A slider threading method capable of producing ultra-short zippers and an automatic threading machine

A technology for wearing sliders and zippers, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problem that ultra-short zippers cannot be produced automatically, and achieve the effect of more intelligent equipment and improved equipment utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

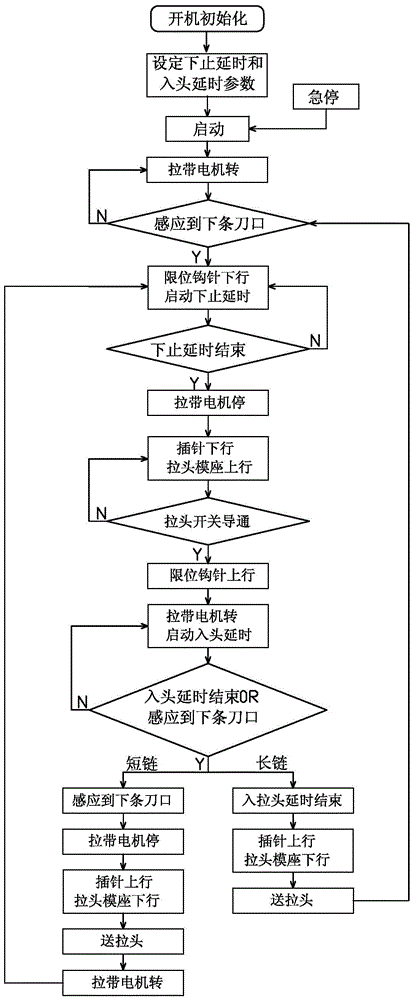

[0017] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The lower knife edge described below is the knife edge between the link where the slider is currently worn and the next link.

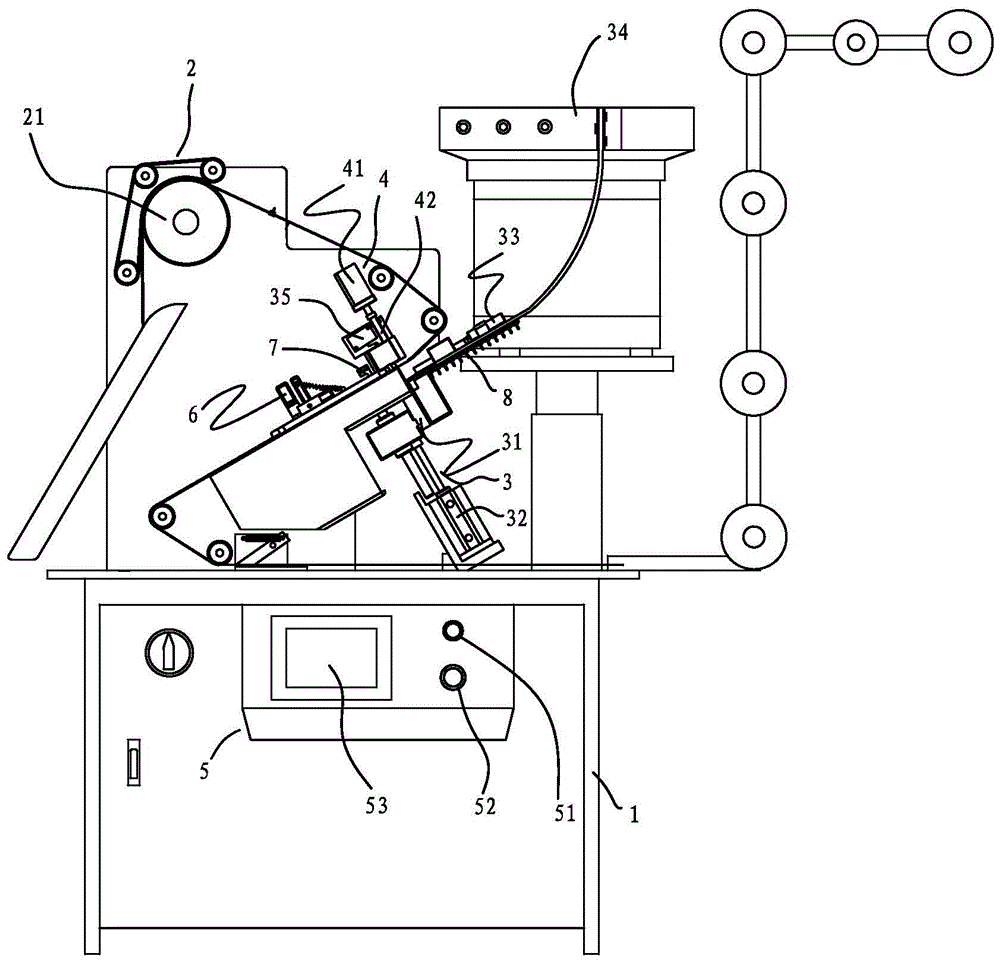

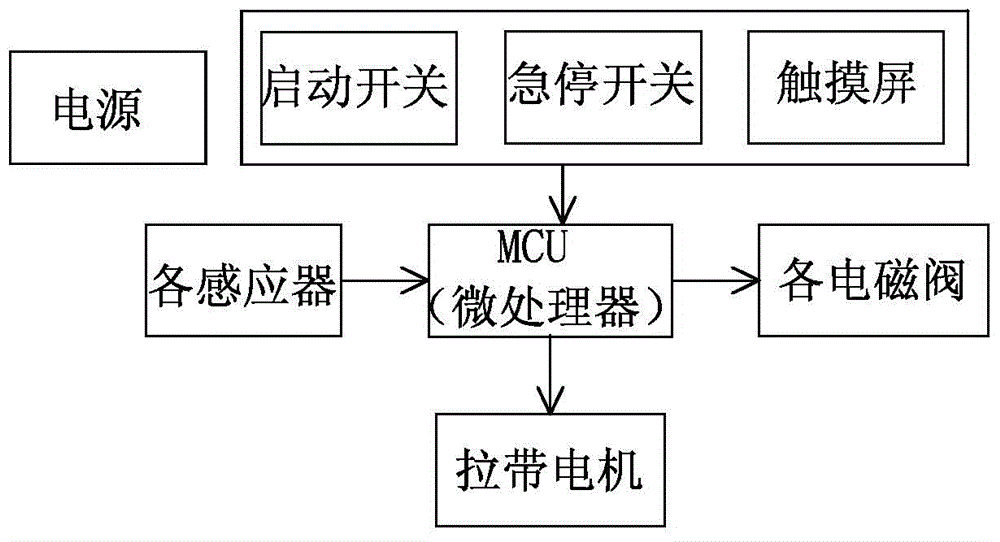

[0018] Such as figure 1 and image 3 As shown, a kind of automatic head-threading machine that can produce ultra-short zipper provided by the present invention includes frame 1, drawstring mechanism 2, feeding mechanism 3, chain splitting mechanism 4 and control system, drawstring mechanism 2, feeding mechanism 3 , the split chain mechanism 4 and the control system are arranged on the frame 1. Wherein, the pull belt mechanism 2 is used for pulling chain belts, and the pull belt mechanism 2 is provided with a pull belt motor 21; 32 and the pusher device, the pusher device is provided with a pusher cylinder 33, through the action of the pusher cylinder 33, the slider 8 sent by the feeding tray 34 is pushed into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com