A plane shaping machine

A sizing machine and plane technology, applied in the sizing/elongation of circular fabrics, fabric surface trimming, textiles and papermaking, etc., can solve the problems of high height of the sizing machine, large space occupation, long time spent on loading and unloading socks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

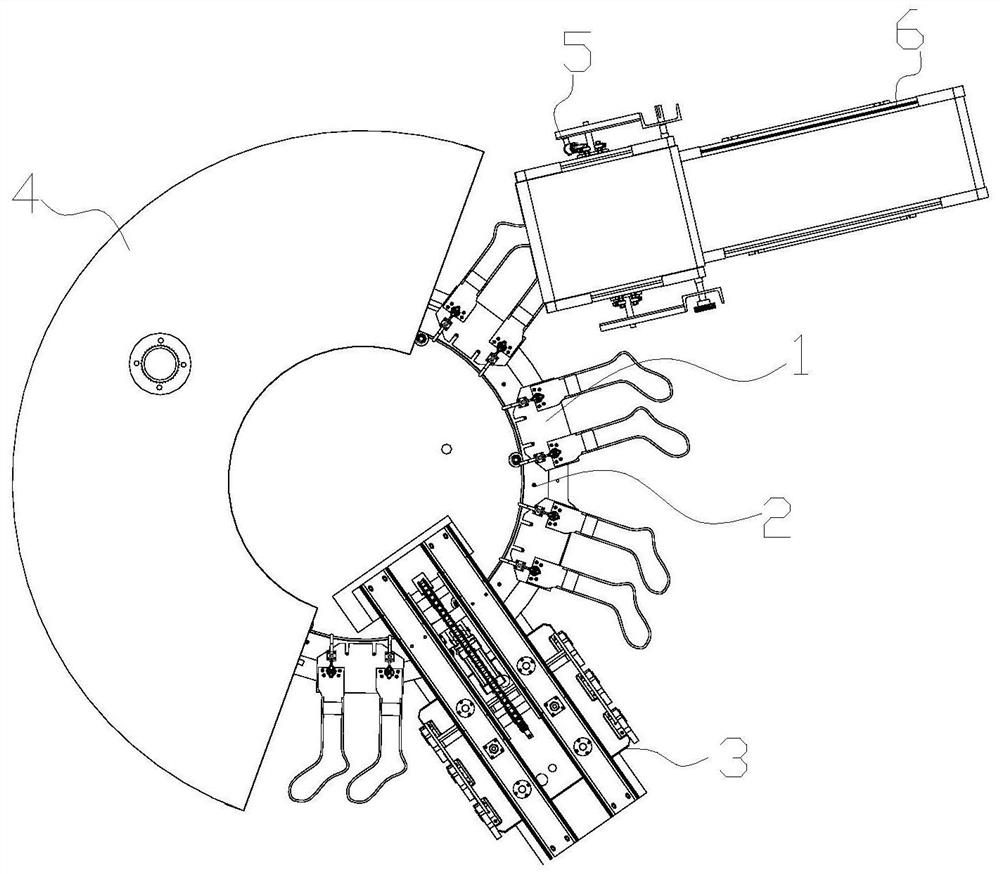

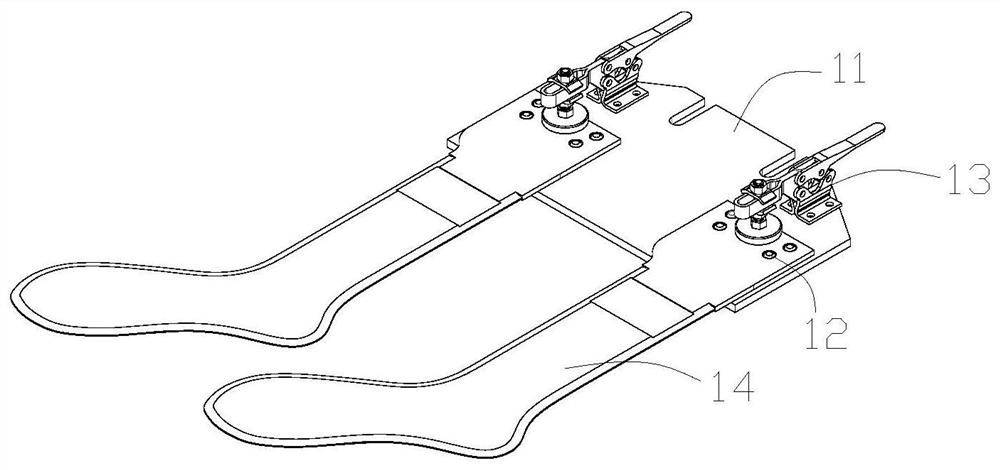

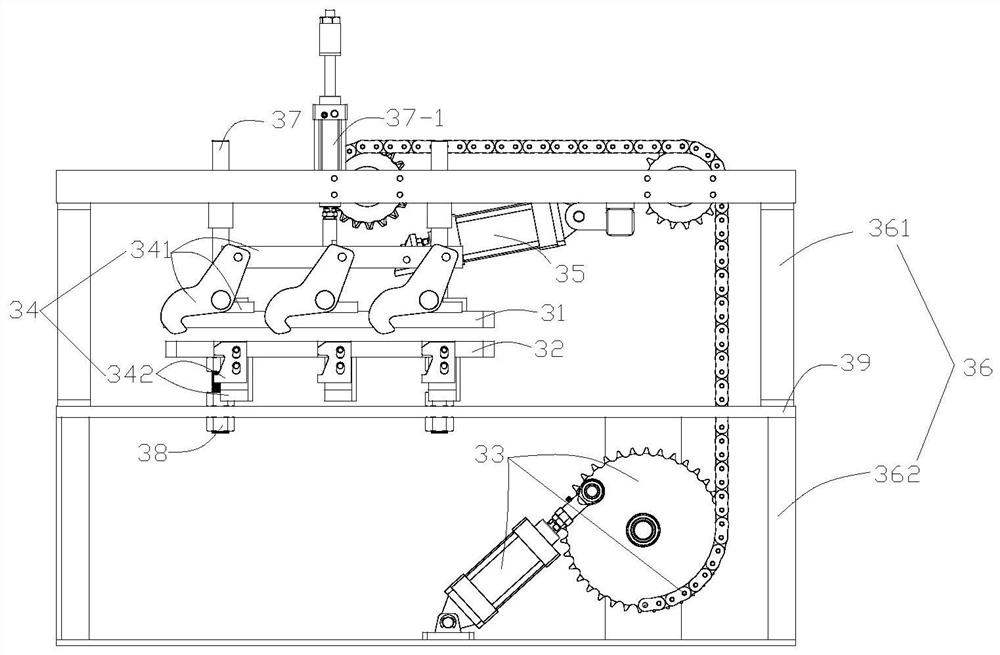

[0019] Please refer to figure 1 , a plane setting machine, including a turntable 2, a drying device 4, a sock delivery device 6, a sock steam setting device 3, and a sock removing device 5, a setting seat 1, and a plurality of setting seats 1 installed on the turntable 2 The sock removing device 5 is connected to the sock discharging conveying device 6 , and the sock steam setting device 3 , drying fan 4 and sock removing device 5 are sequentially arranged outside the turntable 2 .

[0020] Further, the turntable 2 includes a fixed base, a rotating round frame and a servo motor, the rotating round frame is movably arranged on the top surface of the fixed base, and the outer periphery of the rotating round frame is provided with teeth extending along its circumferential direction, The servo motor is arranged on the fixed chassis, and the drive shaft of the servo motor is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com