Ultralow-resistance chip resistor and manufacturing method thereof

A manufacturing method and technology of resistors, which are applied in the direction of resistors, resistor manufacturing, and resistor components, etc., can solve problems such as unstable electrical performance, large fluctuations in resistor resistance, and low processing efficiency, and achieve stable and reliable electrical performance , highly automated production, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

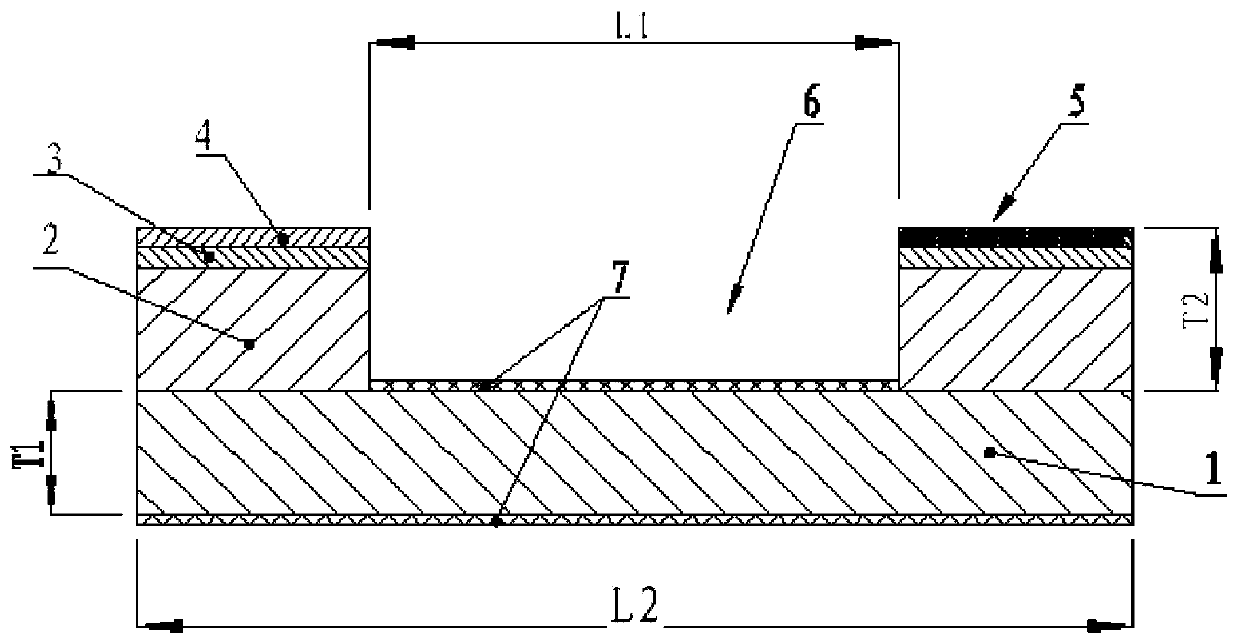

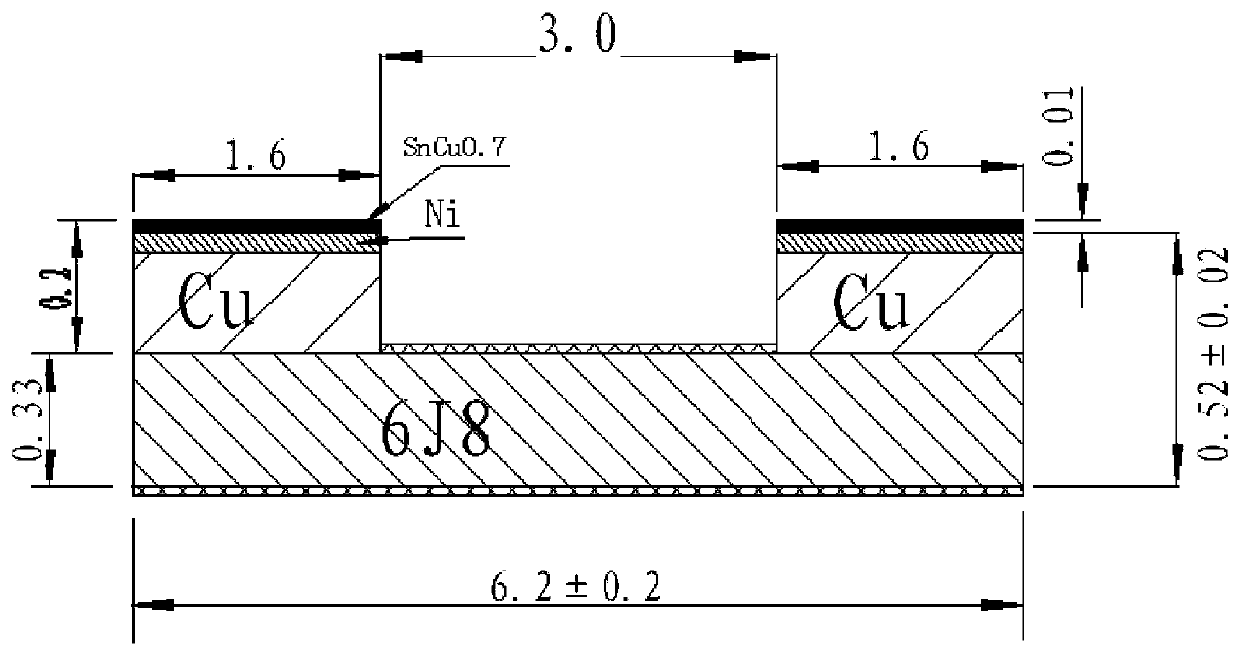

[0045] Embodiment 1: as figure 2 An ultra-low resistance chip resistor of a typical chip resistor model 6432-1 is shown. The resistance value of the ultra-low resistance chip resistor is 1 milliohm. The manufacturing method includes the following steps:

[0046] Step 1) Take a pure nickel strip with a thickness of 0.05mm, the weight percentage of nickel is Ni≥99.9%, take a pure copper strip with a thickness of 1.0mm, and the weight percentage of copper is Cu≥99.9%, and take a thickness of 1.5mm precision resistance alloy strip, the material of the precision resistance alloy strip is one of manganese copper or copper nickel or constantan or nickel-chromium resistance alloy, and its typical grades are 6J8, 6J12, 6J13, 6J40, 6J20, 6J22, 