Spray container of grille type float-prevention cover cap

A spray device and grid technology, applied in spray devices, liquid spray devices, etc., can solve the problems of lack of prevention and control of droplet drift, effective use of fine droplets, low effective utilization of pesticides, difficulty in adapting to biological characteristics, etc., and achieve improvement Pesticide deposition effect, improvement of liquid deposition characteristics, and improvement of pesticide utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, the present invention will be described in detail through the accompanying drawings and specific implementation.

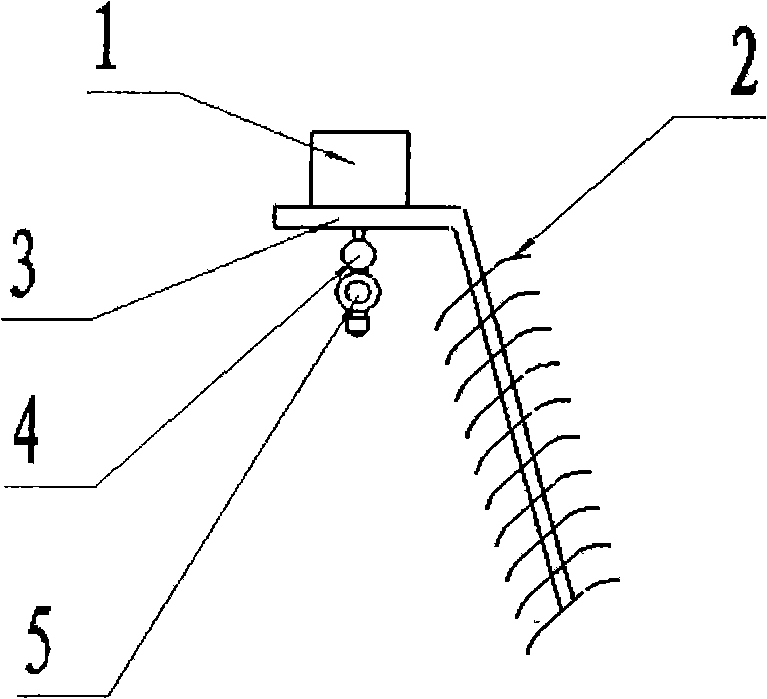

[0014] The present invention is matched with boom sprayer and used, as figure 1 As shown, it includes: truss 1, grid 2, frame 3, spray bar 4, spray head body 5 and other components.

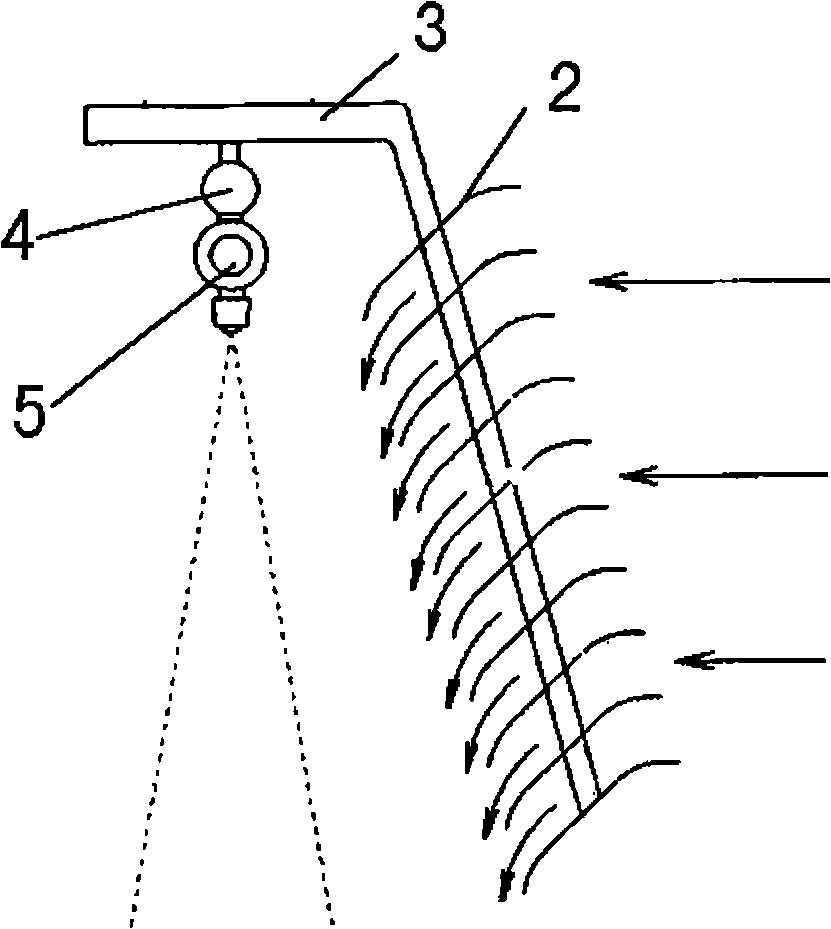

[0015] The main anti-drifting part of the grid cover is composed of a group of grids 2, and a group of diversion channels are formed between the grids, which can change the direction of movement of the horizontal airflow acting on the spray fan, so that the movement direction of the airflow is consistent with the mist flow during spraying. movement in the same direction, thus forming a wind curtain, such as figure 2 As shown, it can not only prevent the front horizontal airflow from acting on the mist flow, and blow the fine mist droplets away from the spray fan to cause drifting, but also can force the mist droplets to enter the canopy, increasing the penetrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com