Integral hoisting battery box stacking vehicle

An integral hoisting and battery box technology, applied in the field of electric stacker trucks, can solve problems such as increasing assembly time, reducing work efficiency, troubles, etc., and achieves the effect of improving safety, reliability and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

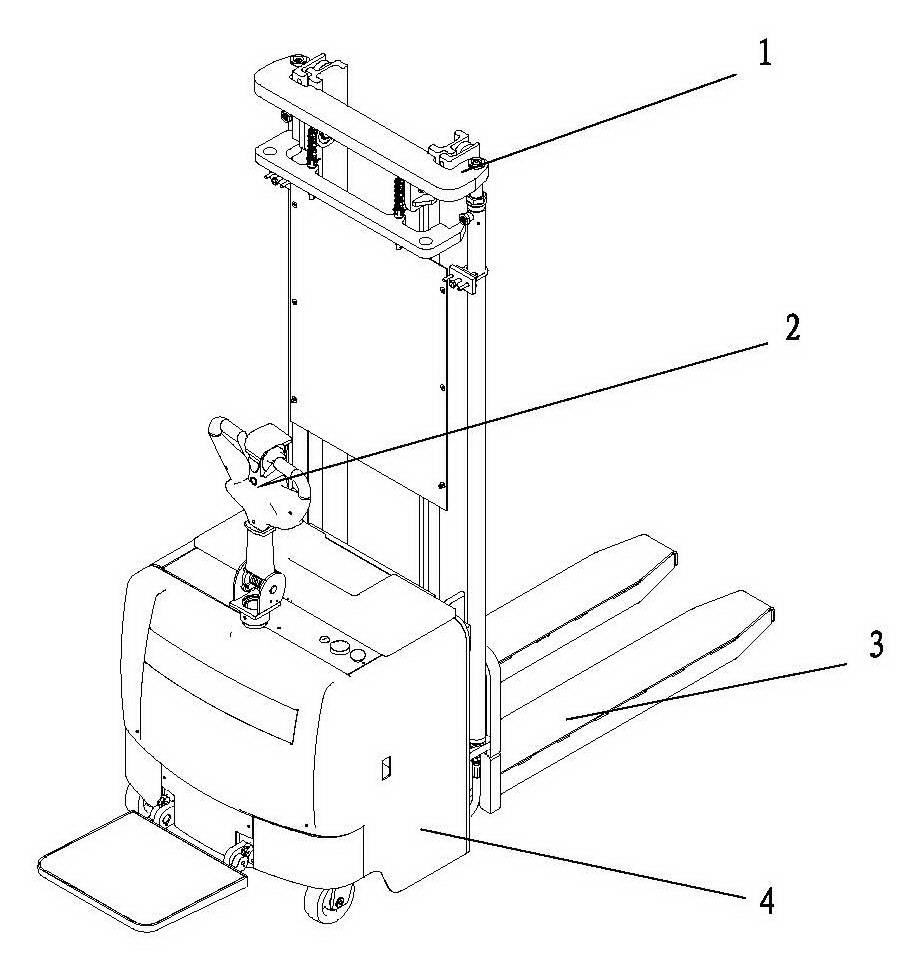

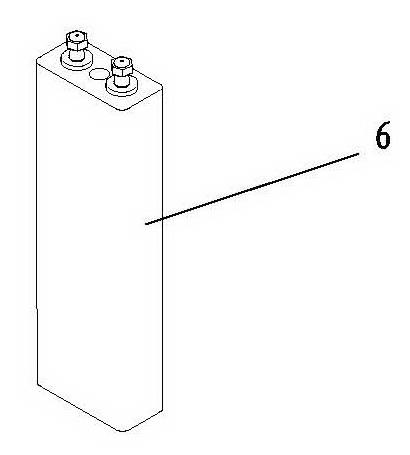

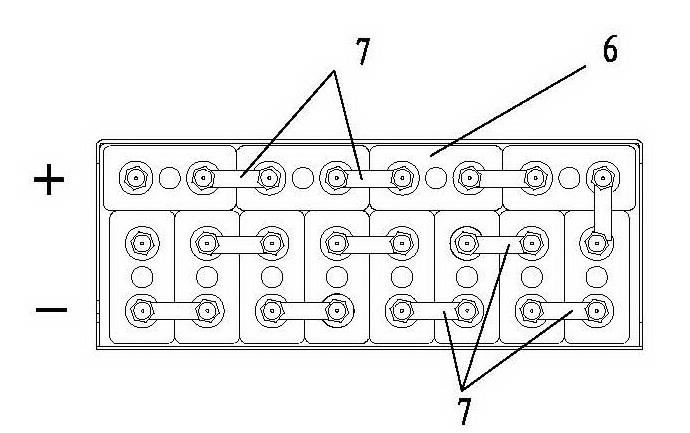

[0026] Figure 6 It shows the overall hoisting battery box stacker truck of the present invention, including a door frame system 1, a handling system 2, a fork and a shelf system 3, a body system 4 and a battery pack, and a battery is arranged in the body system 4 cavity, the battery cavity is a cuboid cavity, a battery box 5 is matched in the battery cavity, the battery box 5 opens upwards, and a hanging hole 501 is provided on the box wall at the opening, and the battery box 5 A storage battery group consisting of 12 rectangular parallelepiped 2-volt direct-current storage batteries 6 is embedded in a matching arrangement in the box 5. The electrodes of the storage batteries 6 are all facing the opening of the battery box, and the positive and negative terminals of two adjacent storage batteries 6 are connected by wires 7. The negative pole connects the battery 6 in series, and leaves two positive and negative output ends, and corrugated paper for isolation is arranged betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com