Energy-saving acid pickling method and acid pickling system

A technology of pickling and pickling tank, applied in the field of production waste liquid treatment, can solve the problems of reducing the service life of the furnace body, high furnace consumption cost, affecting the surface quality of strip steel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of energy-saving pickling method provided by the invention, described pickling method comprises the following steps:

[0027] Step 1, arrange the nozzle system in the pickling tank, so that the iron powder and acid liquid are discharged out of the tank under the action of the nozzle;

[0028] Step 2, after the acid solution mixed with metal powder is discharged from the tank, most of the metal powder is filtered and intercepted through a microfilter, which has a filtering function, so that the iron powder is discharged in the form of dry slag, and The filtration accuracy of the microfilter is 0.1-1um. The clean acid is still returned to the line for recycling, because there is no accumulation of metal oxides at the bottom of the acid tank, and no continuous chemical radical reaction with the acid, which prolongs the continuous etching ability of the acid and reduces the frequency of adding new acid. Emissions are reduced while strip production is increased.

[...

Embodiment 2

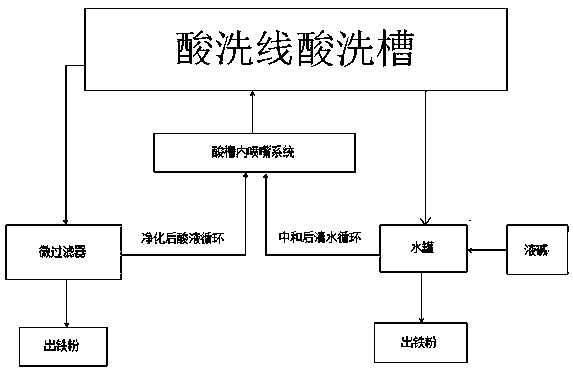

[0032] The present invention also provides an energy-saving pickling system. The pickling system includes a pickling tank, a microfilter, and a water tank, wherein a nozzle system is arranged in the pickling tank, and the nozzle system injects water into the pickling tank. Spray circulating acid to discharge iron powder and acid from the tank; the microfilter is connected to the first outlet of the pickling tank for filtering out the metal powder, and the outlet of the microfilter is connected to the The nozzle system forms an acid liquid circuit; the water tank is connected to the nozzle system through a pipeline, and clean water is sprayed into the pickling tank to clean the pickling tank.

Embodiment 3

[0034] In order to further improve the filtering performance of metal powder, the second outlet of the pickling tank is connected to the water tank, and the pickling system is also provided with a device for providing liquid caustic soda, which is added into the water tank, so There is a valve at the bottom of the water tank, and the iron powder will naturally settle to the bottom of the tank due to gravity, and the iron powder will be discharged from the valve at the bottom of the tank.

[0035] The microfilters provided in the above-mentioned embodiment 2 and embodiment 3 are microfilters with a drying function, so that the iron powder is discharged in the form of dry slag, and the filtration precision of the microfilter is 0.1-1um.

[0036] Further, the nozzle system is composed of nozzles with different functions. The spraying distance, spraying height and spraying area of various nozzles under the liquid are efficiently combined through computer-aided design, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com