High-precision and stable discharging device in lithium battery industry and control method thereof

A high-precision, industry-leading technology, applied in conveyor control devices, packaging, loading/unloading, etc., can solve problems such as large space occupation, poor stability, and product quality impact, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

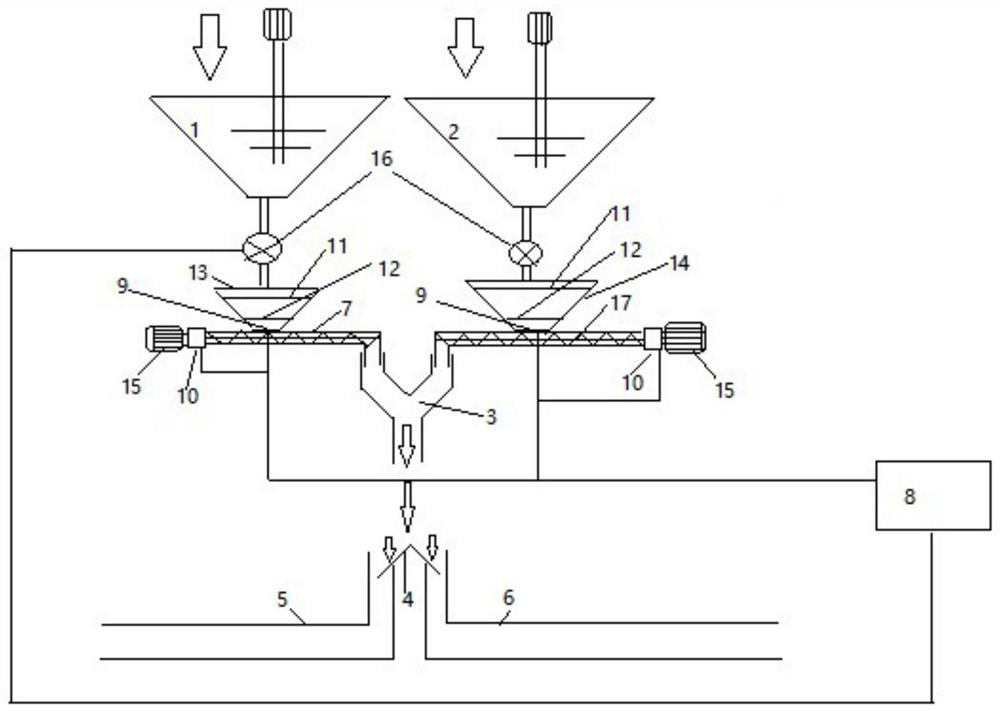

[0034] Such as figure 1 As shown, a high-precision and stable feeding device for the lithium battery industry includes at least two buffer storage bins, and the feeding port of each buffer storage bin is connected to the feeding bin through a feeding pipeline, and each feeding pipeline Feed valves 16 are installed on the top, and the bottom of the feed bin is equipped with a loss-in-weight scale 9. The inside of the loss-in-weight scale 9 is provided with a loss-in-weight scale sensor. Speed-feeding mechanism, the adjustable speed-feeding mechanism through the controller 8 to adjust the speed, the controller 8 is connected to the feed valve 16 and the weight loss sensor. Wherein, the adjustable-speed feeding mechanism includes a feeding screw and an adjustable frequency conversion driver, one end of the feeding screw is used as a discharge end, and the other end is connected with an adjustable frequency conversion driver, and the adjustable frequency conversion driver includes...

Embodiment 2

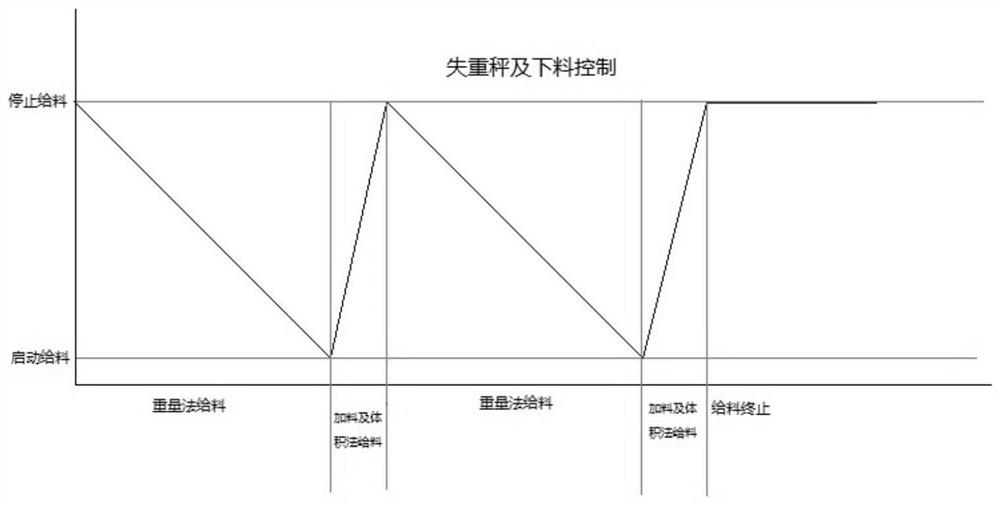

[0040] A method for controlling a high-precision and stable feeding device in the lithium battery industry, comprising the following steps:

[0041] Step 1: Preset the working mode in the control module. Each working mode corresponds to different materials for mixing, and according to different materials, each working mode also corresponds to different feeding speeds, upper limit weights of materials and lower limit weights of materials ;

[0042] Step 2: According to the material in the buffer silo, select the working mode suitable for the material. After the mode is selected, the controller adjusts the feeding speed to the speed in this mode through the frequency converter;

[0043] Step 3: During the feeding process, the weight loss sensor inside the weight loss scale transmits the detected weight signal to the controller of the control module in real time;

[0044] Step 4: When the detected weight of the material in the feed bin is lower than the preset lower limit weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com