Floor sweeping machine

A sweeper and body technology, applied in the field of sweepers, can solve the problems of high use cost, low power, poor practicability, etc., and achieve the effects of low use cost, large driving force, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

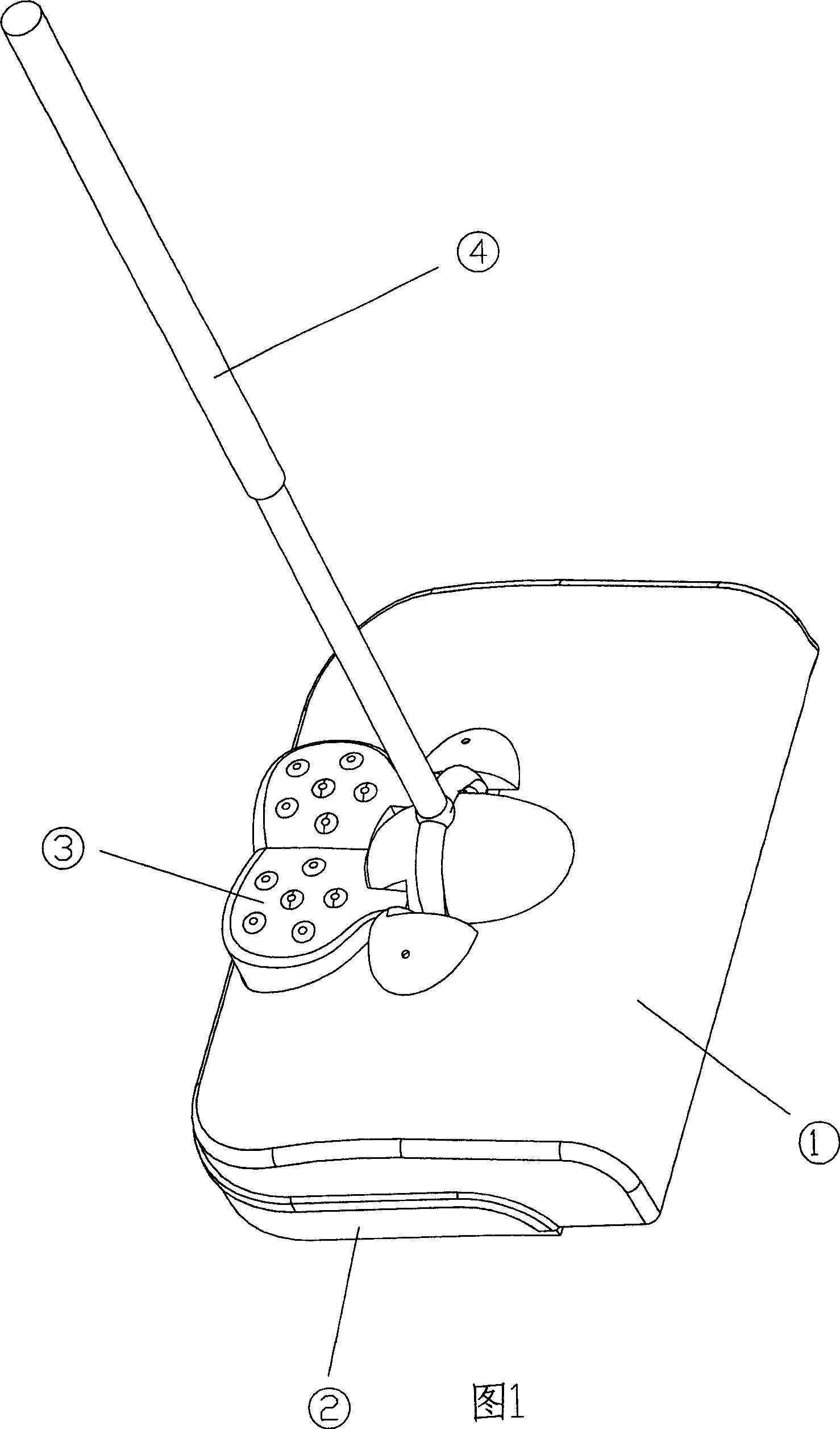

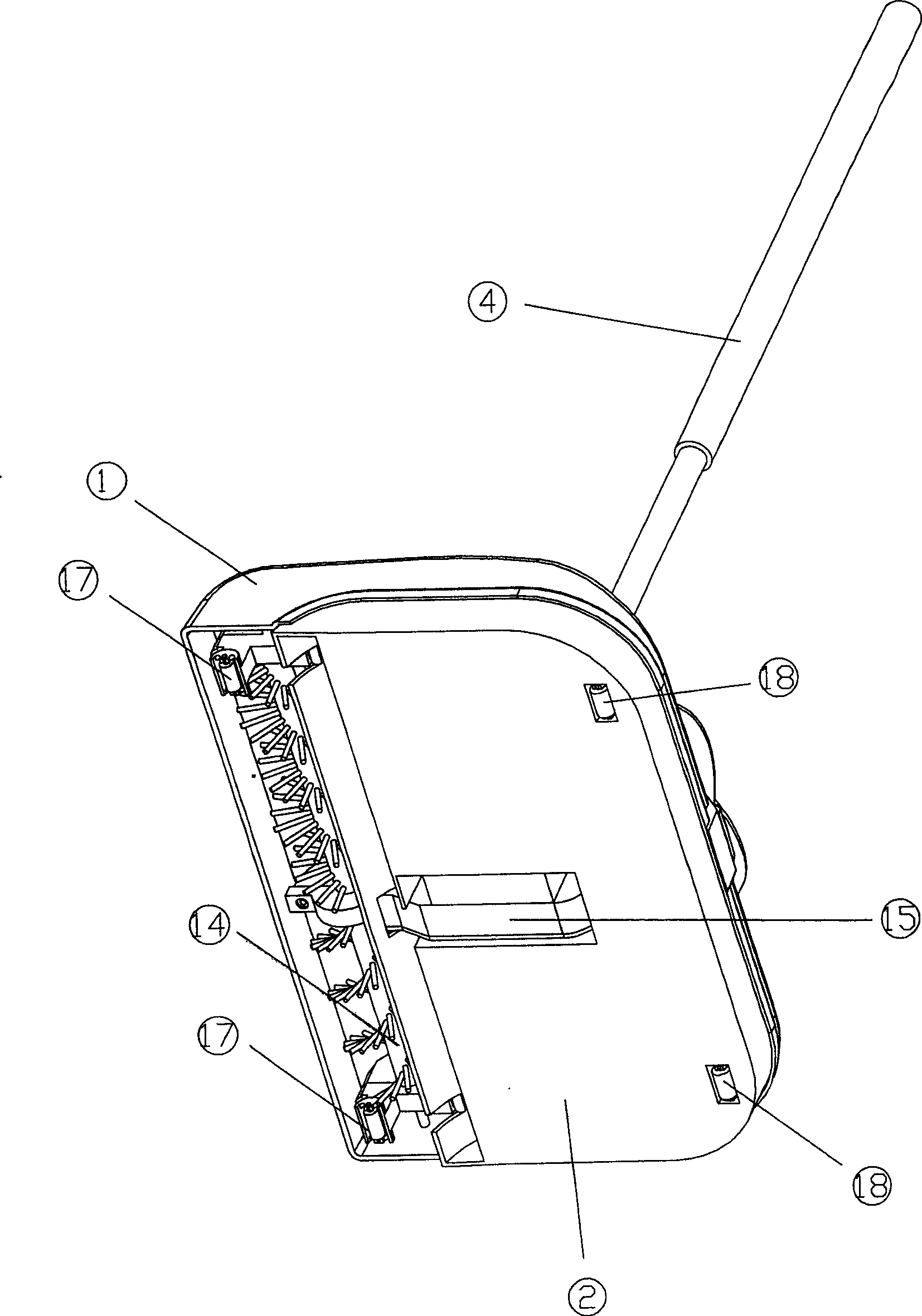

[0018] In Figure 1, figure 2 Among them, the body is formed by connecting the upper cover 1 and the garbage shovel 2 arranged at the bottom of the upper cover 1 using conventional structures such as male and female joints (not shown in the figure). The handle 4 is hinged on the top of the upper cover 1 . The axles of two front casters 17 are contained in the bottom of mounting bracket 20, and mounting bracket 20 is located at the two ends of garbage shovel 2 front sides. Two rear casters 18 then pass the hole of the garbage shovel 2 and its axle is installed on the garbage shovel 2.

