Ice cream mold spiral pressing equipment

A mold and ice cream technology, applied in the field of ice cream mold spiral pressing equipment, can solve the problems of low equipment versatility, cumbersome adjustment process, increased production cost, etc., and achieve the effects of strong versatility, controllable running speed, and stable pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

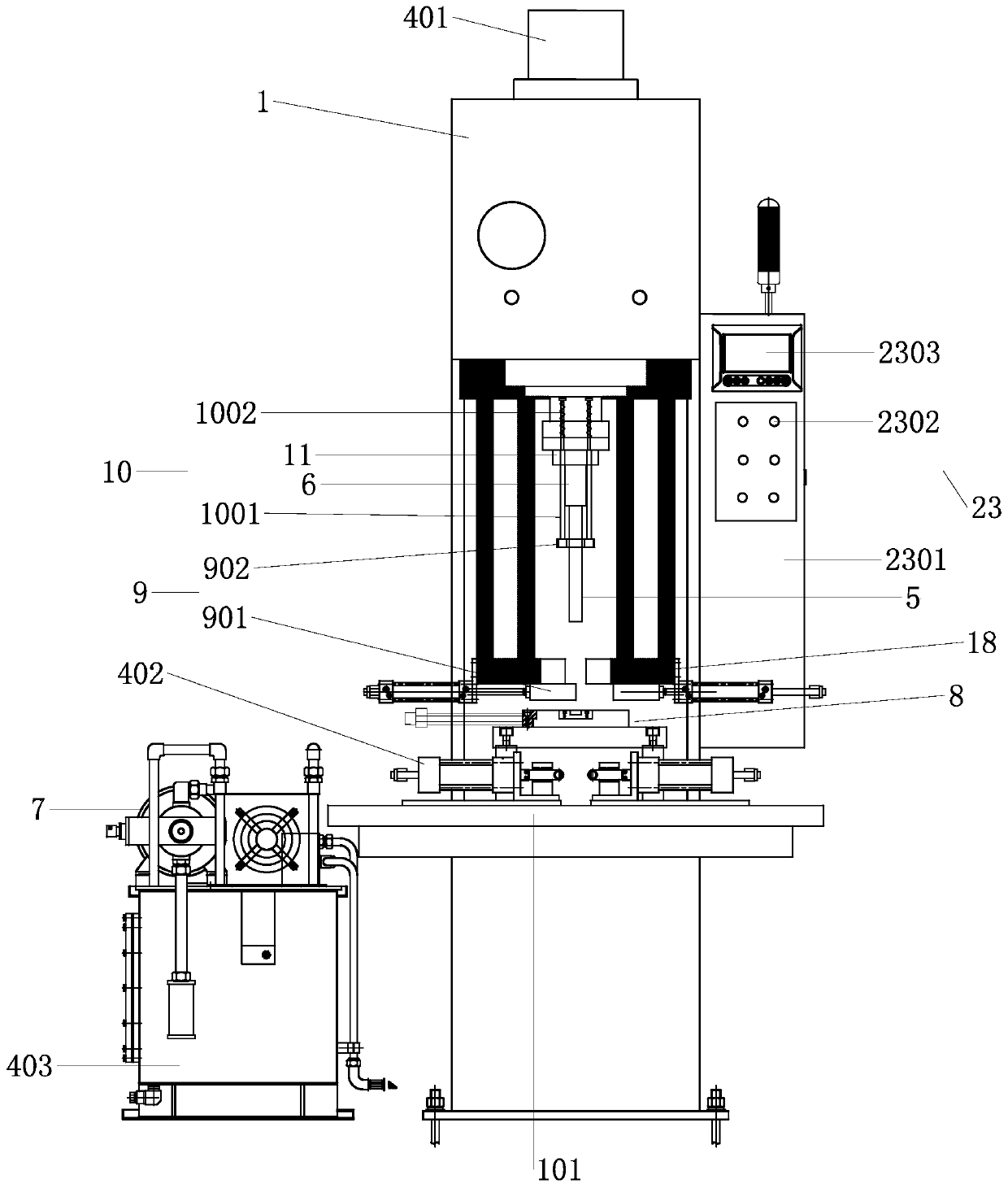

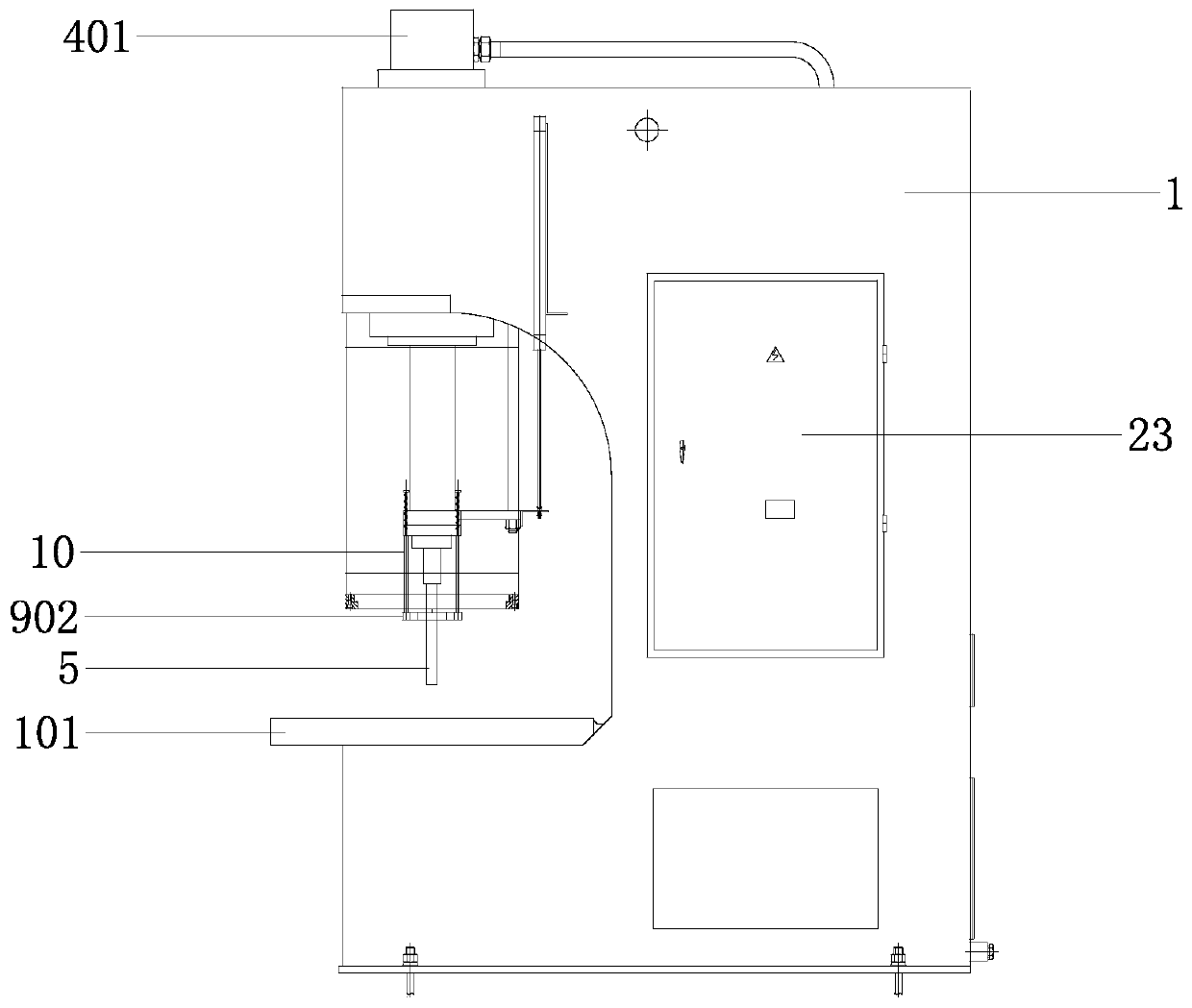

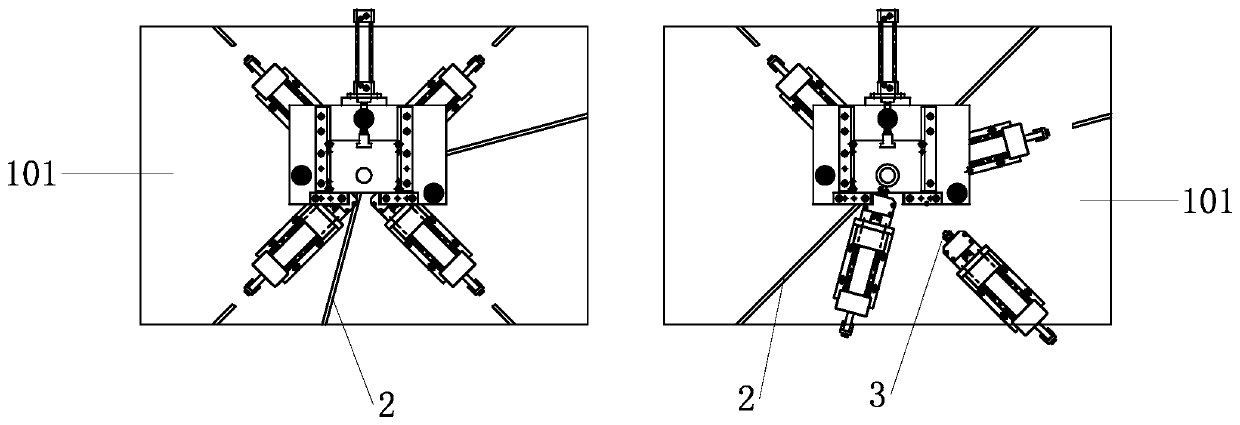

[0036] like Figure 1 to Figure 4 As shown in the figure, an ice cream mold spiral pressing equipment, its main body is provided with a press body 1 and a pressing mechanism, a worktable 101 is formed on the pressing body 1, the worktable 101 is arranged horizontally, and its upper surface is provided with a positioning groove 2, at least one of the positioning grooves 2 is provided, and the number of the positioning grooves 2 is selected here to be six. Three-slot structure and four-slot structure, wherein, the three-slot structure corresponds to three positioning slots 2, and the angle between adjacent positioning slots 2 is 120 degrees; the four-slot structure corresponds to four positioning slots 2, and the adjacent positioning slots 2 The angle between them is 90 degrees. The two structural states enable this screw pressing device to produce molds with two thread structures. If a certain spiral structure needs to be processed on the surface of the mold, the pressing mecha...

Embodiment 2

[0050] This embodiment is different from Embodiment 1, the difference is that, as Figure 4 As shown, one side of the pretensioning device 8 is provided with a limit block 24, and the limit block 24 is arranged on the side of the pretension block 802 away from the pretension cylinder 801 and is fixedly connected to the bottom plate 15 by bolts. The purpose of the block 24 is to further position the movement of the pretensioning device 8, to ensure that the pretensioning block 802 is completely matched with the end of the screw rod 5 and the ice cream mold through the placement groove 16, thereby reducing the collision damage of the ice cream mold Rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com