Lower slag jacking machine used for vacuum-smelting reduction device

A vacuum smelting and slag topping machine technology, applied in descaling devices, lighting and heating equipment, furnace components, etc., can solve the problems of high labor intensity, large amount of smoke and dust, poor working environment, etc. The effect of protecting the environment and simple structure

Active Publication Date: 2018-06-01

巢湖云海镁业有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to solve the problems of high labor intensity of workers, relatively poor working environment, etc. in the prior art using artificial slag, which produces a large amount of smoke and dust, which is harmful to health, and proposes a method for vacuum smelting reduction Lower top slag machine

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

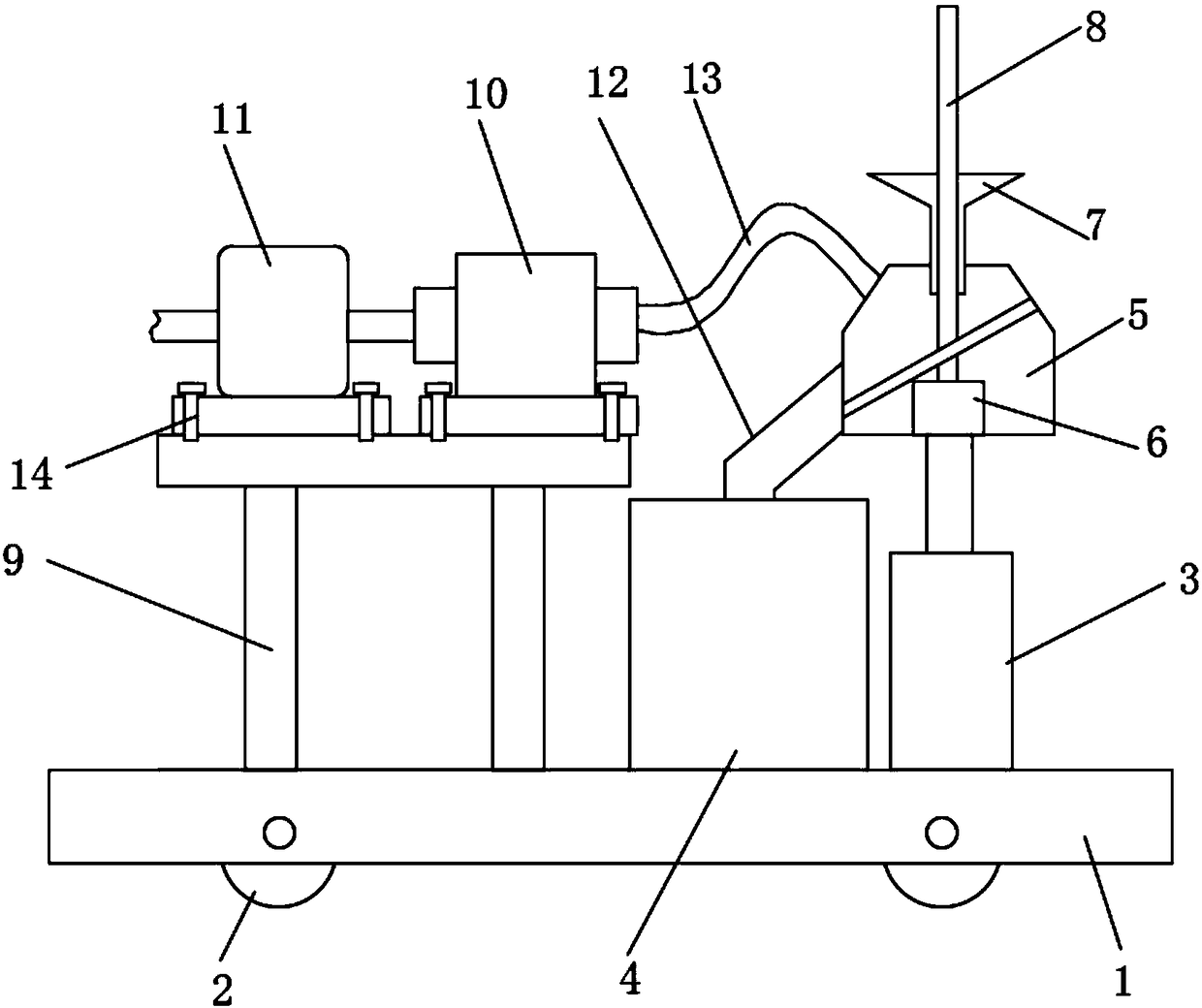

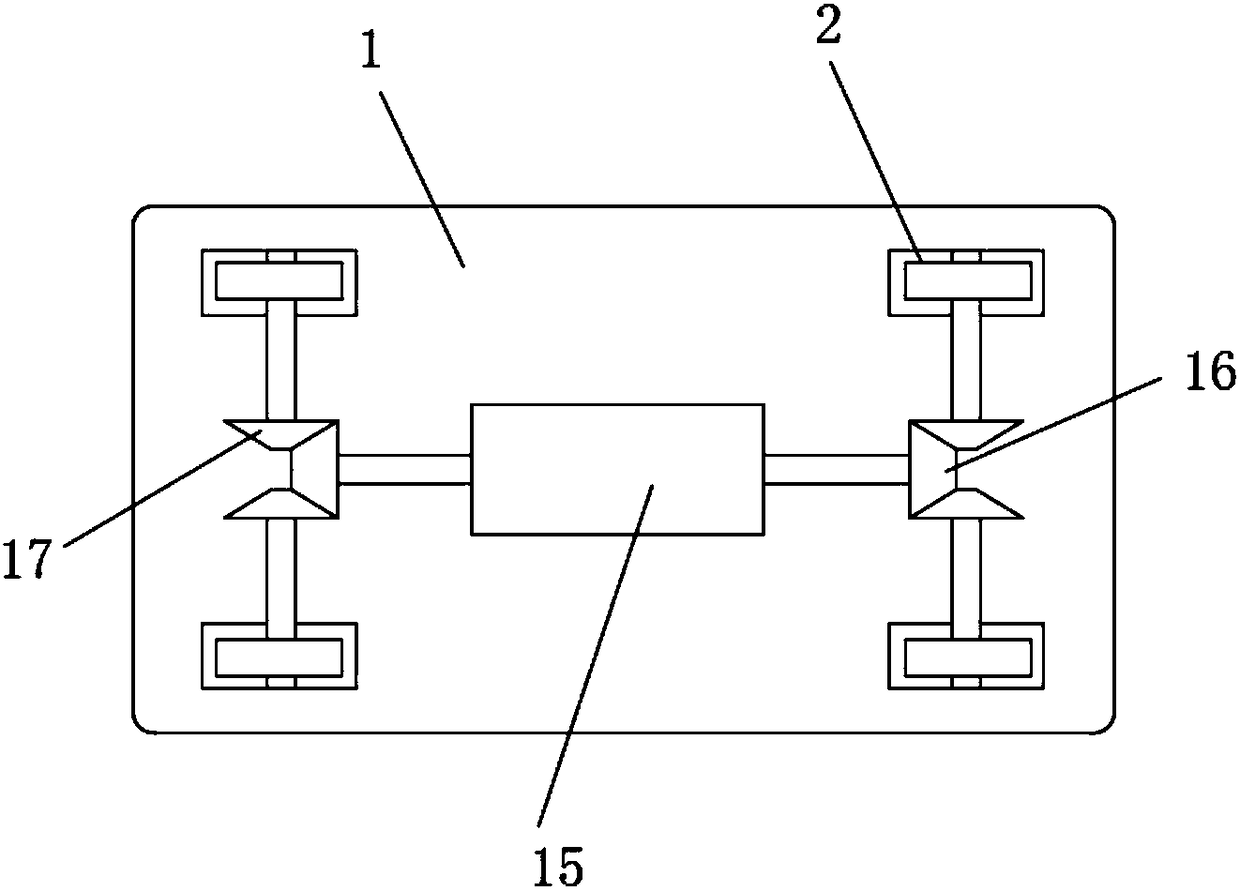

The invention discloses a lower slag jacking machine used for a vacuum-smelting reduction device. The lower slag jacking machine comprises a bottom plate, wherein the lower side wall of the bottom plate is equipped with four rollers; the upper side wall of the bottom plate is equipped with a servo oil cylinder; the drive end of the servo oil cylinder is connected with a receiving slot; a funnel isinserted into the upper end of the receiving slot; the funnel communicates with the inner part of the receiving slot; an inclined plate is arranged inside the receiving slot; the inner bottom of thereceiving slot is equipped with a rotary motor; the drive end of the rotary motor is connected with a rotary rod; the upper end of the rotary rod penetrates through the inclined plate and extends