A processing equipment for holes on the indexing circle of disc parts

A processing equipment and indexing circle technology, which is applied in metal processing equipment, drilling/drilling equipment, metal processing, etc., can solve the problems that the indexing circle is difficult to realize automation, and achieve the effect of promoting automated production and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

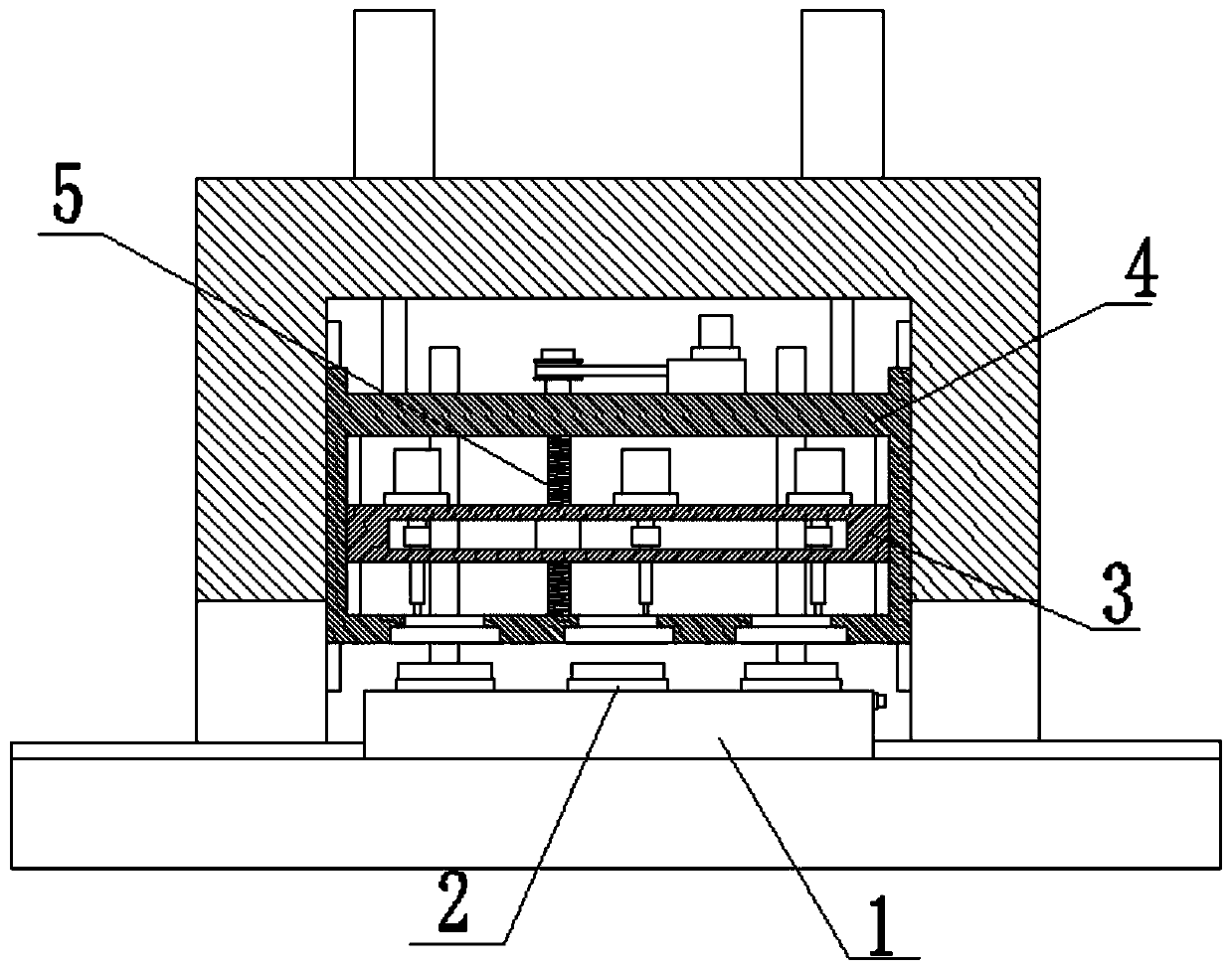

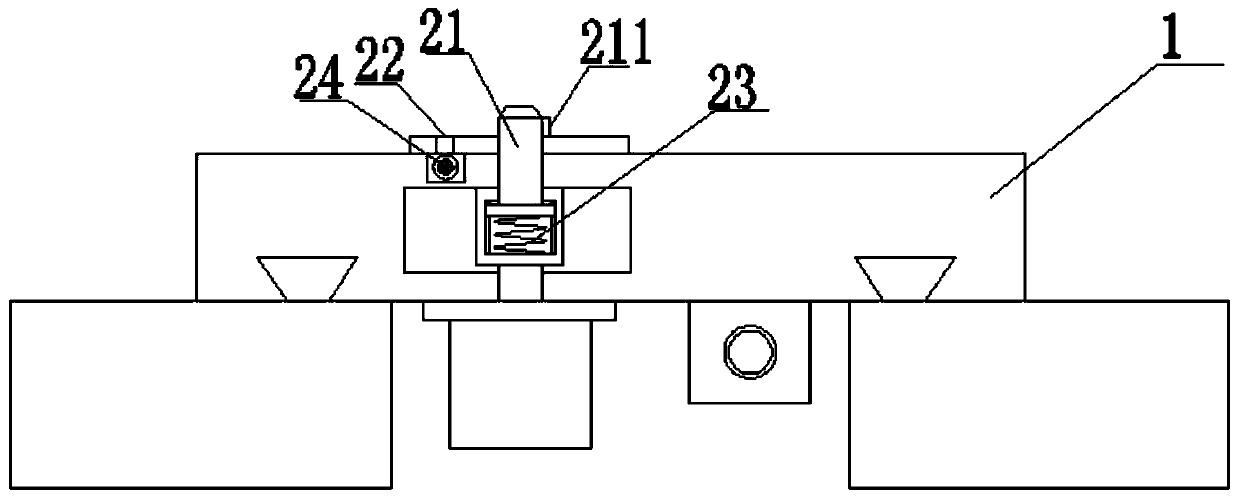

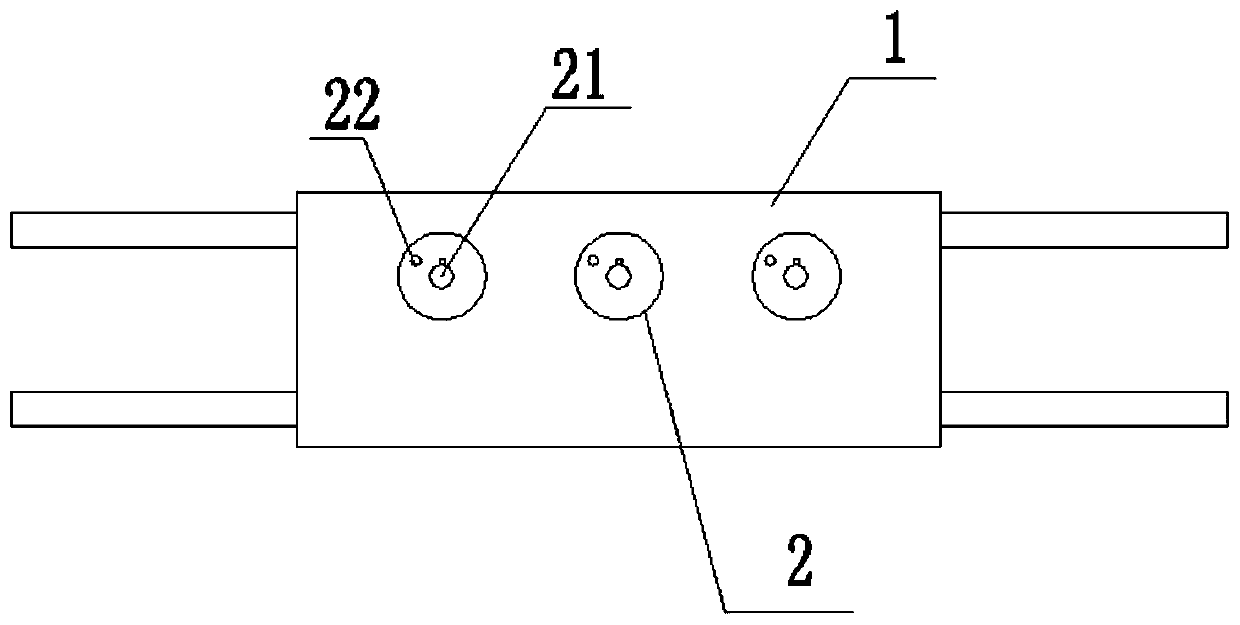

[0018] Such as Figure 1-3 As shown, as one of the embodiments of the present invention, a processing equipment for holes on the index circle of discs is provided, including a workbench 1 and a drilling device for conveying discs; the workbench 1 is arranged along its conveying direction. There are a plurality of turntables 2 that can position disk parts. The drilling device includes a drill bit arranged along the conveying direction of the workbench 1. The drill bit is driven by the lifting device and the rotating motor to rotate and feed toward one of the hole positions. The rotating motor is fixed on the lifting device, and the diameter of the drill bit gradually increases along the conveying direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com