Automatic residue discharging method of food processor

A technology of food processing machine and automatic slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

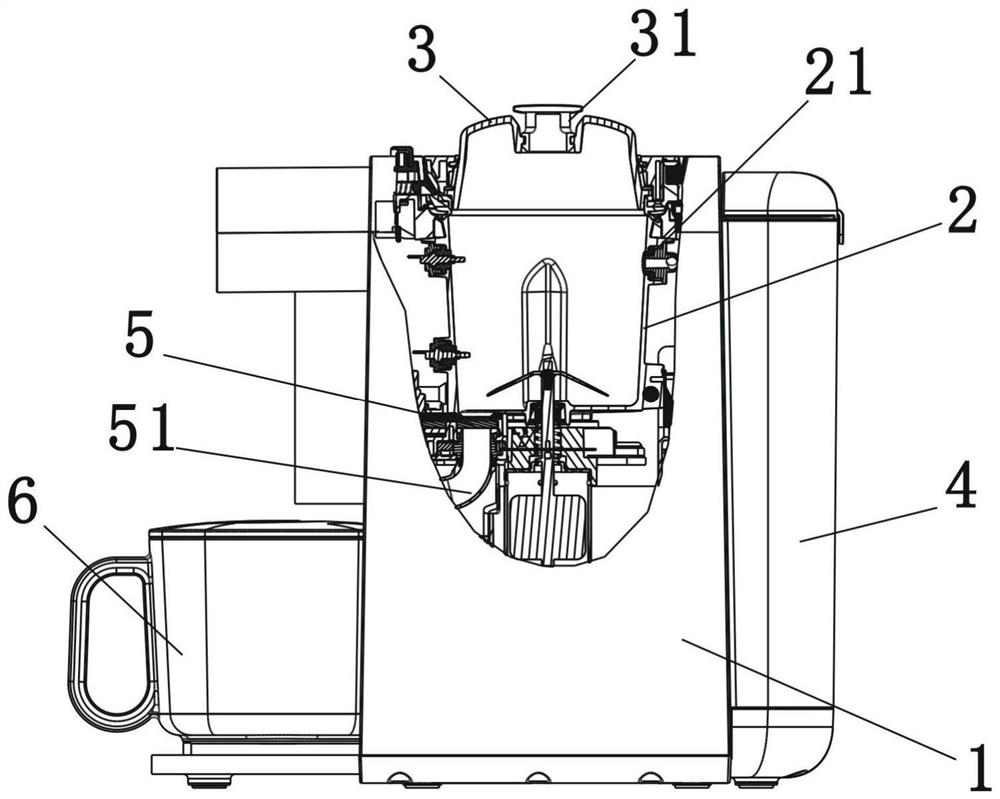

[0026] like figure 1 As shown, it is a food processor according to the first embodiment of the present invention, a food processor comprising a body 1, a crushing cup 2 installed in the body 1 and a cup cover 3 mounted on the top of the crushing cup 2. A silica gel plug 31 is installed on the cup cover 3, and the pulverizing cup 2 and the cup cover 3 are enclosed to form a non-closed pulping chamber. Simultaneously, a water tank 4 is installed on one side of the body 1, and a heating device (not shown) that heats the water tank and generates steam is arranged in the water tank 4, wherein the cup wall of the crushing cup 2 is provided with a The water inlet or steam inlet nozzle 21 of the crushing cup 2 is fed into, wherein the water inlet nozzle 21 is communicated with the water tank 4 through a pipeline (not shown in the figure). Wherein, the water tank 4 and the heating device form a steam generating device for feeding steam into the pulping chamber. In addition, the botto...

Embodiment 2

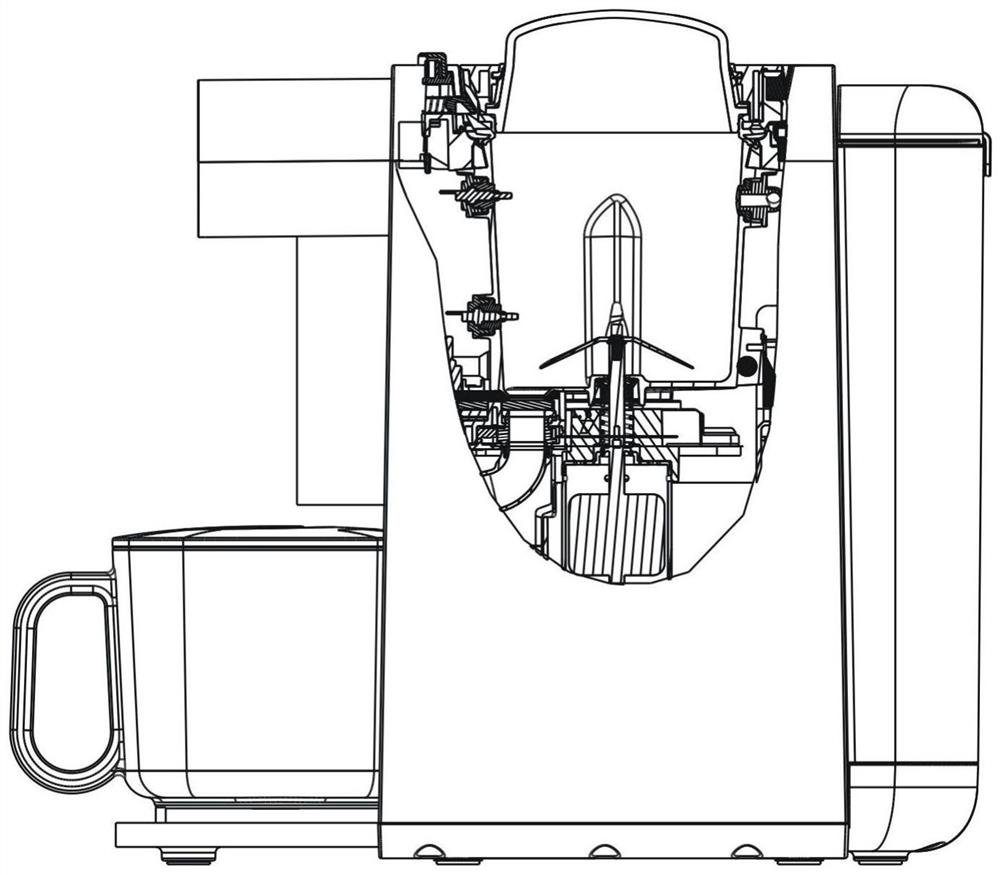

[0038] like figure 2 Shown is a schematic structural diagram of the second embodiment of the present invention. The difference between this embodiment and the first embodiment is that in this embodiment, the cup cover has no air holes and no silicone plugs, and the pulping chamber formed by the cup cover and the pulverizing cup is a cavity with a closed structure. When steam is introduced into the pulping chamber, the liquid discharge assembly is the only outlet for the steam to discharge.

[0039] For the food processor of this embodiment, thick soybean milk can be prepared. Its pulping process has the following steps:

[0040] 1) Crushing stage: The pulverizing blade beats and pulverizes the mixture of the material and water in the pulping chamber to prepare a thick raw pulp mixed with pulp juice and pulp residue.

[0041] 2) Slurry discharge stage: open the liquid discharge assembly, and the slurry and pulp residue mixed with the slurry are discharged into the slurry re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com