Feeding device for sponge foaming machine

A foaming machine and sponge technology, applied in the field of machinery, can solve the problems of manpower splashing, easily damaged foaming machine, iron filings inclusion, etc., to improve processing quality and efficiency, improve automatic production, and avoid clogging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

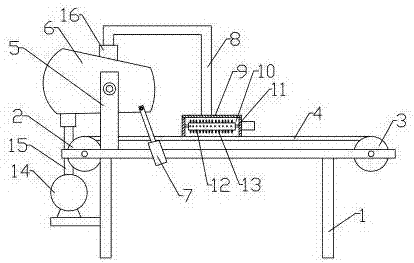

[0013] Combine below figure 1 And further illustrate the technical solution of the present invention through specific examples.

[0014] A feeding device for a sponge foaming machine, comprising: a basic support 1, a driving roller 2 and a passive roller 3, the driving roller 2 and the passive roller 3 are respectively arranged at the two ends of the basic support 1, and the driving roller 2 and the The passive roller 3 is covered with an endless conveyor belt 4 for transmission connection, and the material to be foamed is poured into the endless conveyor belt for transportation.

[0015] One side of the driving drum 2 is provided with a support rod 5 located on the base support 1, and the support rod 5 is hingedly provided with a bucket 6, and one end of the bucket 6 is hinged with a telescopic device 7 located on the base support 1, Drive bucket 6 to carry out angle adjustment, is convenient to unloading.

[0016] The top of the feed barrel 6 is provided with a feed pipe 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com