Four-corner rotating piston engine

A technology of rotating piston and engine, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of component processing, maintenance difficulty, engine sealing difficulty, increase engine weight, etc., to achieve weight reduction, simple structure, overall Lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

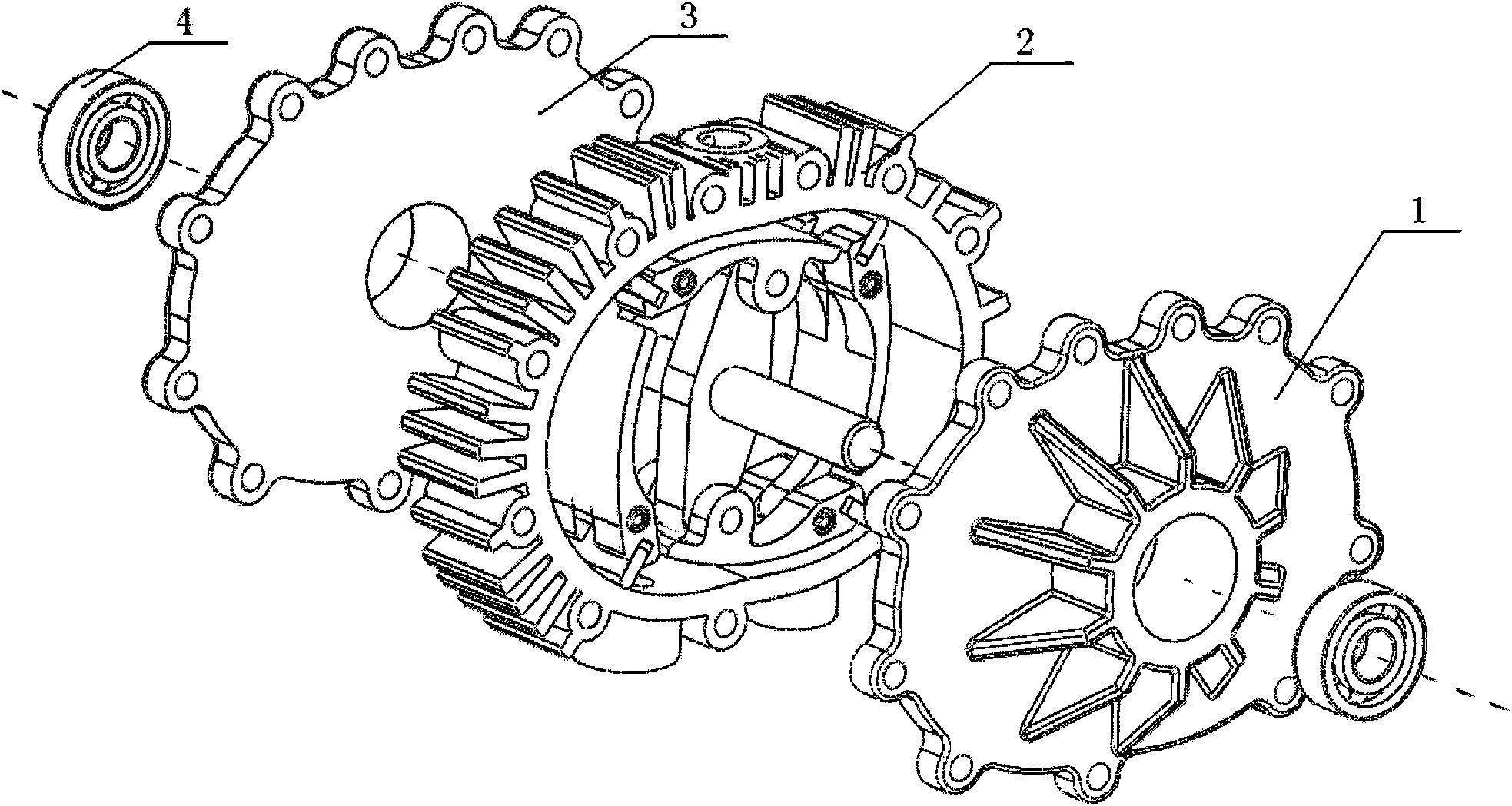

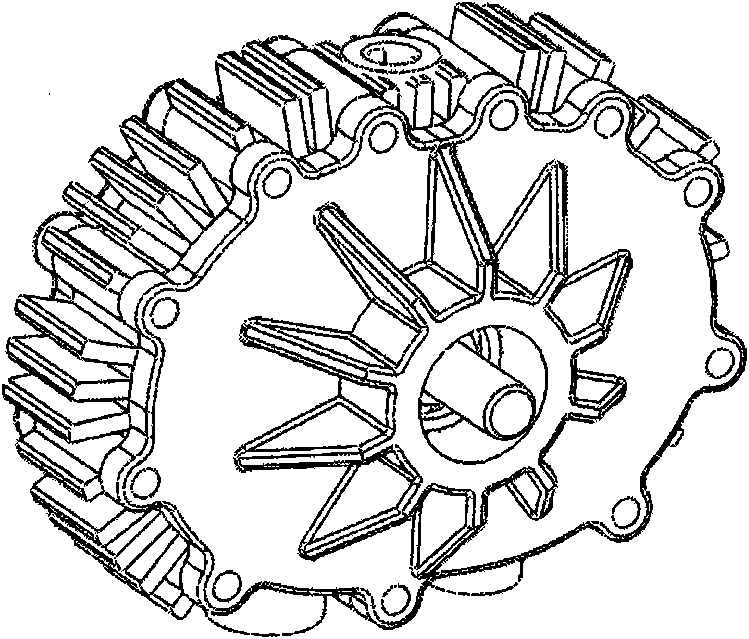

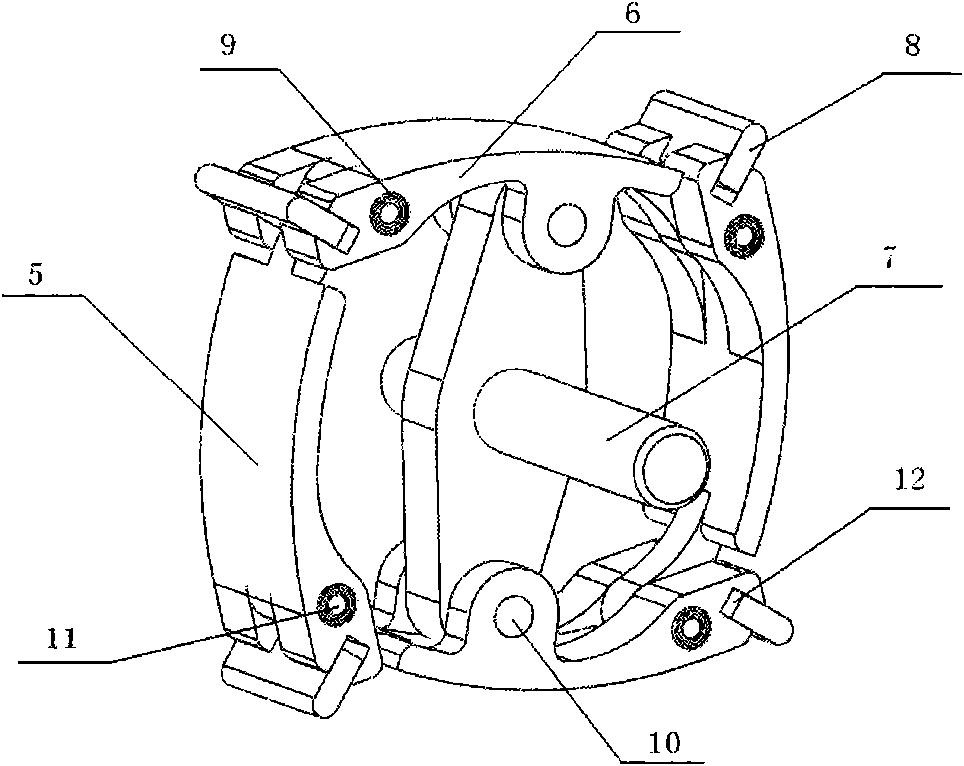

[0052] Such as figure 1 , figure 2 with image 3 Shown, a kind of four angle rotary piston engine of the present invention, it is made of front cylinder cover 1, cylinder 2, rear cylinder cover 3, bearing 4, piston 5, transmission piston 6, main shaft 7, seal 8, small bearing 9, drive pin 10. The piston pin 11 and the spring leaf 12 are composed of the position connection relationship: the small bearing 9 is installed in the three inner holes of the piston 5 and the transmission piston 6, and a pair of pistons 5 and a pair of transmission pistons of the small bearing 9 are installed. 6 form a quasi-square piece, the concave surface of the piston 5 and the transmission piston 6 faces the inner side of the quasi-square piece, the inner holes of the small bearings 9 on the piston 5 and the transmission piston 6 are respectively concentrically aligned, and the piston pin 11 passes through all the small bearings 9 inner holes, so that this type of square piece can freely change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com