to the outer part of the funnel; two supporting plates and a storage box are further arranged on the upper side wall of the bottom plate; and the upper ends of the two supporting plates are equipped witha fixed plate. The lower slag jacking machine realizes automatic slag discharge work of magnesium slag, saves labor power, improves working efficiency, performs adsorption treatment on flue gas and dust in the magnesium slag, protects the environment, is simple in structure, and is convenient to popularize.

Description

technical field [0001] The invention relates to the technical field of nonferrous metallurgy production equipment, in particular to a slag lowering machine used for a vacuum smelting reduction device. Background technique [0002] At present, there are basically two production methods for Pidgeon method vacuum thermal reduction of metal magnesium, calcium, strontium, etc., horizontal reduction and vertical reduction. Most of the horizontal reduction furnaces use horizontal reduction tanks for Pidgeon reduction. It is relatively troublesome to discharge magnesium slag, and there are disadvantages such as high labor intensity and poor working environment; the vertical reduction tank used in the vertical reduction furnace needs to be on the platform when the magnesium slag is discharged, and the operator uses the crane to lift the central pipe , After the central tube is raised for a certain distance, the operator needs to continuously swing the central tube hook rod, which is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F27D25/00C22B26/20C22B26/22

CPCC22B26/20C22B26/22F27D25/00

Inventor 王青锋杨全海

Owner 巢湖云海镁业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com