Catalytic cracking device for biodiesel preparation

A catalytic cracking and biodiesel technology, which is applied in the fields of biofuels, petroleum industry, fatty acid production, etc., can solve the problems of insufficient contact between waste edible oil and catalyst, unutilized waste heat, and difficulty in removing residues, and achieves a beneficial effect. The effect of promoting production, saving resources and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

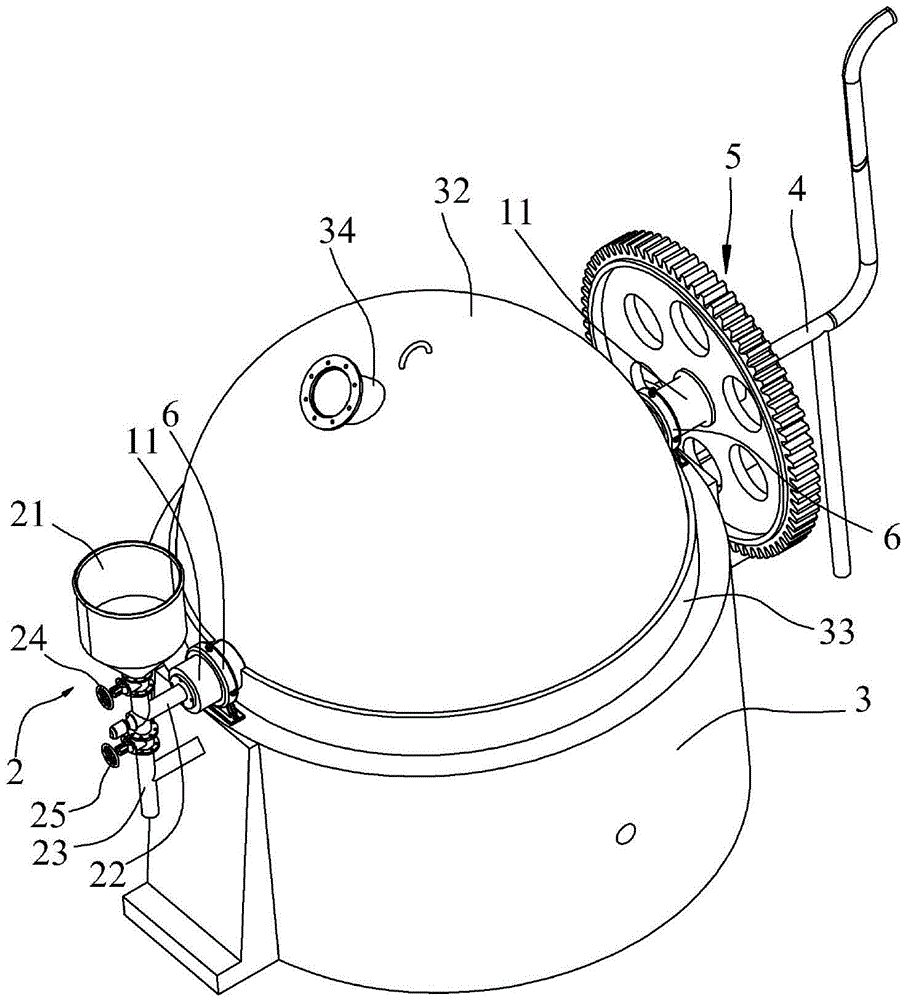

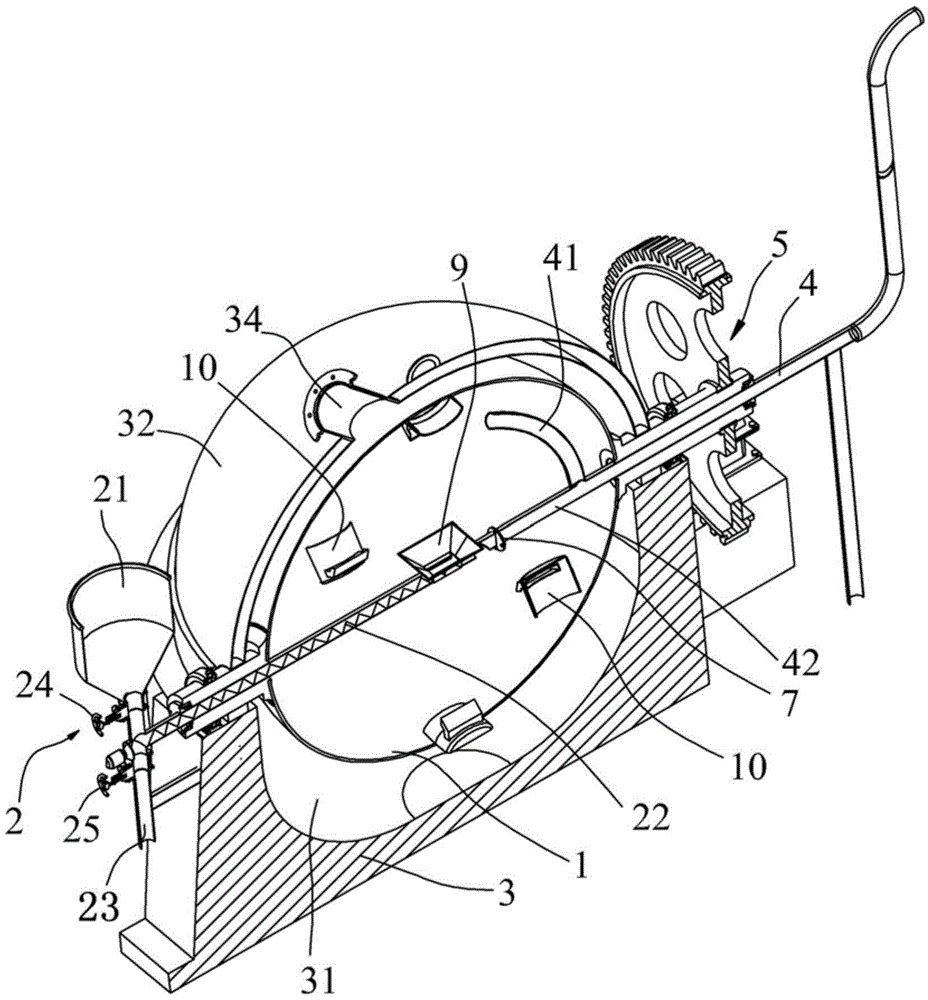

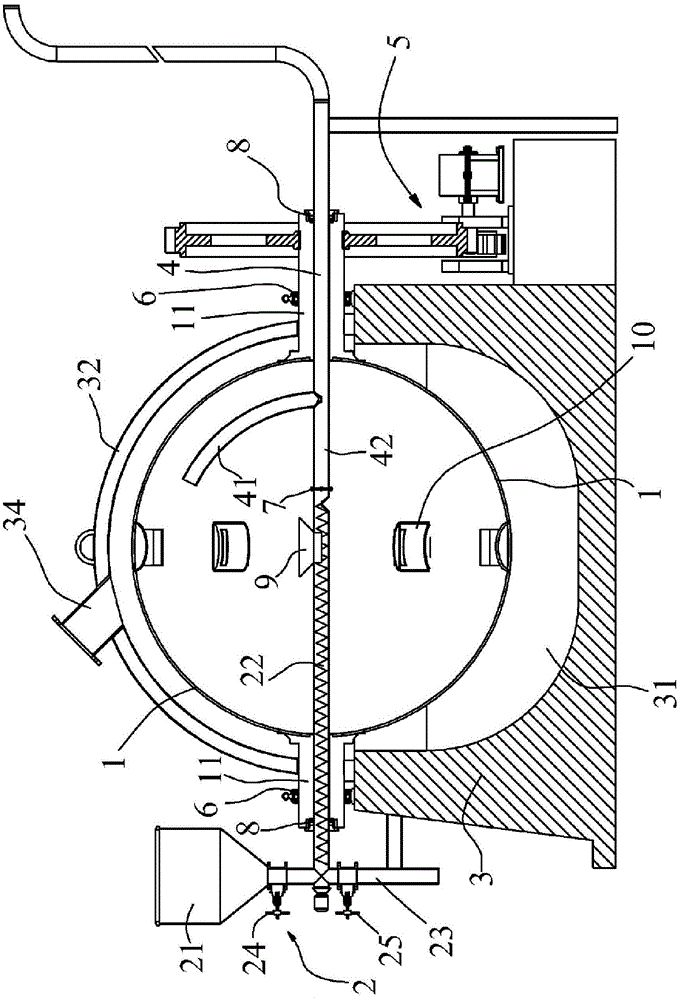

[0032] Such as figure 1 A catalytic cracking device for preparing biodiesel is shown, which includes a reactor 1 , a feeding and discharging device 2 , a heating furnace 3 , a gas collecting pipe 4 and a rotary driving device 5 . Among them, such as Figure 2~3 As shown, the reactor 1 is a hollow spherical shell, a steel container, which is used to hold waste edible oil; output residue; the heating furnace 3 is made of refractory materials and is equipped with a conventional heating device (not shown in the figure) for heating the reactor 1; the gas collecting pipe 4 is used to collect and export the oil and gas in the reactor 1; the rotating drive device 5 is a driving device composed of a motor, a reducer and a gear transmission mechanism, and is used to drive the reaction kettle 1 to rotate.

[0033] Axial tubes 11 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com