Base fabric post-processing technology for superfine fiber synthetic leather

A technology of superfine fiber and synthetic leather, applied in the direction of fiber treatment, improved hand feeling fiber, fabric elongation, etc., can solve the problems of uneven distribution of force, low tear strength, difficult to eliminate, etc., to improve hand feel, Good effect and enhanced affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

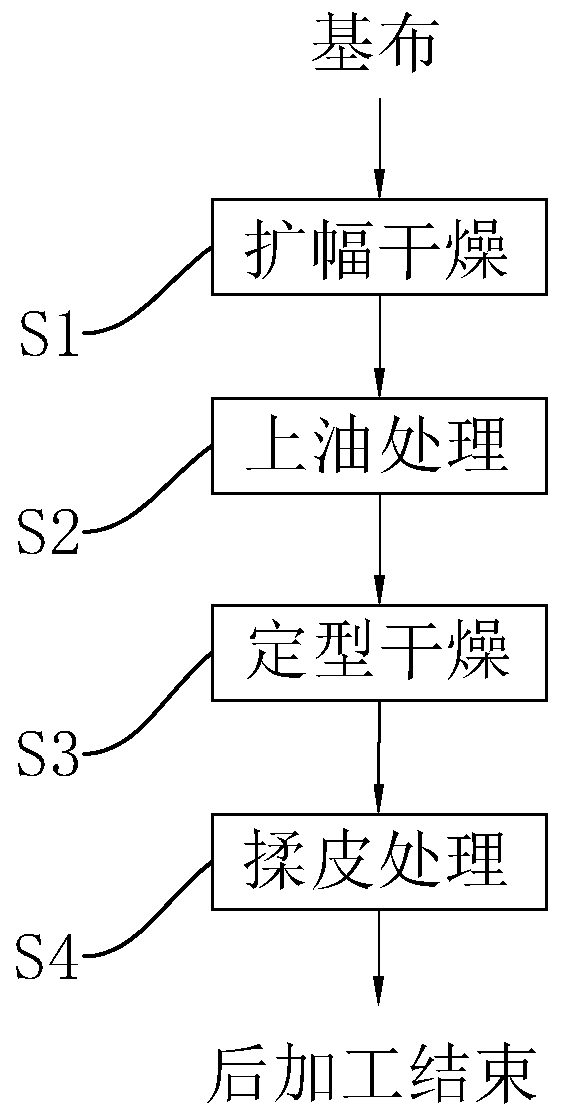

[0036] Reference figure 1 , A post-processing technology for the base fabric of microfiber synthetic leather. The base fabric after weight reduction is sprayed with water, and the spray amount of water is 100ml / m 2 . Then input the base fabric into the tensioning roller group to make the fabric tensioned. The tensioned base fabric is processed as follows:

[0037] S1: Spreading and drying. Input the base fabric into the drying room, and expand while drying, the expansion rate is controlled to 6%, and the drying temperature of the base fabric in the drying room is 120°C. The drying time of the base cloth in the drying room is 20 minutes.

[0038] S2: Oiling treatment. The oiling agent is first input into the oiling tank, the liquid level of the oiling agent in the oiling tank is always maintained above 2 / 3, and the liquid temperature of the oiling agent is controlled to 35°C. Then input the base fabric after S1 treatment into the oiling tank containing the oiling agent, and repea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com