Grinding fluid automatic circulation and physicochemical precipitation filter press purification device for centerless grinder

An automatic cycle, centerless grinding machine technology, used in grinding/polishing safety devices, grinding machines, grinding/polishing equipment, etc., can solve the problems of large consumption of filter paper, high moisture content of waste residue, scratches on workpieces, etc., to achieve comprehensive equipment. The effect of improved efficiency, low moisture content of slag, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

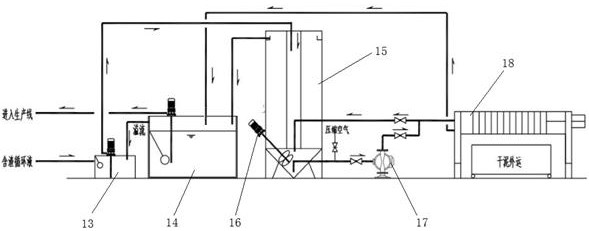

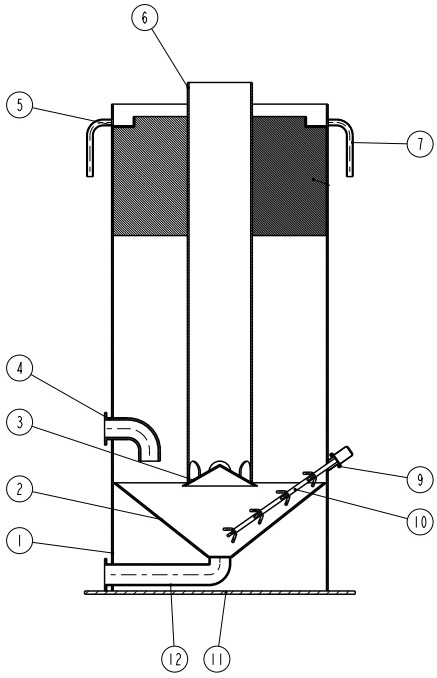

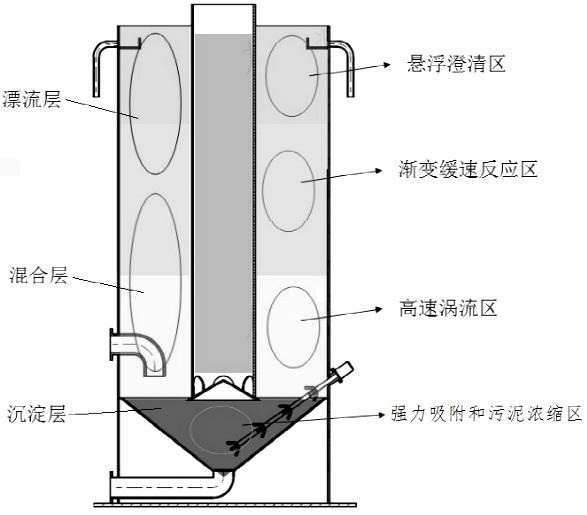

[0026] combine figure 1 As shown, a grinding fluid automatic circulation and physicochemical sedimentation filter press purification device for a centerless grinder includes a slag-containing wastewater collection box 13, a clean circulation fluid collection box 14, an agitated four-partition integrated precipitator 15, and a submersible mixer 16. Mortar pump 17 and centrifugal filter press 18.

[0027] The slag-containing wastewater collection box 13 receives the slag-containing circulating fluid. The slag-containing wastewater collection box 13 is equipped with a wastewater submerged pump, and the wastewater submerged pump pumps the slag-containing circulating fluid into the agitated four-partition integrated precipitator 15 . The waste water submerged pump is connected with a float level control switch....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com