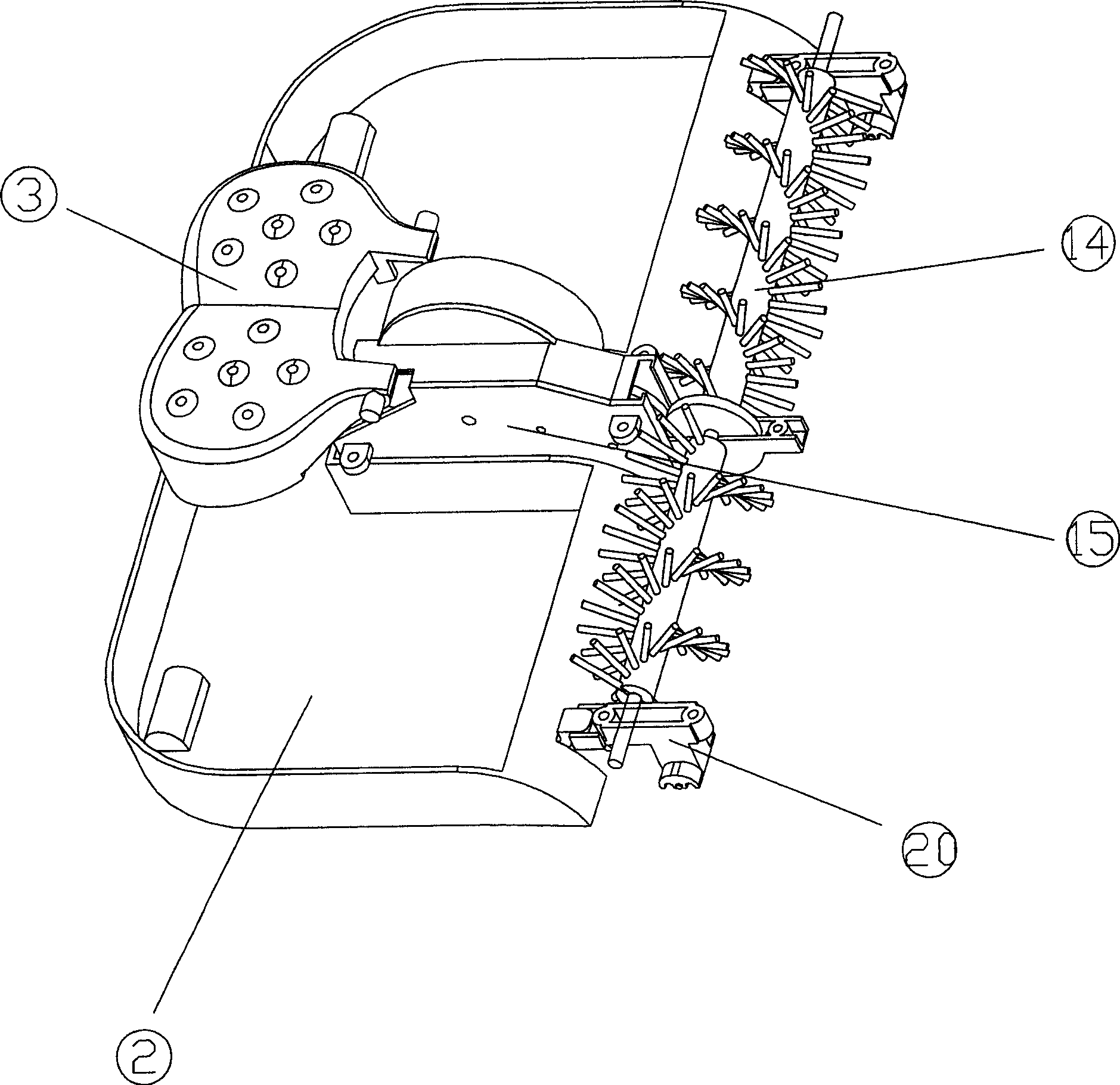

[0019] Such as image 3 , Figure 4 ,Figure 5, Figure 6 shown.

[0020] Pedal 3 is positioned at loam cake 1 hole, and the both sides of its front end are hinged on loam cake 1, and pedal 3 bottom is fixedly connected with thumb wheel 5. Back-moving spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com