6J23, CuMnSn, germanium-manganese-copper, etc. In this example, the typical grade of 6J8 manganese-copper alloy strip is selected. After the surface is cleaned and cleaned, the nickel strip is used as the upper layer, the copper strip is used as...

Embodiment 2

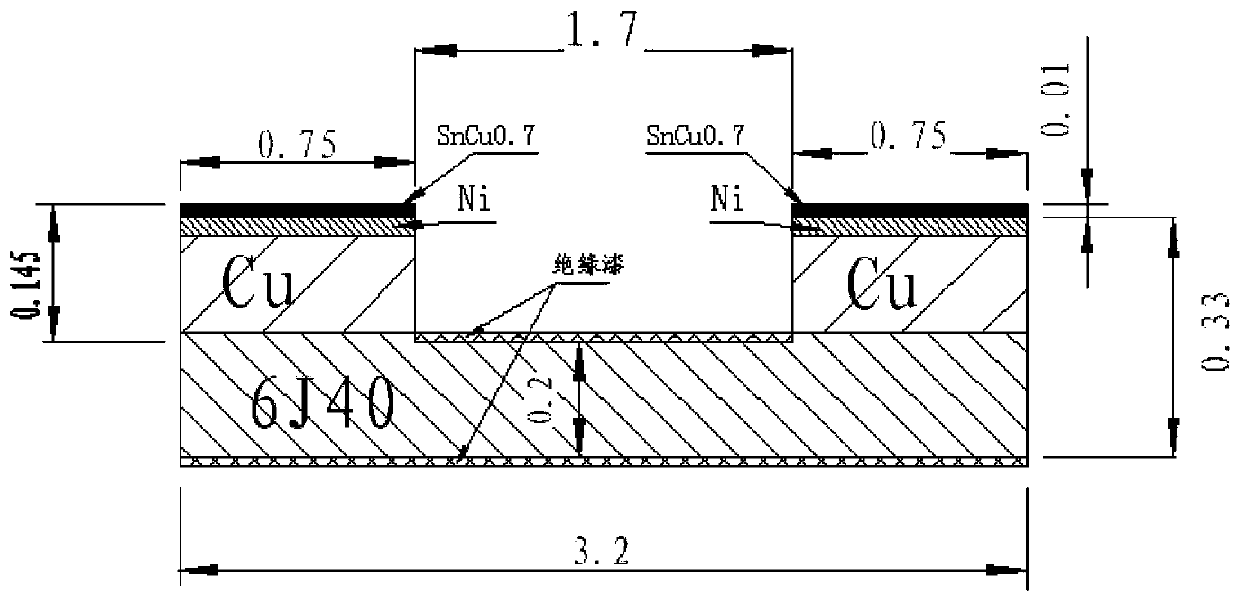

[0054] Embodiment 2: as image 3 As shown, an ultra-low resistance chip resistor of a typical chip resistor model 3216-3, the resistance value of the ultra-low resistance chip resistor is 3 milliohms, and its manufacturing method includes the following steps:

[0055] Step 1) Take a pure nickel strip with a thickness of 0.05mm, the weight percentage of nickel is Ni≥99.9%, take a pure copper strip with a thickness of 1.0mm, and the weight percentage of copper is Cu≥99.9%, and take a thickness of 1.5mm precision resistance alloy strip, the material of the precision resistance alloy strip is one of manganese copper or copper nickel or constantan or nickel-chromium resistance alloy, and its typical grades are 6J8, 6J12, 6J13, 6J40, 6J20, 6J22, 6J23, CuMnSn, germanium-manganese-copper, etc. In this example, a copper-nickel alloy strip with a typical grade of 6J40 is selected. After the surface is cleaned and cleaned, the nickel strip is used as the upper layer, the copper strip is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com