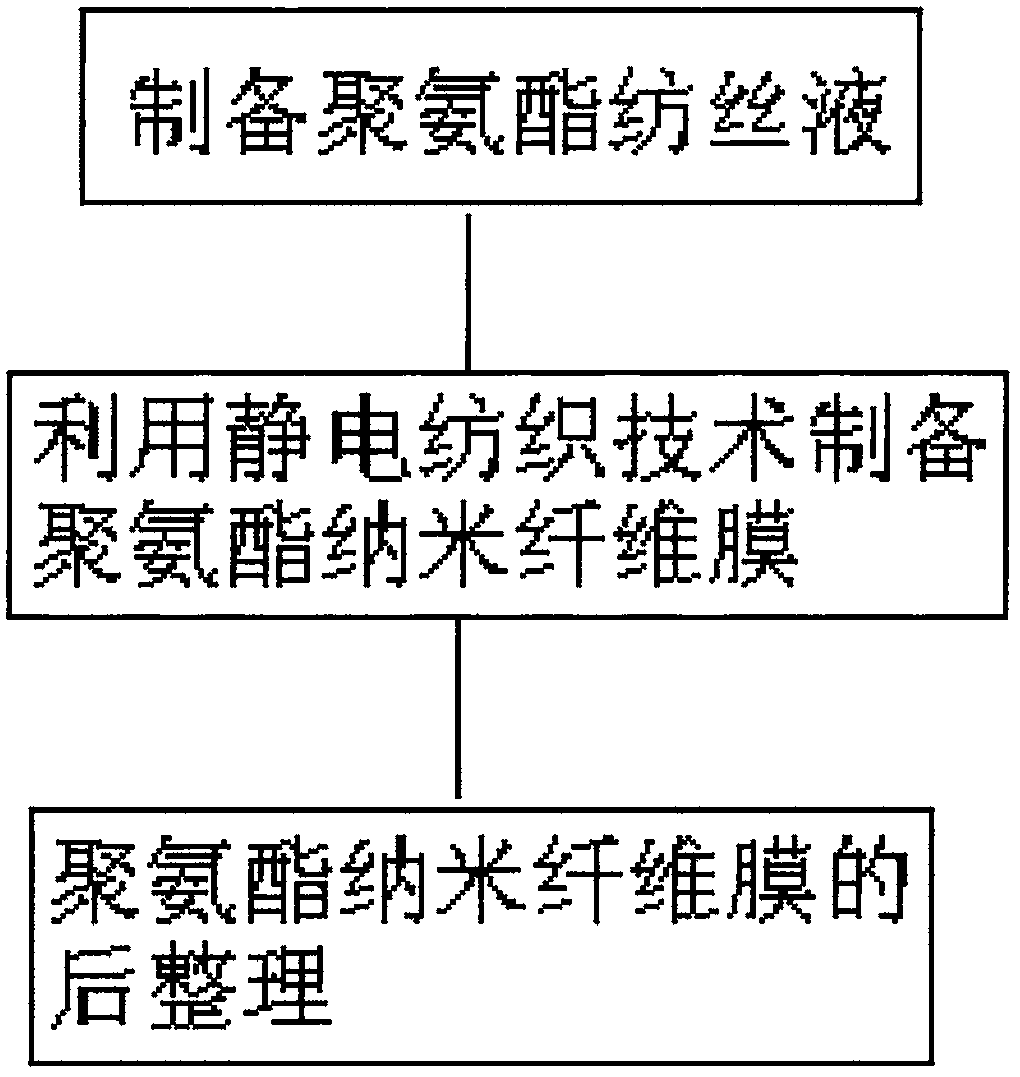

[0023] like figure 2 Shown, a kind of preparation method of thermoplastic ...

Embodiment 2

[0028] like figure 2 Shown, a kind of preparation method of thermoplastic polyurethane nanofiber membrane comprises the following steps:

[0029] 1) Prepare polyurethane spinning solution; the preparation method of polyurethane spinning solution: weigh N,N-dimethylformamide and tetrahydrofuran in a mass ratio of 1:1 and mix evenly to prepare a solvent system, and add polyurethane powder to the In the above solvent system, the rotating speed is 50r / h, stirred at 30°C for 6h, the concentration of the obtained spinning solution is 12%, cooled to room temperature, and set aside;

[0030] 2) Deposit the polyurethane spinning solution on the nanofiber membrane by using the needle-free electrospinning technology to obtain a spider web-like fiber membrane; the electrospinning technology utilizes two electrode wires to construct an electrostatic field from the positive pole to the negative pole, The small droplets of polyurethane spinning solution are charged, stretched, deformed, an...

Embodiment 3

[0033] like figure 2 Shown, a kind of preparation method of thermoplastic polyurethane nanofiber membrane comprises the following steps:

[0034] 1) Prepare polyurethane spinning solution; the preparation method of polyurethane spinning solution: weigh N,N-dimethylformamide and tetrahydrofuran in a mass ratio of 1:2 and mix evenly to prepare a solvent system, and add polyurethane powder to the In the above solvent system, the rotating speed is 50r / h, stirred at 30°C for 6h, the concentration of the obtained spinning solution is 12%, cooled to room temperature, and set aside;

[0035] 2) Deposit the polyurethane spinning solution on the nanofiber membrane by using the needle-free electrospinning technology to obtain a spider web-like fiber membrane; the electrospinning technology utilizes two electrode wires to construct an electrostatic field from the positive pole to the negative pole, The small droplets of polyurethane spinning solution are charged, stretched, deformed, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com