A Boiler Slag Discharging Device Convenient for Collection and Disposal

A boiler and boiler wall technology, which is applied in the field of boiler slag removal devices that are easy to collect and process, can solve the problems of large discharge volume, time-consuming and laborious coal cleaning, and difficulty in storing and transporting waste slag, so as to improve cleaning efficiency and save manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

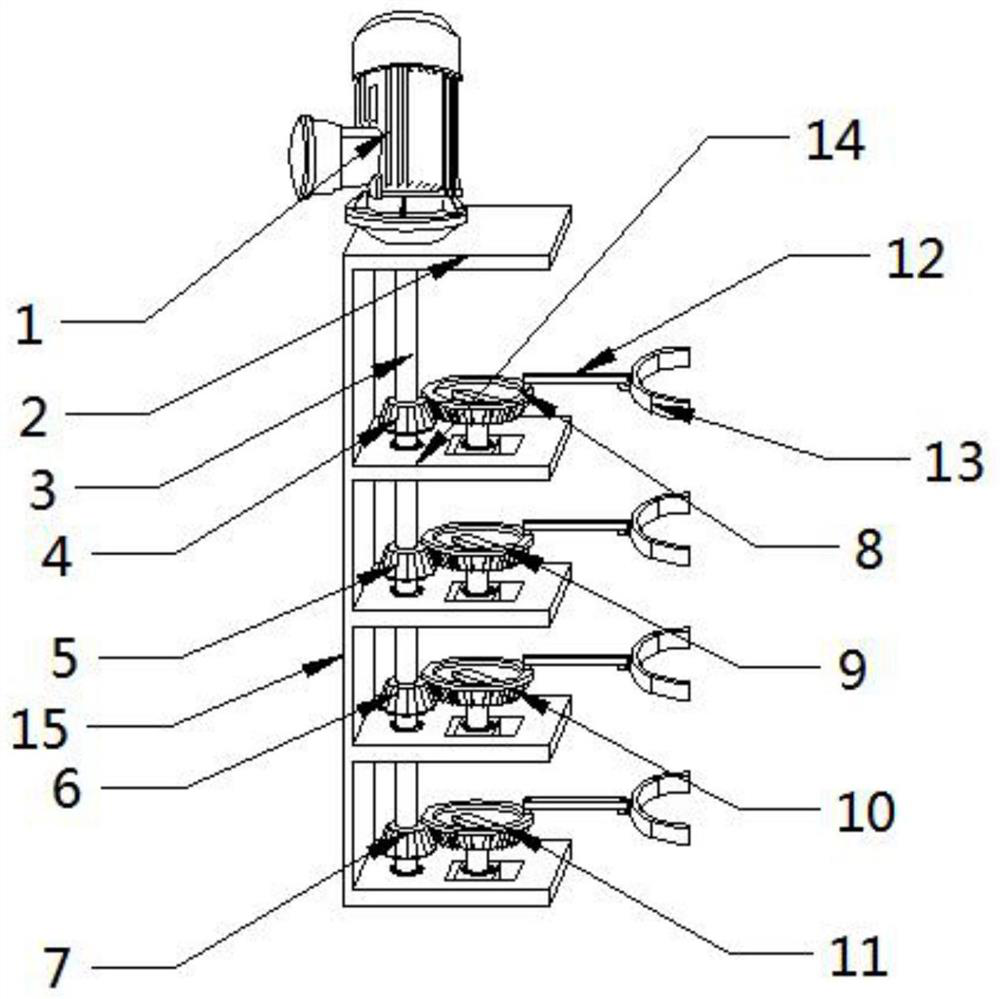

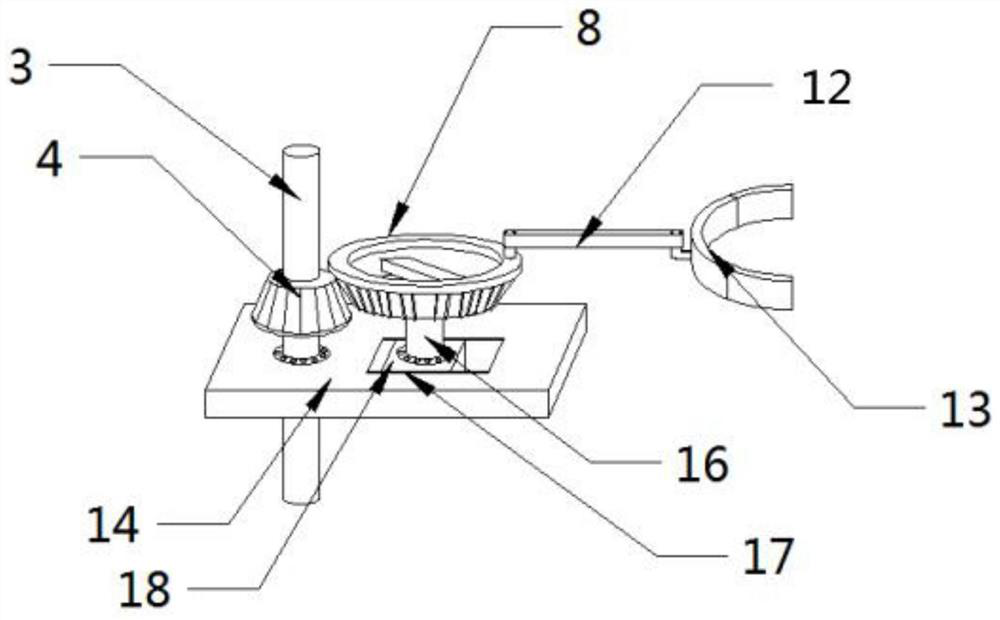

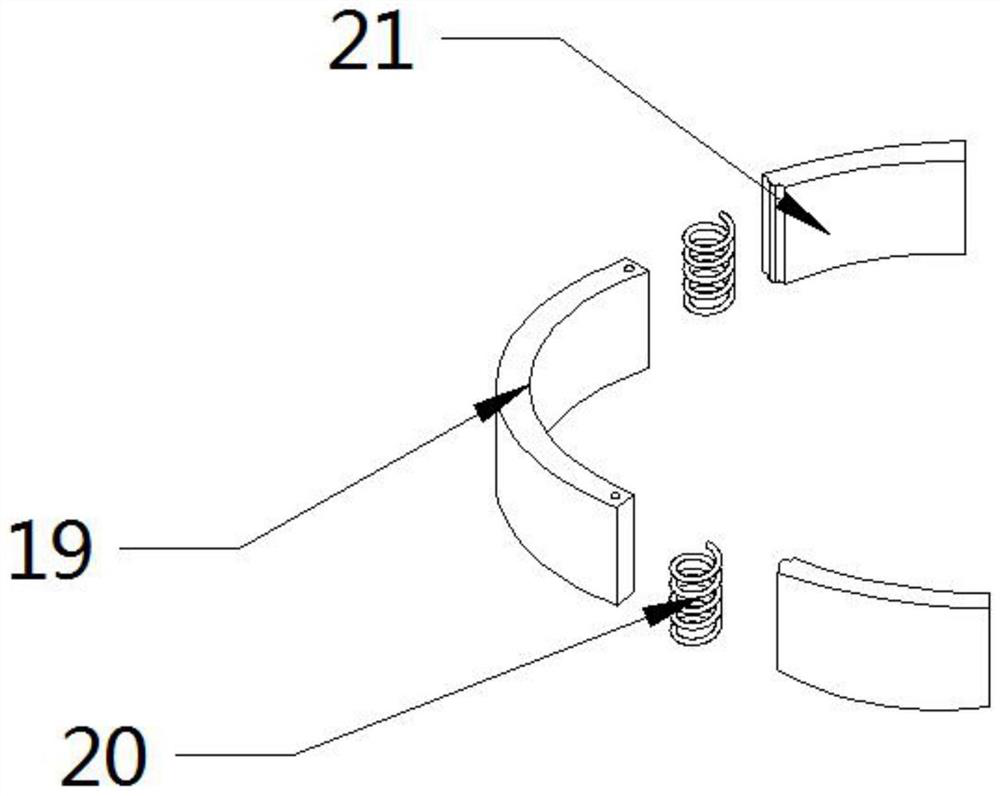

[0024] like Figure 1-Figure 7 As shown, a boiler slagging device that is convenient for collection and processing provided in this embodiment includes a top support plate 2 installed at the bottom of the boiler wall, and a vertical fixing plate 15 is installed on the top support plate 2 away from the boiler wall. On the fixed plate 15, the same side as the top support plate 2 is welded with a horizontal fixed plate 14 along the vertical fixed plate 15 axially equidistant. To the rotating shaft 3 of each group of horizontal fixing plates 14, the top of each group of horizontal fixing plates 14 is provided with a transmission assembly, the transmission assembly incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com