High efficiency oil sludge incinerator

A technology of oily sludge and incinerator, which is applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of insufficient incineration and low efficiency of oily sludge incineration, achieve stable incineration, isolate heat transfer, and promote full combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

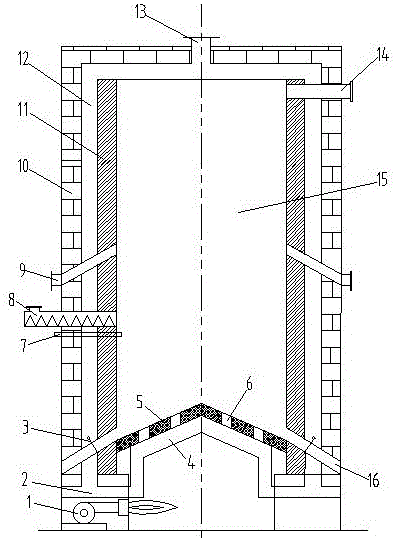

[0023] Such as figure 1 shown.

[0024] A high-efficiency oil sludge incinerator, which includes a diesel fuel burner 1, a primary air pipe 2, a slag discharge control valve 3, an air distribution plate 4, a furnace bottom 5, a furnace bottom air outlet 6, a high-temperature thermocouple 7, and a screw feeder 8. Secondary air inlet channel 9, outer furnace wall 10, inner furnace wall 11, air interlayer 12, primary air inlet 13, flue gas outlet channel 14, furnace 15 and slag outlet 16, such as figure 1 . The inner furnace wall 11 and the outer furnace wall 10 form a furnace body, and the inner furnace wall 11 is a furnace 15 for burning oily sludge, and oil pollution is sent into the furnace by a screw feeder 8 . The inner furnace wall 11 is made of high-temperature-resistant and heat-conducting materials (such as metal materials), so that the heat d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com